High-reliability battery installation system

A technology of installation system and reliability, applied in the field of automobiles, can solve problems such as automobile failures and damages, and achieve the effects of protecting battery packs, reducing rigid collisions, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

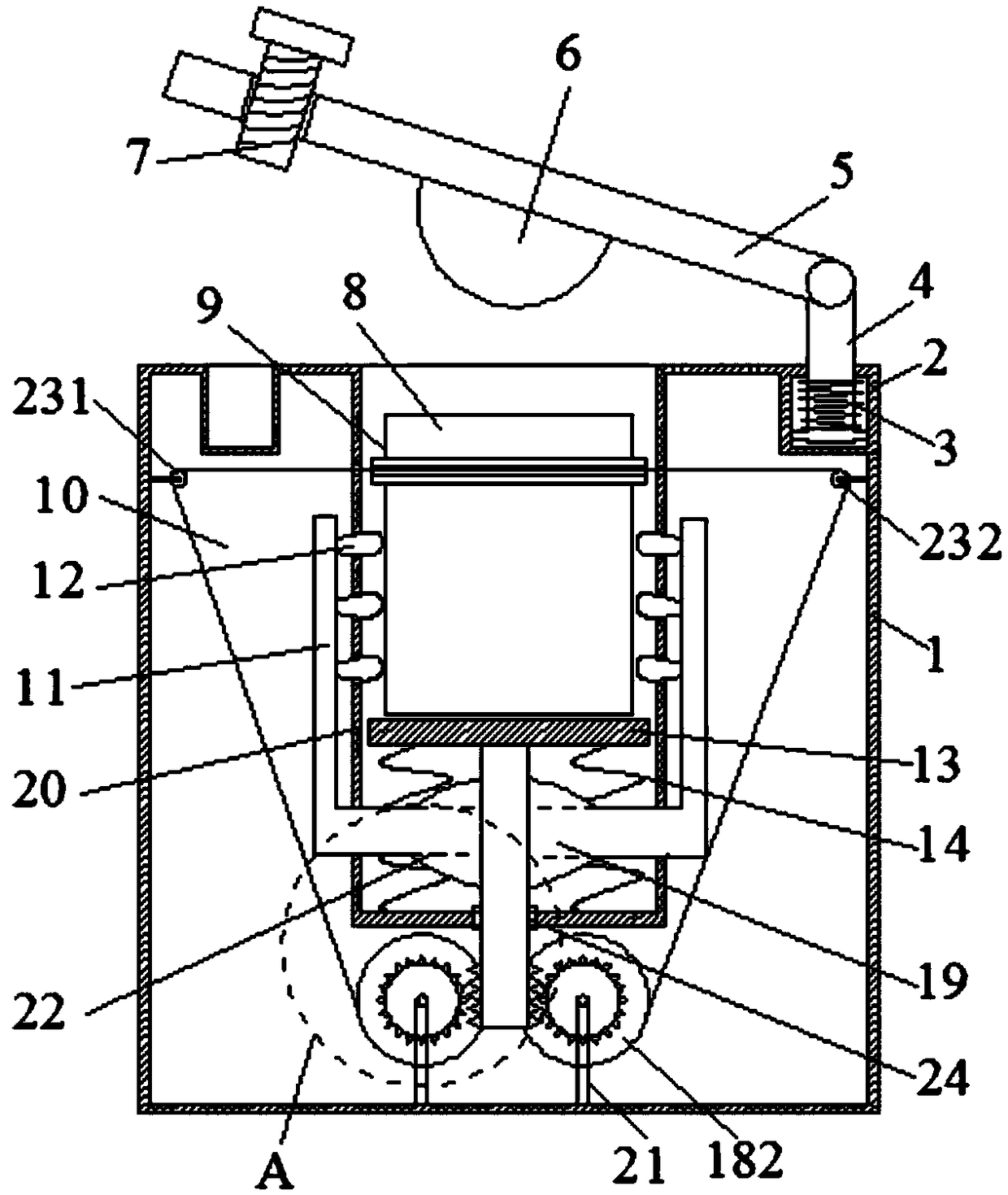

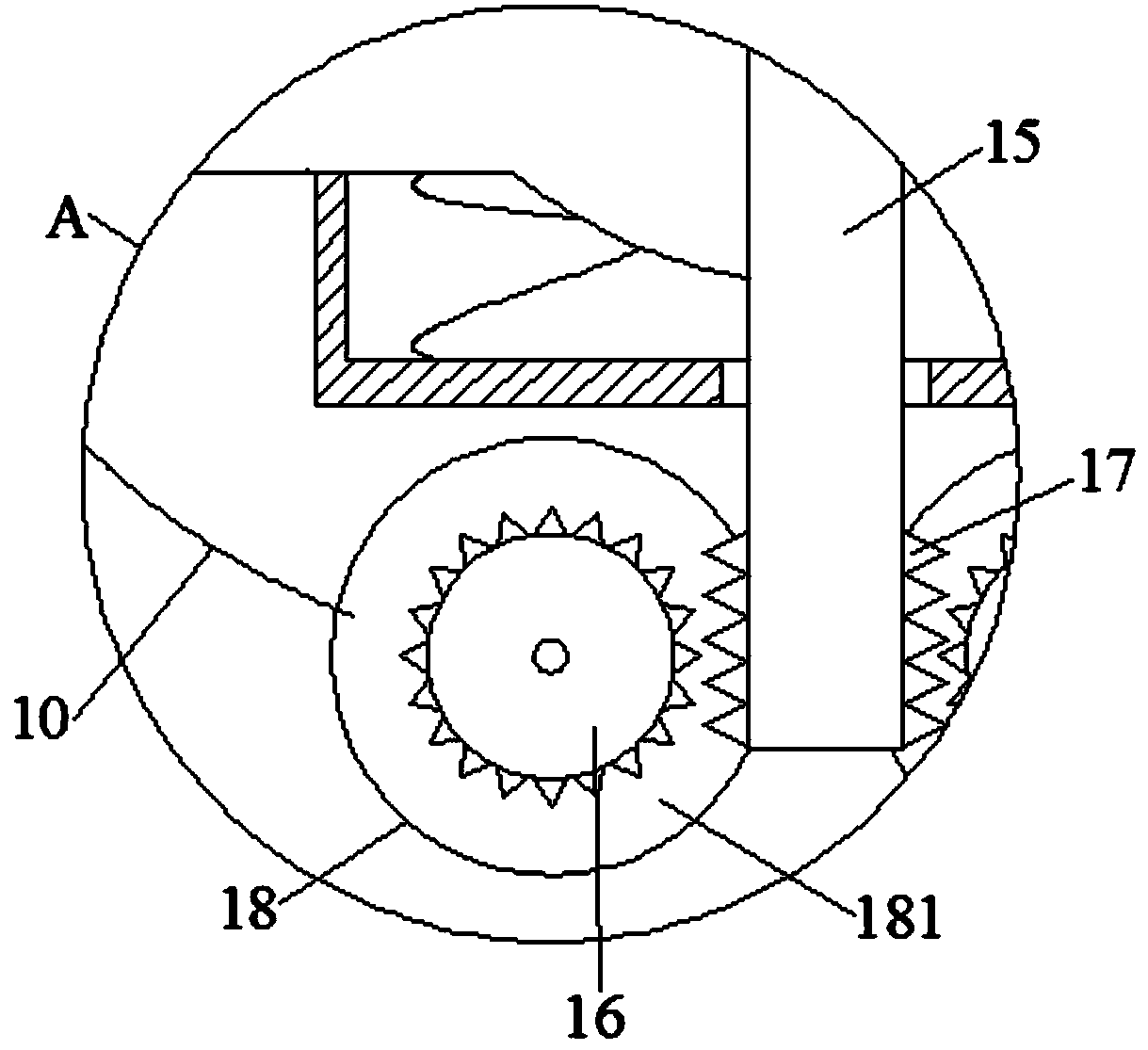

[0023] Embodiment 1: A high-reliability battery installation system, including an installation box body 1, a battery pack 8, a cover plate 5, an elastic rope 10, a main airbag 19 and several secondary airbags 12, and the upper part of the installation box body 1 has a The storage chamber 20 opening upwards, the battery pack 8 is located in the storage chamber 20, a support plate 13 is located below the battery pack 8 and contacts its lower surface, and a lifting rod 15 is installed on the lower surface of the support plate 1313, the support plate 13 At least three first springs 14 are arranged at equal intervals around the lifting rod 15 between the bottom of the storage chamber 20;

[0024] The upper surface of the installation box 1 is located on both sides of the storage chamber 20 and is respectively provided with installation grooves 2 and threaded holes. One end of the cover plate 5 is installed to one end of the installation box body 1 through a through hole inner pole 4...

Embodiment 2

[0031] Embodiment 2: A high-reliability battery installation system, including an installation box body 1, a battery pack 8, a cover plate 5, an elastic rope 10, a main airbag 19 and several secondary airbags 12, and the upper part of the installation box body 1 has a The storage chamber 20 opening upwards, the battery pack 8 is located in the storage chamber 20, a support plate 13 is located below the battery pack 8 and contacts its lower surface, and a lifting rod 15 is installed on the lower surface of the support plate 1313, the support plate 13 At least three first springs 14 are arranged at equal intervals around the lifting rod 15 between the bottom of the storage chamber 20;

[0032] The upper surface of the installation box 1 is located on both sides of the storage chamber 20 and is respectively provided with installation grooves 2 and threaded holes. One end of the cover plate 5 is installed to one end of the installation box body 1 through a through hole inner pole 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com