Impact-wear-resistant excavator bucket tooth and production process thereof

An excavator bucket tooth and impact-resistant technology, which is applied to earth movers/shovels, mechanical equipment, metal processing equipment, etc., can solve problems such as reducing the service life of bucket teeth, affecting excavation efficiency, and increasing resistance, achieving The effect of increasing service life, speeding up work efficiency and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

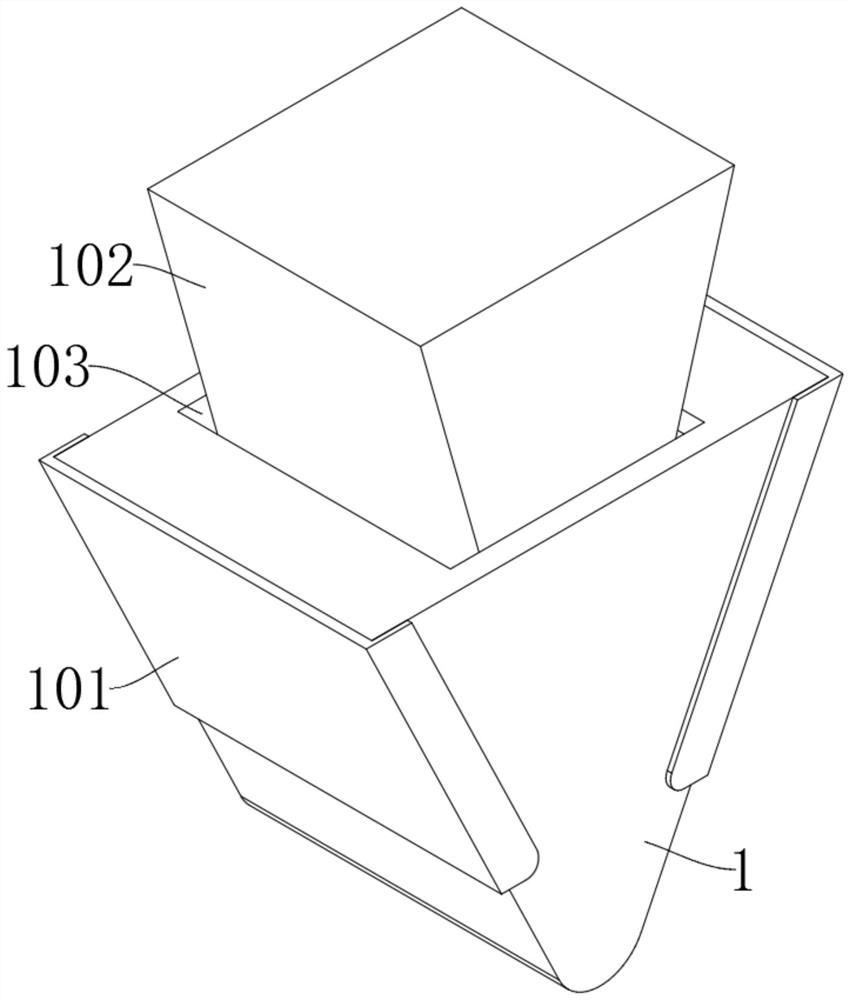

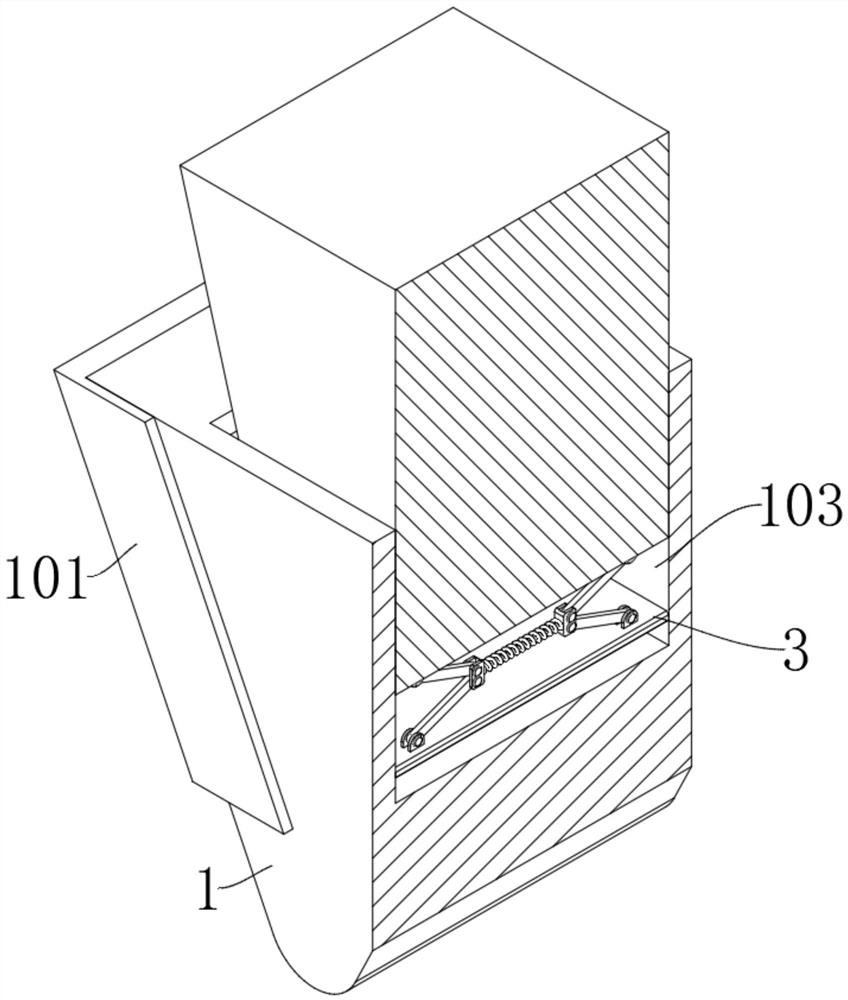

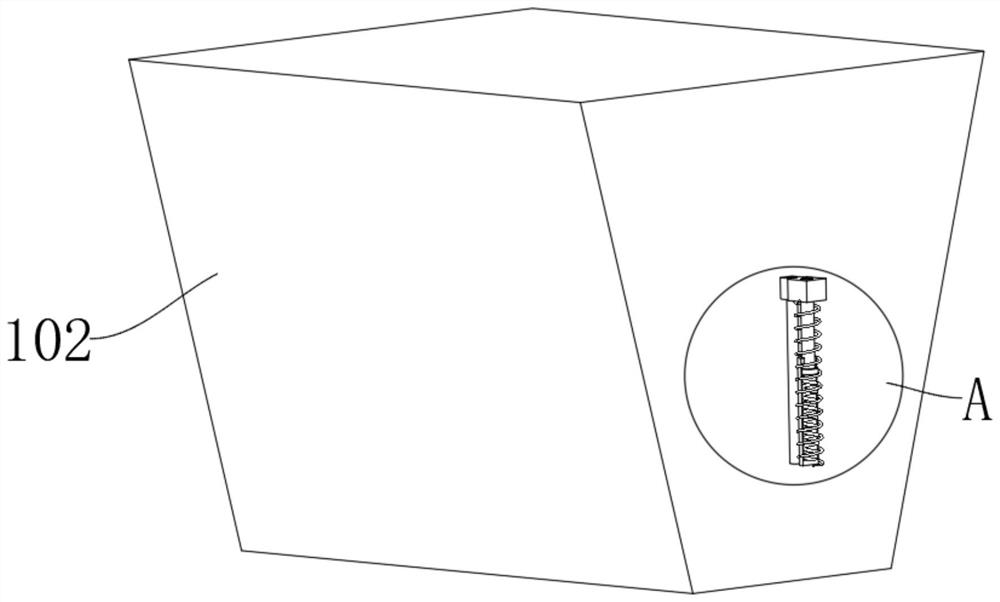

[0043] see Figure 1-13 , the present invention provides the following technical solutions: an excavator bucket tooth resistant to impact and wear, including a main bucket tooth part 1, a storage space 103 is opened in the main bucket tooth part 1, and an auxiliary bucket tooth part is provided in the storage space 103 102, the auxiliary bucket tooth 102 is connected with the main bucket tooth 1 through an elastic damping mechanism;

[0044] A shock absorbing plate 3 is provided in the accommodation space 103, and the shock absorbing plate 3 is arranged on the bottom side of the auxiliary bucket tooth part 102. The shock absorbing plate 3 is used to reduce the impact on the bucket teeth. The shock absorbing plate 3 passes through the shock absorbing mechanism and the auxiliary Bucket teeth 102 are connected;

[0045] The side end of the main bucket tooth part 1 is provided with a bucket tooth protection shell 101. The bucket tooth protection shell 101 is used to reduce the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com