Self-locking mechanism of synchronizer

A synchronizer and self-locking technology, which is applied to clutches, mechanical equipment, mechanical drive clutches, etc., can solve problems such as reducing synchronizer self-locking, synchronizer damage, and shortening the effective compression distance of springs, so as to prevent synchronizer damage and improve Self-locking ability, avoiding unreliable self-locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

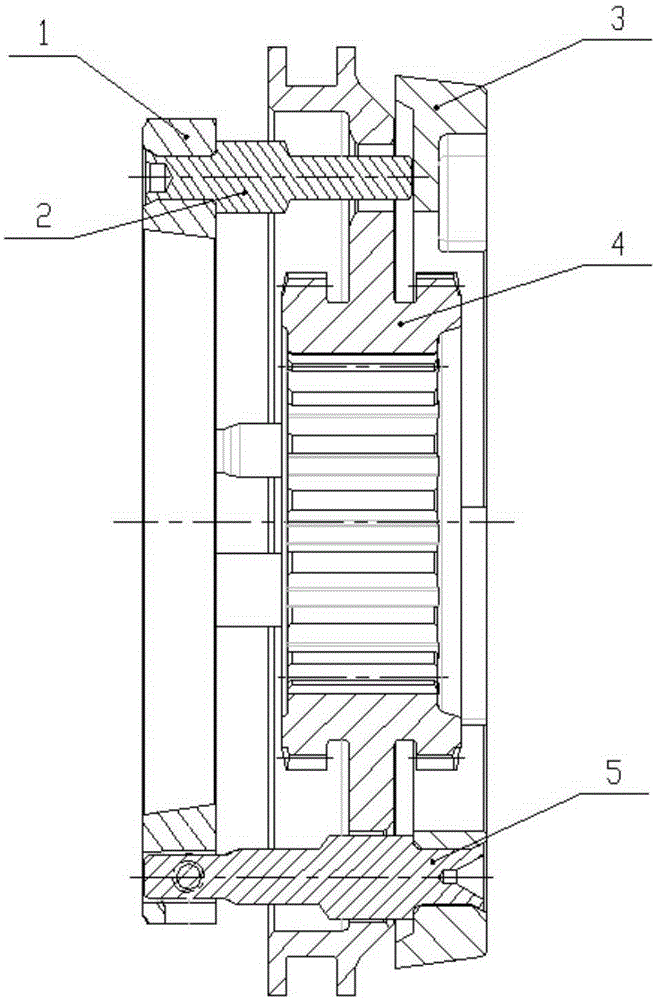

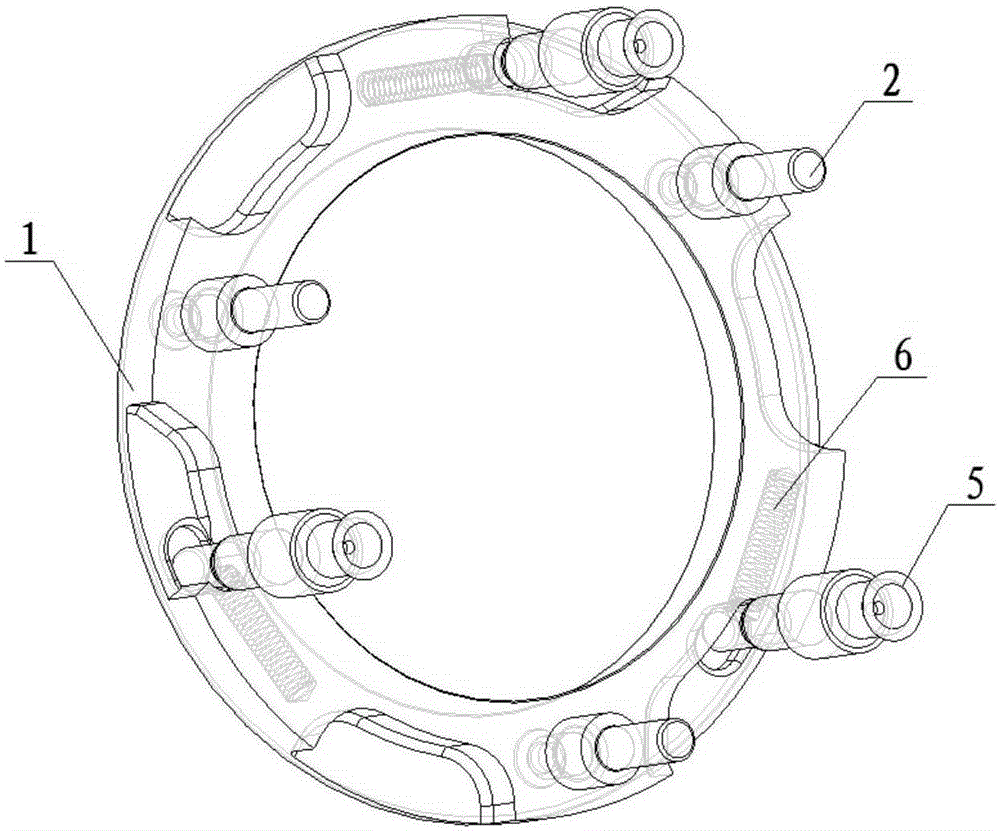

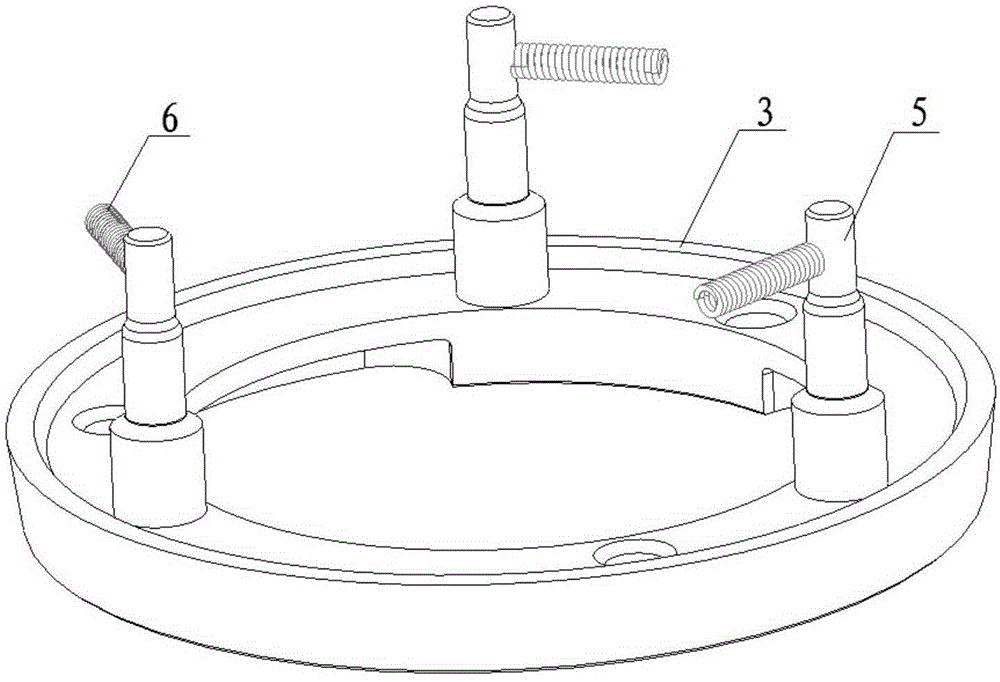

[0027] see Figure 1 to Figure 7 , a synchronizer self-locking mechanism, comprising a high-grade cone ring 1 and a low-grade cone ring 3, three high-grade locking pins 2 are interspersed on the high-grade cone ring 1, and three low-grade locking pins 5 are interspersed on the low-grade cone ring 3, There is a sliding gear sleeve 4 between the high-grade cone ring 1 and the low-grade cone ring 3. There are two groups of holes on the sliding gear sleeve 4, a total of six, three holes at intervals form a group, and the two groups of holes are not equally distributed. , respectively set the high-grade lock pin 2 and the low-grade lock pin 5, and the high-grade cone ring 1 is provided with three springs 6 that cooperate with the low-grade lock pin 5 in the circumferential direction. 5. One end of the force transmission area is tightly folded into the embedded spring 6-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com