Bi-directional skip car

A feeder and pulley technology, applied in the field of two-way feeder, can solve the problems of the push rod and the drive gear, which affect the operation of the heat treatment production line, and get stuck, and achieve the effect of avoiding the punching or sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

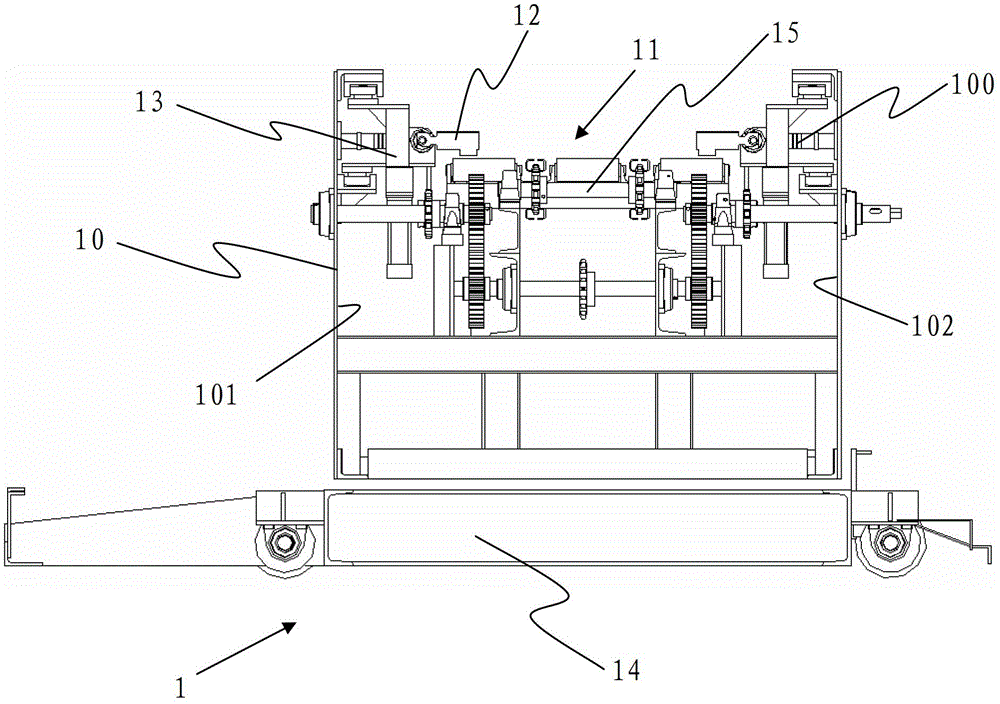

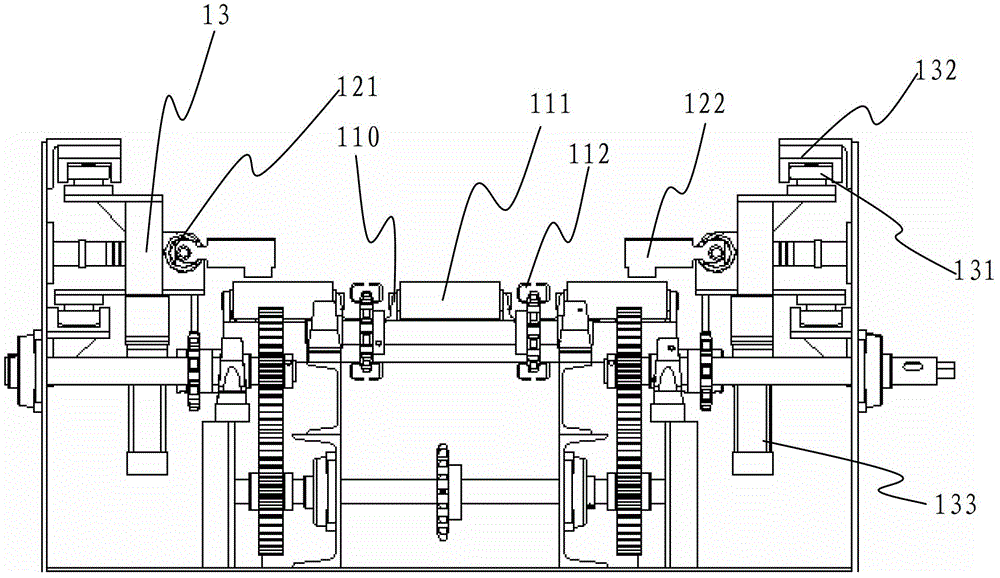

[0023] refer to figure 1 and figure 2 As shown, the two-way feeding cart 1 of the present invention is mainly composed of a feeding cart frame 10, a roller table transmission 11, two push rods 12 and speed-increasing pulleys 13.

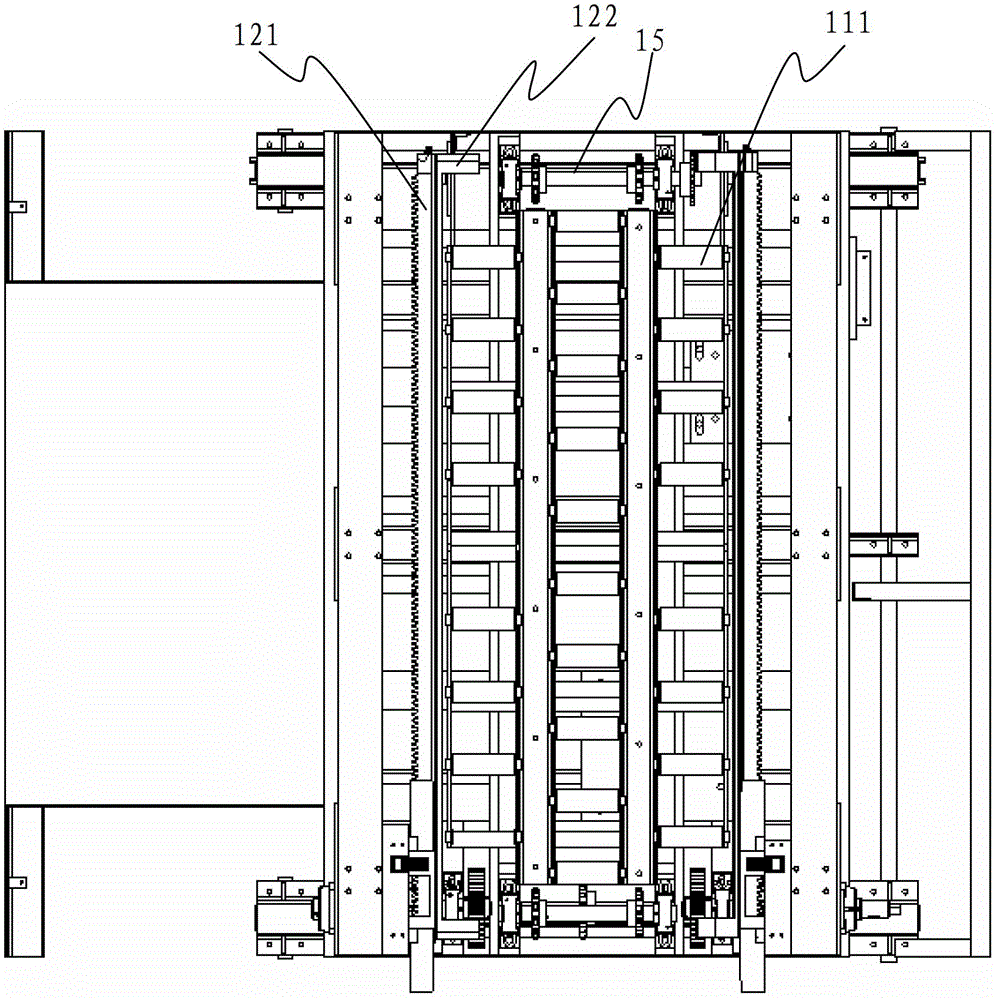

[0024] The material truck frame 10 is a rectangular frame erected on the traversing chassis 14 of the two-way material truck 1, wherein the material vehicle frame 10 and the traversing chassis 14 are welded by carbon steel sections, and the structure is firm. The front inner side 101 and the rear end inner side 102 of the feeding cart frame 10 are horizontally provided with a fixed rack 100 . The central part of the feed car frame 10 is horizontally provided with a plurality of roller table supports 110, which cooperate with image 3 As shown, a plurality of rollers 111 are erected on the roller table su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com