Arc extinguishing chamber for high-voltage circuit breaker

A high-voltage circuit breaker and arc extinguishing chamber technology, applied in the field of arc extinguishing chambers, can solve problems such as affecting reliability, reducing breaking reliability, and sticking, so as to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

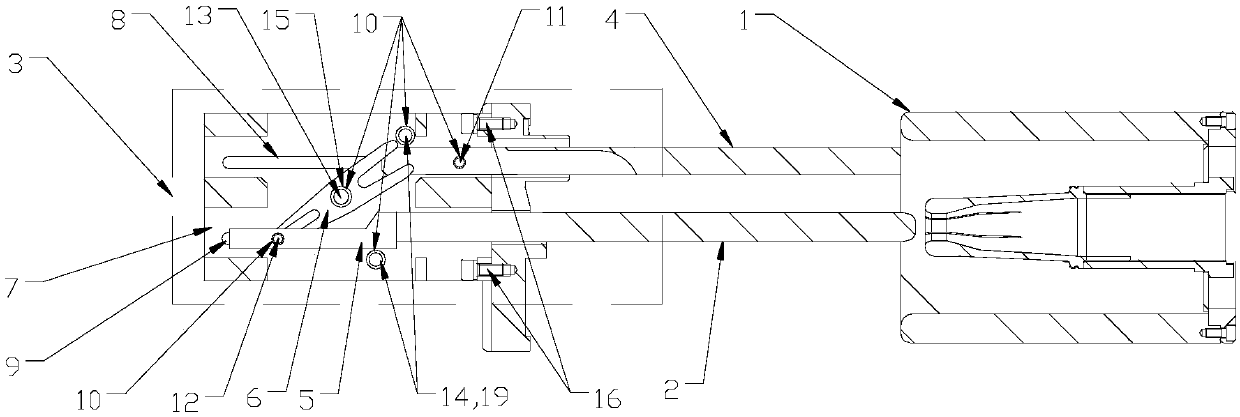

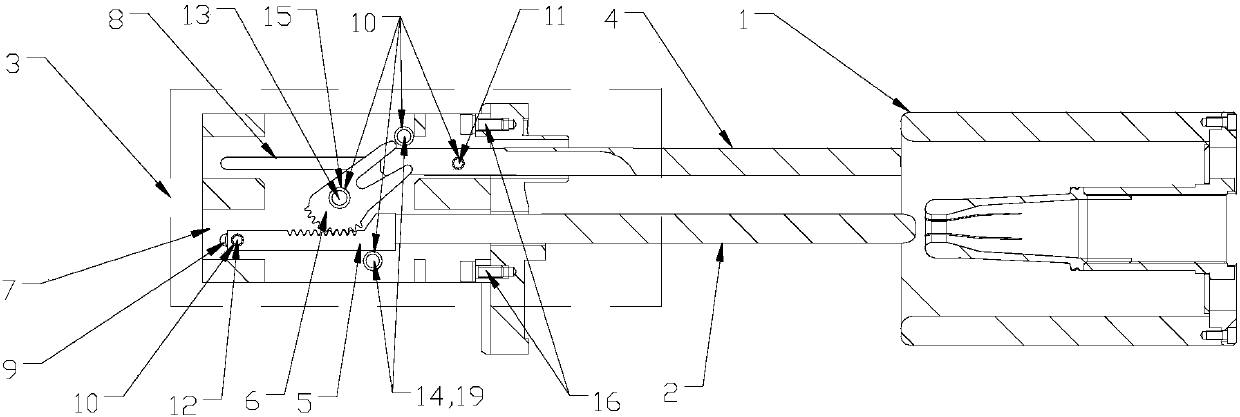

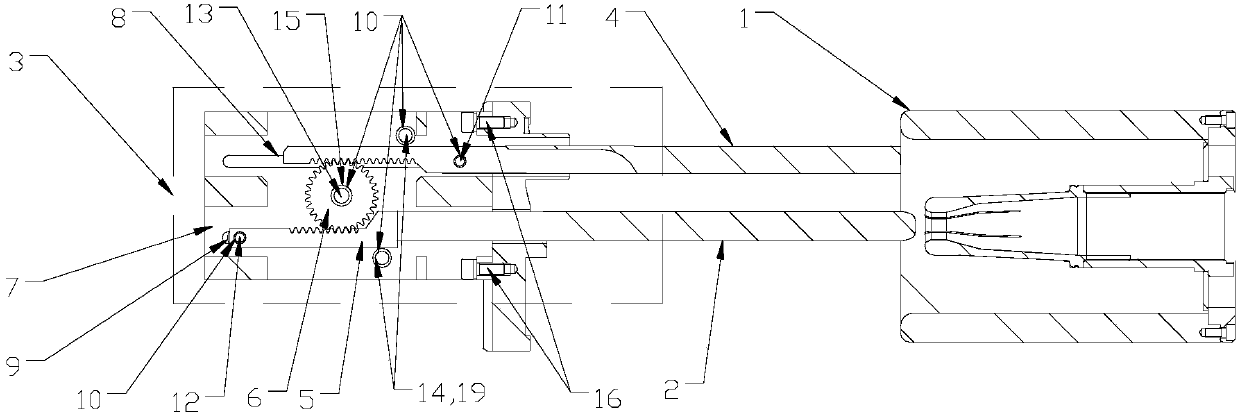

[0031] Such as Figure 1 ~ Figure 3 As shown, an arc extinguishing chamber for a high-voltage circuit breaker, the arc extinguishing chamber is composed of the active side contact 1, the driven side contact 2, and the movement reversing mechanism connecting the contacts on both sides. 3 components; wherein, the motion reversing mechanism 3 includes the active side push-pull rod 4, the driven side push-pull rod 5, the reversing device 6 and the guide rail 7. Wherein, the reversing device 6 can adopt such as figure 1 The shown double shift fork structure, figure 2 Fork-rack-and-pinion configuration shown or image 3 The double rack and pinion structure shown.

[0032] When assembling the conduction device of the double-action arc extinguishing chamber, the assembly method that can be ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com