Large-span prestressed dome structure and manufacturing method thereof

A prestressed, long-span technology, applied to roofs, building components, building structures, etc., can solve the problems of large supporting structures, threats to life and property safety, inconvenient construction, etc., to improve earthquake resistance and stability And safety, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

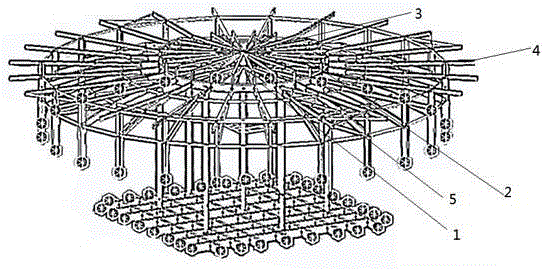

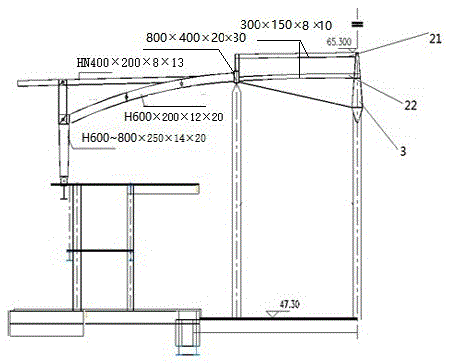

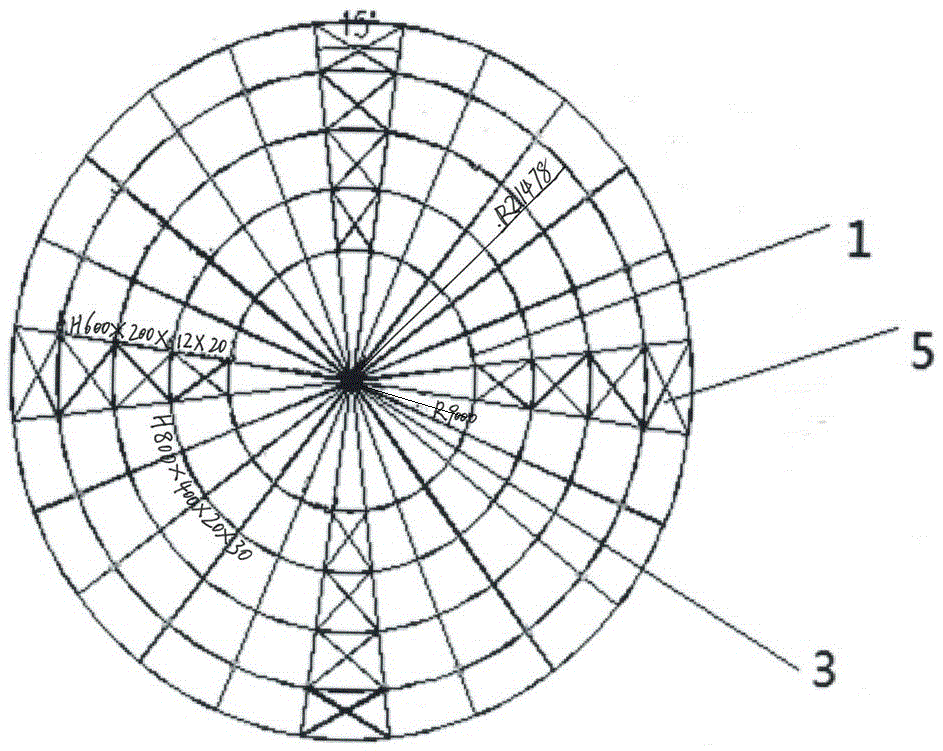

[0032] Such as figure 1 The shown large-span prestressed dome structure includes: ring steel beam 1, inner ring steel beam 2, conical node 3, "Γ" type member 4 and connecting rod 5, wherein the ring steel beam 1 is spliced by curved steel beams, and the inner ring steel beam 2 is composed of an upper steel beam 21 and a lower steel beam 22.

[0033] The connections of the above structures are as follows:

[0034] The ring-shaped steel beam 1 is arranged above the temporary support column, the inner ring steel beam 2 is arranged on the inner side of the ring-shaped steel beam 1, and the tapered node 3 is arranged in the middle of the inner ring steel beam 2, so The above-mentioned "Γ"-shaped member 4 is arranged on the outer side of the ring steel beam 1, and is arranged opposite to the inner ring steel beam 2, and the described connecting rod 5 is arranged between the two "Γ"-shaped members 4, and the two arcs An air docking port and a ground assembly docking port are prov...

Embodiment 2

[0039] In the manufacturing method of a long-span prestressed dome structure described in this embodiment, the dome structure is the same as the dome structure in Embodiment 1.

[0040] Such as figure 1 The shown large-span prestressed dome structure includes: ring steel beam 1, inner ring steel beam 2, conical node 3, "Γ" type member 4 and connecting rod 5, wherein the ring steel beam 1 is spliced by curved steel beams, and the inner ring steel beam 2 is composed of an upper steel beam 21 and a lower steel beam 22.

[0041] The connections of the above structures are as follows:

[0042]The ring-shaped steel beam 1 is set above the temporary support column, the inner ring steel beam 2 is set on the inner side of the ring-shaped steel beam 1, the tapered node 3 is set in the middle of the tapered node 3, and the The "Γ"-shaped member 4 is set on the outer side of the ring steel beam 1, and is set opposite to the inner ring steel beam 2. The connecting rod 5 is set between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com