Firm supporting and smooth lubricating type differential mechanism assembly

A smooth lubricating, differential technology, applied in the direction of differential transmission, transmission parts, belts/chains/gears, etc., to achieve the effect of increasing limit capacity, reducing rigid deformation, and increasing support rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

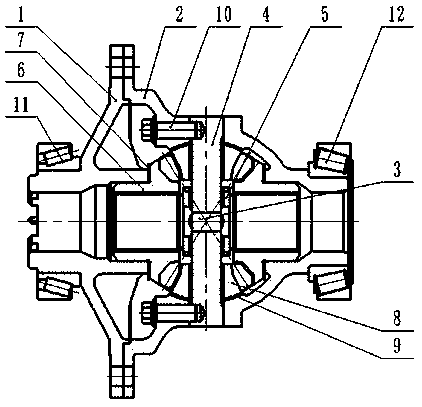

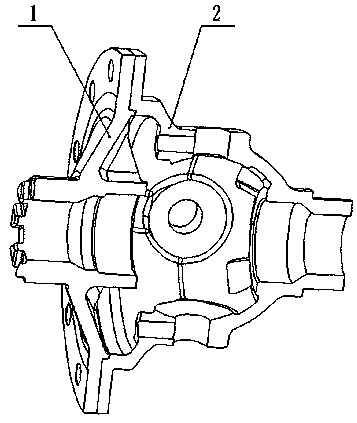

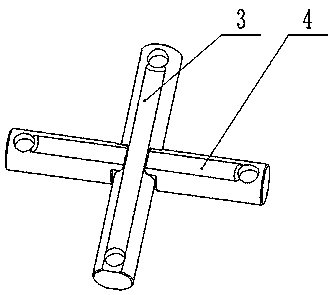

[0015] Example 1, see figure 1 , 2 , 3 and 4, according to the design needs to be processed into differential left case 1, differential right case 2, cross shaft long shaft 3, cross shaft short shaft 4, cross shaft fixing sleeve 5, half shaft wheel 6, half shaft Wheel pad 7, planetary wheel 8, planetary wheel pad 9, anti-loosening bolt 10, differential left bearing 11 and differential right bearing 12; the differential housing assembly is processed on the differential left housing 1 respectively Mounting end face and outer spigot, half-shaft wheel and spacer installation position and differential bearing installation position; differential housing assembly installation end face, inner spigot, half shaft are respectively processed on the right housing 2 of the differential The wheel and spacer installation position and the differential bearing installation position are also processed with an inner spherical surface for planetary wheel and spacer installation, and 4 cross shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com