Cam type ring bobbin collecting device

A collecting device, cam-type technology, applied in the field of cam-type bobbin collecting device, can solve the problems of low efficiency, heavy workload, time-consuming and labor-intensive, etc., and achieve a simple and compact structure, reduce rigid collision, and occupy a small area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

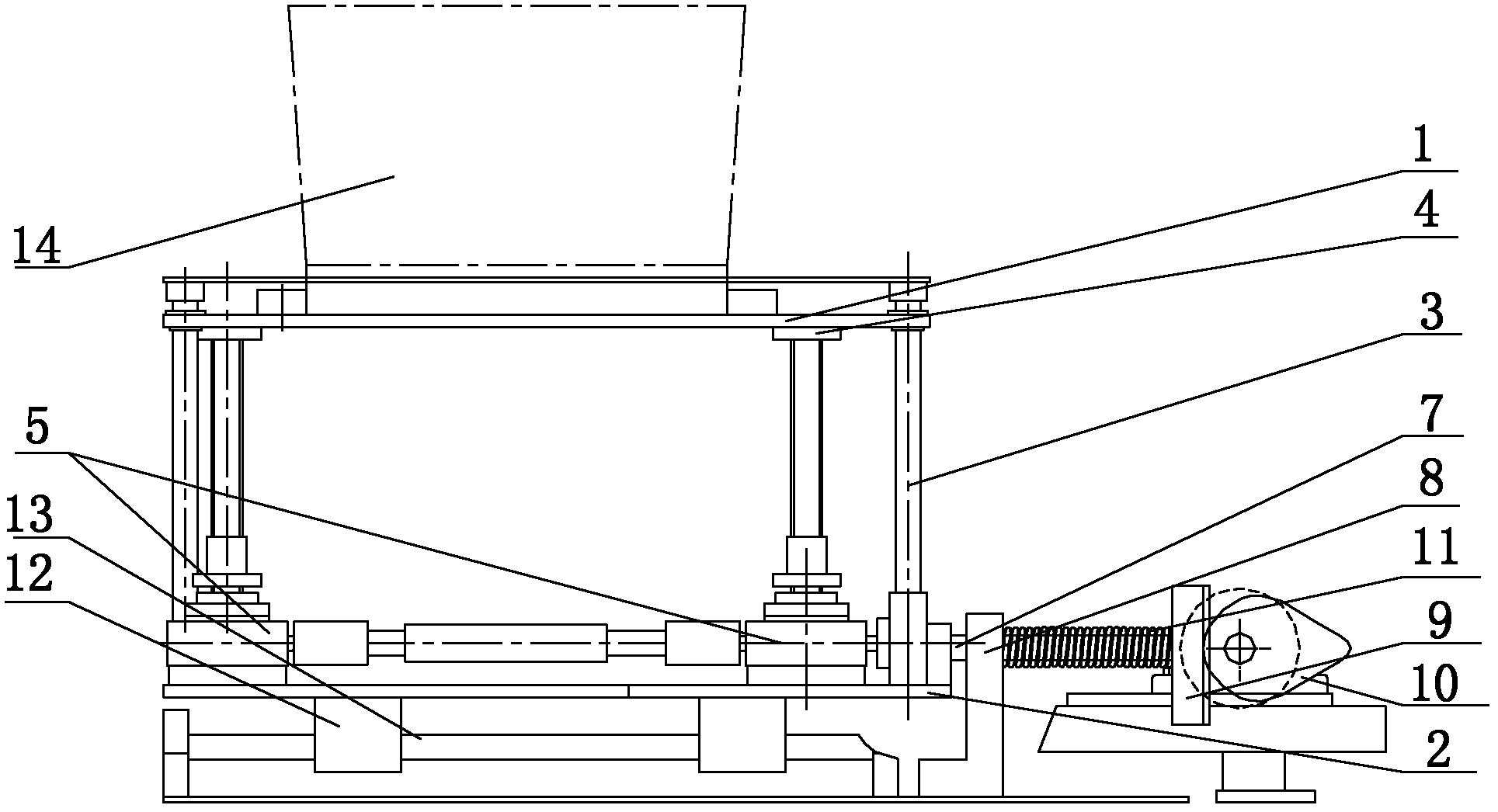

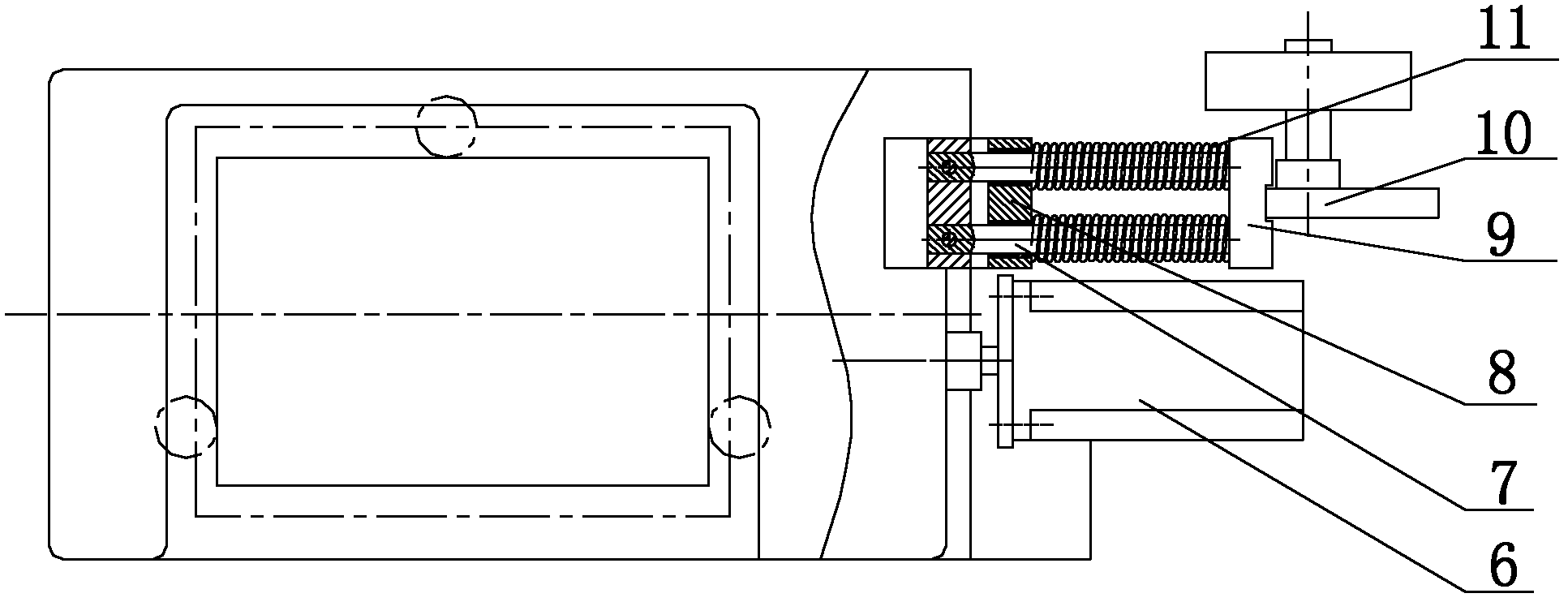

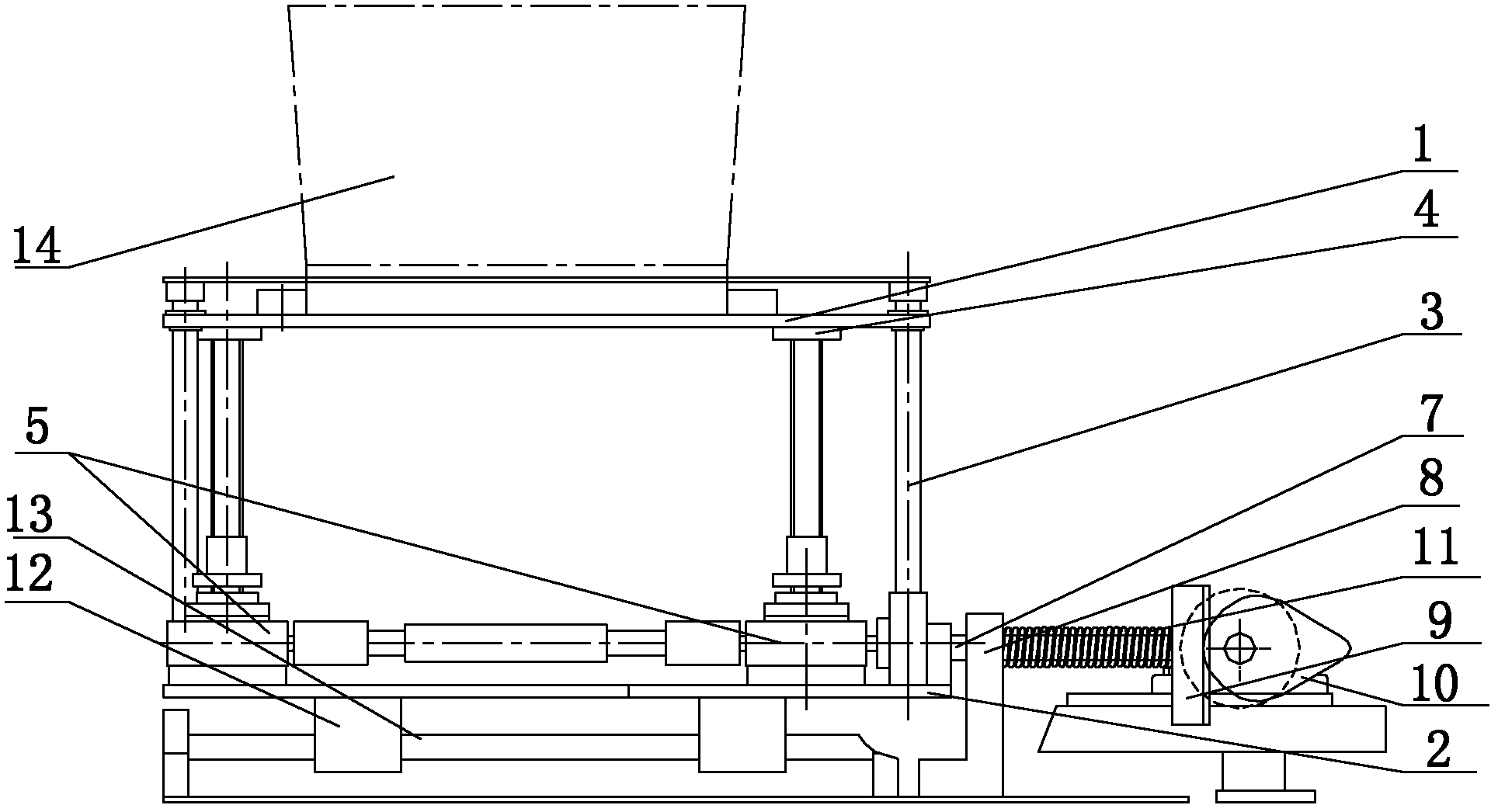

[0010] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0011] See Figure 1 ~ Figure 2 , a cam type bobbin collecting device, comprising a bobbin box 14 and a trolley, the bobbin box 14 is placed on the trolley; the trolley includes a car body, which is provided with an up and down lifting mechanism and a horizontal swing mechanism; The upper support plate 1 and the lower base plate 2 of the bobbin box 14, the lower base plate 2 is affixed with a vertical guide rod 3, the upper support plate 1 is slidably connected to the vertical guide rod 3, and the up and down lifting mechanism includes a fixed support on the upper support plate. The screw nut 4 on the board 1 and the lifter 5 fixed on the lower base plate 2, the screw nut 4 and the lead screw of the lifter 5 are connected by threads, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com