Vehicle reverse gear synchronous mechanism

A technology of synchronous mechanism and reverse gear, which is applied in the direction of mechanical equipment, transmission devices, gear transmission devices, etc., which can solve the problems of gear grinding, gear grinding, and affecting the service life of gears, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Before describing in detail, it should be noted that the "fixed" in the specification of the present invention, unless otherwise specified, means that it can be connected by various well-known means, such as screw connection or riveting. , Welding, card slot type, embedded, etc. to achieve.

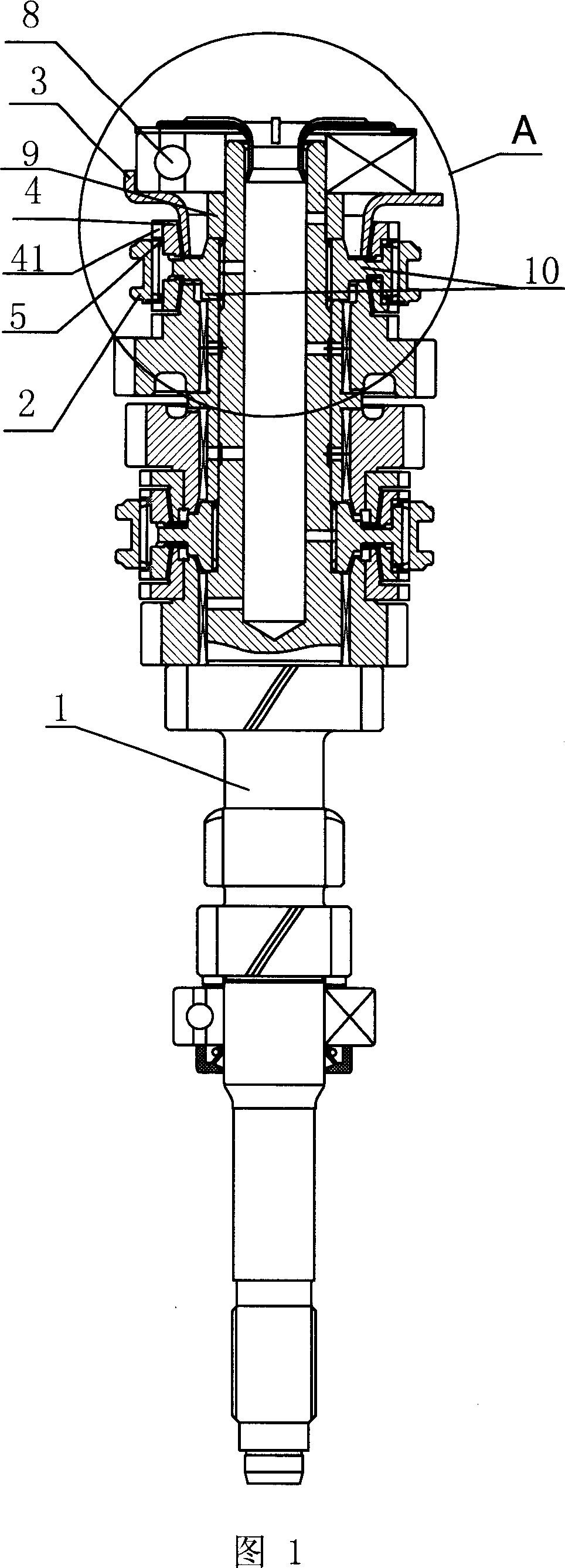

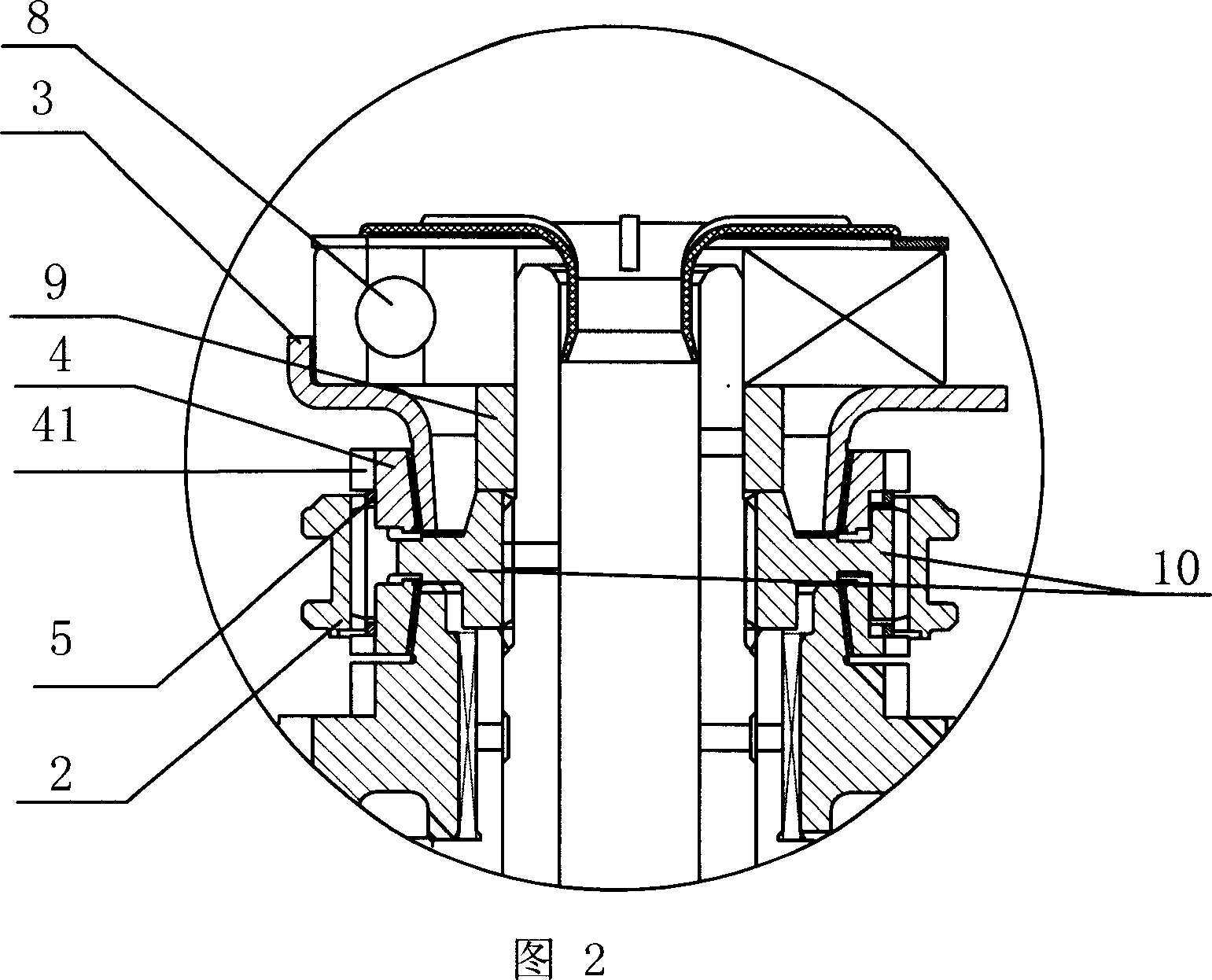

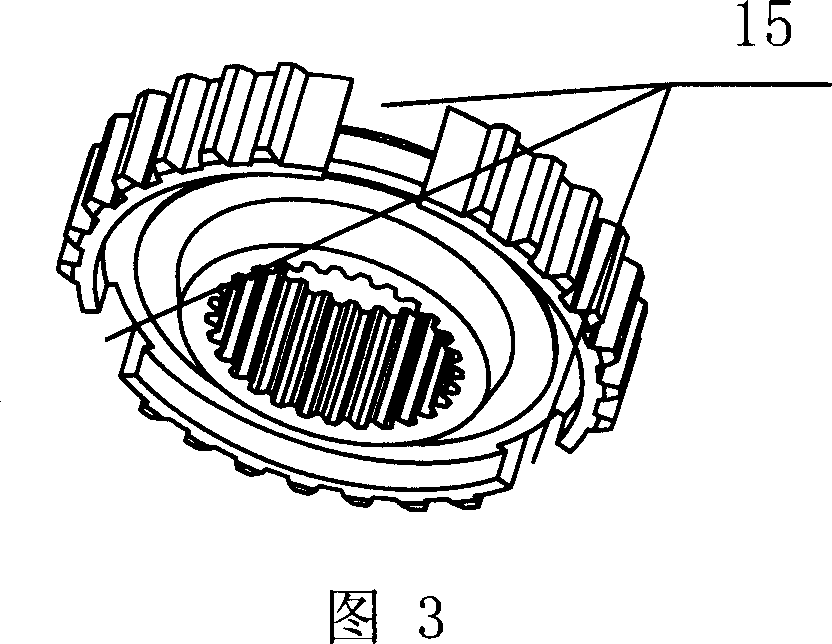

[0021] As shown in Figures 1 to 5, the reverse gear synchronization mechanism of the present invention includes a reverse gear sleeve 2, a reverse gear shift fork 13 fixed on a fork shaft 12, and a conical ring 3 mounted on the main shaft 1. And the synchronization ring 4, the main shaft 1 is provided with a bearing 8, the inner ring of the bearing 8 is fixed on the main shaft 1, and the outer ring is fixed on the rear case of the transmission; the fixed pitch teeth 9 are fixed on the main shaft, and the tapered ring 3 It is sleeved on the fixed pitch teeth 9 and fixedly connected with the rear box body to be installed (that is, fixed connection). There is a clearance fit between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com