Patents

Literature

115results about How to "Weaken Rigid Collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

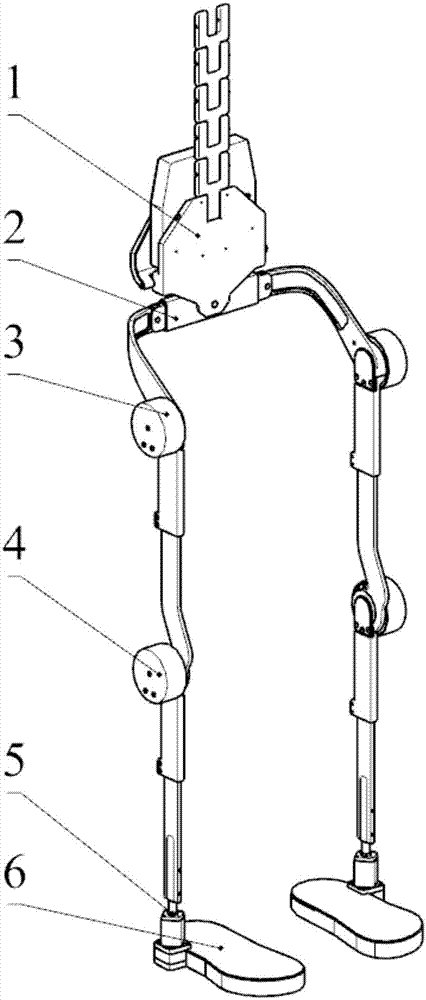

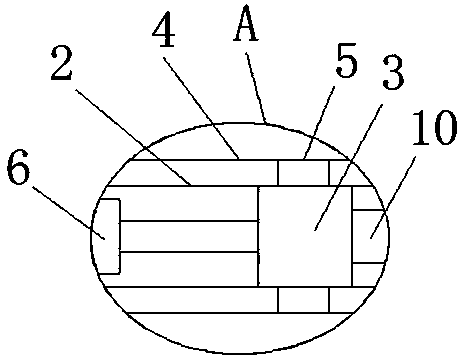

Tubular and modular wearable exoskeleton assisting device and control method thereof

PendingCN107320292ASimple structureCompact structureProgramme-controlled manipulatorChiropractic devicesKnee JointEngineering

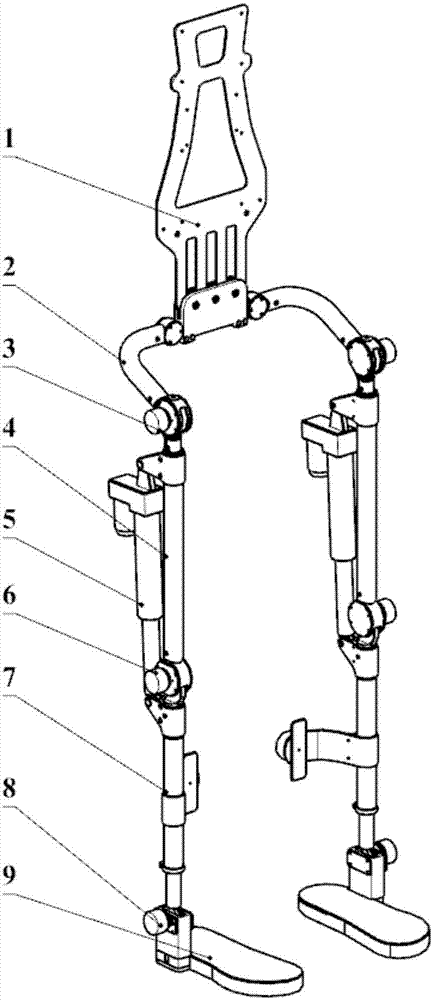

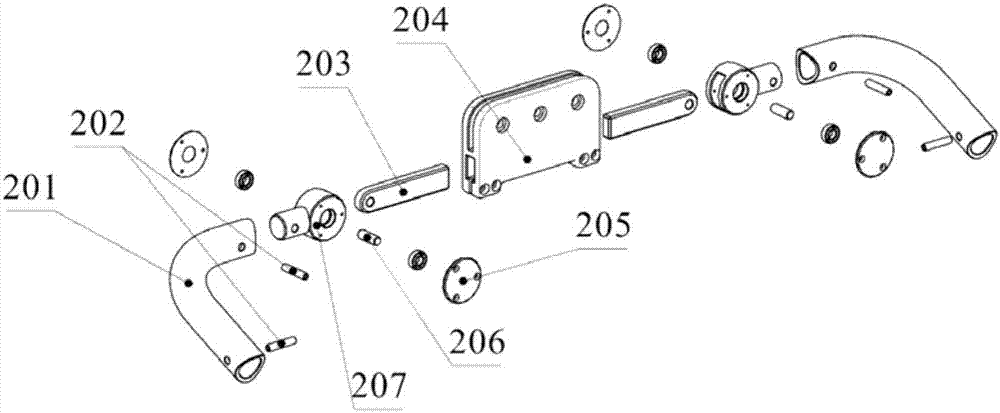

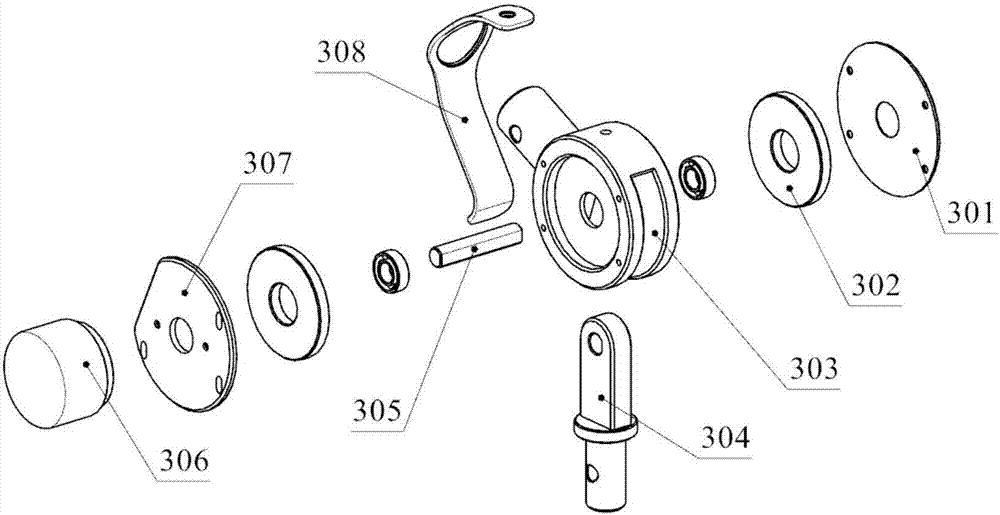

The invention discloses a tubular and modular wearable exoskeleton assisting device and a control method thereof. The tubular and modular wearable exoskeleton assisting device comprises a back plate, a length-adjustable tubular thigh mechanism, a length-adjustable tubular shank mechanism, a width-adjustable tubular waist mechanism, ankle joints, a foot mechanism, hip joints and knee joints, wherein the hip joints and the knee joints are modularly adjustable in parts; the tubular and modular wearable exoskeleton assisting device has 14 degrees of freedom, 7 on each side and accordingly can simulate various motions of human lower limbs. The control method comprises collecting man-machine interaction information of a wearer and the device through sensors of the tubular shank mechanism and the foot mechanism, and taking joint encoder information as feedback to control an executor to drive the tubular and modular wearable exoskeleton assisting device to move. The tubular and modular wearable exoskeleton assisting device is simple in structure, modularized in replacement of parts and easy to control, and meanwhile, can be applied to enhancing loading capacity and assisting walking for a wearer and performing walking assistance and rehabilitation training on patients suffering from lower limb motor disturbance or myasthenia.

Owner:NANJING UNIV OF SCI & TECH

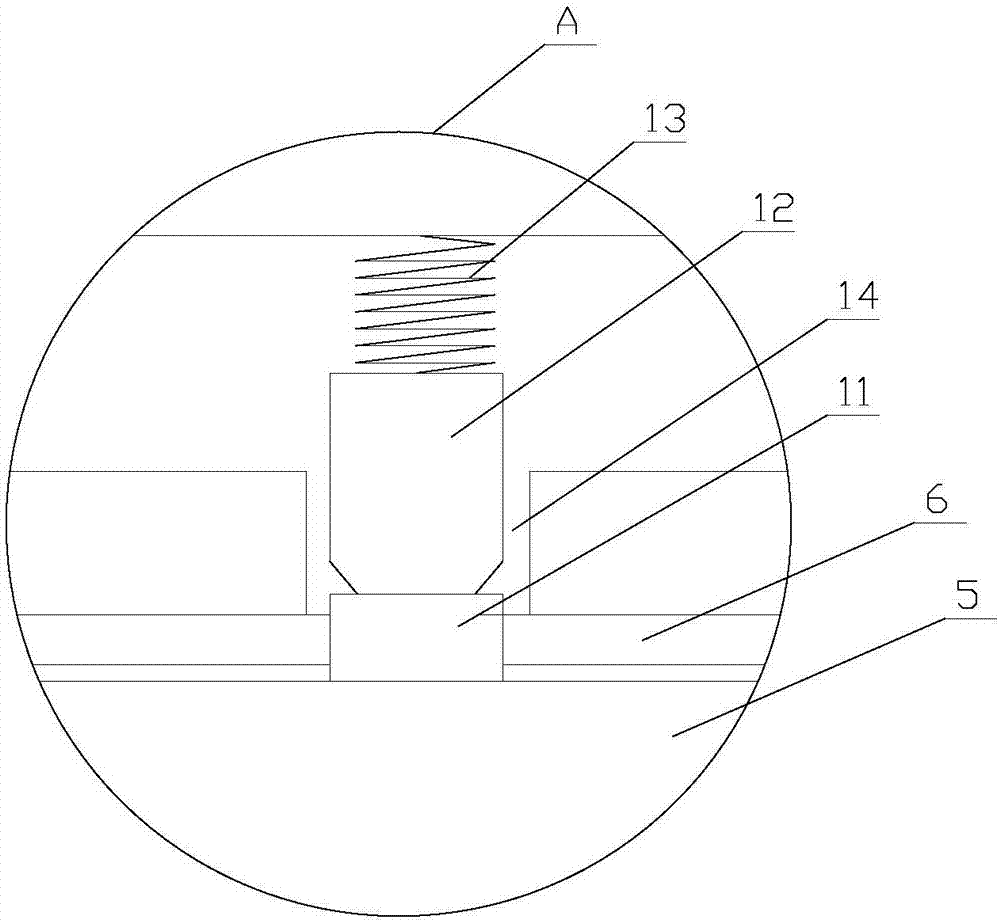

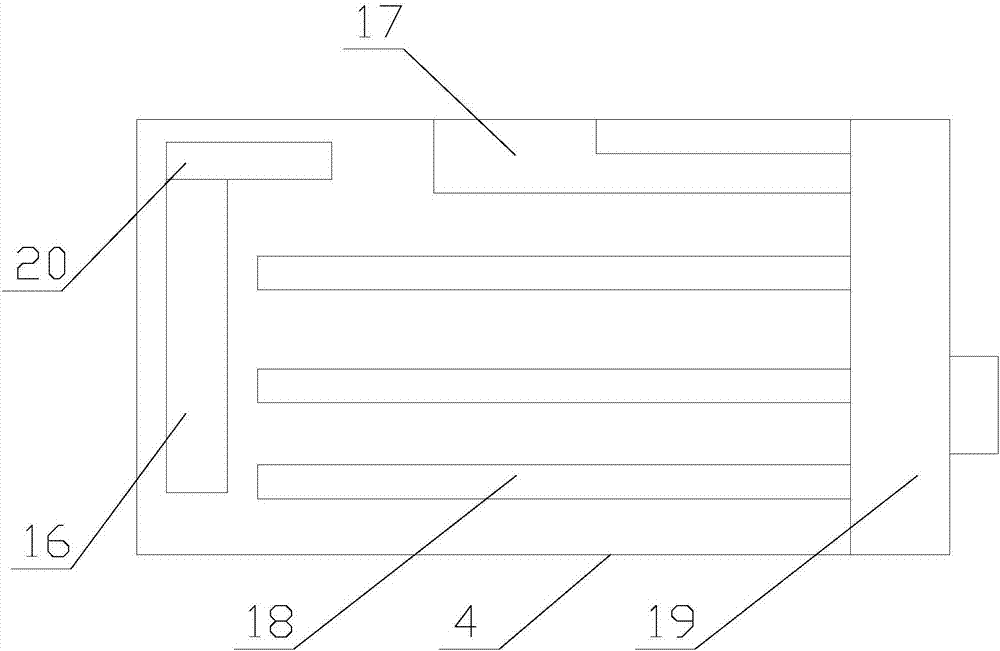

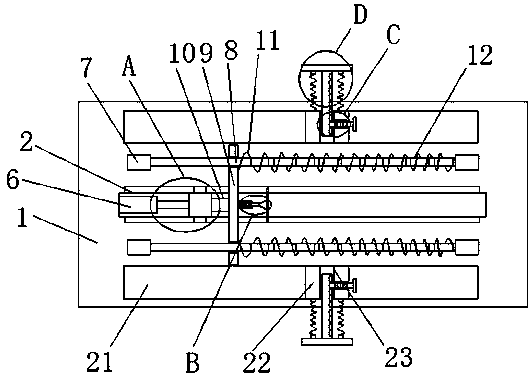

New energy automobile battery with collision protection function

ActiveCN107146865AReduced speed of hitting the first airbagProtection securityFinal product manufactureBattery isolationLow voltageNew energy

The invention relates to a new energy automobile battery with a collision protection function. The new energy automobile battery comprises a protection shell, a battery box and a collision preventing assembly; the battery box comprises a box top, a battery pack, an air inlet pipe, a distribution box, a battery management module, a high-voltage wiring harness, a low-voltage wiring harness, a cooling fan, air outlet pipes and a base; the collision preventing assembly comprises guiding grooves, limiting units, a first airbag, a first ventilating pipe, a second airbag and a second ventilating pipe; each limiting unit comprises a first spring and a limiting block; when the new energy automobile is in collision, a safety airbag inflates the first airbag and the second airbag, so that the limiting block leaves the corresponding limiting hole; and the battery box slides on the guiding grooves with certain buffering, and then is collision with the first airbag to be detected, so that the rigid collision is greatly lowered, thereby protecting the new energy automobile battery with the collision protection function from being damaged, and ensuring the normal operation of the automobile.

Owner:JILIN UNIV

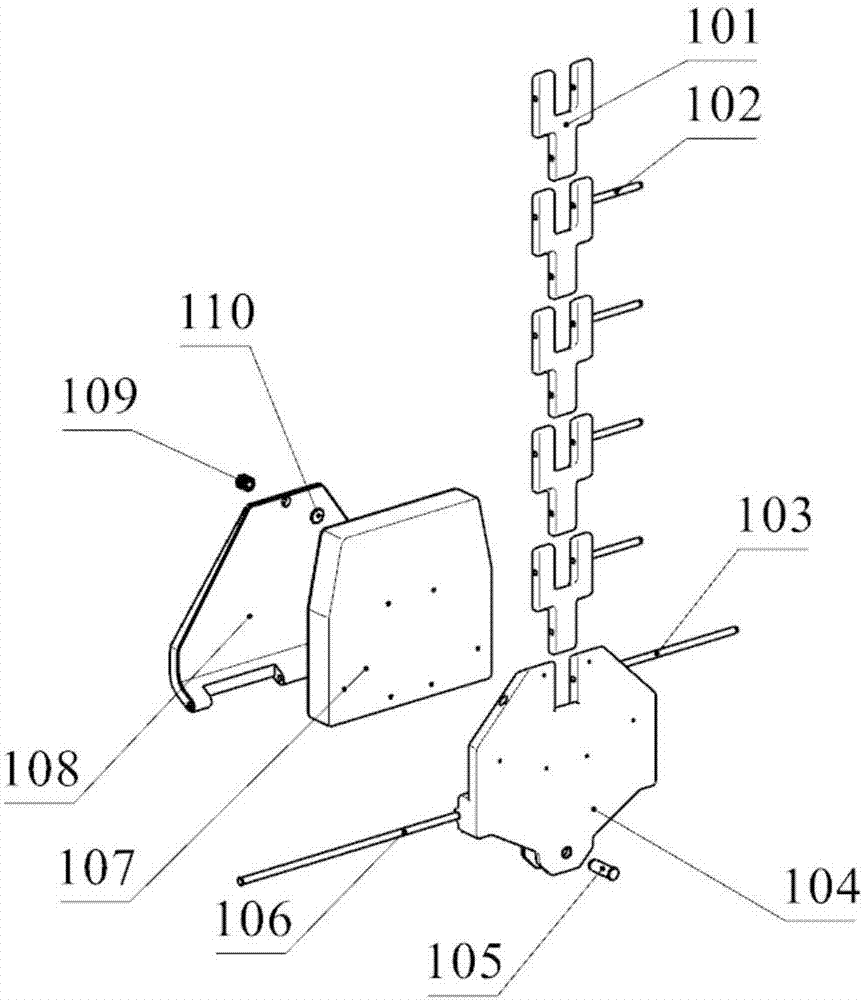

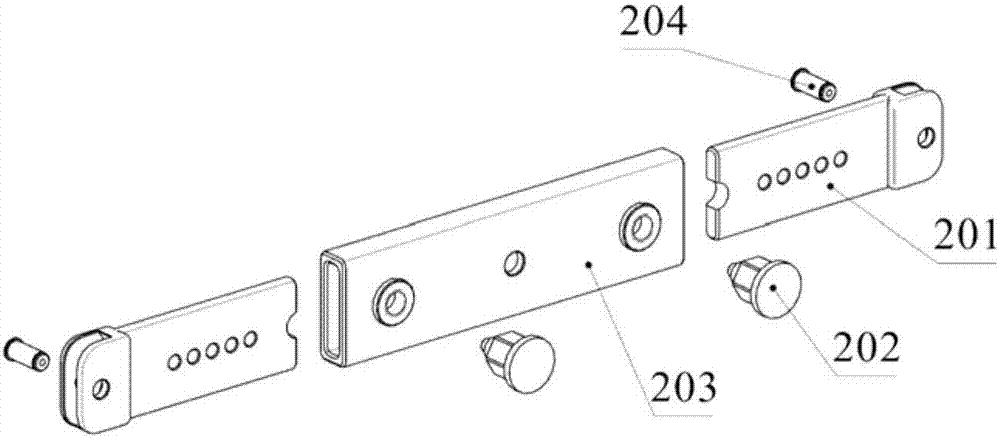

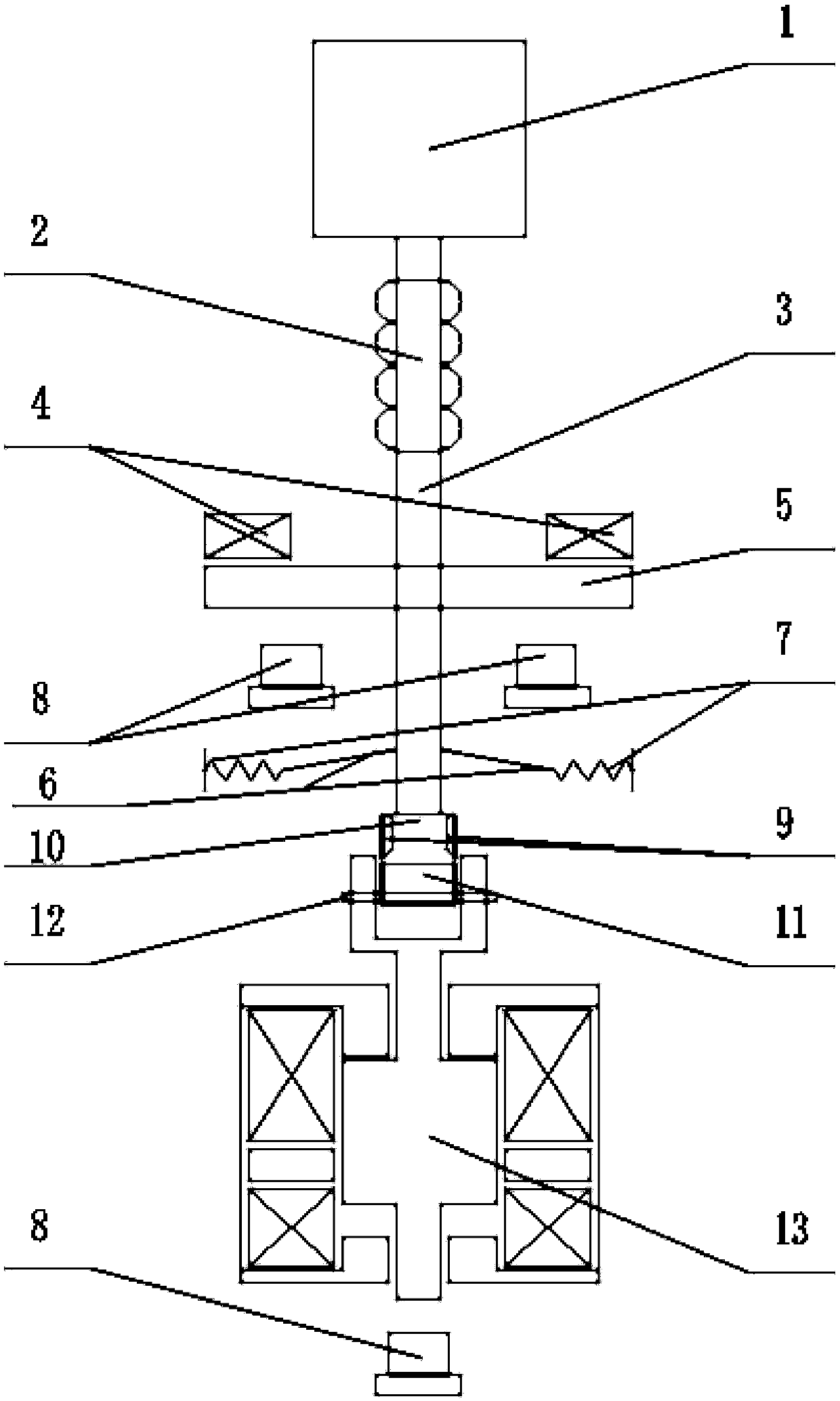

Light clutch type assisting exoskeleton device and control method thereof

ActiveCN107510575ASimple structureCompact structureProgramme-controlled manipulatorDiagnosticsKnee JointEngineering

The invention discloses a light clutch type assisting exoskeleton device and a control method thereof. The light clutch type assisting exoskeleton device can simulate human motions to assist the human body to bear load and comprises a frame carrier, a waist mechanism, hip joints, knee joints, ankle joints and feet which are sequentially arranged from top to bottom. The light clutch type assisting exoskeleton device has multiple freedom degrees, can simulate multiple motions of the human body and can better achieve matching with the human motions. A clutch type joint driven assistance mode is adopted, required sensing hardware requirements are low, control is convenient to achieve, clutch type driving energy can be integrally designed with the structure of the light clutch type assisting exoskeleton device, and the mass and volume of the light clutch type assisting exoskeleton device are effectively decreased. The light clutch type assisting exoskeleton device is simple and reliable in structure, high in integration and easy to control and can be used for strengthening the load-bearing capability of a wearer and assisting walking, and the fatigue feeling of load-bearing motions of the human body is effectively reduced.

Owner:NANJING UNIV OF SCI & TECH

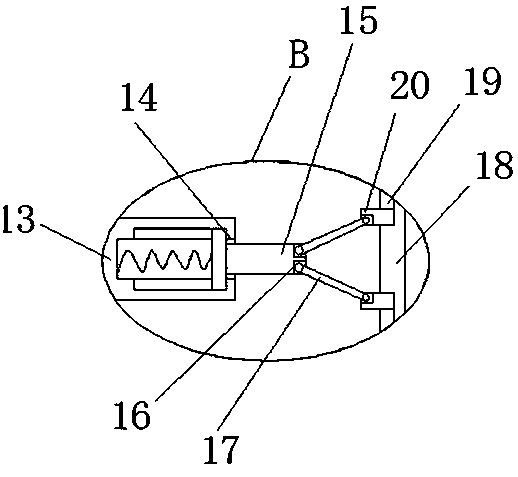

Electronic actuator with reset function

The invention discloses an electronic actuator with a reset function. The electronic actuator comprises a base, wherein a first chute is formed in the base, a first sliding block is installed in the first chute in a sliding mode, one side of the first sliding block extends to the outer side of the first chute, clamping grooves are symmetrically formed in the inner walls of both sides of the firstchute, clamping blocks are symmetrically welded on both sides of the first sliding block, the clamping blocks are installed in the clamping grooves in a sliding mode, an electric air cylinder is fixedly installed on the inner wall of one side of the first chute, an output shaft of the electric air cylinder makes contact with the first sliding block, a push rod which is welded on one side, which isfar from the electric air cylinder, of the first sliding block is arranged above the base, a reset plate is welded on one side, which is far from the first sliding block, of the push rod, the reset plate is located above the base, and reset modules are arranged on the both sides of the first chute. The electronic actuator has the advantages of simple structure and convenience in operation, materials can be effectively prevented from being damaged by rigid collision by virtue of a buffer module, and additionally, the push distance can be set as required.

Owner:合肥雷光动力科技有限公司

Vehicle-mounted cup holder

The invention relates to the technical field of automobile interior decoration, A vehicle-mounted cup holder is disclosed, the vehicle-mounted cup holder includes a cup holder body, A side wall of thecup holder body is provided with a cavity, a first support plate and a second support plate are fixedly connected with the cup holder body, a second support plate is slidably connected with a slidingrod, one end of the sliding rod is fixedly connected with a limiting plate, both sides of the sliding rod are slidably connected with a first pushing rod, an elastic pulling rope is connected betweenthe lower end of the sliding rod and the first pushing rod, and a through hole is arranged on the side wall of the cup holder body; A first cylinder body and a second cylinder body are arranged in the cavity, a piston is slidably connected with the first cylinder body, and a second push rod is fixedly connected with one side of the piston block; An elastic air bag is fixedly connected with the inner surface of the cup holder body; The second cylinder body is provided with a baffle plate sliding through the side wall of the second cylinder body. The invention has the advantage that the water cup can be prevented from being broken by collision.

Owner:埃维尔汽车部件(苏州)有限公司

Cup holder for automobile

The invention relates to the technical field of automobile interior decoration, and discloses a cup holder for an automoible, which comprises a cup holder body, wherein the side wall of the cup holderbody is rotatably connected with a lead screw, the lead screw is threadably connected with a sliding block, the cup holder body is hinged with a dialing rod, the upper end of the dialing rod is slidably connected with a slide plate, the slide plate is slidably arranged in the cup holder body, an arc block is slidably connected with the slide plate, a baffle plate is arranged on one side of the arc block, and a first spring is connected between the baffle plate and the arc block; A support block is fixedly connected with that cup support body, and a flexible pulling rope is connected between the support block and the arc-shaped block; A support block is provided with a groove, and a cylinder body is arrange in that support block, a piston is slidably connected with the cylinder body, the piston divides the cylinder body into a first chamber and a second chamer, a push rod is fixedly connected with one side of the piston, a push rod is fixedly connected with a push plate, an elastic airbag is fixedly connected with the side wall of the groove, and an air vent pipe is communicated between the elastic air bag and the second chamber. The invention has the advantages that the water cupcan be clamped and fixed, and the water cup can be prevented from being broken due to collision.

Owner:宁波隆锐机械制造有限公司

Computer mainframe box

InactiveCN104536544AHelp limitHelp with shock absorptionDigital processing power distributionFixed-functionEngineering

Owner:ANHUI YUHUI ELECTRONICS TECH

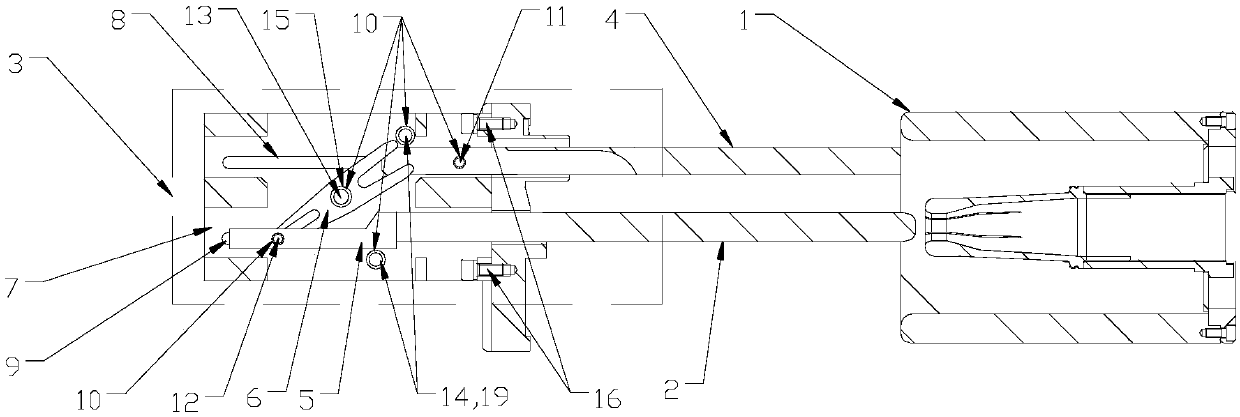

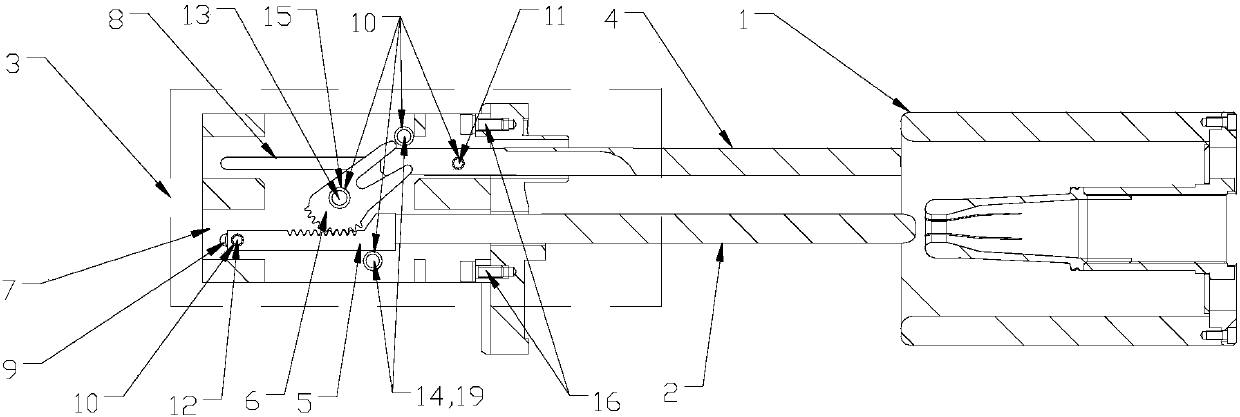

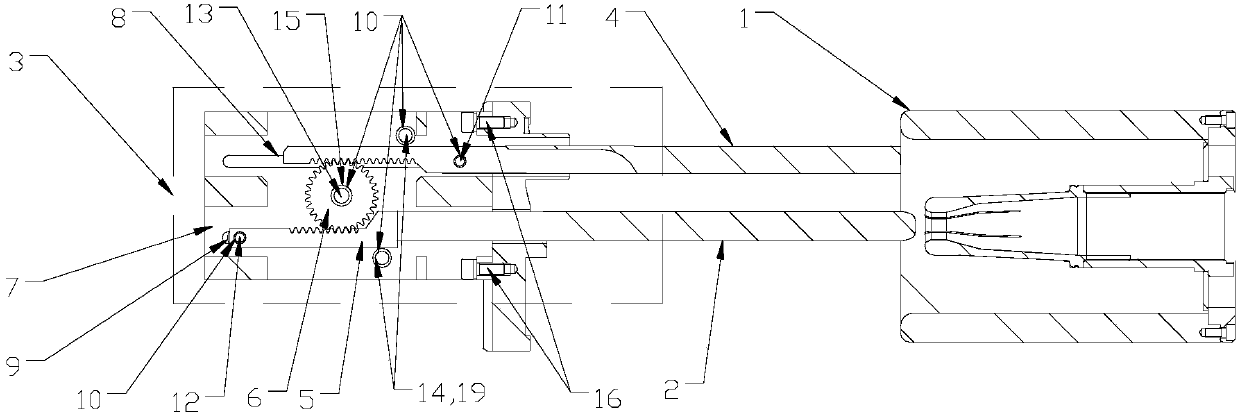

Mechanical quick switch based on electromagnetic repulsion mechanism

PendingCN110875162AWill not affect the opening speedImprove reliabilityElectromagnetic relay detailsMiniaturizationEngineering

The invention discloses a mechanical quick switch based on an electromagnetic repulsion mechanism, and belongs to the technical field of switch cabinets. The mechanical quick switch comprises a connecting rod, a bistable holding mechanism, an operating mechanism and a set of electromagnetic repulsion mechanism, wherein the connecting rod moves under the driving of the electromagnetic repulsion mechanism or the operating mechanism so as to enable the mechanical quick switch to open; the connecting rod moves under the driving of the operating mechanism so as to enable the mechanical quick switchto close; during the opening or closing movement of the connecting rod, the bistable holding mechanism applies a holding force to the opening and closing state of the connecting rod; in the quick opening process, the electromagnetic repulsion mechanism and the operating mechanism are completely independent; and the electromagnetic repulsion mechanism and the operating mechanism can realize the opening operation. According to the invention, the miniaturization and intensification of a circuit breaker can be realized; the problem of rigid collision between the electromagnetic repulsion mechanism and the closing holding mechanism is solved; different opening operation modes can be adopted under the normal working condition and the fault working condition.

Owner:JIANGSU KAIFAN ELECTRICAL APPLIANCES

Arc extinguishing chamber for high-voltage circuit breaker

ActiveCN107658175AControl motion overshootGuaranteed stabilityHigh-tension/heavy-dress switchesAir-break switchesPush pullRelative motion

The invention provides an arc extinguishing chamber for a high-voltage circuit breaker. The arc extinguishing chamber comprises a motion reversing mechanism, a driving side contact and a driven side contact, wherein the driving side contact and the driven side contact are arranged on the motion reversing mechanism separately and move oppositely; the motion reversing mechanism comprises a driving side push-pull rod connected with the driving side contact, a driven side push-pull rod connected to the driven side contact, a reversing device and an integrally molded guide rail; two motion channelsfor opposite motion of the driving side push-pull rod and the driven side push-pull rod are arranged in the guide rail; the guide rail is provided with a driving side push-pull rod sliding rail and adriven side push-pull rod sliding rail; the driving side push-pull rod and the driven side push-pull rod are arranged in the corresponding sliding rails through shaft pins in a sliding manner; a limiter is arranged at one side of the driving side push-pull rod sliding rail and / or the driven side push-pull rod sliding rail for limiting and auxiliary guiding of the driving side push-pull rod and the driven side push-pull rod. A double-acting arc extinguishing principle is adopted by the arc extinguishing chamber, so that the arc extinguishing chamber is simple in structure, reasonable in design, simple in operation and reliable in working, the stability is greatly improved and the mechanical life is greatly prolonged.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

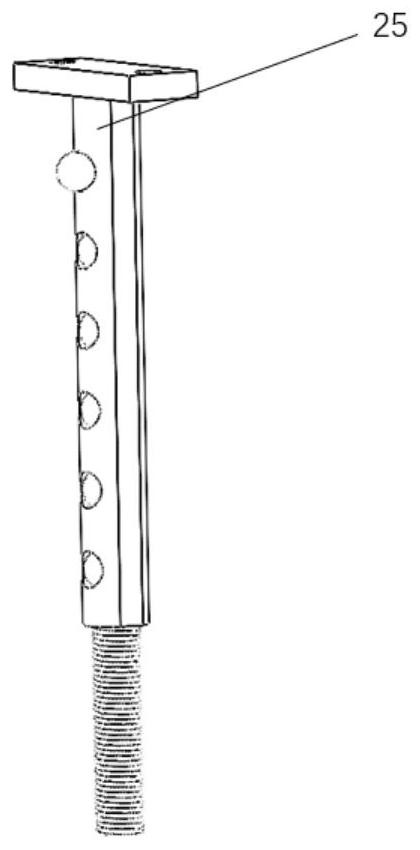

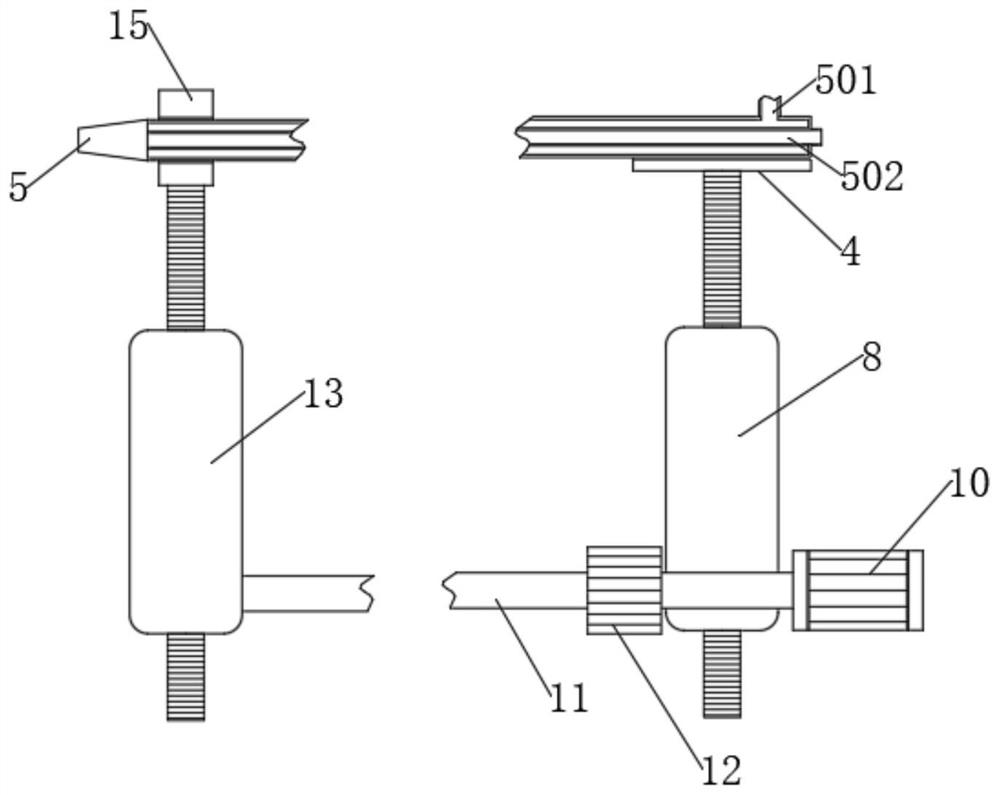

Auxiliary steel bar pulling tool for neckband rubber-coated product

InactiveCN110900949AAvoid damageHigh precisionVibration suppression adjustmentsSteel barProcessing accuracy

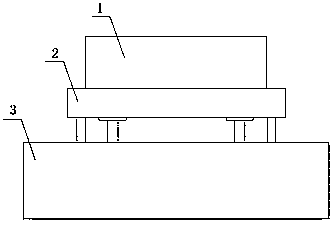

The invention discloses an auxiliary steel bar pulling tool for a neckband rubber-coated product, which includes a tool body, a base and a support base. The tool body is fixedly installed on the upperend of the base. The base is located above the support base. Four groups of buffer mechanisms are fixedly installed at the bottom inside the support base. A buffer plateis fixedly installed at the upper ends of the four groups of buffer mechanisms. Support rods are fixedly installed at the four corners on the upper end of the buffer plate. The tops of the support rods penetrate through the support base and are fixedly connected to the bottom of the base. Through the installed buffer mechanisms and the cooperation of a first spring and a second spring, the buffer plate has very good cushioningand resilience, can effectively reduce damage to the tool body caused by vibration, can not only improve the processing accuracy of the tool body, but also extend its service life.

Owner:深圳市兴盛达橡塑制品有限公司

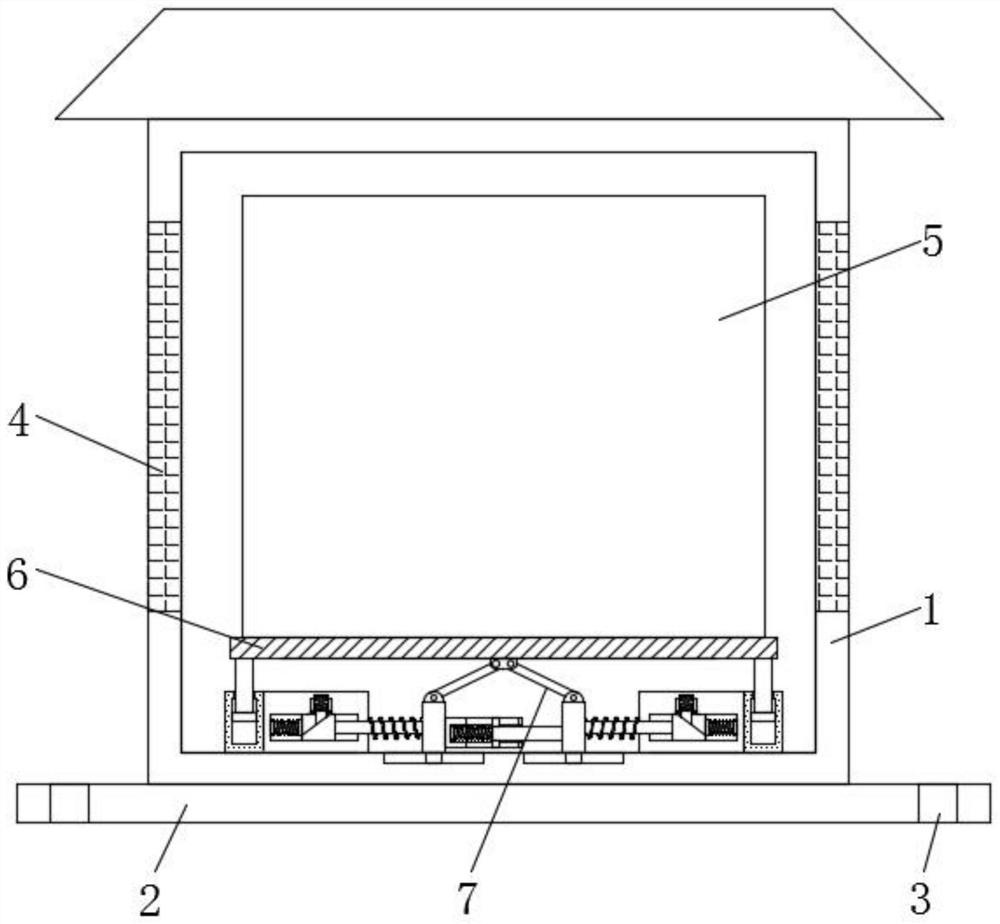

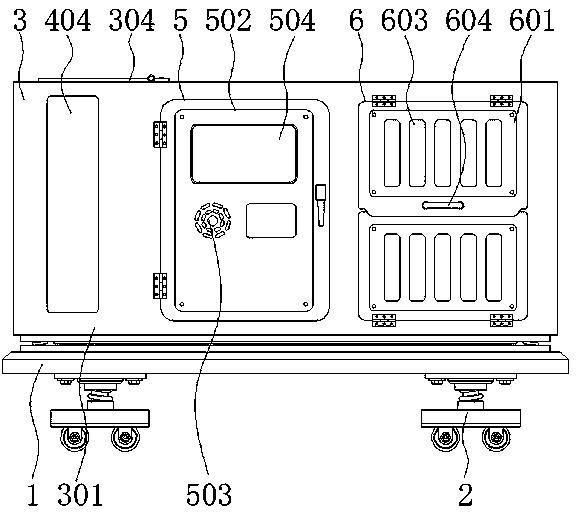

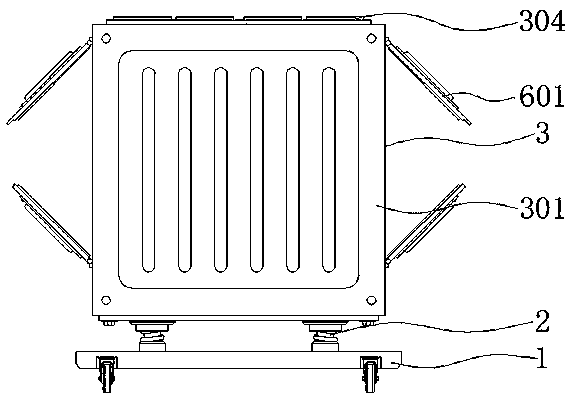

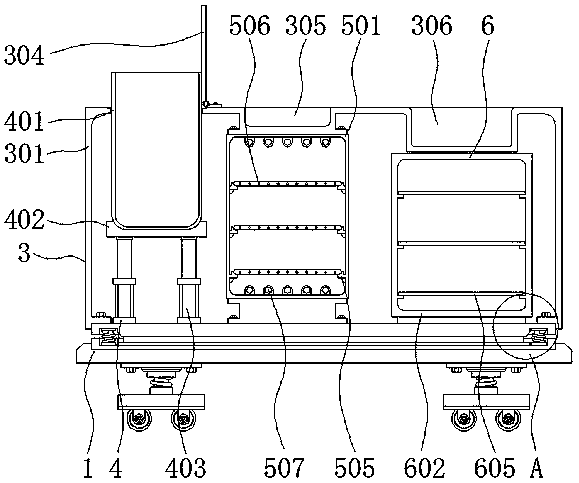

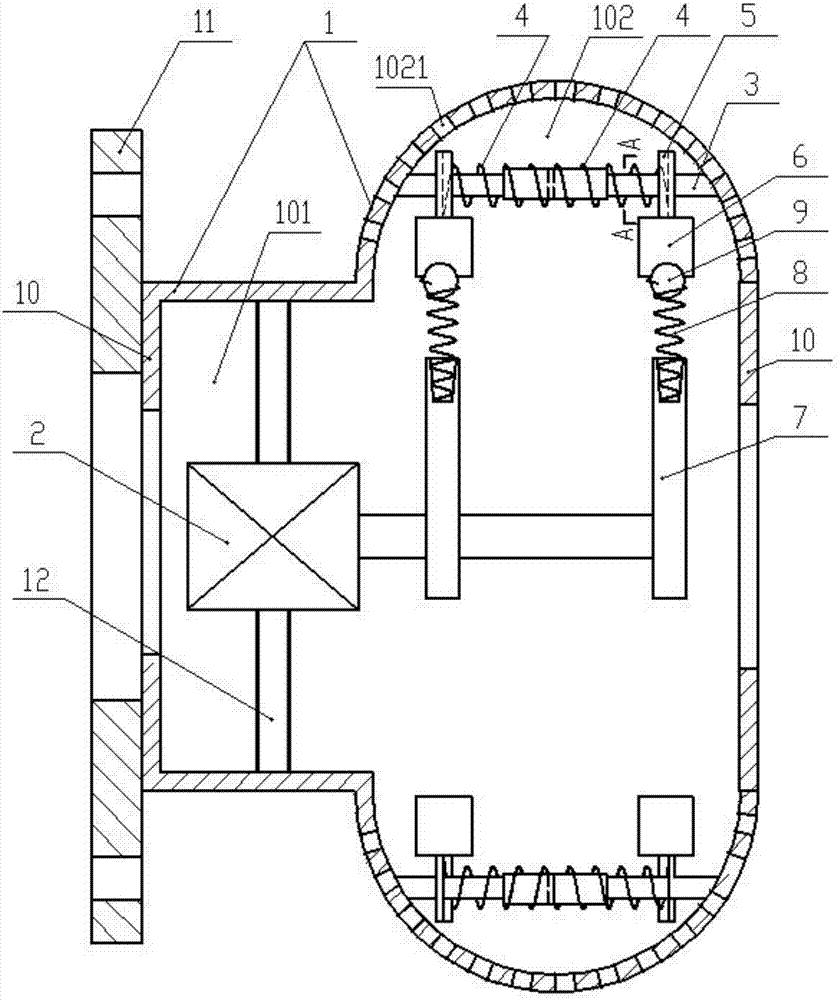

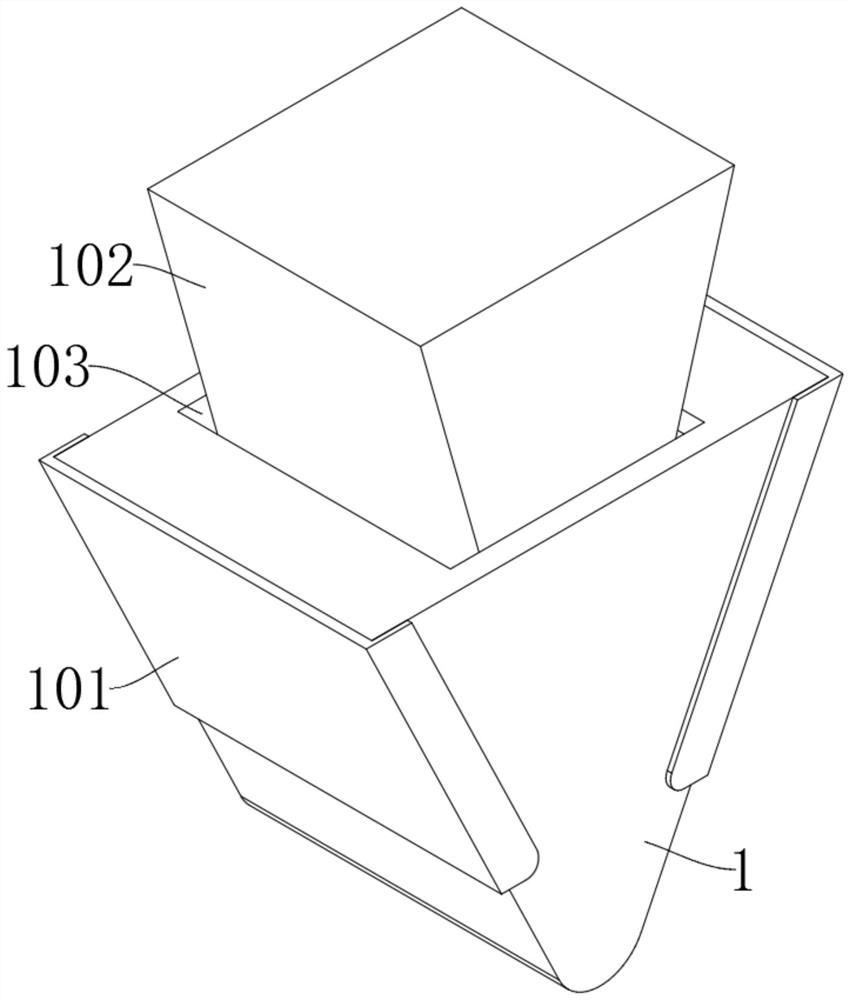

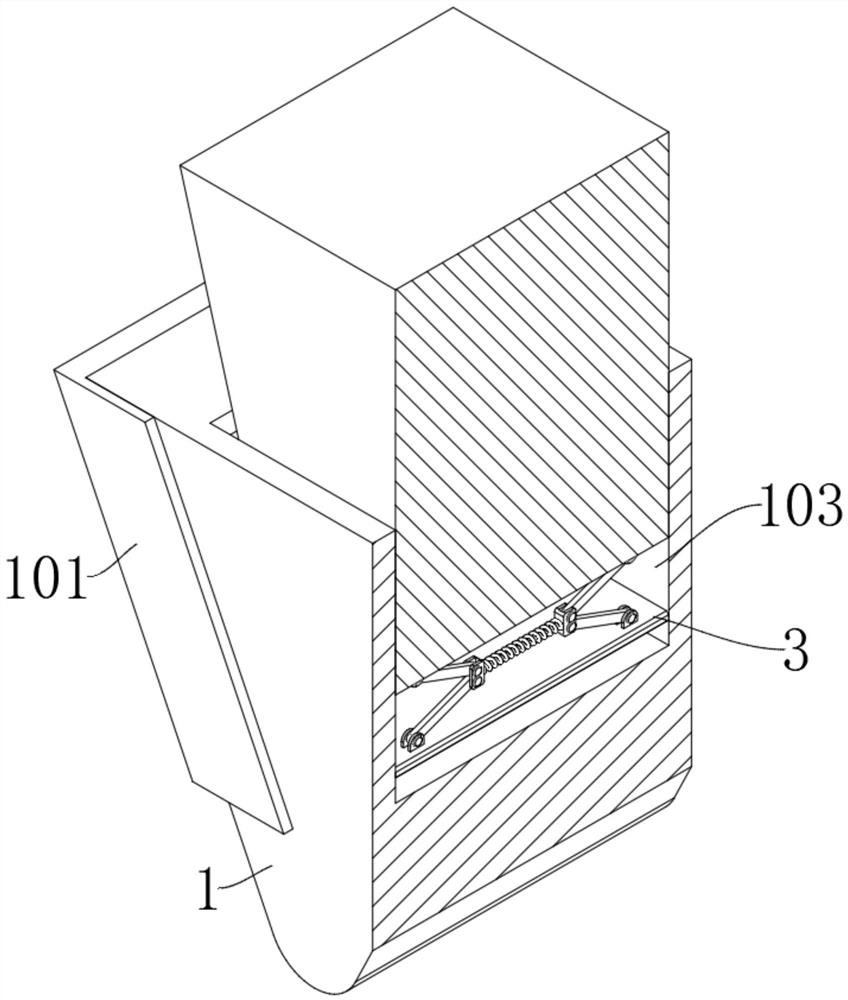

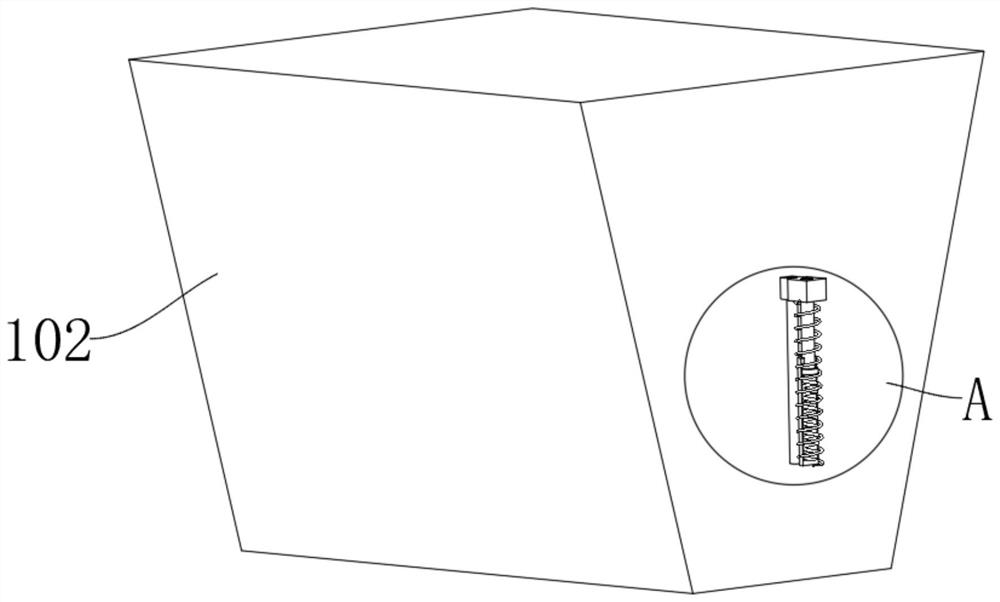

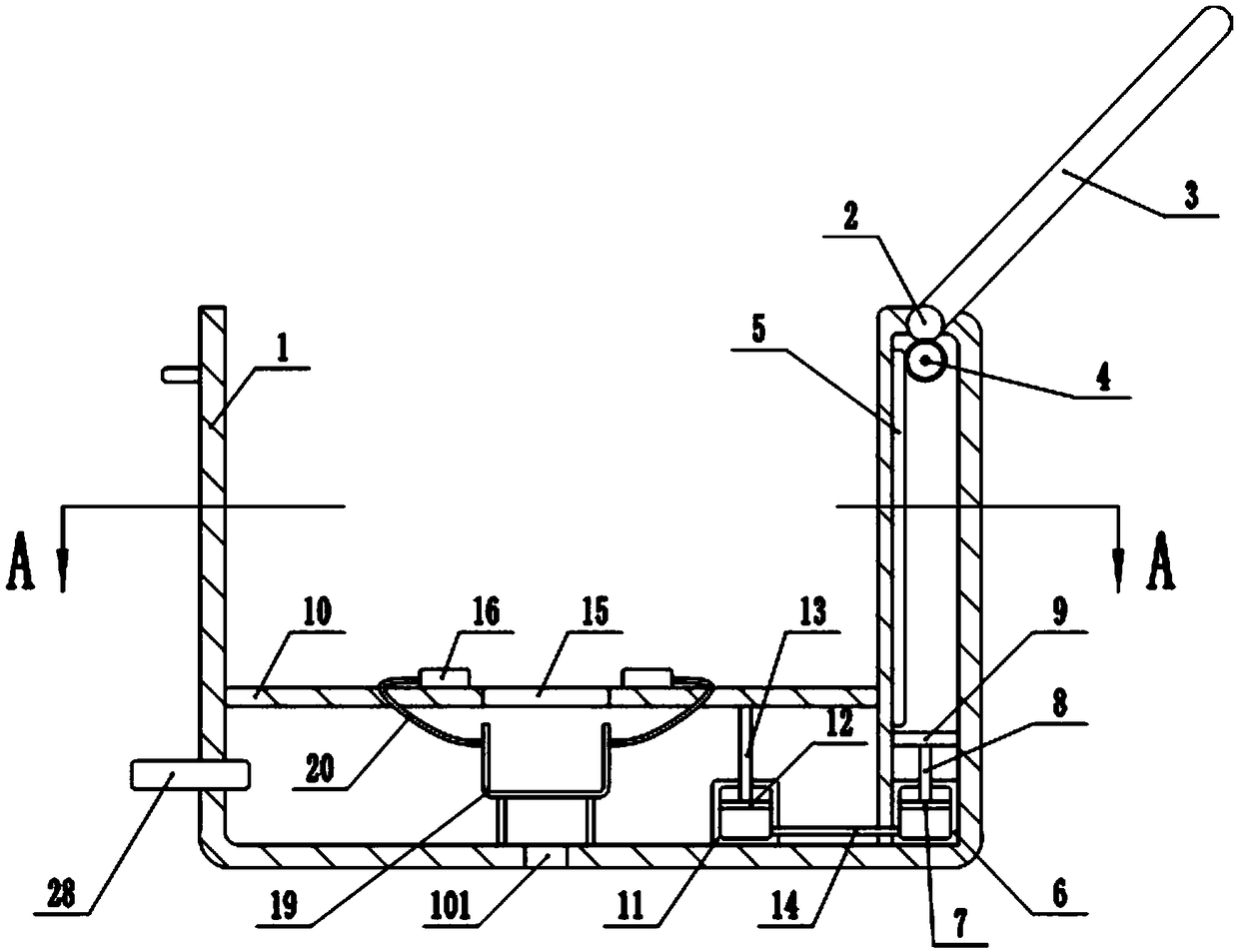

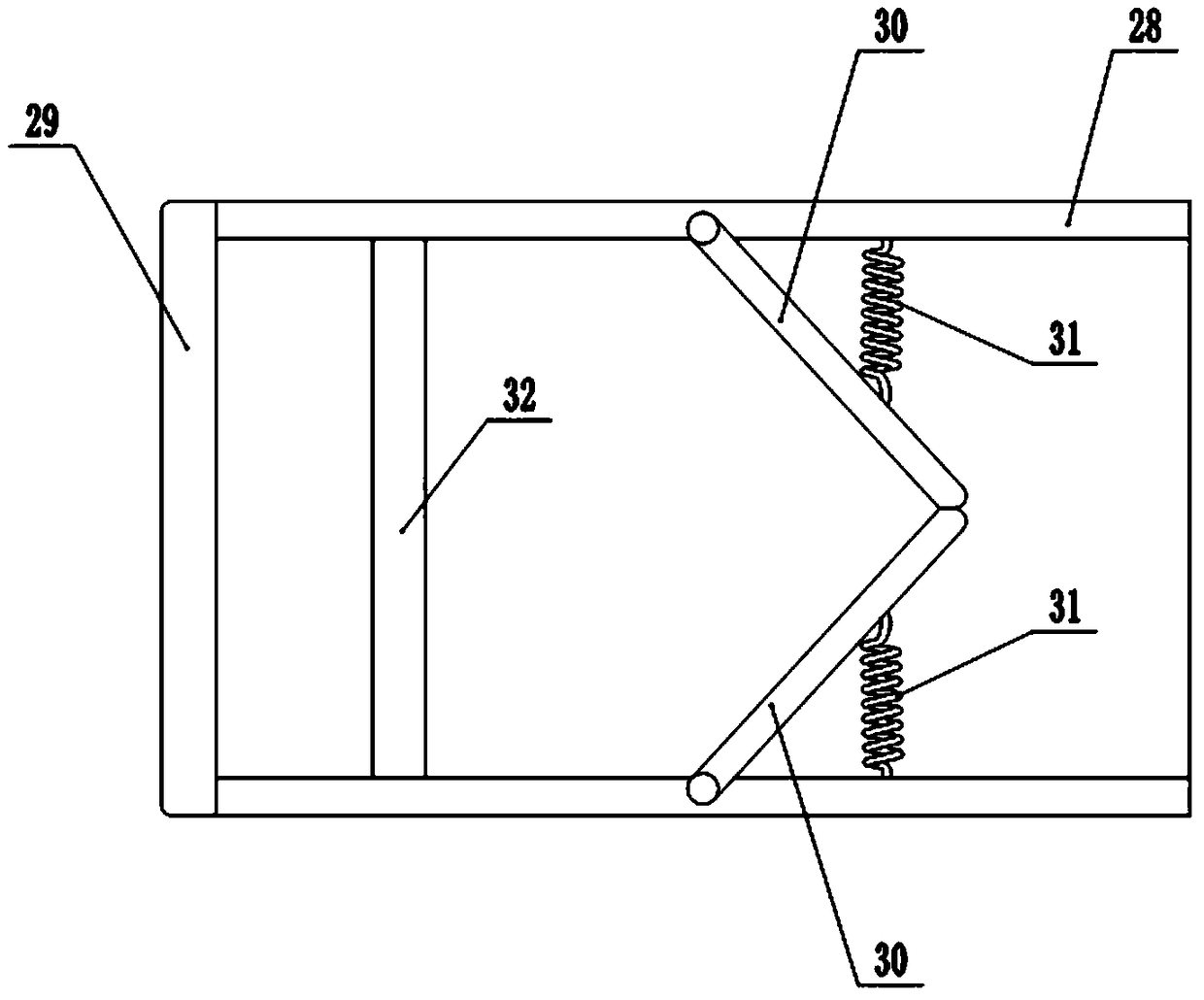

Low-noise prefabricated substation

ActiveCN111817143AWeaken Rigid CollisionReduce vibrationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringStructural engineering

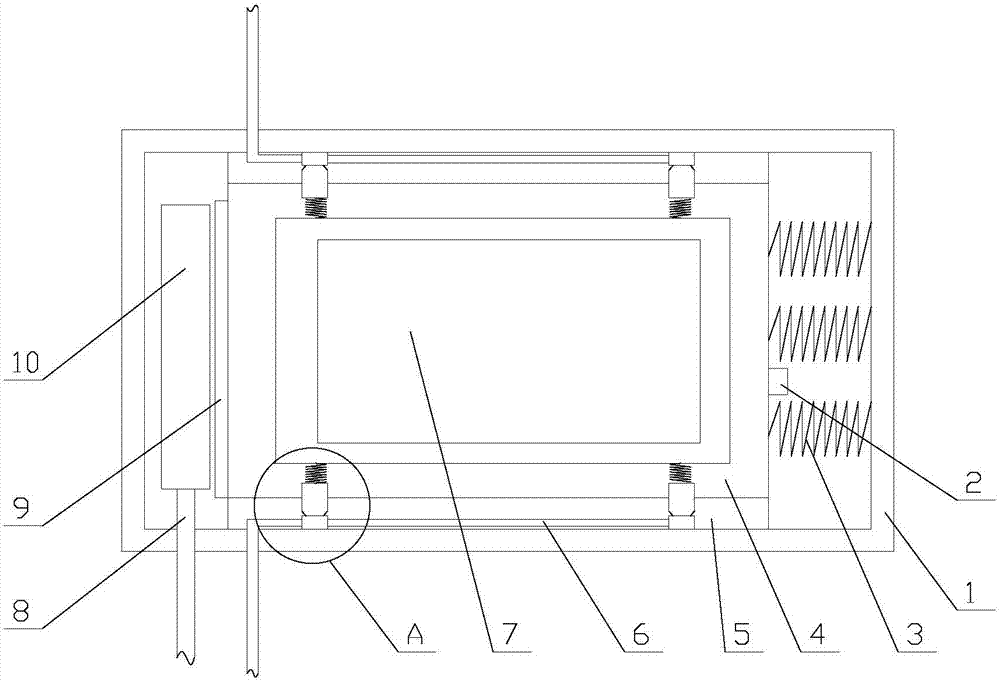

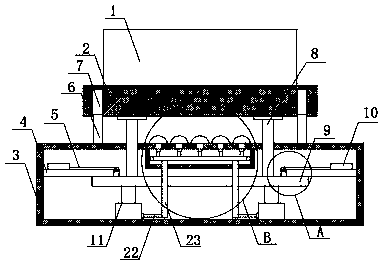

The invention belongs to the technical field of prefabricated substations, and discloses a low-noise prefabricated substation. The prefabricated substation comprises a shell, a mounting plate is fixedly connected to the bottom of the shell, mounting holes are formed in the four corners of the top of the mounting plate, heat dissipation nets are embedded in the left side and the right side of the shell, a left-right machine body are arranged in the shell, and a fixing block is fixedly connected to the bottom of the machine body. The machine body operates and vibrates, a guide device makes the fixing block and the machine body move up and down in the vertical direction, and with the up-and-down movement of the machine body, the limitation and guidance of a sliding block and a horizontal groove make two inclined rods drive two connecting blocks to get close to each other and get away from each other, so that force in the vertical direction is converted into force in the horizontal direction, stress is counteracted through mutual cooperation of a first-stage vibration and noise reduction assembly and a second-stage vibration and noise reduction assembly, vibration is reduced, rigid collision between the machine body and the shell is red cuced, and noise is lowered.

Owner:JIANGXI MINGZHENG SUSTION EQUIP

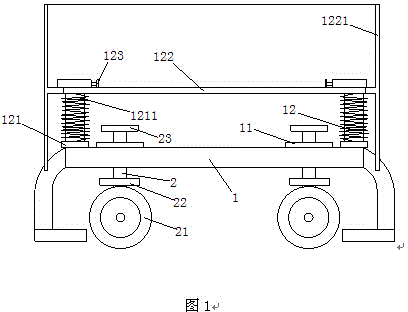

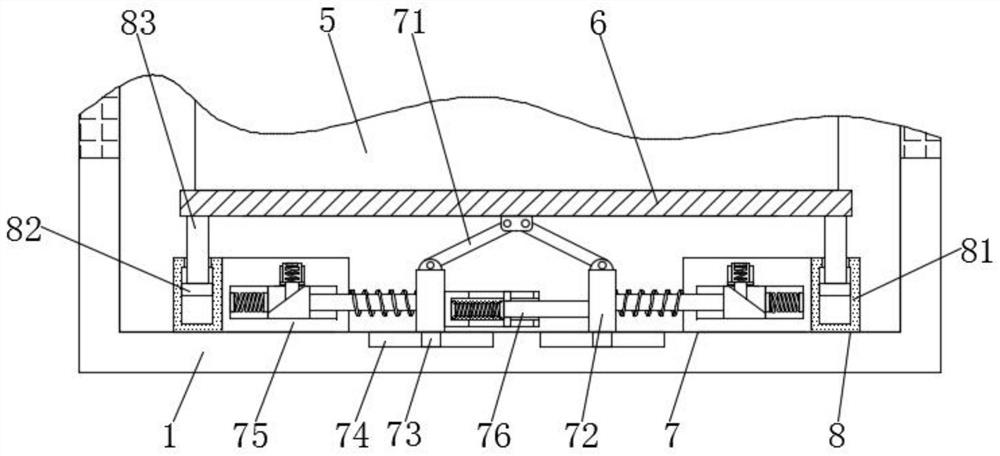

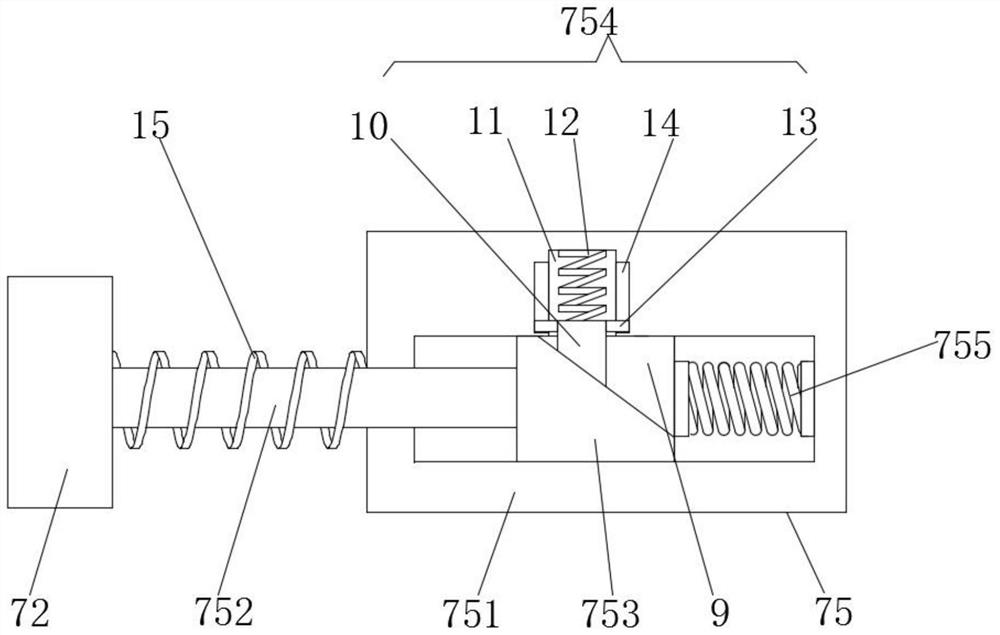

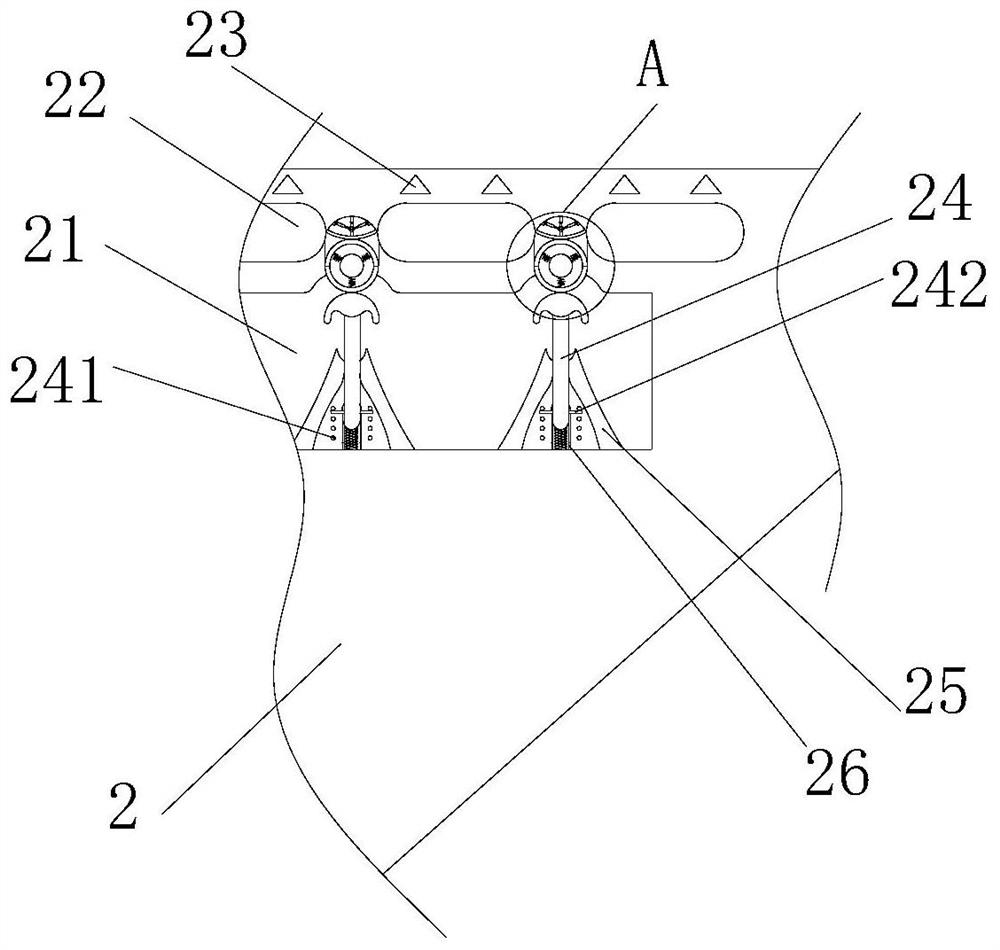

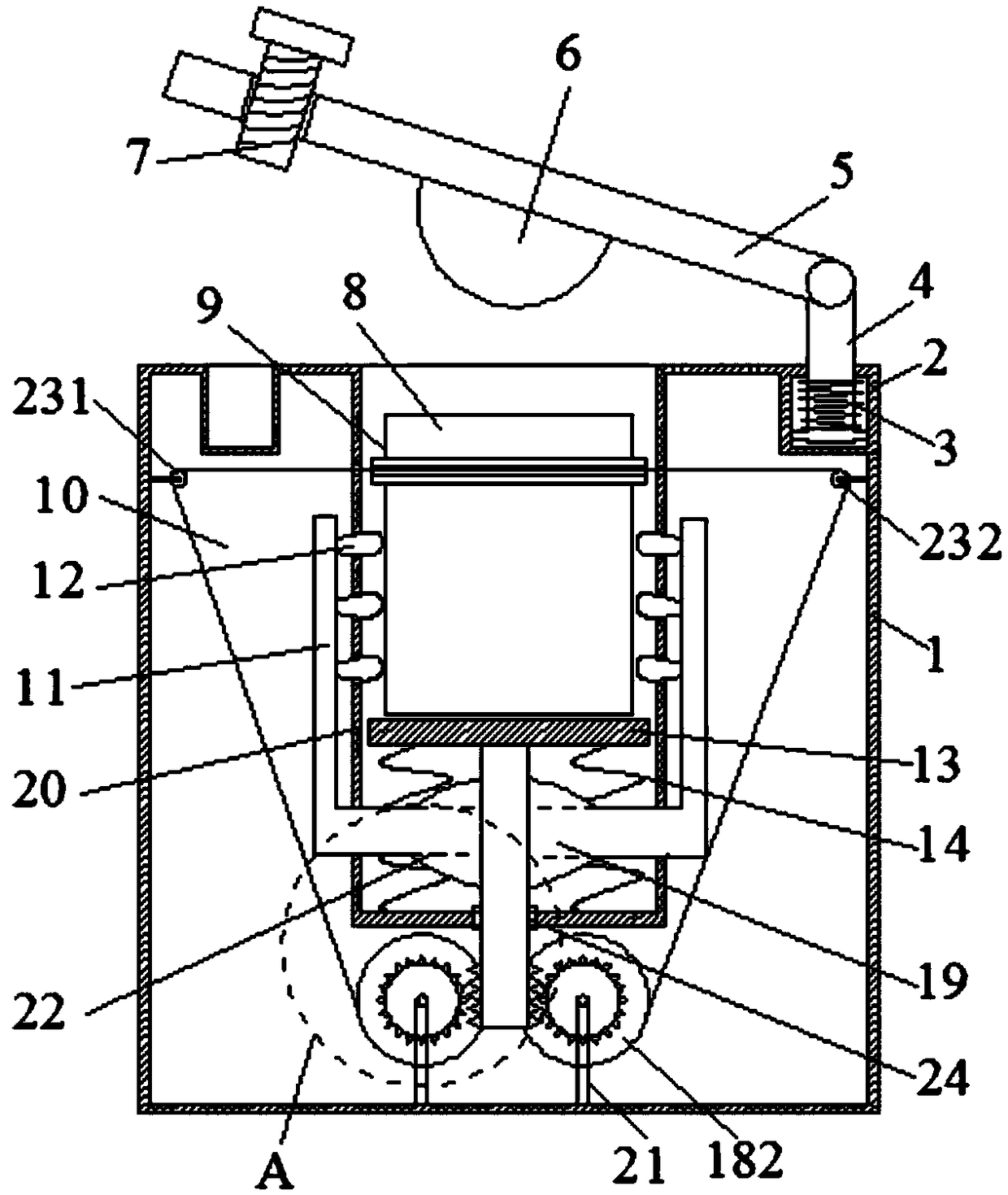

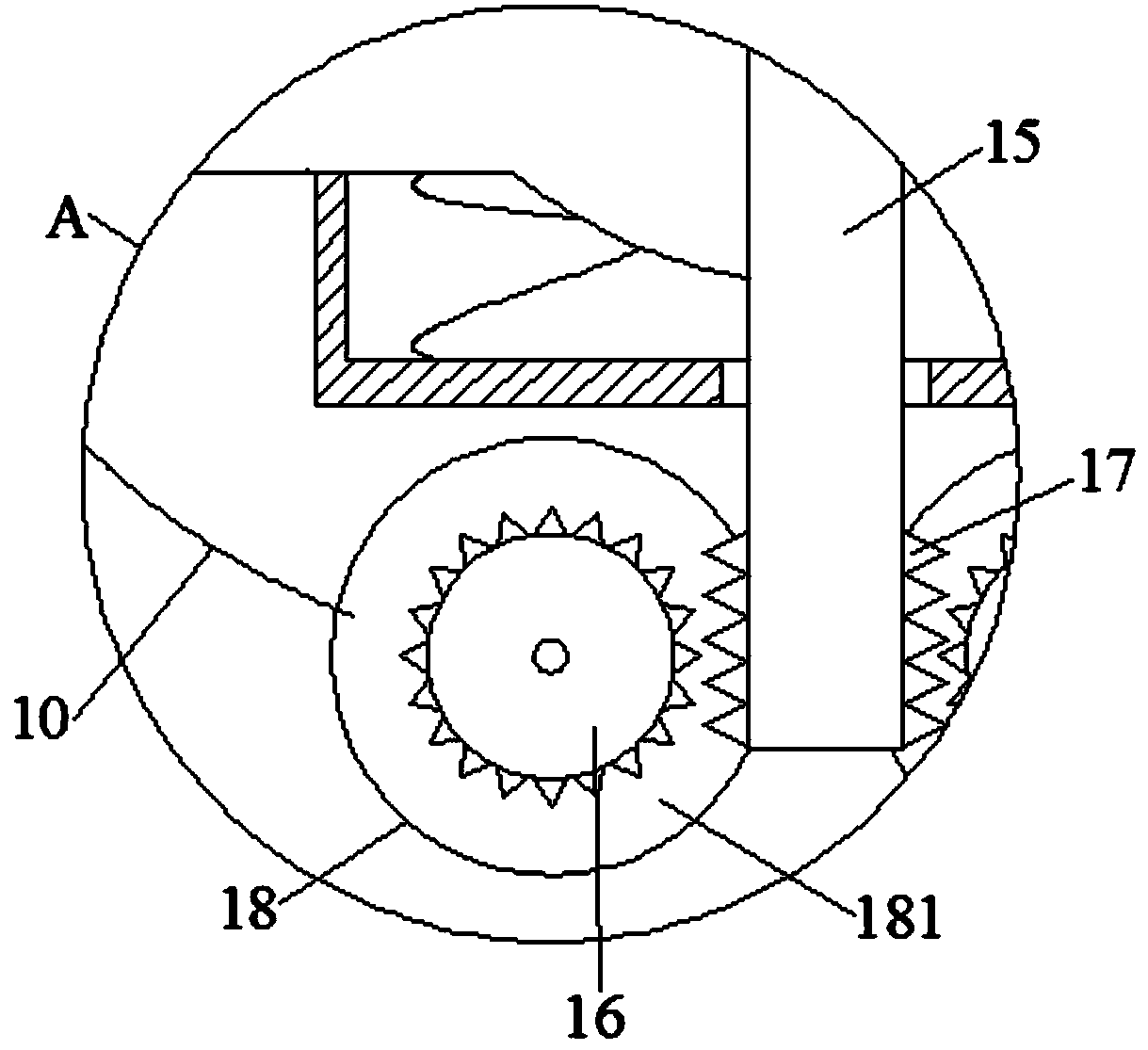

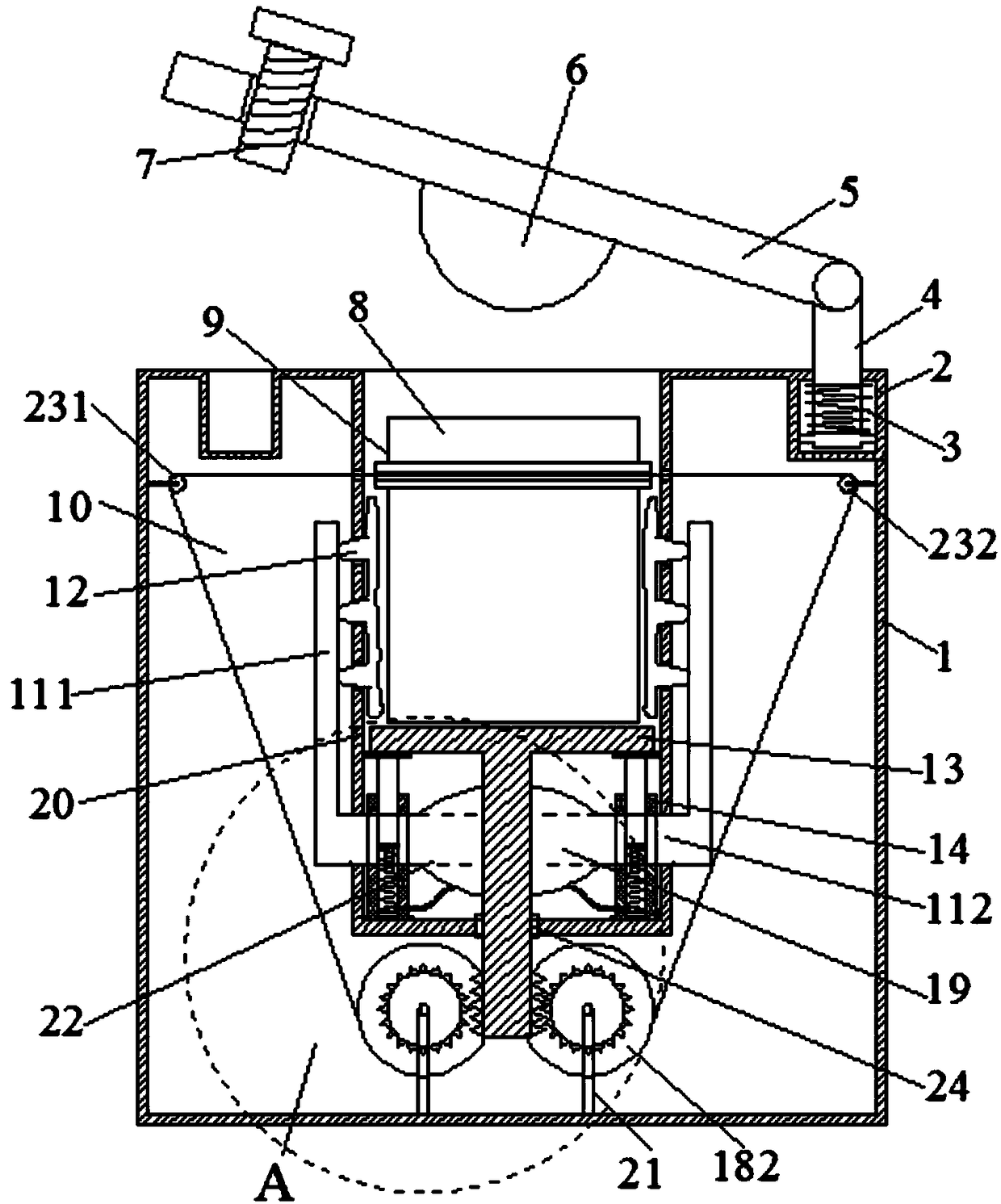

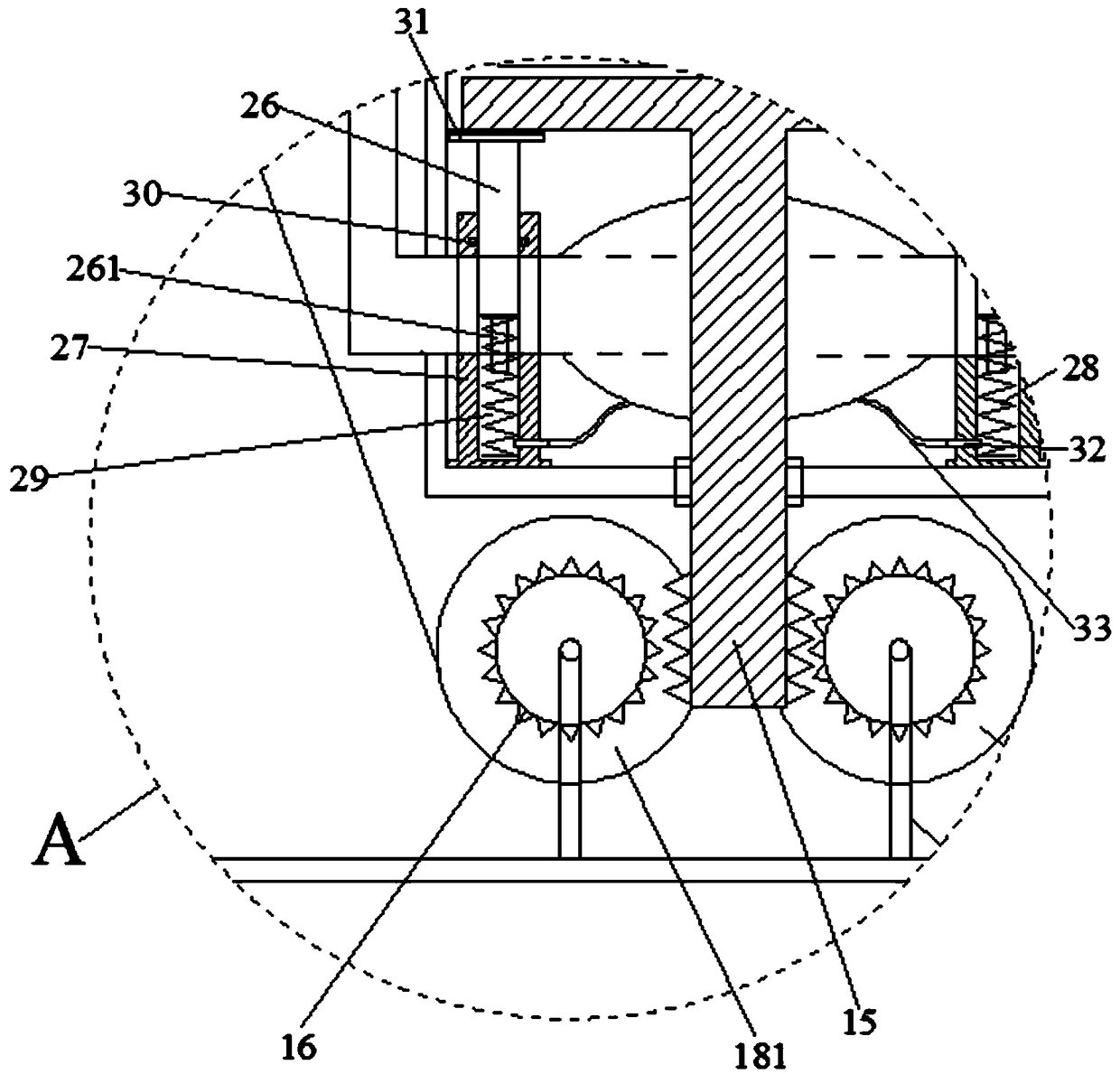

Wheel type convenient-to-move medical assistance robot

InactiveCN110304373AAvoid rigid contactReduce wearRefuse receptaclesRefuse cleaningMedical robotWaste collection

The invention discloses a wheel type convenient-to-move medical assistance robot, and relates to the technical field of medical robots, in particular to the wheel type convenient-to-move medical assistance robot. The wheel type convenient-to-move medical assistance robot comprises a composite base and wheel type mechanisms, wherein the wheel type mechanisms are arranged below the composite base; each wheel type mechanism comprises a jointing base, an internal spring, a fixed base, a locking screw and a movable wheel, the locking screw is arranged inside the jointing base, the fixed base is arranged below the internal spring; a garbage collecting mechanism is arranged at the left side inside a main body housing; and a storage mechanism is arranged at the right side of a disinfection cabinet. The wheel type convenient-to-move medical assistance robot disclosed by the invention reduces internal structures of the robot as many as possible while keeping equipment functionality; and improvedequipment is simpler to operate in use, and more different functions are increased, so that the robot can be suitable for more departments and medical service conditions, and therefore, use needs ofpeople are effectively met.

Owner:DONGGUAN UNIV OF TECH

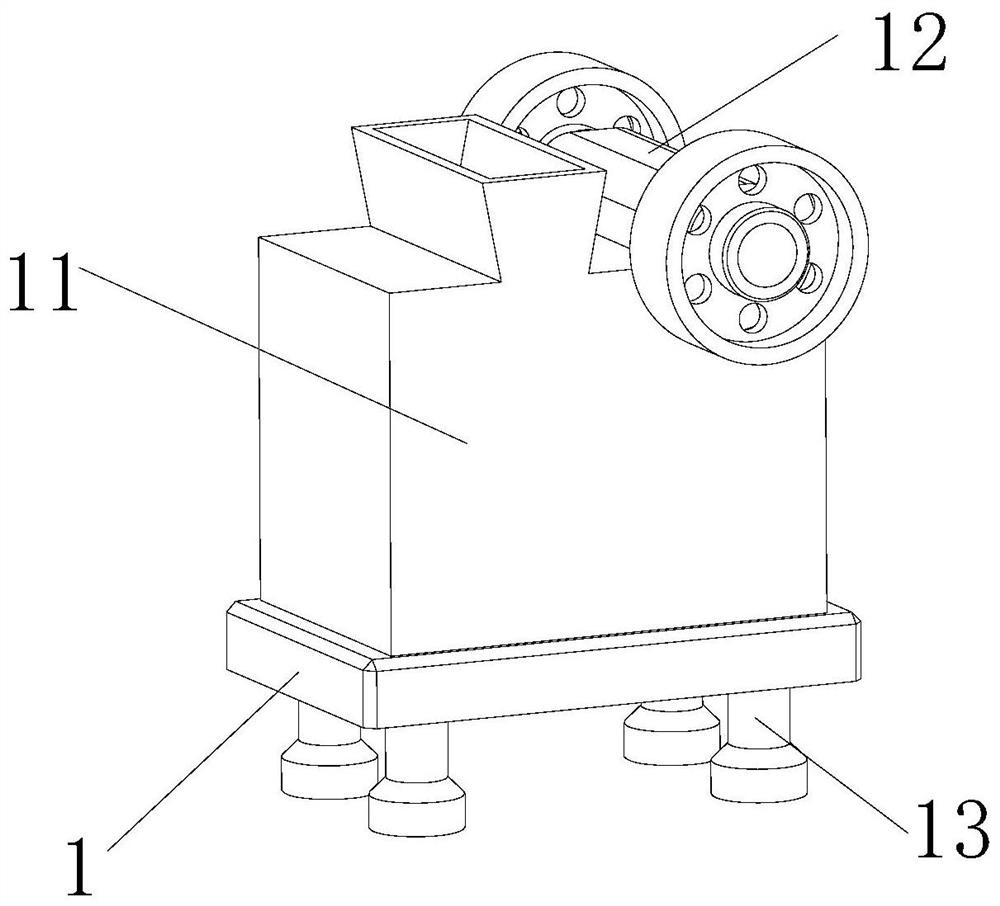

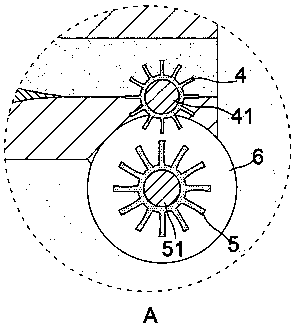

Coal mine crushing device

The invention discloses a coal mine crushing device. The coal mine crushing device comprises a crusher body, wherein a plurality of supporting legs are fixedly connected to the bottom of the crusher body, an anti-skid base is fixedly connected to the bottoms of the supporting legs, a crushing chamber is fixedly arranged on the crusher body, a driving motor is fixedly installed on the outer wall of the crushing chamber, a static jaw plate is fixedly installed inside the crushing chamber, a feeding port is formed in the crushing chamber, the feeding port is located at the upper end of the static jaw plate, a plurality of fixed teeth are fixedly installed on the static jaw plate, and a movable jaw plate is installed at the output end of the driving motor. Compared with the prior art, the coal mine crushing device has the advantages that extrusion can be generated between a grinding wheel and ore, and pressure can be generated on a crushing block, so that the crushing block extrudes a reset spring to contract inwards; and rigid collision between the grinding wheel and the ore can be reduced, meanwhile, the grinding wheel can rotate on a rotating shaft, so that loss of movable teeth in the ore crushing process can be reduced, and the service life of the crusher can be prolonged.

Owner:HUAIBEI HUAXING GONGMAO

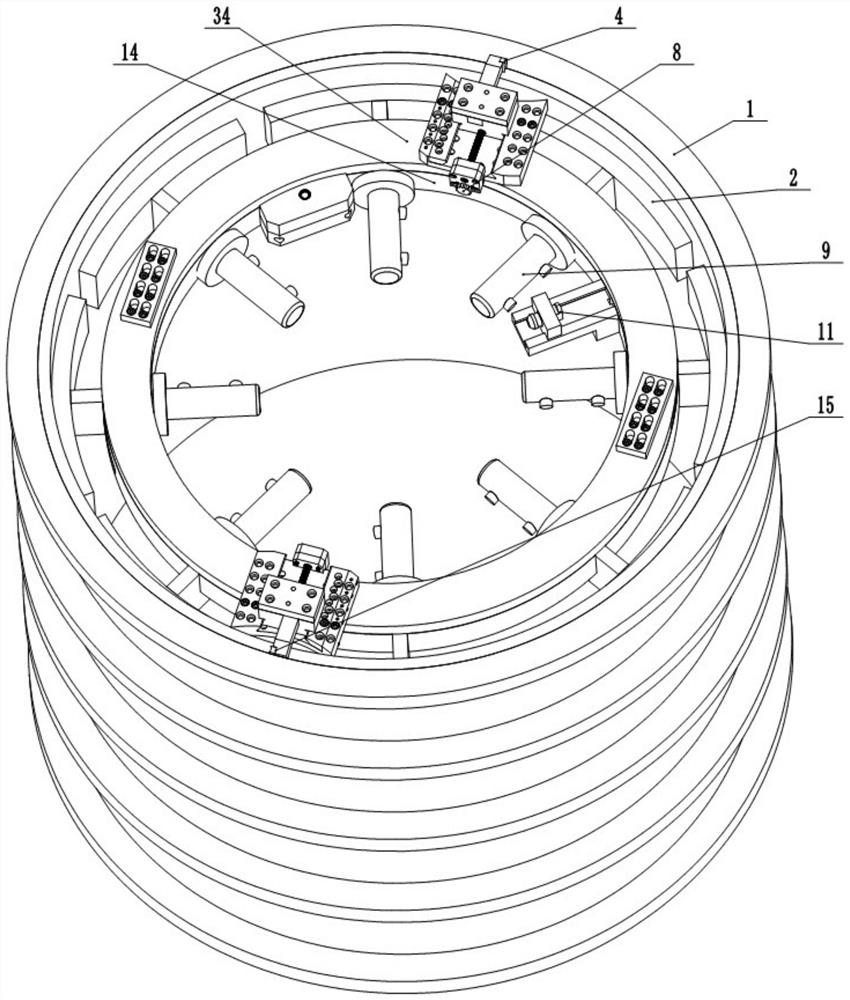

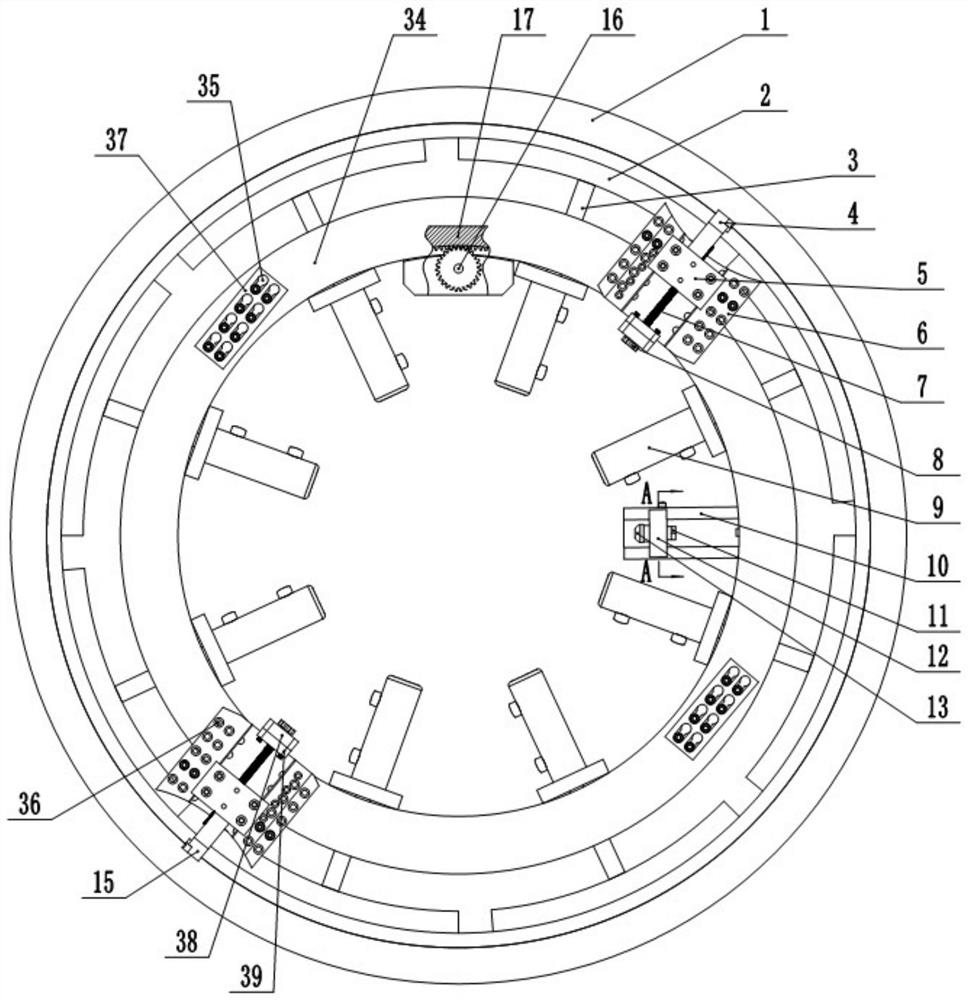

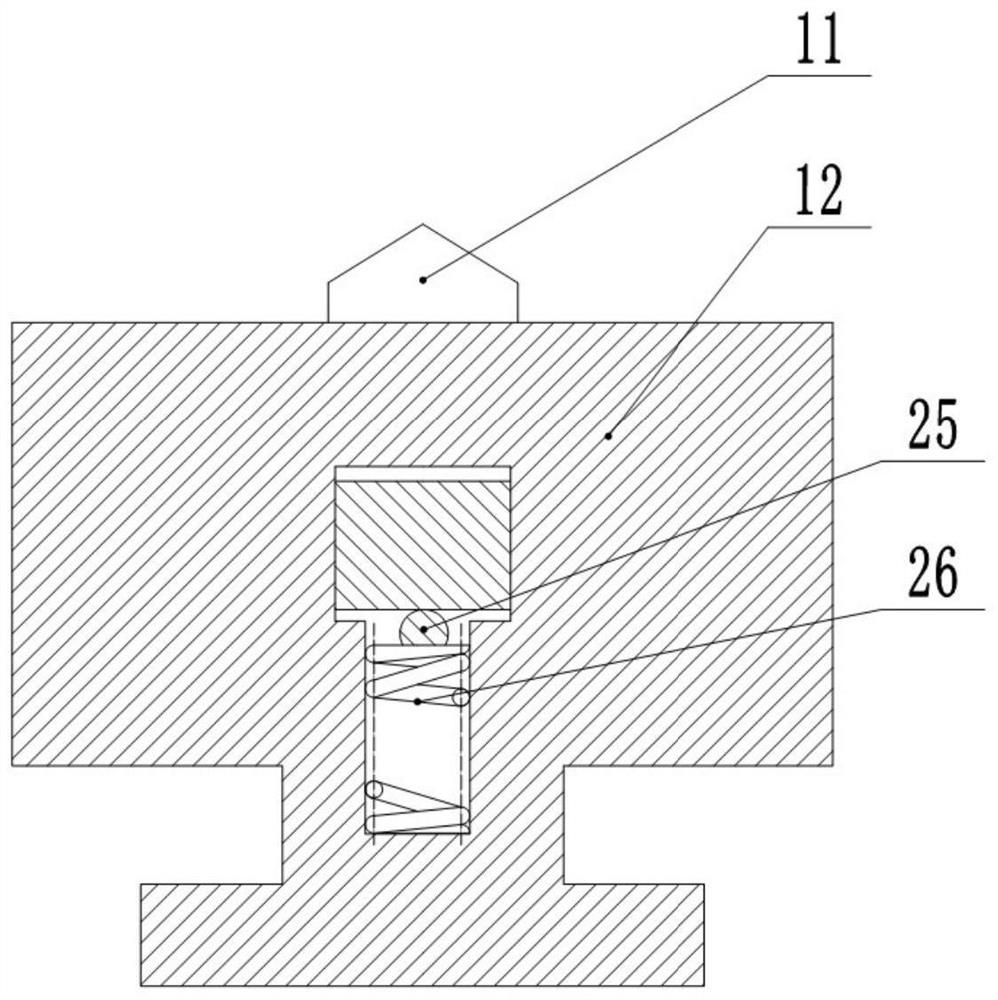

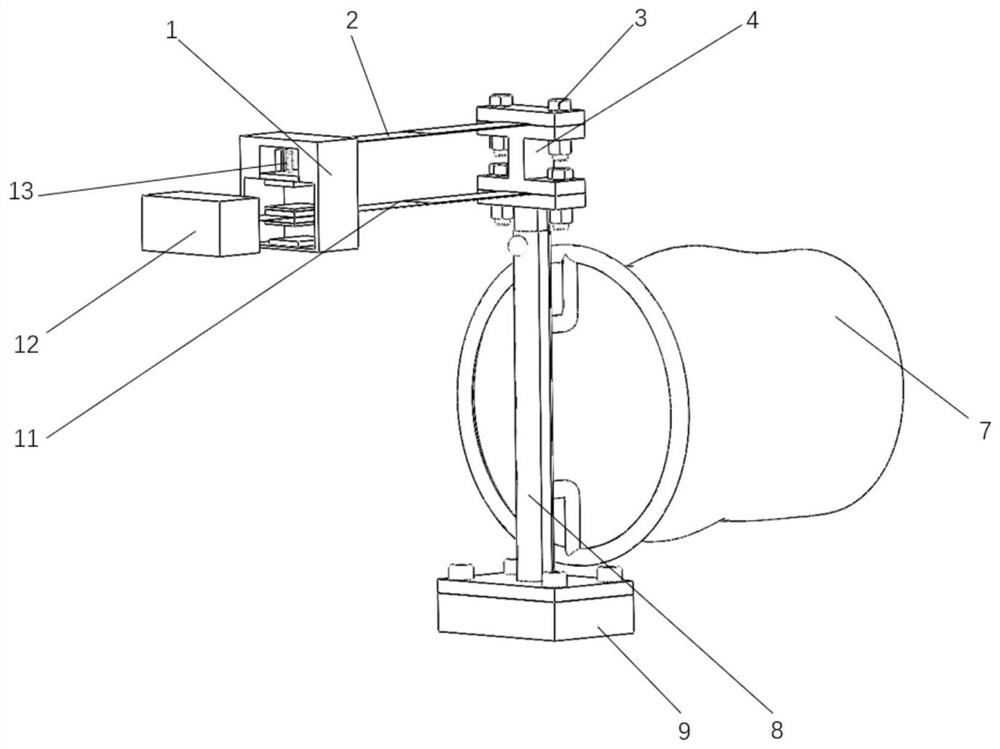

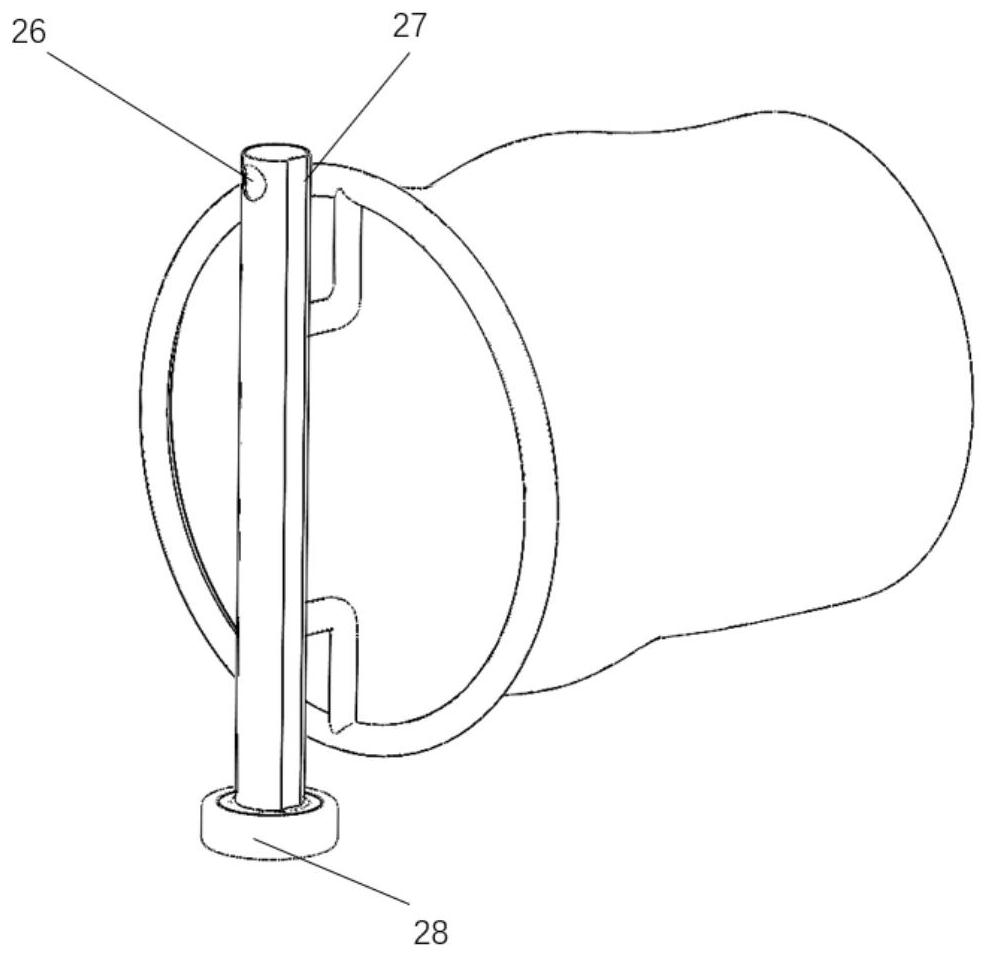

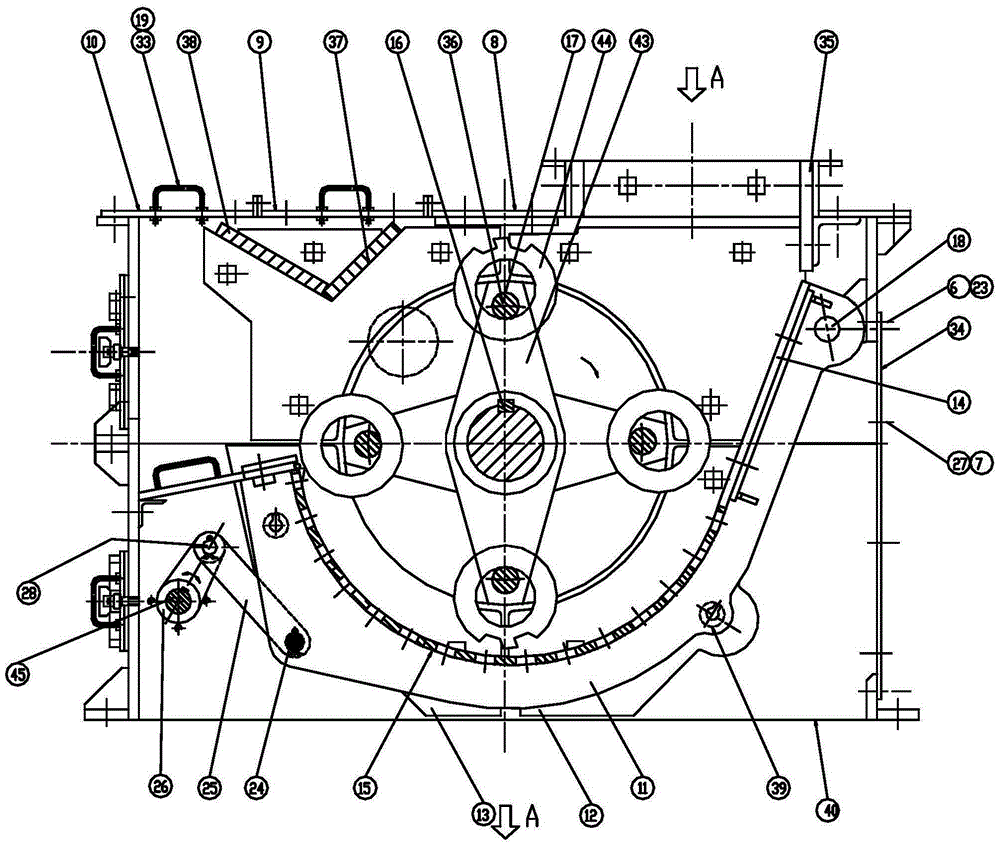

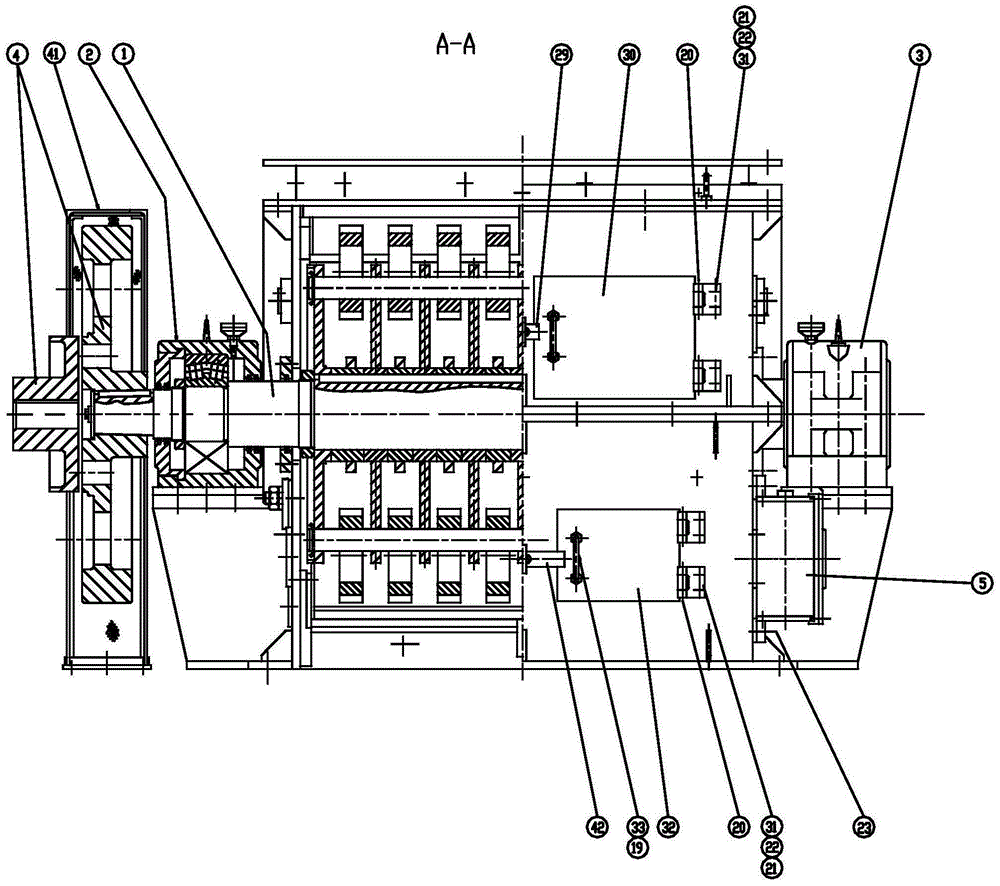

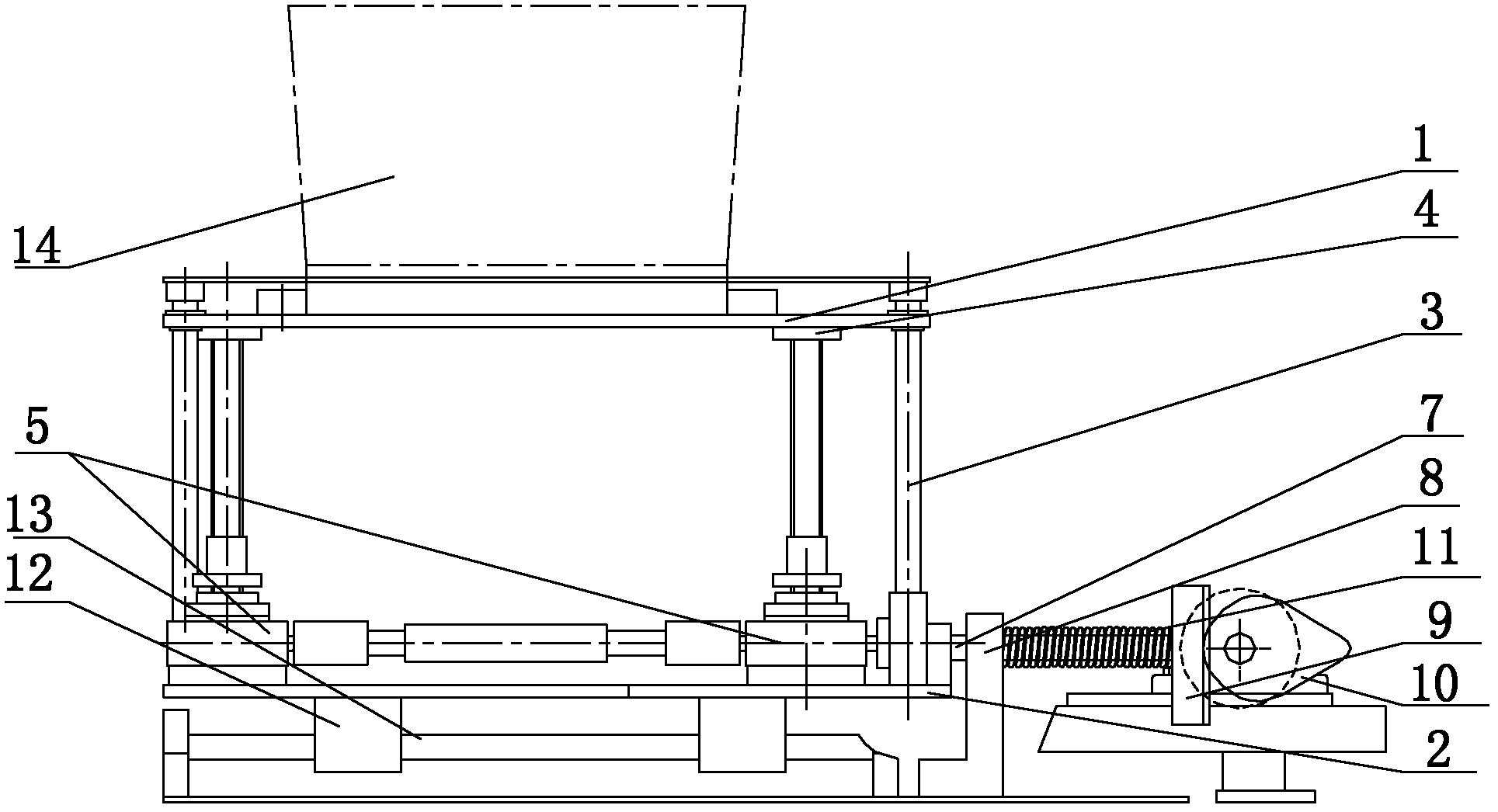

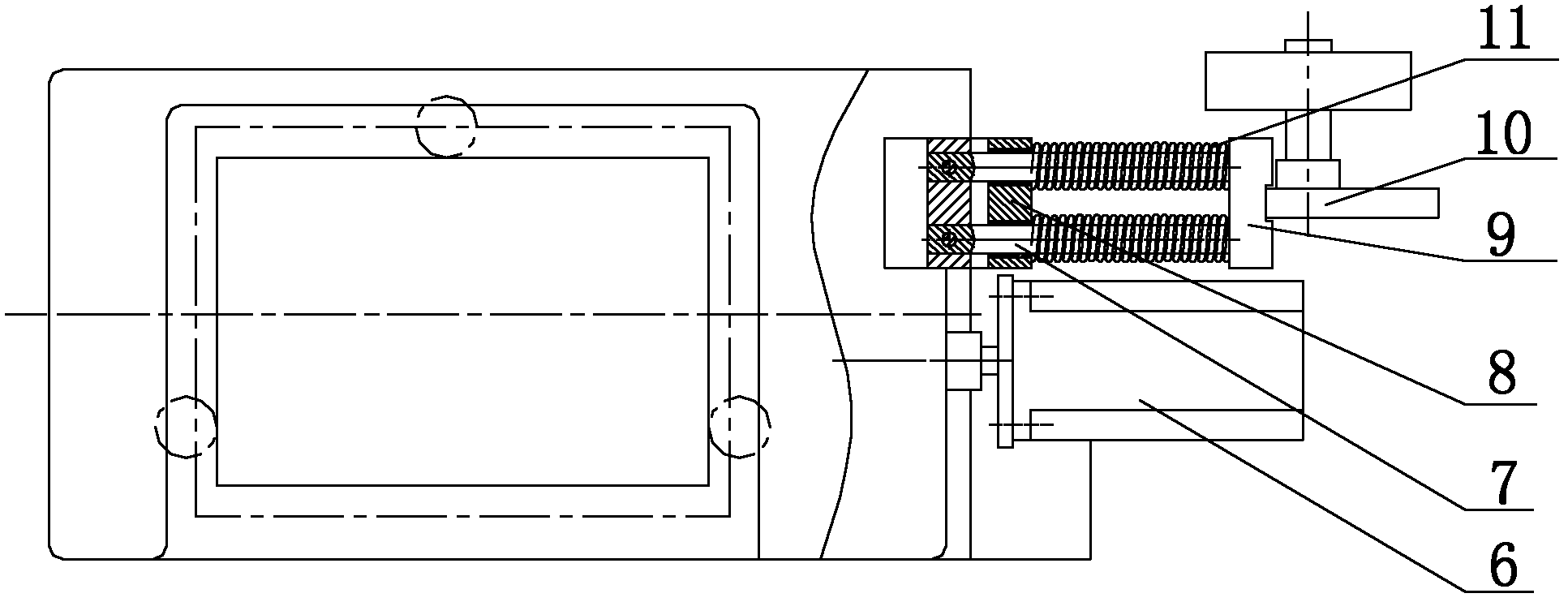

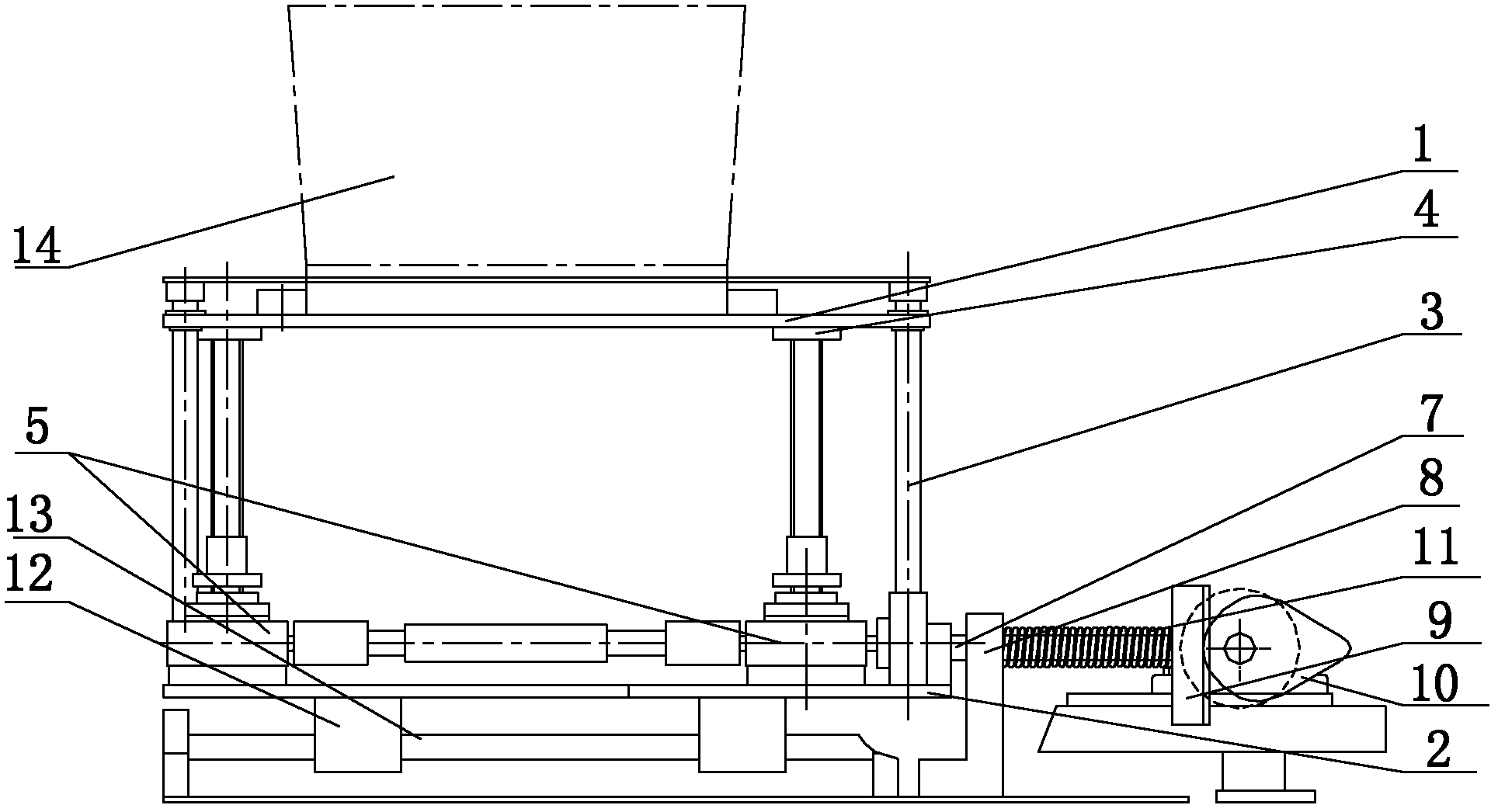

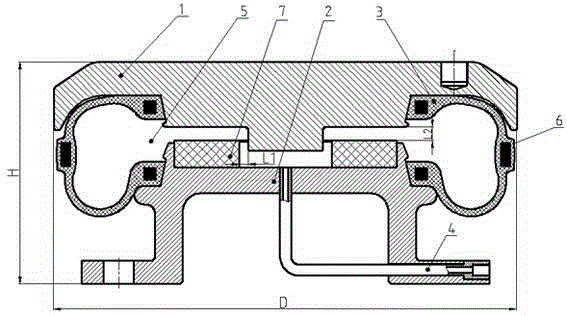

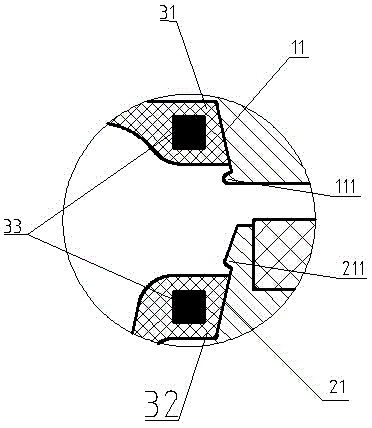

Inner supporting type pipe end face automatic welding and cutting groove machining equipment

The invention relates to the technical field of machining, in particular to inner supporting type pipe end face automatic welding and cutting groove machining equipment. The inner supporting type pipe end face automatic welding and cutting groove machining equipment comprises a machine body, an expansion mechanism assembly, a rotating fluted disc, a driving transmission mechanism and a mechanical cutting executing mechanism, wherein the machine body is in a circular ring shape and is hollow, the rotating fluted disc is also in a circular ring shape and is installed in the machine body, the top of the machine body is provided with a mounting disc, the mounting disc is fixedly connected with the rotating fluted disc in the machine body, and the mechanical cutting executing mechanism is fixedly installed on the mounting disc; and the expansion mechanism assembly comprises a driving device, expansion adjusting rods and expansion blocks, each expansion block is in a circular arc shape, the radian of one side of each expansion block is consistent with that of the inner wall of a pipe, the other side of each expansion block is fixedly connected with the corresponding expansion adjusting rod, the other ends of the expansion adjusting rods penetrate through the machine body and are connected with the driving device, and the driving device is fixed to the machine body. Therefore, the defects that an existing beveling machine for the pipe is large in size and weight, cannot automatically center and clamp and the like are overcome. The inner supporting type pipe end face automatic welding and cutting groove machining equipment is mainly used for machining the pipe.

Owner:上海宝四机械工程有限公司

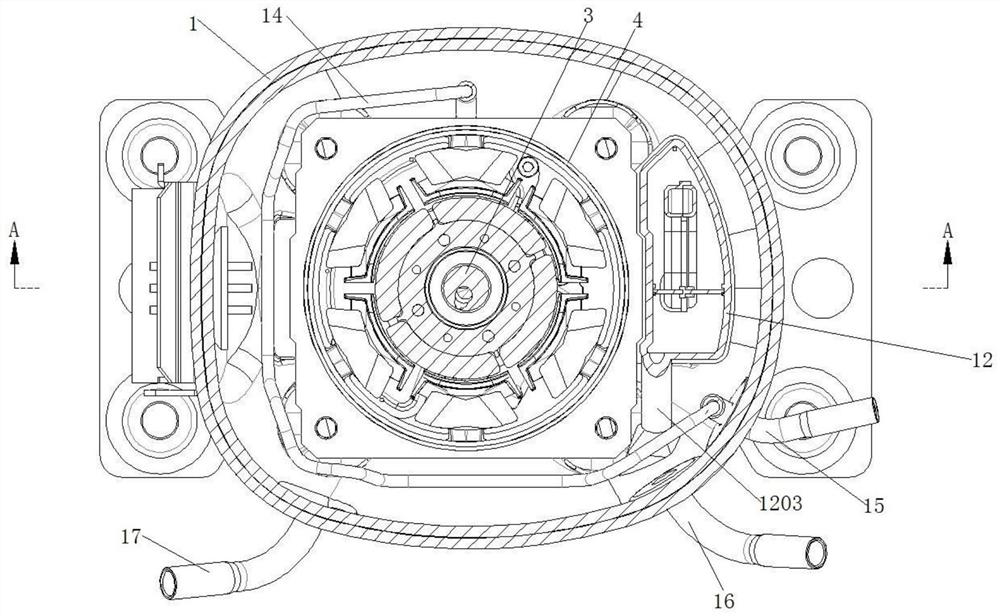

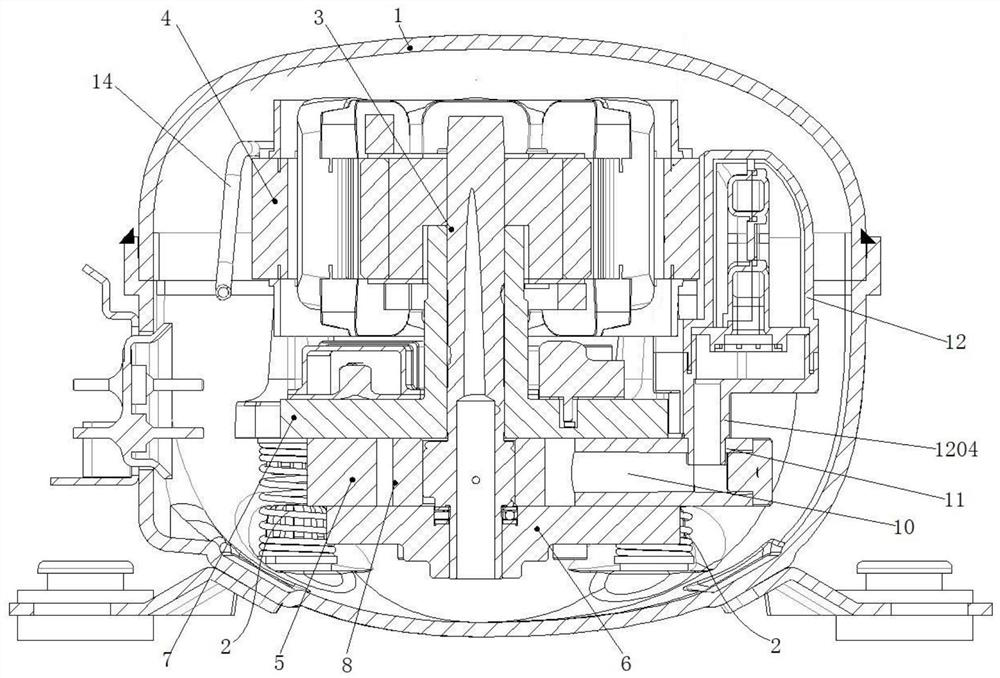

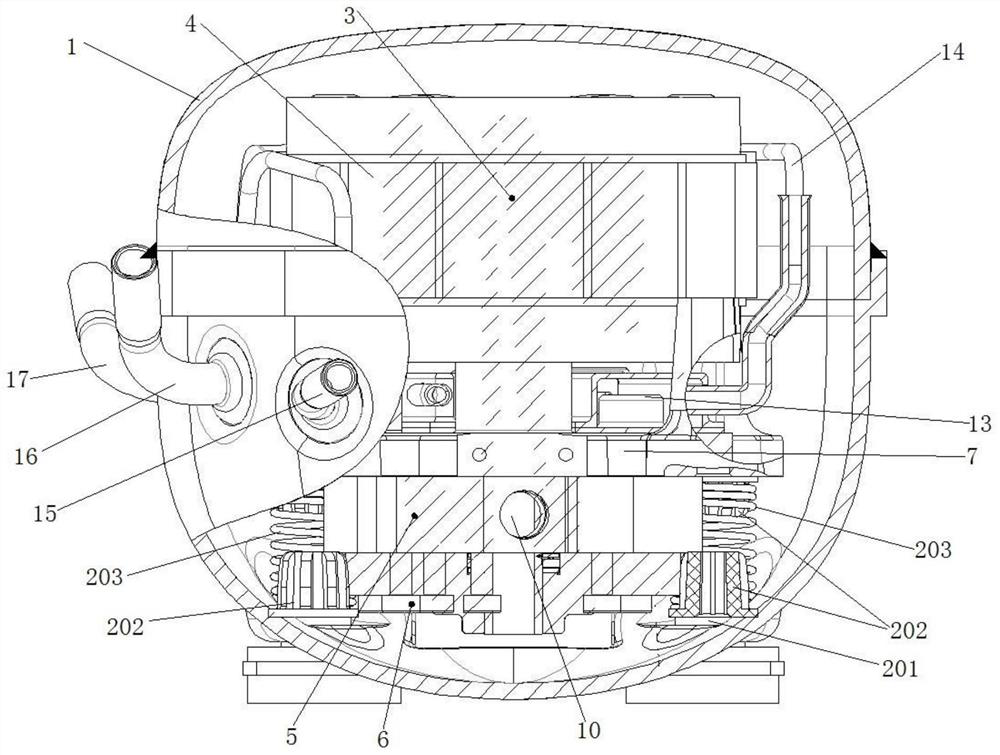

Novel swinging rotor compressor with low-pressure cavity in shell

PendingCN111720326ASolve the vibrationSolve the noiseRotary/oscillating piston combinations for elastic fluidsOscillating piston pumpsElectric machineryRefrigeration

The invention discloses a novel swinging rotor compressor with a low-pressure cavity in a shell. The novel swinging rotor compressor with the low-pressure cavity in the shell comprises a machine shelland a pump body; the pump body comprises an air cylinder component; a crankshaft is arranged on the air cylinder component in a sleeving manner; a motor is arranged above the crankshaft in a sleevingmanner; the pump body further comprises a swinging rotor arranged in the air cylinder component; the swinging rotor is connected to the air cylinder component through a sliding piece; the inner cavity of the air cylinder component is divided into a first compression chamber and a second compression chamber through the swinging rotor and the sliding piece; the first compression chamber is connected with an air suction silencing chamber through an air inlet channel; the second compression chamber is connected to an integrated exhaust cover component through an exhaust channel; and the exhaust cover component is connected to a shell exhaust pipe through an inner exhaust coil pipe. The compressor is low in vibration, low in noise, high in refrigeration amount, and excellent in starting performance.

Owner:黄石东贝压缩机有限公司

Anti-impact safety bridge

InactiveCN110258284AFast spinWeaken Rigid CollisionClimate change adaptationBridge structural detailsDrive shaftEngineering

The invention relates to an anti-impact safety bridge. The anti-impact safety bridge comprises a bridge body and a bridge mast for supporting the bridge body; a flow discharging passage is formed in the bridge body; the two end parts of the flow discharging passage are in flat shapes; the middle section of the flow discharging passage is in a tall and thin shape; a flow guiding device is arranged at a water outlet end; the flow guiding device comprises a flow guiding shifting wheel, a transmission shaft, a driving shifting wheel and a driving shaft; the driving shaft is in engaged connection with the transmission shaft through an accelerating gear set; the rotation speed of the flow guiding shifting wheel is higher than that of the driving shifting wheel; blades of the flow guiding shifting wheel extend into the flow discharging passage from the lower end surface of the water outlet end; and blades of the driving shifting wheel extend out of the bridge body from the lower surface of the bridge body. The anti-impact safety bridge has the advantages that the structure is novel, the principle is special, the transverse impact force of river water on the bridge body can be effectively reduced on the premise of guaranteeing the supporting capacity of the bridge, the service life of the bridge can be prolonged, and the normal passing of residents is guaranteed.

Owner:武汉公路桥梁建设集团有限公司

Door bell

InactiveCN107507374AReliable structureNot prone to mechanical failureMechanical audible signallingFault rateMiddle segment

The invention discloses a doorbell, which comprises a shell with perforations on the surface, a motor compartment and a ringing compartment inside the shell, a motor is fixedly installed in the motor compartment, and a mandrel parallel to the main shaft of the motor is arranged in the ringing compartment. The two ends of the mandrel are respectively fixed on the two opposite side walls of the ring chamber. The middle of the mandrel is large and the two ends are small. Two torsion springs arranged symmetrically on the mandrel are sleeved on the mandrel, and half of the torsion spring is fixedly grounded It is tightly sleeved on the larger shaft section in the middle of the mandrel, and the other half is not fixedly connected with the smaller shaft section of the mandrel, and the end of the half torsion spring is fixedly connected with the rotating plate rotatably sleeved on the mandrel. The side of the plate facing the motor shaft is connected with a vibrating reed; a pair of connecting rods perpendicular to the main shaft are fixed on the shaft, a spring is installed at the end of the connecting rod, and a steel ball is fixed at the end of the spring away from the connecting rod. When the motor rotates , the steel ball can touch the vibrating reed. The doorbell has reliable structure, low failure rate, and can effectively avoid excessively long reverberation.

Owner:重庆亚唐科技有限公司

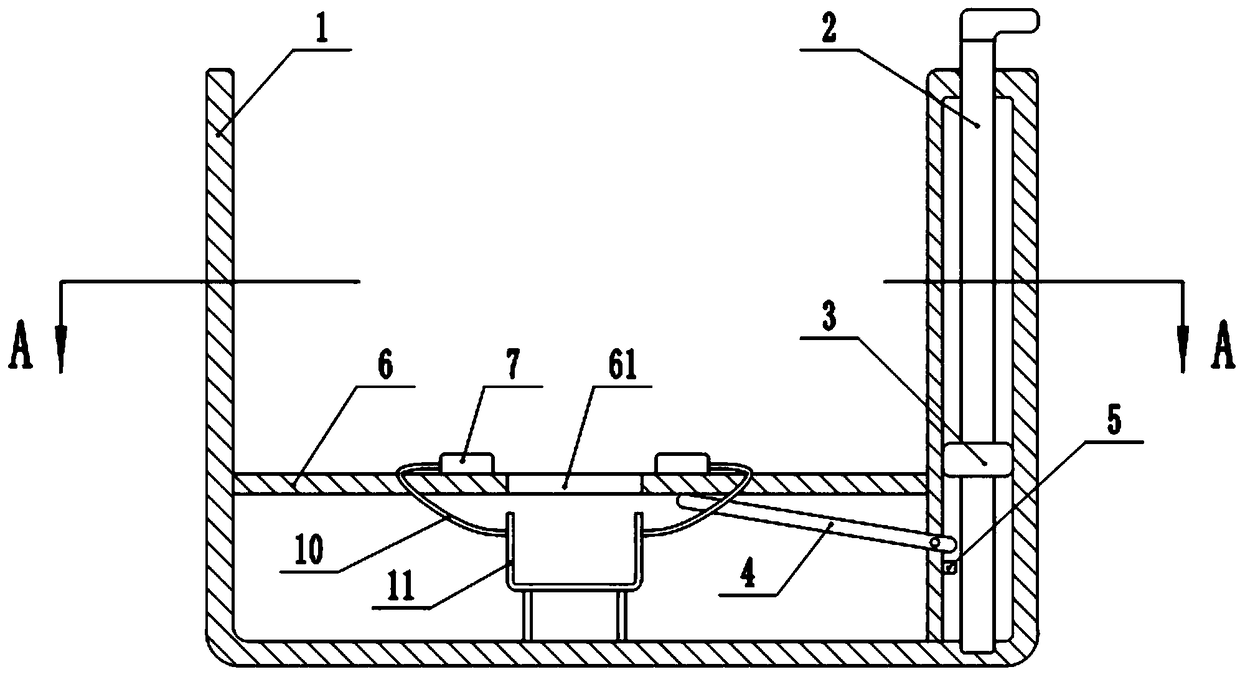

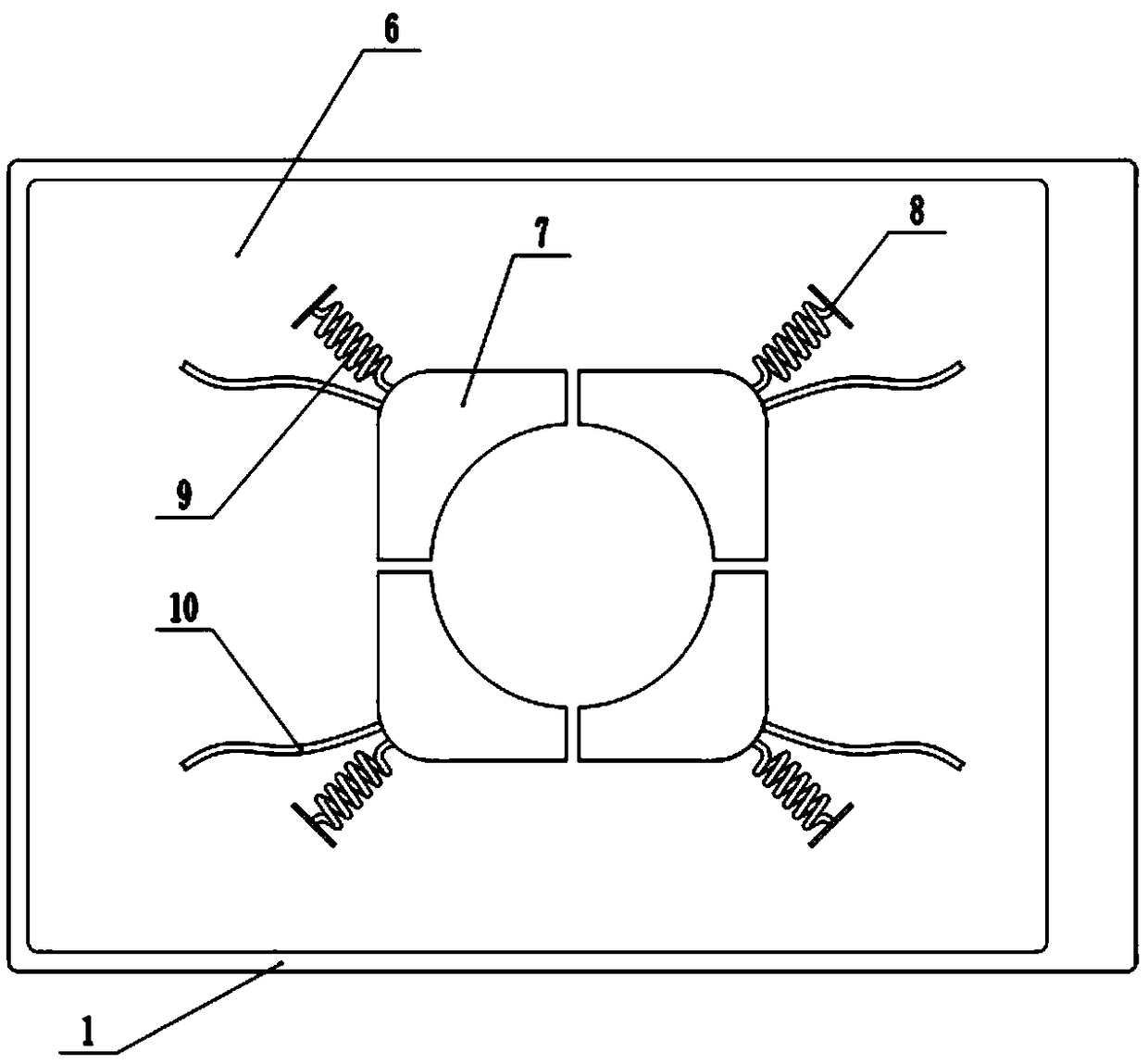

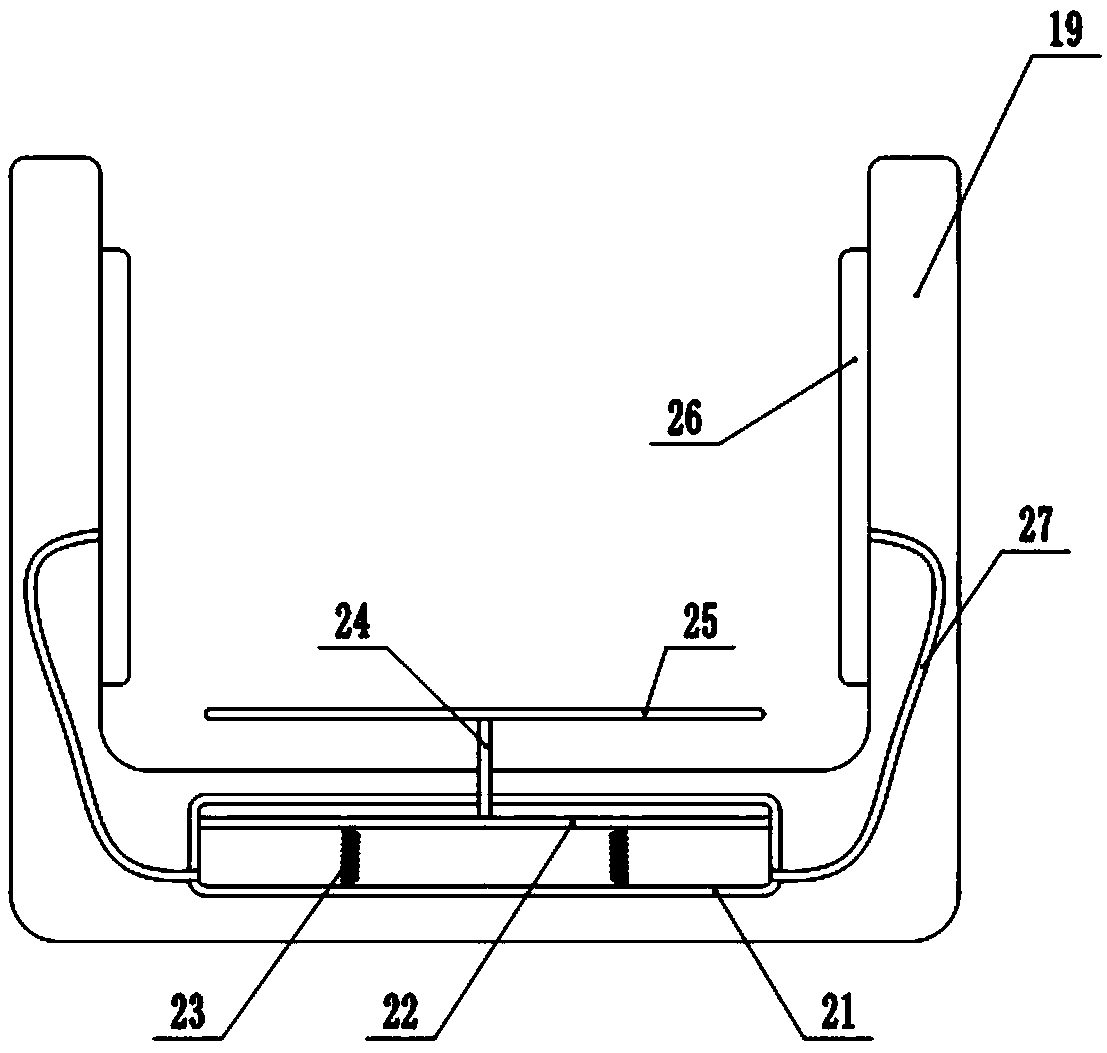

High-reliability battery installation system

PendingCN109119568ASo as not to damageEasy to take outElectric propulsion mountingBattery isolationRubber ringCushioning

A high-reliability battery installation system is disclosed, which includes an installation box body, a battery pack, a cover plate, an elastic rope, a primary airbag and several secondary airbags, anupper part of the installation box body is provided with an object cham with an upward opening, the battery pack is positioned in the object chamber, a support plate is position below the battery pack and in contact with a lower surface of the support plate, a lifting rod is mounted on the lower surface of the support plate, and at least three first springs are equally spaced around the lifting rod between the support plate and the bottom of the object chamber; The elastic rope winds around the upper part of the battery pack, and a rubber ring is arranged between the elastic rope and the battery pack. The left end and the right end of the elastic rope after winding pass through the left guide wheel installed on the installation box body respectively, and the right guide wheel is connectedto the left drum and the right drum. In an unfixed state, the left guide wheel and the right guide wheel are flush with the rubber ring. The invention fixes the position of the battery pack, so thatthe battery pack and the installation parts on the automobile have certain cushioning action, thereby greatly reducing rigid collision during the driving process of the automobile and protecting the battery pack from damage.

Owner:SUZHOU UNIV OF SCI & TECH

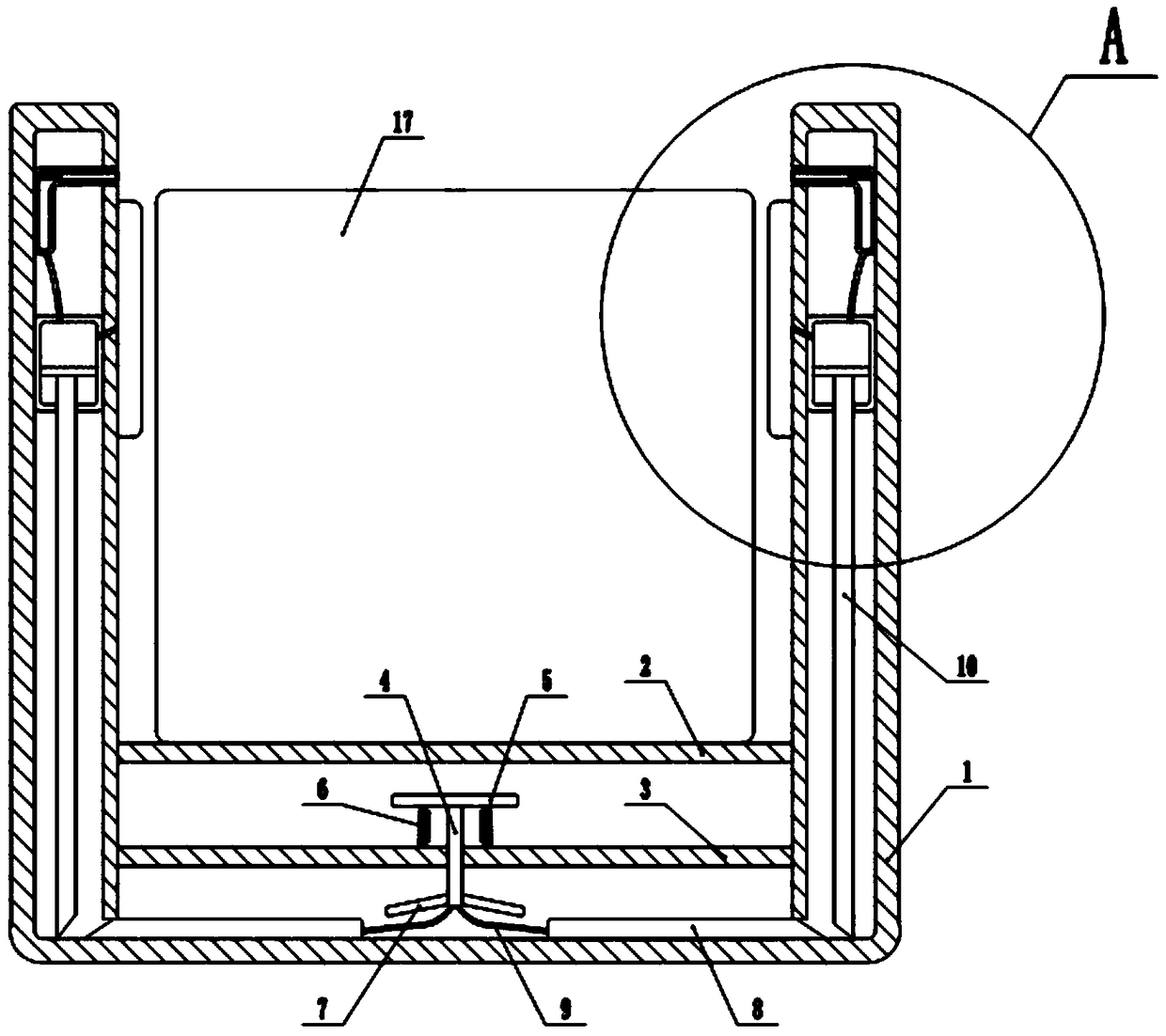

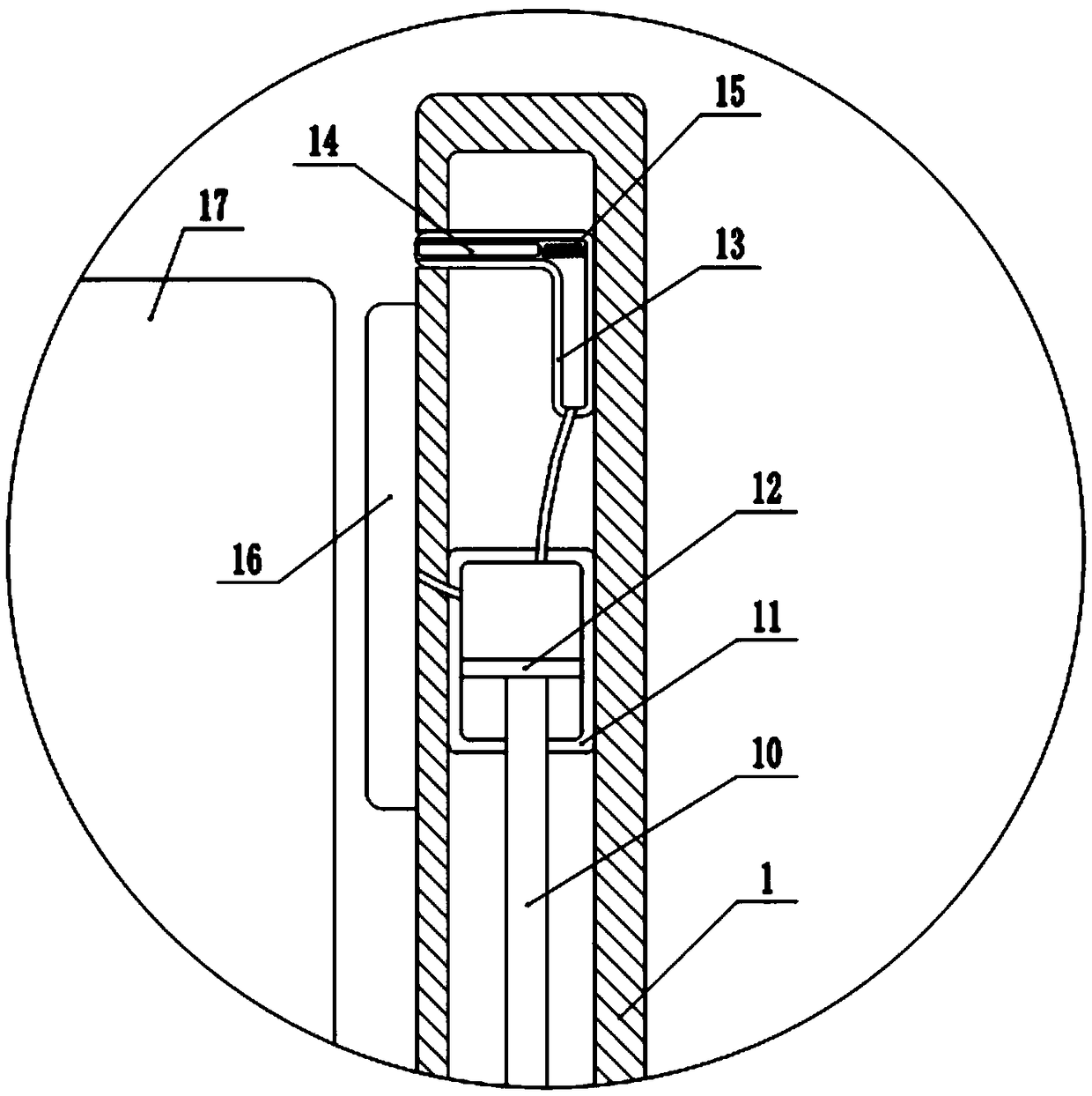

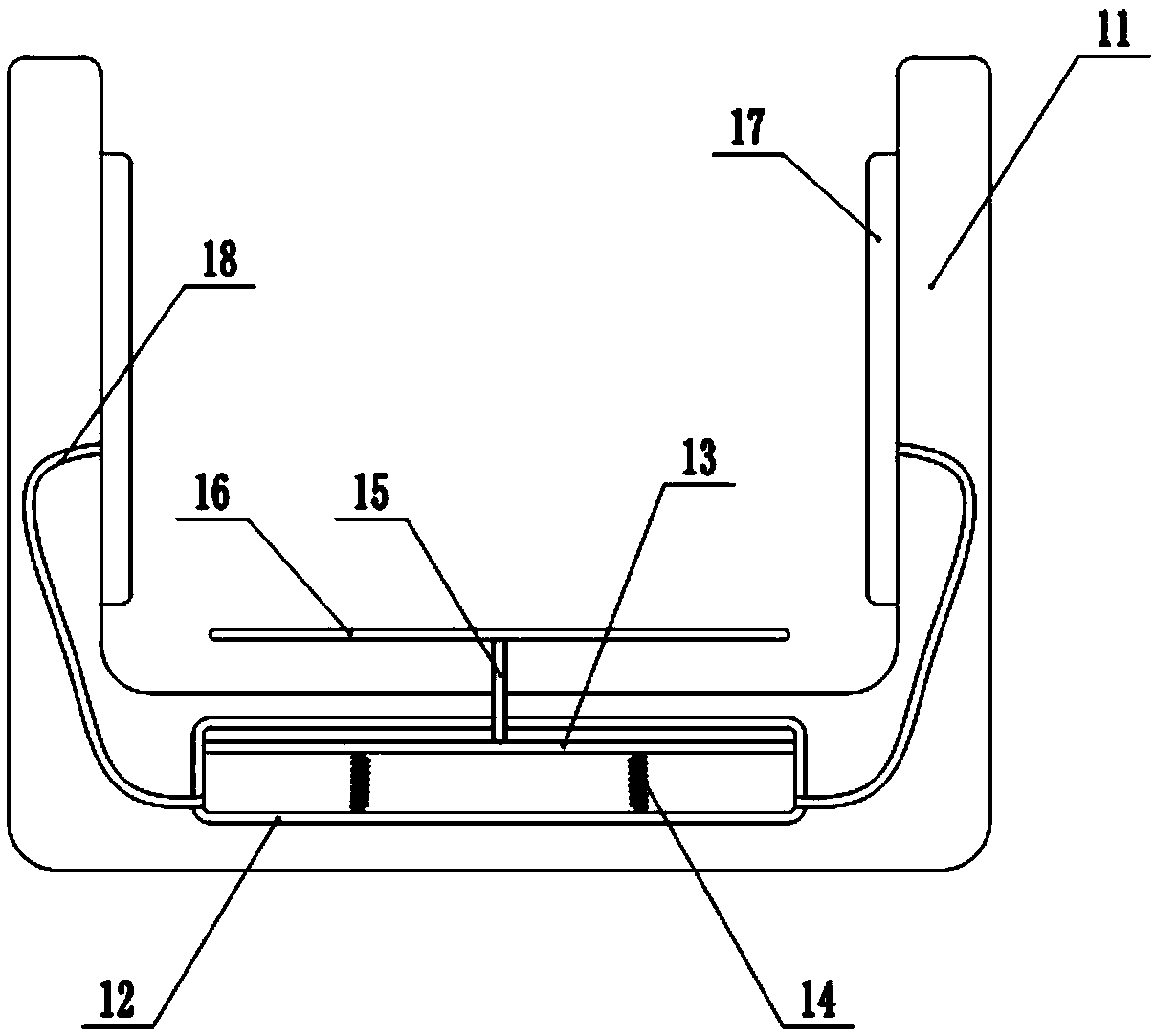

New energy vehicle battery box

InactiveCN109216619AWeaken Rigid CollisionSo as not to damageCell component detailsBatteriesRubber ringNew energy

The invention discloses a new energy vehicle battery box, comprises a mounting box body, a battery pack, a cover plate, an elastic rope, a main air bag and a plurality of side air bags, wherein the upper part of the mounting box body is provided with an upwardly-opened storage cavity, the battery pack is positioned in the storage cavity, a support plate is positioned below the battery pack and isin contact with the lower surface thereof, and a lifting rod is mounted on the lower surface of the support plate; An upper surface of that mount box is respectively provided with an mount groove anda threaded hole on both sides of the object chamber, and one end of the cover plate is mounted to one end of the mounting box body through a through hole inner strut embedded in the mounting groove; At least two pair of guide bumps and guide groove are symmetrically arranged between that support plate and the mounting box body, so that the support plate can slide along the side wall of the mounting box body; The elastic rope winds around the upper part of the battery pack, and a rubber ring is arranged between the elastic rope and the battery pack. The new energy vehicle battery box reduces the rigid collision in the driving process of the automobile, enhances the air pressure given to the side airbag, and greatly reduces the rigid collision in the driving process of the automobile.

Owner:SUZHOU UNIV OF SCI & TECH

Impact-wear-resistant excavator bucket tooth and production process thereof

ActiveCN113774986AWeaken Rigid CollisionExtended service lifeMetal-working apparatusSoil-shifting machines/dredgersExcavatorFriction force

The invention provides an impact-wear-resistant excavator bucket tooth and a production process thereof, and belongs to the technical field of bucket preparation. The impact-wear-resistant excavator bucket tooth comprises a main bucket tooth piece, a containing gap is formed in the main bucket tooth piece, an auxiliary bucket tooth piece is arranged in the containing gap, and the auxiliary bucket tooth piece is connected with the main bucket tooth piece through an elastic cushioning mechanism; and a damping plate is arranged in the containing gap, arranged on the bottom side of the auxiliary bucket tooth piece, used for reducing impact borne by bucket teeth and connected with the auxiliary bucket tooth piece through a damping mechanism. A bucket tooth protection shell is arranged at the side end of the main bucket tooth piece and used for reducing friction force borne by the main bucket tooth piece and reducing abrasion of the main bucket tooth piece, the bucket tooth protection shell is arranged at the side end of the main bucket tooth piece through a reciprocating circulation assembly, and a transmission mechanism is arranged in the main bucket tooth piece and used for driving the reciprocating circulation assembly to move. Rigid collision between the bucket teeth and a tooth holder is effectively reduced, and the service life of the bucket teeth is greatly prolonged.

Owner:宁波吉威熔模铸造有限公司

Bicycle basket

The invention relates to the technical field of bicycle parts, and discloses a bicycle basket, comprising a basket body, wherein the basket body side wall is rotatably connected with a rotating shaft,and the rotating shaft is fixedly connected with a flip cover; A side wall of the vehicle basket body is provided with a cavity, and a rotating shaft is connected with a first gear, the first gear meshes with a second gear, the second gear meshes with a rack, and a first cylinder is fixedly connected with the cavity; A slide plate is slidably arranged in the vehicle basket body, a second cylinderis fixedly connected in the vehicle basket body, and a guide pipe is communicated between the first cylinder and the second cylinder; A through hole is arrange on that slide plate, an arc block is slidably connected on the slide plate, a baffle plate is arranged on one side of the arc block, and a first spring is connected between the baffle plate and the arc block; A support block is fixedly connecte with that vehicle basket body, and a flexible pulling rope is connected between the support block and the arc-shaped block. The invention has the advantages that the articles can be clamped andfixed, and the articles can be prevented from being broken due to collision.

Owner:宁波隆锐机械制造有限公司

Wind-induced vibration piezoelectric-triboelectricity coupling energy collection device

PendingCN114865943AImprove conversion efficiencyWind disturbancePiezoelectric/electrostriction/magnetostriction machinesWind energy generationEngineeringMechanical engineering

The invention discloses a piezoelectric-triboelectric coupling energy collection device with wind-induced vibration. The problems that in the prior art, a wind-induced vibration energy collector is low in output power, narrow in working wind speed range and single in energy conversion form are solved. According to the invention, a double-cantilever beam structure is arranged, and piezoelectric ceramics are fixed on the surfaces of the long cantilever beam and the short cantilever beam; the rectangular bluff body is fixed at the free end of the cantilever beam; an elastic sliding block is arranged in a first bluff body fixed with the short cantilever beam; a friction material and a conductive metal layer are respectively fixed on the opposite surfaces of the long cantilever beam and the first bluff body; the fixed end of the double-cantilever beam and the supporting rod are fixed by a plurality of jump springs; a wind direction bag is fixed to the pipe sleeve and forms a rotating pair with the fixed base. The collecting device can be adjusted in a self-adaptive mode and is parallel to the wind direction all the time, the wind energy utilization rate is increased, the vibration frequency is improved, meanwhile, high potential difference is generated through piezoelectric ceramics and friction materials, and the energy output power of the device is improved.

Owner:HANGZHOU DIANZI UNIV

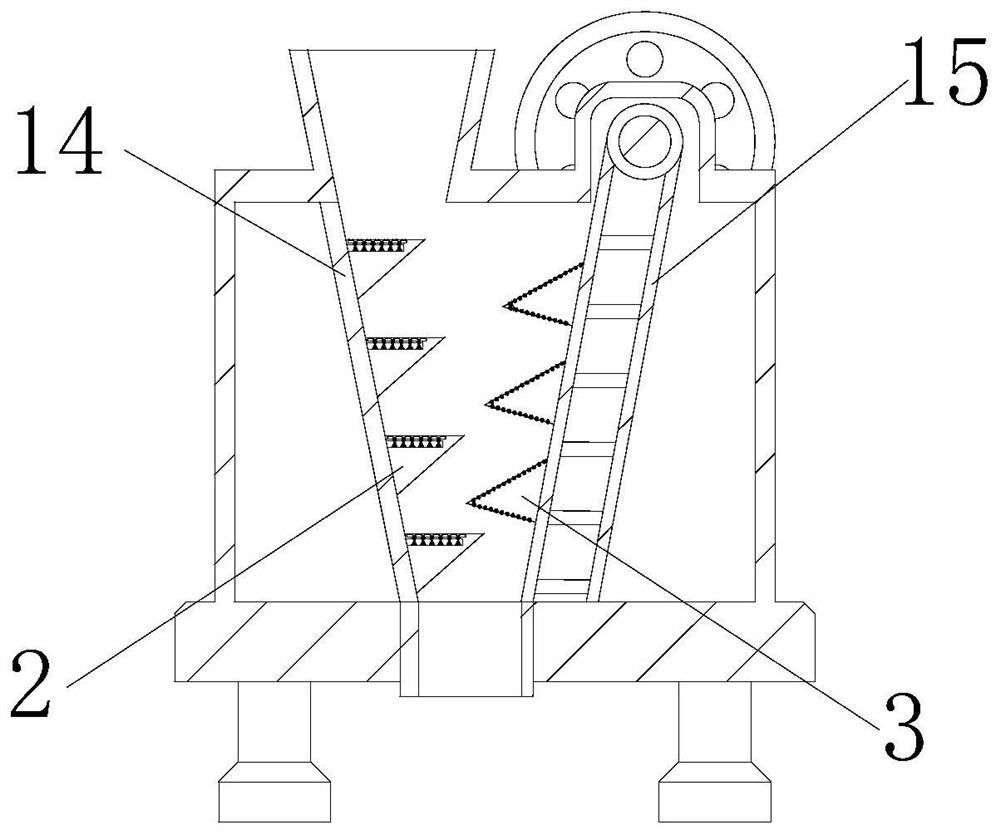

Ring hammer crusher

InactiveCN105170236AIncrease production capacityImprove efficiencyGrain treatmentsEngineeringCrusher

The invention discloses a ring hammer crusher which is used for crushing beneficiation. The ring hammer crusher comprises a box body. A material inlet is formed in the top of the box body. A rotor is installed in the box body. A plurality of sets of crushing arms are installed on the rotor. Every two adjacent sets of crushing arms are arranged in a crossed manner. Holes are formed in the two ends of each crushing arm. Pin shafts are installed in holes in the same ends of the crushing arms. A plurality of crushing hammers are arranged on the pin shafts in a sleeving manner. Each crushing hammer is located between corresponding two adjacent crushing arms. A middle structure, a structure I and a structure II are installed on the lower portion in the box body and used for connecting a net plate and a crushing plate. The right end of the middle structure is hinged to the inner wall of the box body, and the left end of the middle structure is hinged to one end of a connecting rod. The other end of the connecting rod is connected with one end of a stirring rod, and the other end of the stirring rod is connected with the inner wall of the box body. The structure I and the structure II are connected with the middle structure. The crushing plate is installed below the material inlet and at the right end of the middle structure. A first counter-attack plate and a second counter-attack plate are installed on the upper right part in the box body.

Owner:SHAANXI UNIV OF SCI & TECH

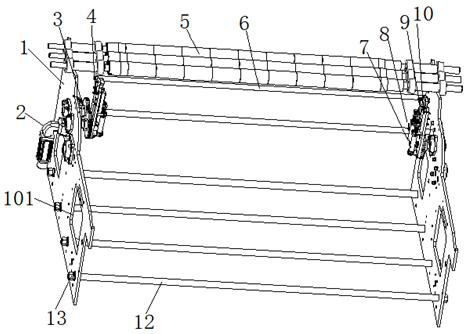

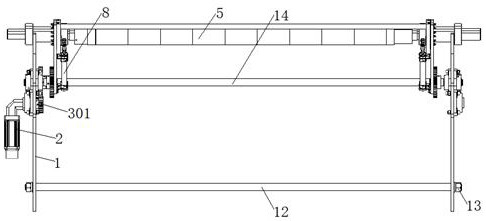

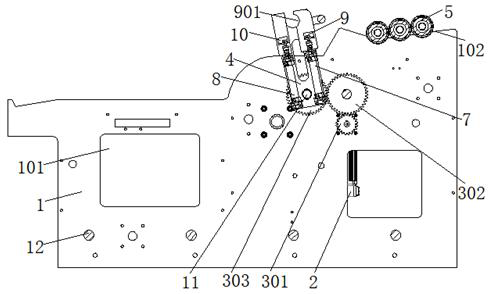

Automatic bobbin changing device of non-woven fabric winding machine

The invention discloses an automatic bobbin changing device of a non-woven fabric winding machine, and belongs to the technical field of non-woven fabric production. The automatic bobbin changing device of the non-woven fabric winding machine comprises wall plates, and further comprises a winding bobbin, gear sets, bobbin changing swing arms, a first air cylinder, a second air cylinder, a first sliding block and a second sliding block, wherein the winding bobbin is arranged at the tops of the wall plates, and the two ends of the winding bobbin abut against the outer walls of the tops of the two wall plates correspondingly; the gear sets are connected to the two wall plates correspondingly; the bobbin changing swing arms are connected to the gear sets and matched with the gear sets; the first air cylinder and the second air cylinder are fixedly connected to the bobbin changing swing arms; the first sliding block and the second sliding block are connected to the output end of the first air cylinder and the output end of the second air cylinder correspondingly; and a circular groove is further formed in the first sliding block, and the winding bobbin is matched with the circular groove. According to the automatic bobbin changing device, automatic bobbin taking, changing and supplementing can be completed, the automation degree is higher, rigid collision is less, damage is not prone to occurring, wide adaptability is achieved, accurate control is easy, and good development prospects are achieved.

Owner:WUJIANG WANGONG ELECTROMECHANICAL EQUIP

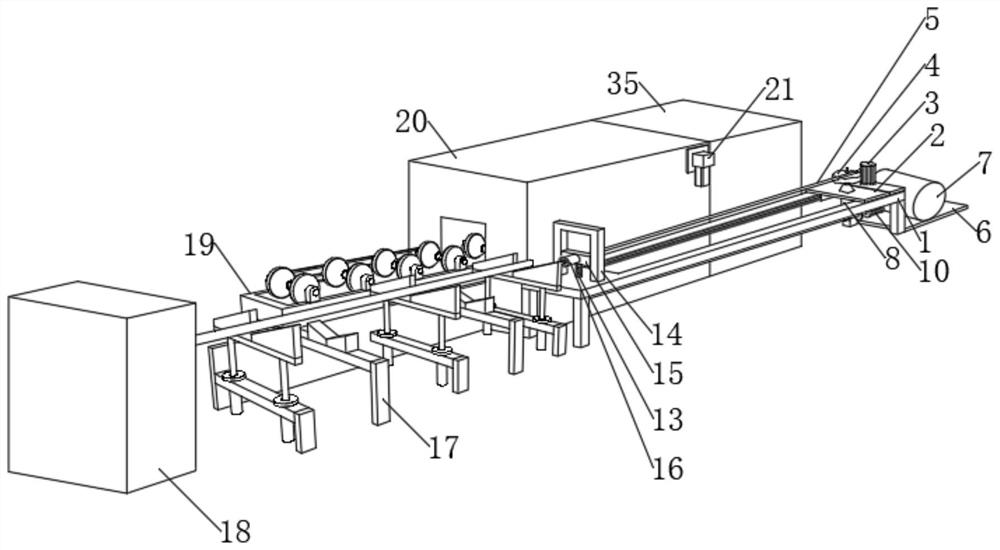

Full-automatic steel pipe cleaning machine with stain removal and rust removal functions

The invention discloses a full-automatic steel pipe cleaning machine with stain removal and rust removal functions, and belongs to cleaning machines. The full-automatic steel pipe cleaning machine with the stain removal and rust removal functions comprises a sliding rail supporting base. According to the invention, the height of an inner wall cleaning pipeline can be adjusted, and when a pipe with a large pipe diameter is encountered, by adjusting the height of the inner wall cleaning pipeline, the circle center of the inner wall cleaning pipeline is consistent with the circle center of the pipe, so that inner wall cleaning can be conducted on the pipes with different pipe diameters; a connecting plate and a water shielding cover form a whole through a connecting frame, and the water shielding cover synchronously ascends or descends while the connecting plate ascends or descends, so that the circle center of the water shielding cover is aligned with the circle center of the pipe, and the outer walls of pipes with different pipe diameters can be cleaned; and in the process of cleaning the inner walls of the pipes, wastewater is collected through a wastewater collecting box, high-pressure flushing is conducted on the outer walls of the pipes through the wastewater, and then flushing is conducted again through low-pressure clear water, so that water resources are greatly saved while the cleaning effect on the pipes is improved.

Owner:温州伟旗自动化设备科技有限公司

Cam type ring bobbin collecting device

The invention discloses a cam type ring bobbin collecting device, which comprises a bogie and a ring bobbin box arranged on the bogie, wherein the bogie comprises a bogie body; an up-and-down elevating mechanism and a horizontal swinging mechanism are arranged on the bogie body; the bogie body comprises an upper supporting plate for supporting the ring bobbin box and a lower bottom plate, the lower bottom plate is fixedly connected with a vertical guide rod, and the upper supporting plate is connected with the vertical guide rod in a sliding manner; the up-and-down elevating mechanism comprises a screw nut fixedly connected with the upper supporting plate and an elevator fixed on the lower bottom plate, the screw nut is in threaded connection with the lead screw of the elevator, and the elevator is driven by a second motor; the horizontal swinging mechanism comprises a horizontal rod, one end of the horizontal rod is fixedly connected with the lower bottom plate, the horizontal rod penetrates through a fixed supporting block, the other end of the horizontal rod is fixedly connected with a swinging block, the swinging block presses the exterior margin of a cam, the cam is driven by a first motor, and a spring sleeved on the horizontal rod is clamped between the swinging block and the fixed supporting block; and a sliding block is arranged at the bottom of the lower bottom plate and is connected with a horizontal fixed guide rail. By adopting the cam type ring bobbin collecting device, the ring bobbins can be stacked levelly layer by layer.

Owner:TIANJIN POLYTECHNIC UNIV

Production device for plastic particles

The invention relates to the technical field of plastic particle production, in particular to a production device for plastic particles. The production device for plastic particles comprises a production equipment body and extrusion equipment, wherein the production equipment body comprises a stirrer, a stirrer motor, a drying and melting device, a plasticizing device, a cooling device, an automatic deashing device, a drying and forming device and an exhaust gas treatment device, wherein a masterbatch port, a raw material port and an auxiliary port are formed in the stirrer; the stirrer motoris arranged on the left side of the stirrer; the stirrer motor is in transmission connection to an auger in the stirrer and the like. The extrusion equipment for plastic particle production is drivenby walking of two lead screws, so that the walking precision of a driving plate is improved, and the extrusion amount is controlled precisely. By arranging a rubber block, rigid collision is reduced;and by arranging a chute in a base, materials are received conveniently, and the production device for plastic particles is convenient to operate.

Owner:长兴悦成塑料制品有限公司

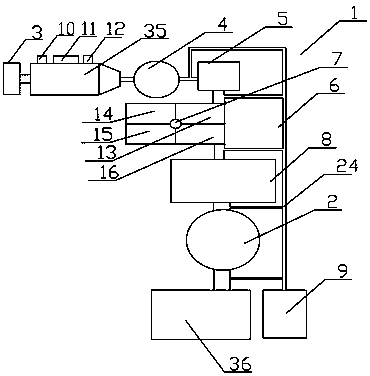

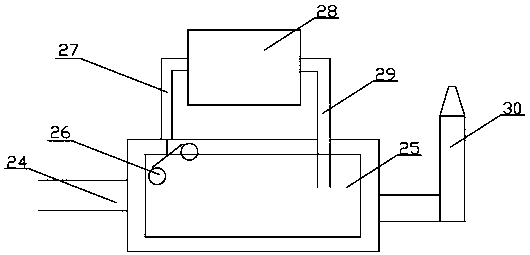

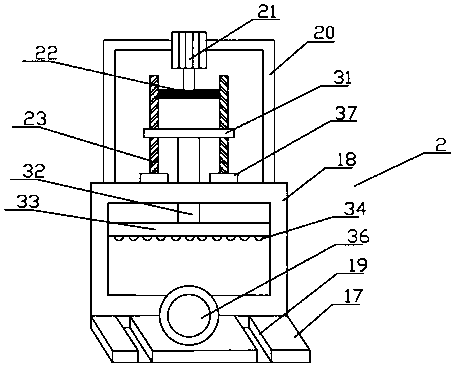

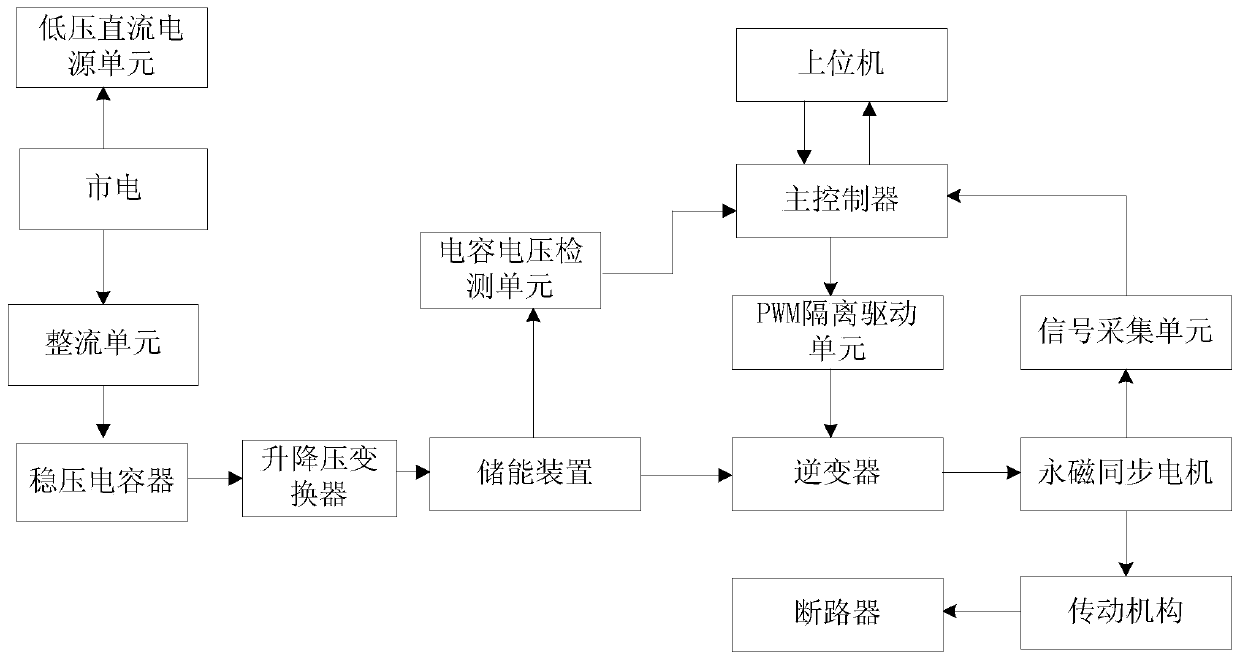

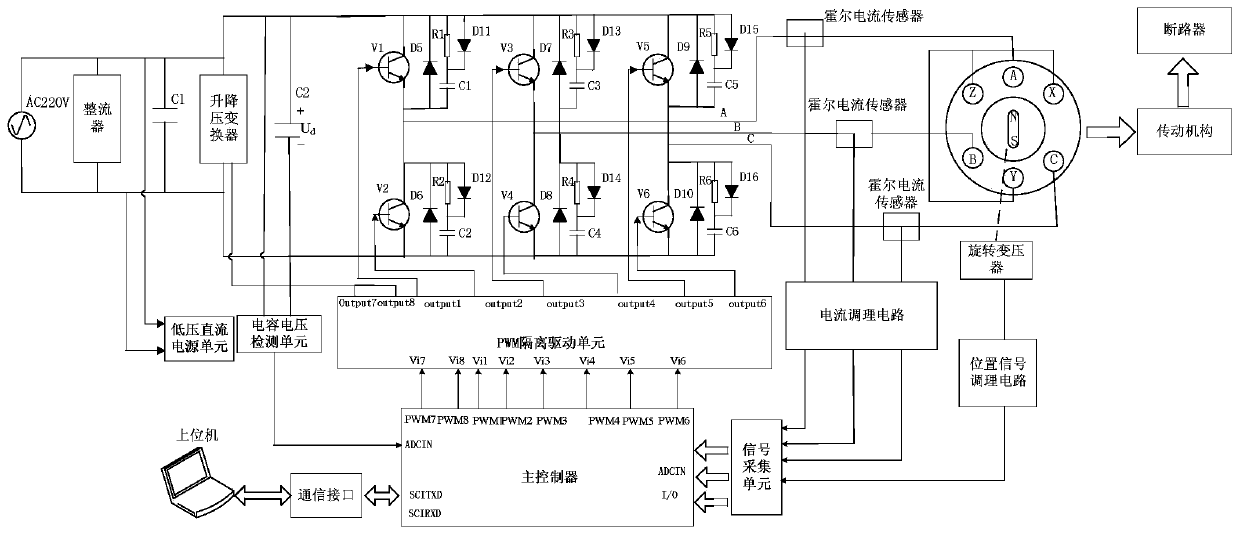

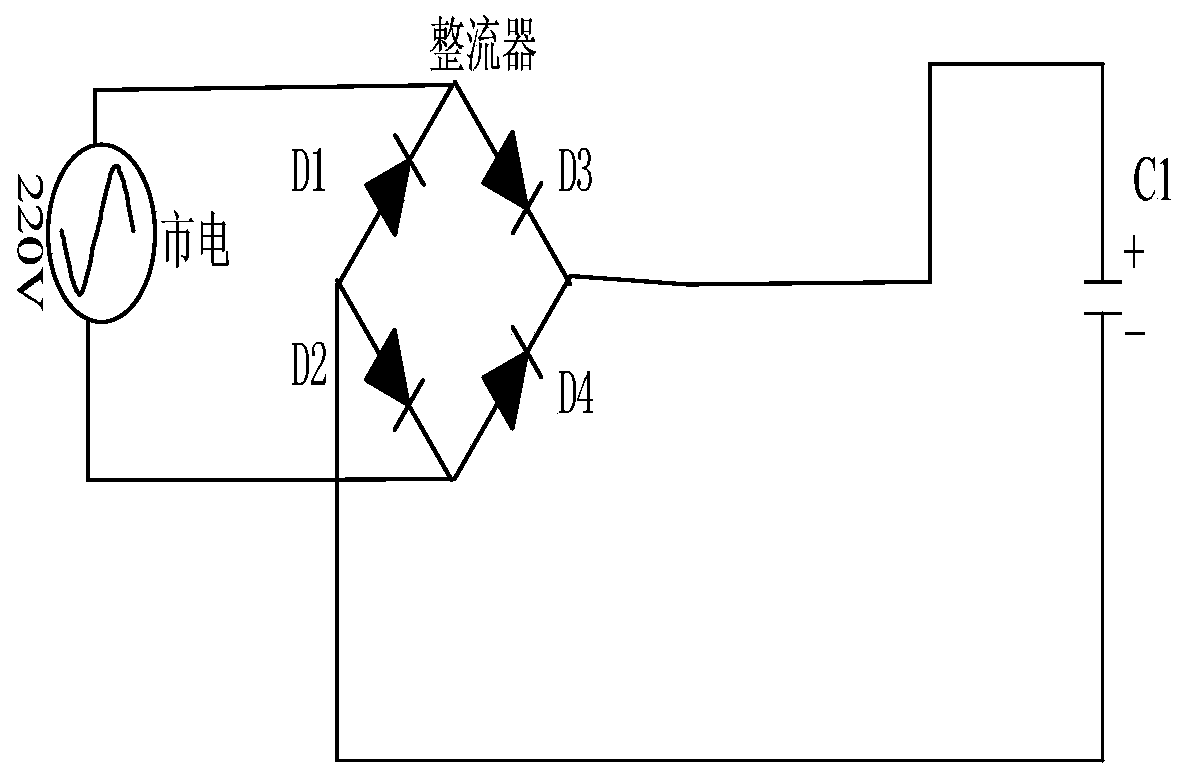

High-power motor operating mechanism control device and method

PendingCN110492796ASimple mechanical structureFew partsSingle motor speed/torque controlProtective switch operating/release mechanismsCapacitanceCapacitor voltage

The invention provides a high-power motor operating mechanism control device and method, and relates to the technical field of electrical automation control. The control device comprises a rectification unit, a voltage stabilizing capacitor, a buck-boost converter, an energy storage device, a signal acquisition unit, a signal processing unit, an inverter, a main controller, a current conditioningcircuit, a position signal conditioning circuit, a capacitor voltage detection unit, an upper computer, a PWM isolation driving unit and a low-voltage DC power supply. The upper computer issues different control instructions to the main controller when a circuit breaker breaks short-circuit current, rated current and no-load working conditions; the main controller sends an instruction to the buck-boost converter and the inverter, the buck-boost converter provides different voltage values for the energy storage device, and a motor operating mechanism moves according to a preset ideal travel speed curve of a moving contact. According to the control device and the control method, the rigid collision between the moving contact and a static contact is effectively reduced, and the reliability ofthe motor operating mechanism of a high-voltage circuit breaker is improved.

Owner:SHENYANG POLYTECHNIC UNIV +3

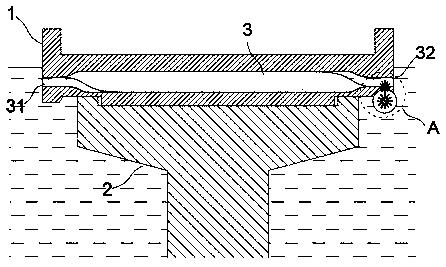

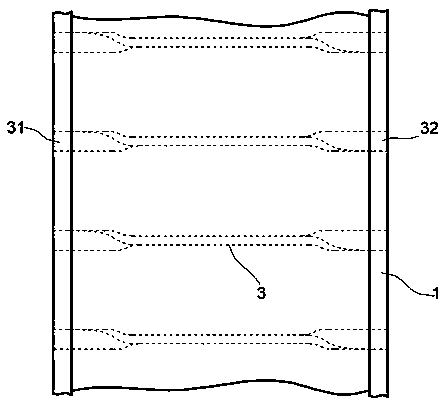

Marine airbag vibration isolator

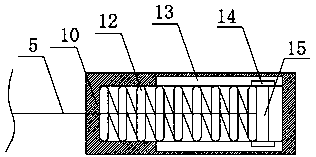

A marine airbag vibration isolator comprises a top plate, a base and a middle airbag from top to bottom, wherein the top plate, the base and the middle airbag are in sealed match to form a sealed space; an air inlet pipe penetrates through the base to stretch into the sealed space; the marine airbag vibration isolator is characterized in that a restraint strap surrounding a middle airbag is arranged at the waist position of the middle airbag; the restraint strap is located in a bag body of the middle airbag and protrudes out of the outer side of the sealed space; a buffering cushion is arranged on the base; the buffering cushion is arranged in the sealed space; the horizontal distance and the vertical distance from the buffering cushion to the top plate are L1 and L2; the value ranges of the L1 and the L2 are 1mm-20mm. The marine airbag vibration isolator has a simple structure and light weight, low self-vibration frequency and high bearing capability.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH +1

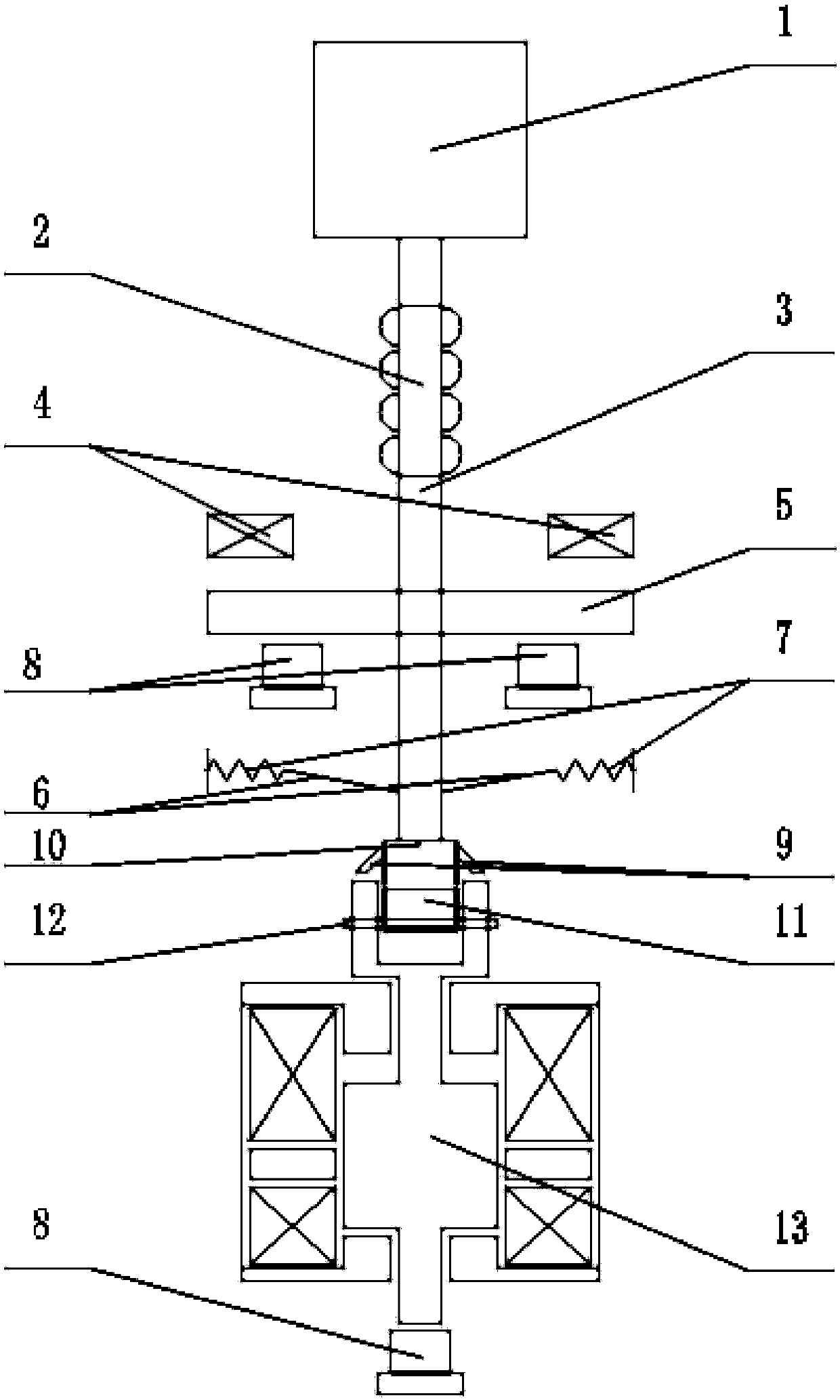

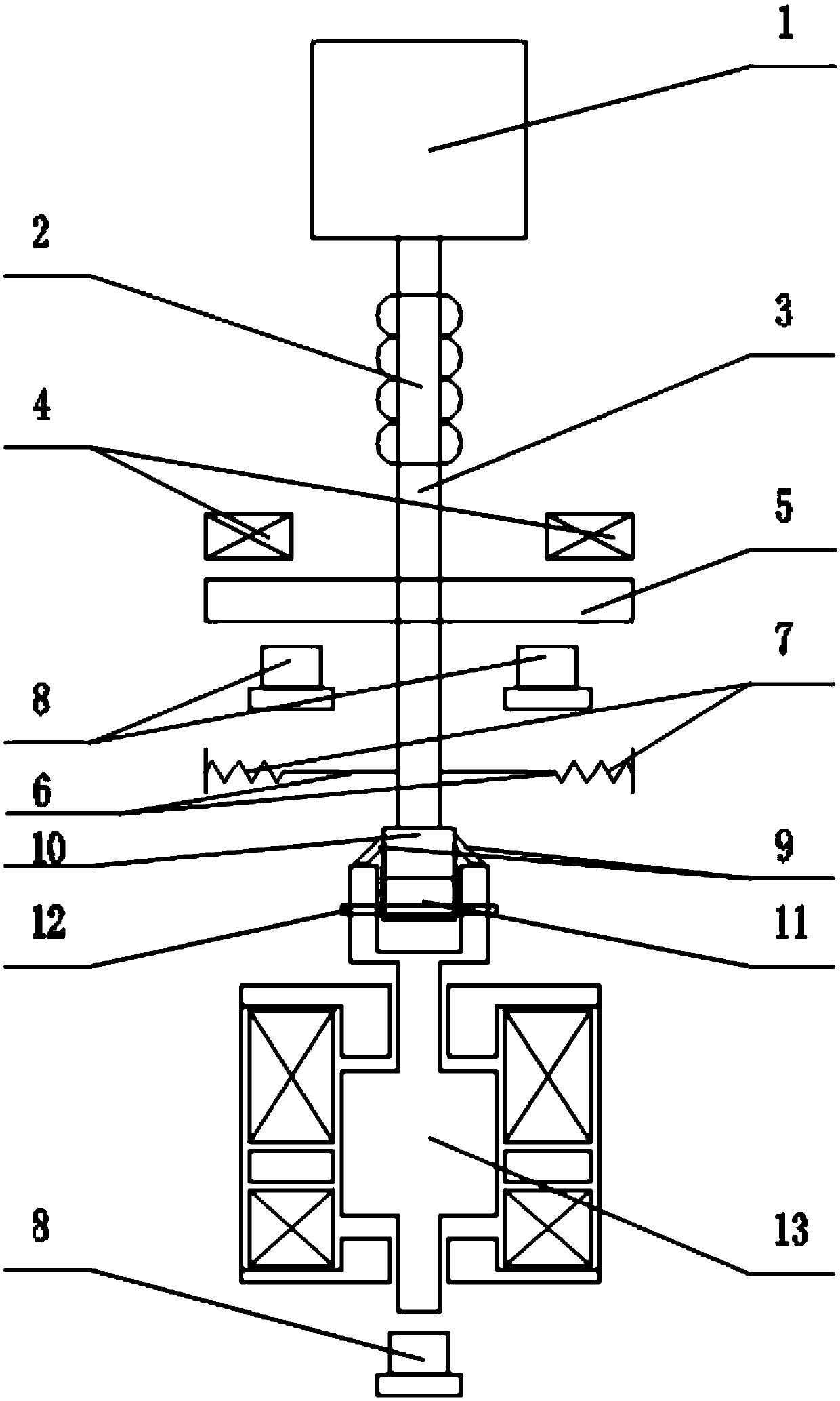

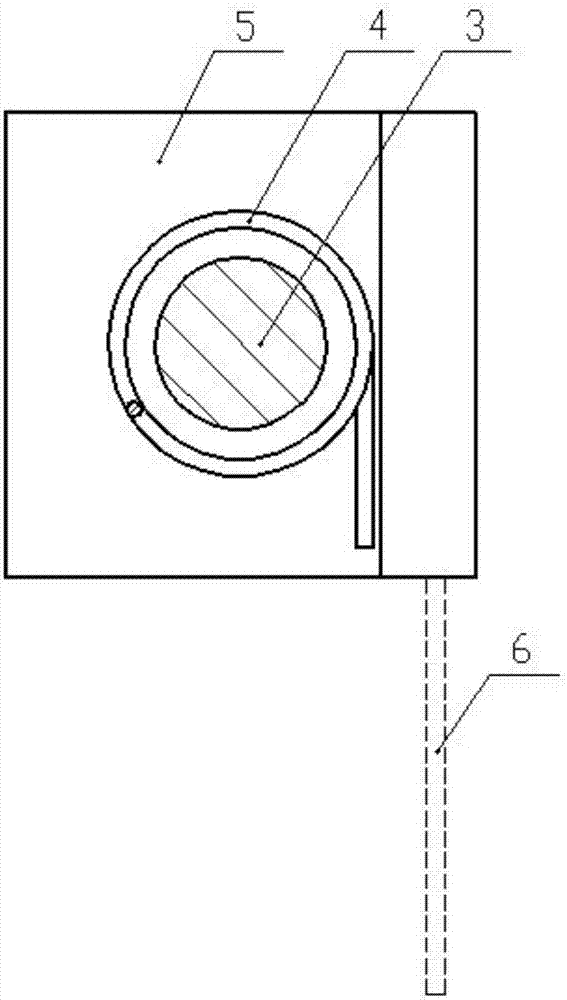

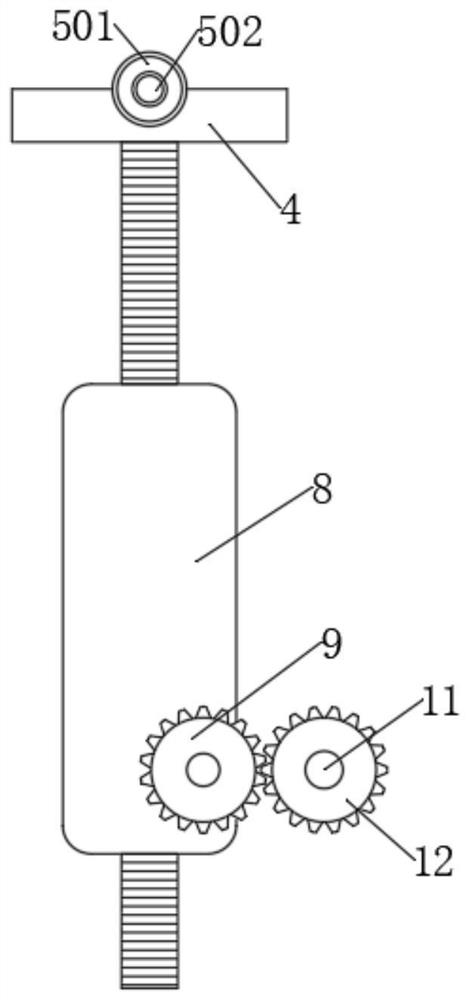

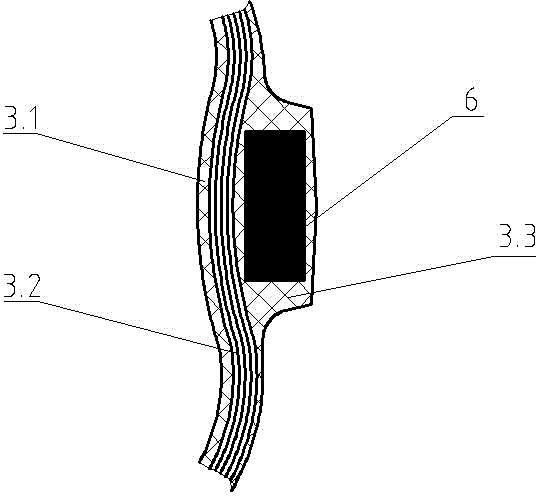

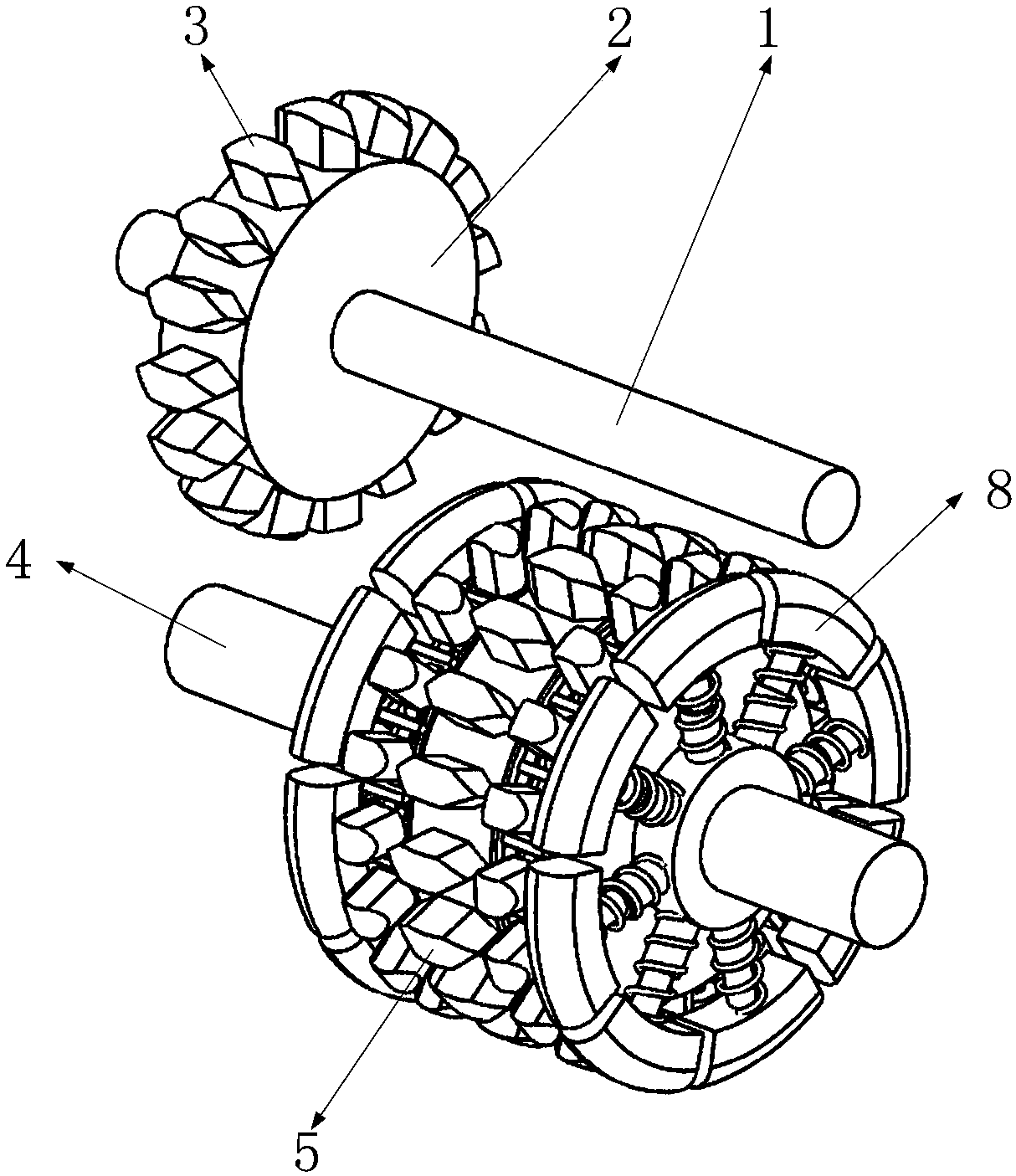

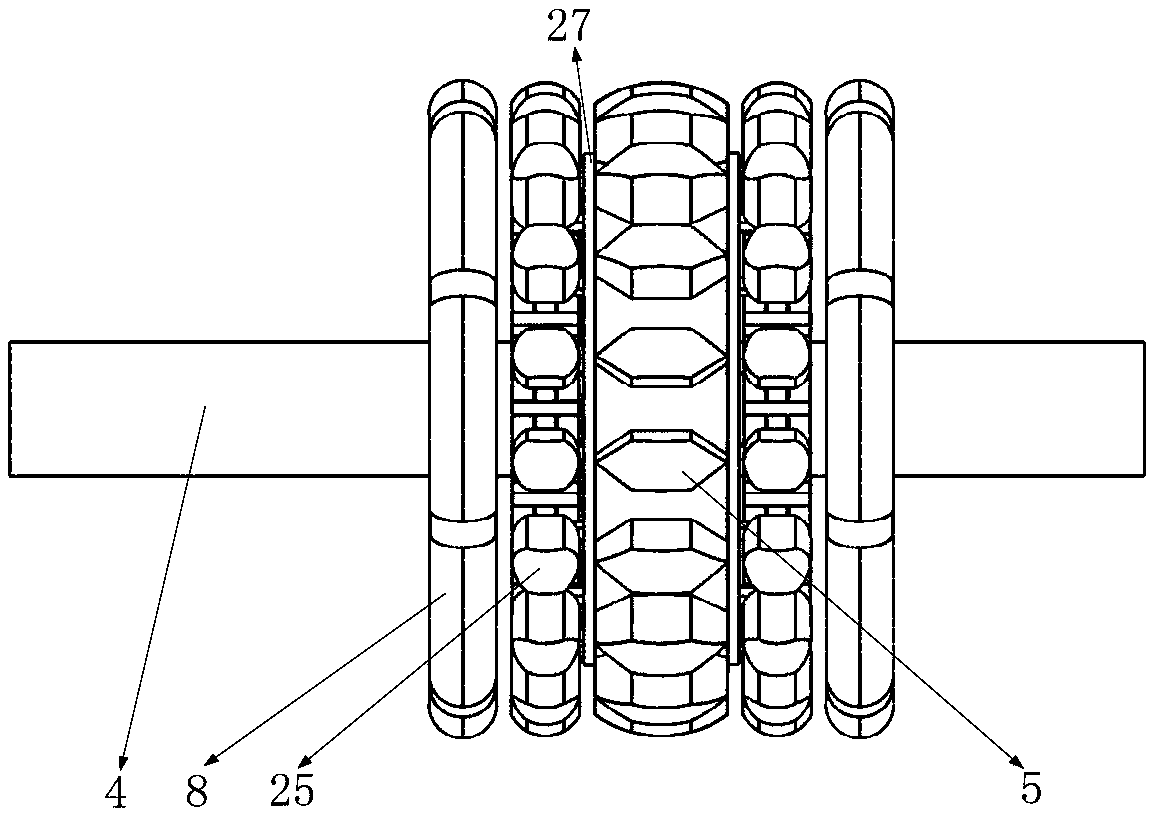

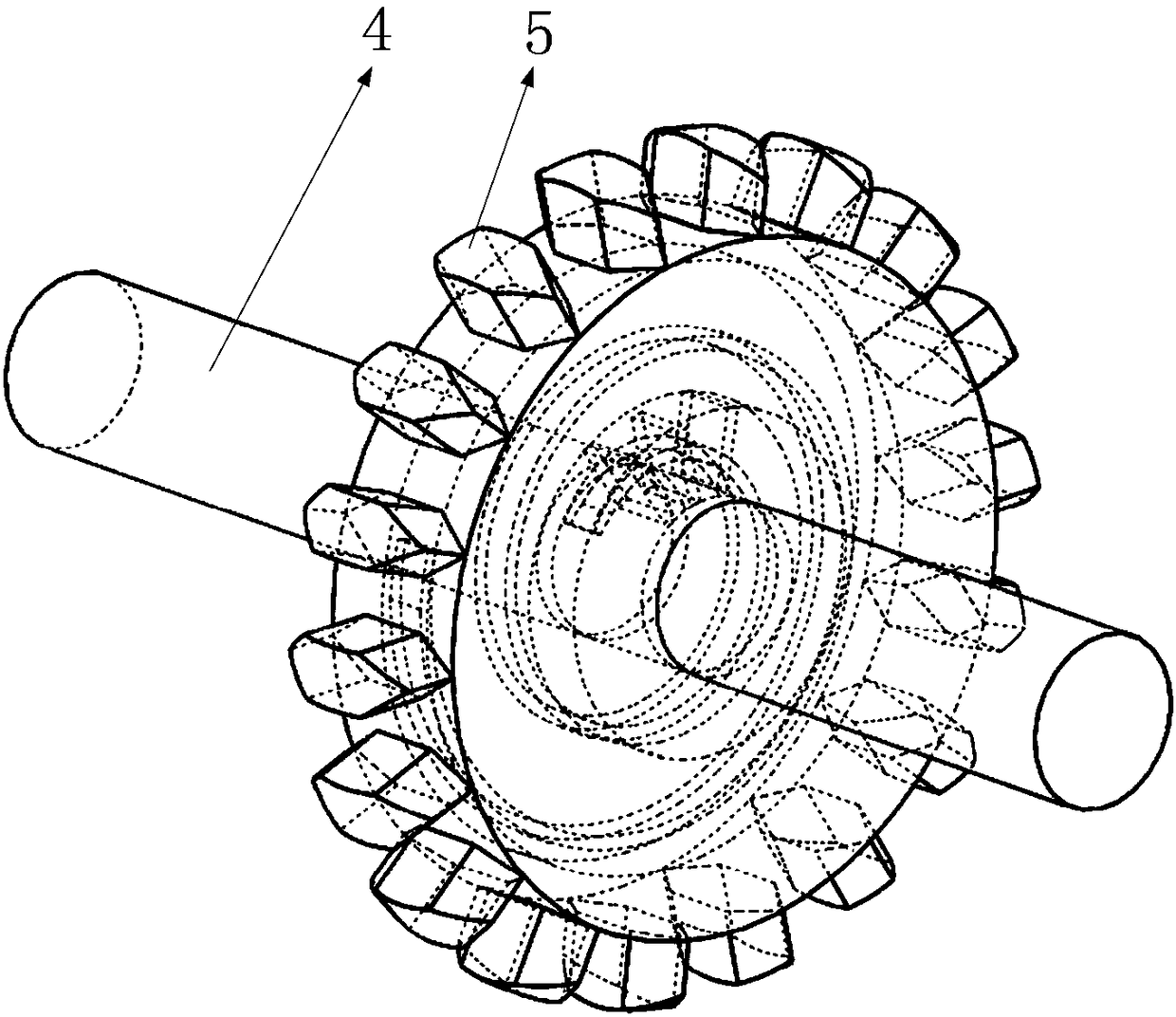

Synchronous tooth collision prevention gear transmission mechanism

ActiveCN108591367AExtended service lifeWeaken Rigid CollisionPortable liftingToothed gearingsDrive shaftGear wheel

The invention belongs to the technical field of gear transmission and particularly relates to a synchronous tooth collision prevention gear transmission mechanism. The gear transmission mechanism comprises a driven shaft, a driven gear, driven teeth, a driving shaft, driving teeth, a driving gear and the like, wherein a driving mechanism is matched with the driven gear to make the rotational speedof the driven gear close to the rotational speed of the driving gear, and rigid collision between the driving gear and the driven gear during engagement of the driving gear and the driven gear is reduced; a synchronization mechanism is matched with the driven gear to make the driven gear and the driving gear rotate synchronously, and rigid collision of the driving gear and the driven gear duringengagement of the driving gear and the driven gear is avoided; besides, when slight rigid collision happens during engagement of the driving teeth and the driven teeth, a volute spiral spring can achieve a certain rigid collision buffering effect. Through the design, the tooth collision phenomenon caused by rigid collision during gear engagement is avoided, and the service life of the gears is prolonged. The synchronous tooth collision prevention gear transmission mechanism is simple in structure and has a good using effect.

Owner:HAIMEN MAOFA ART DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com