Production device for plastic particles

A production device and a technology of plastic particles, applied in cleaning methods and utensils, chemical instruments and methods, and dust removal, etc., can solve problems such as low extrusion accuracy, bulky waste treatment devices, and ecological environment hazards, and achieve structural Simple, good waste gas treatment effect, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

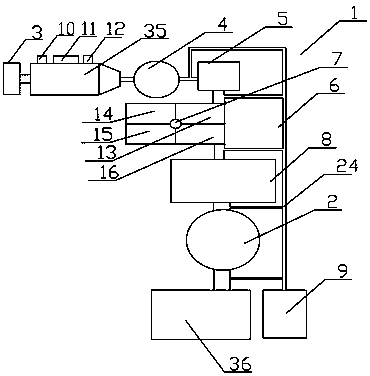

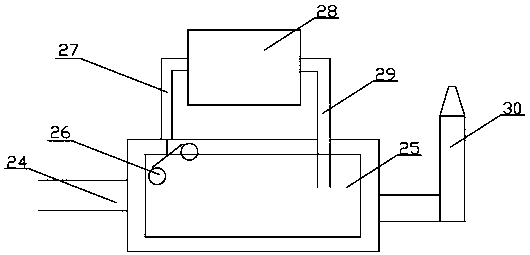

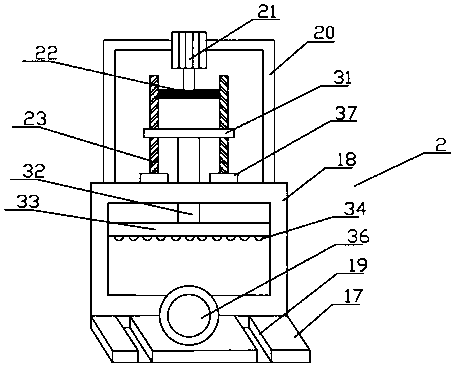

[0018] Such as figure 1 , 2 As shown, a production device for plastic particles includes a production equipment body 1 and an extrusion equipment 2, and the production equipment body 1 includes a mixer 35, a mixer motor 3, a drying and melting device 4, a plasticizing device 5, and a cooling device 6 , automatic dust removal device 7, drying molding device 8 and waste gas treatment device 9; the mixer 2 is provided with a color master batch port 10, a raw material port 11, and an auxiliary material port 12, and the left side of the blender 2 is provided with a blender motor 3 , the mixer motor 3 is driven and connected to the inner auger of the mixer 2, and the outlet at one end of the mixer 2 is connected to the drying and melting device 4 through a pipeline. The pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com