Speed shifting tool and speed shifting control method thereof

A technology of gear shifting tools and control methods, which is applied in the direction of manufacturing tools, transmission device control, gear transmission devices, etc., can solve the problems of complex mechanical structure of gear transmission mechanism and the inability to truly realize the industrialization of automatic gear shifting, and achieve the goal of shortening the pause Time, prolong service life, avoid the effect of grinding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

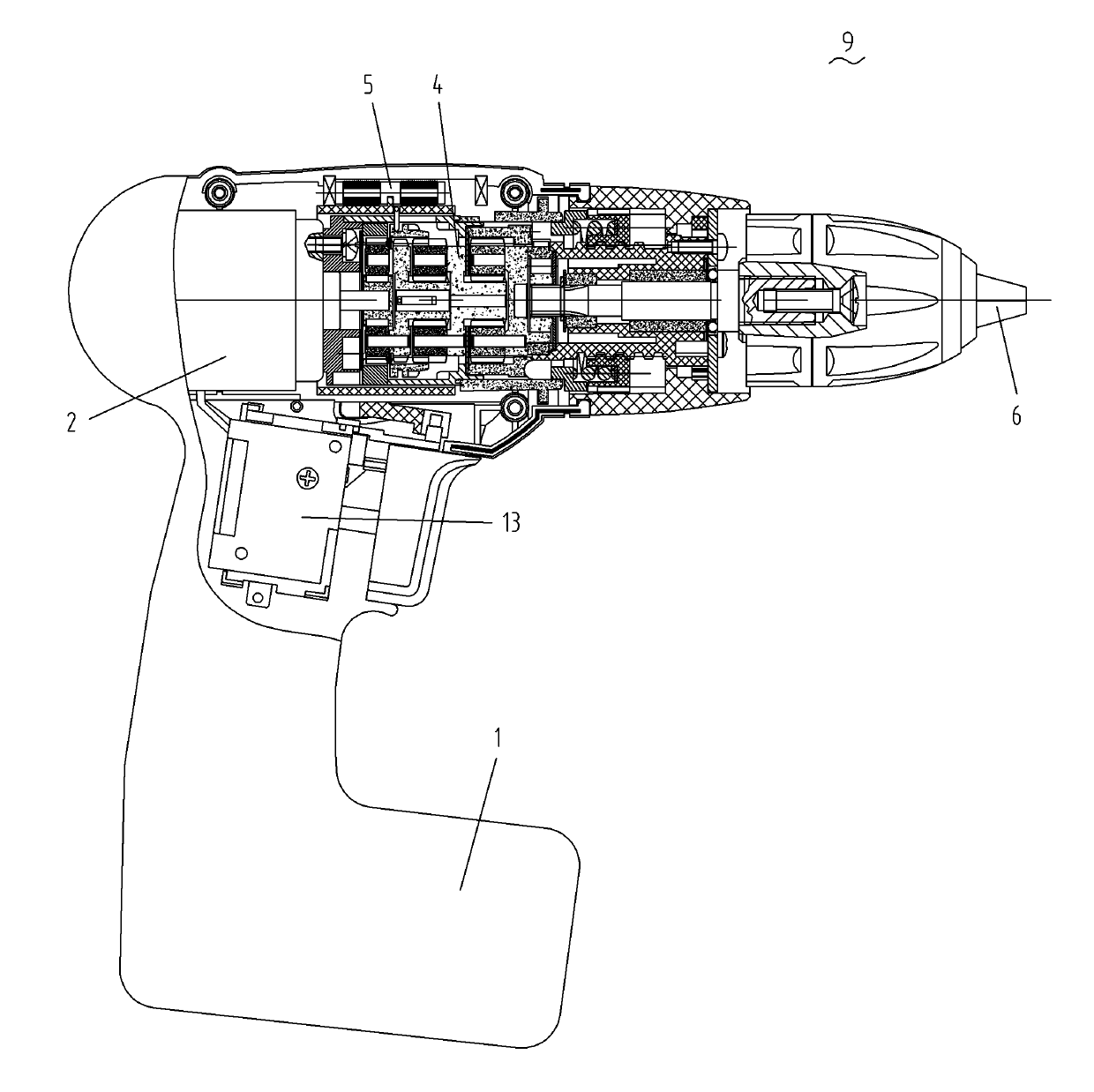

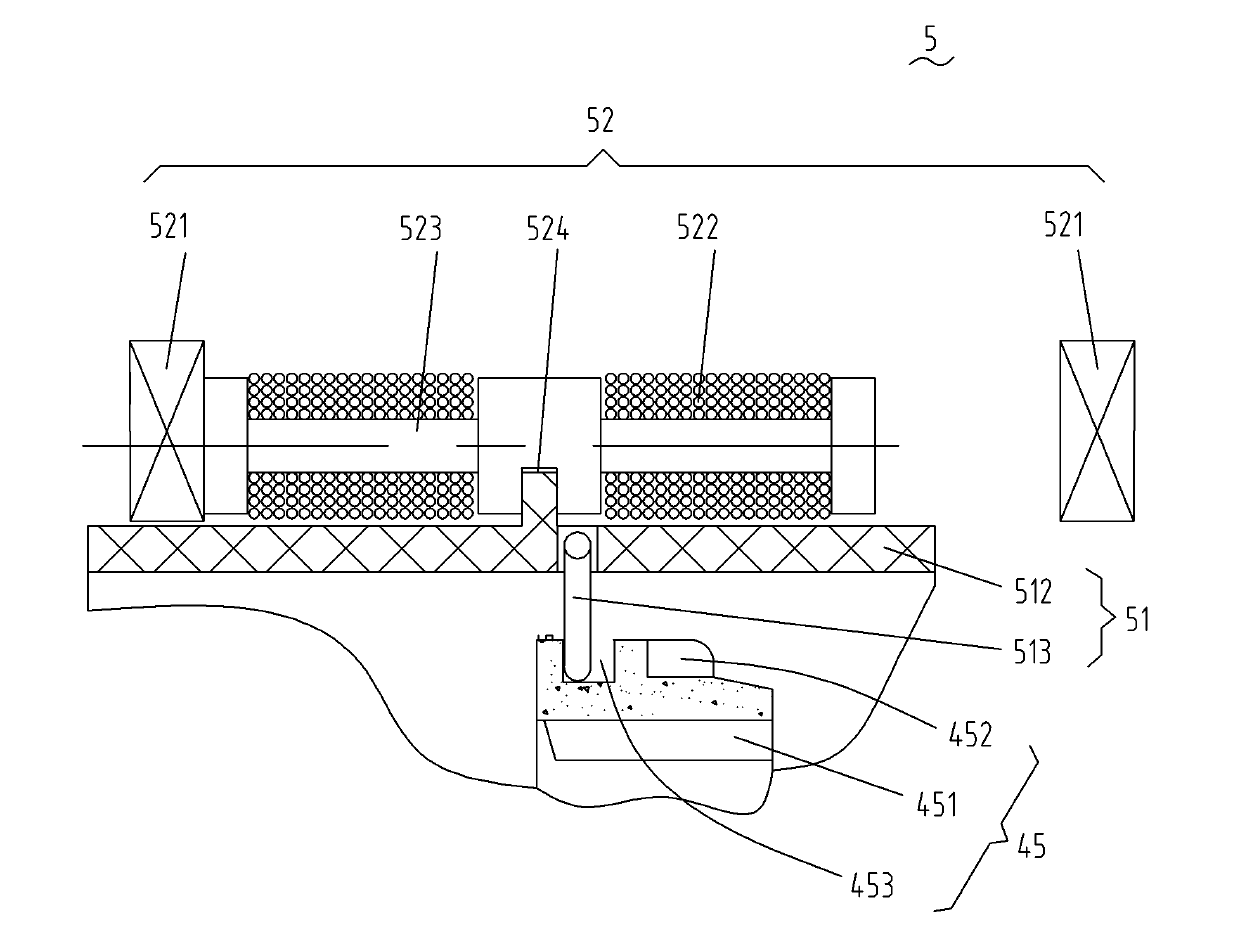

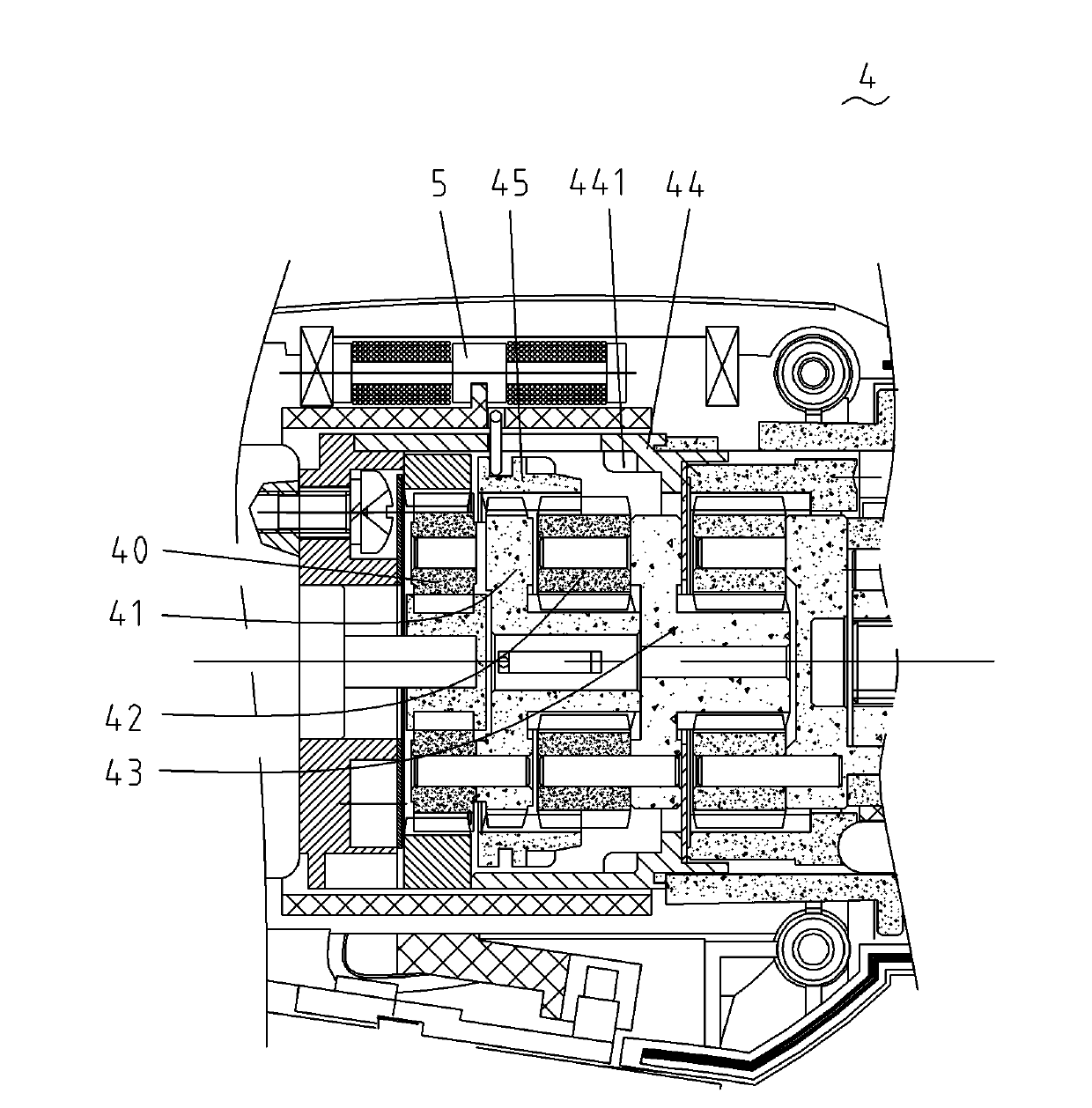

[0050] refer to Figure 1 to Figure 3b As shown, it is a structural schematic diagram of the first embodiment of the driving device of the variable speed tool control system of the present invention. A variable speed tool 9 includes a motor 2 , a motor power supply 1 , a main switch 13 for starting / stopping the motor, an output shaft 6 and a gear transmission mechanism 4 . The gear transmission mechanism 4 includes a first planetary gear set composed of a first planetary gear 40 and a first planetary carrier 41, a second planetary gear set composed of a second planetary gear 42 and a second planetary carrier 43, and is fixedly arranged on the tool housing. The anti-rotation device 44 on the body and the moving part 45 that can move axially. The driving device 5 is arranged on the gear transmission mechanism 4, and comprises a driving member 52 and a transmission member 51. The driving member of the present embodiment adopts an electromagnet device, including two permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com