Bevel tooth differential speed reducer for mechanical main shaft of machine tool

A reducer and mechanical technology, which is applied in the direction of mechanical equipment, differential transmission, belt/chain/gear, etc., can solve the control requirements of increasing or reducing the output power and output torque of the reducer, and the output torque of the motor reducer. Torque drop, unable to meet the rated output torque and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

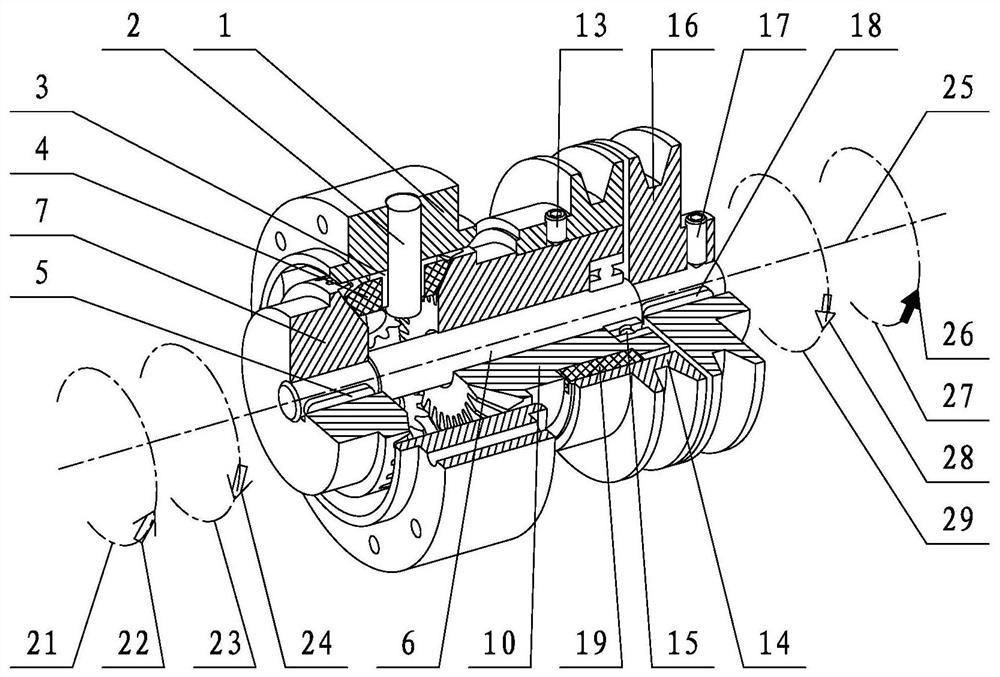

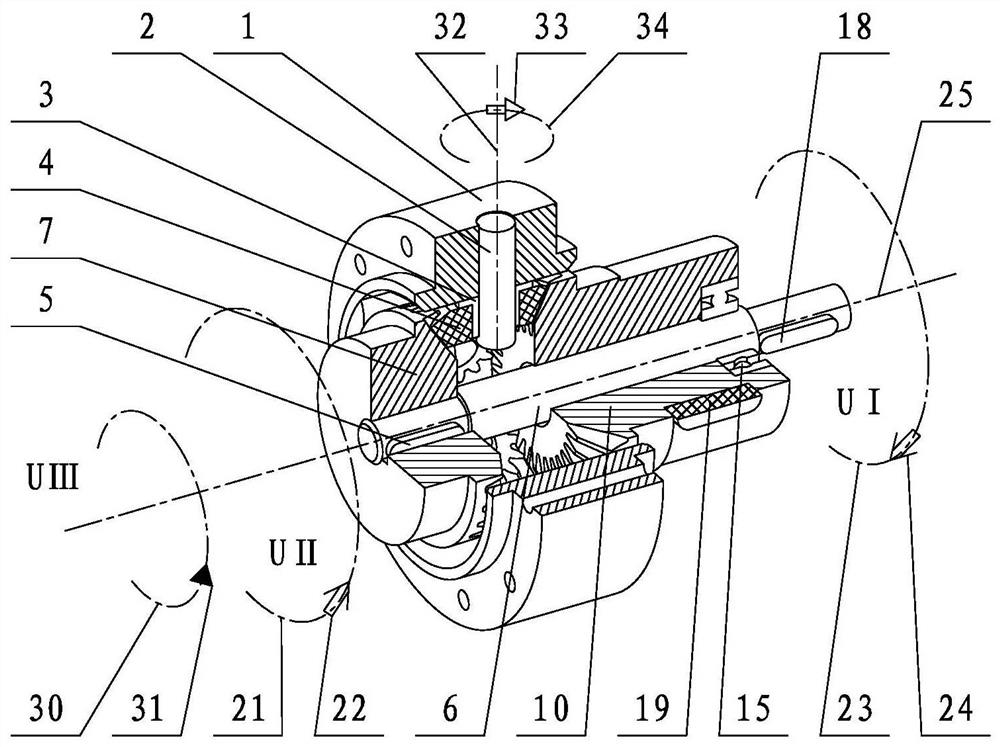

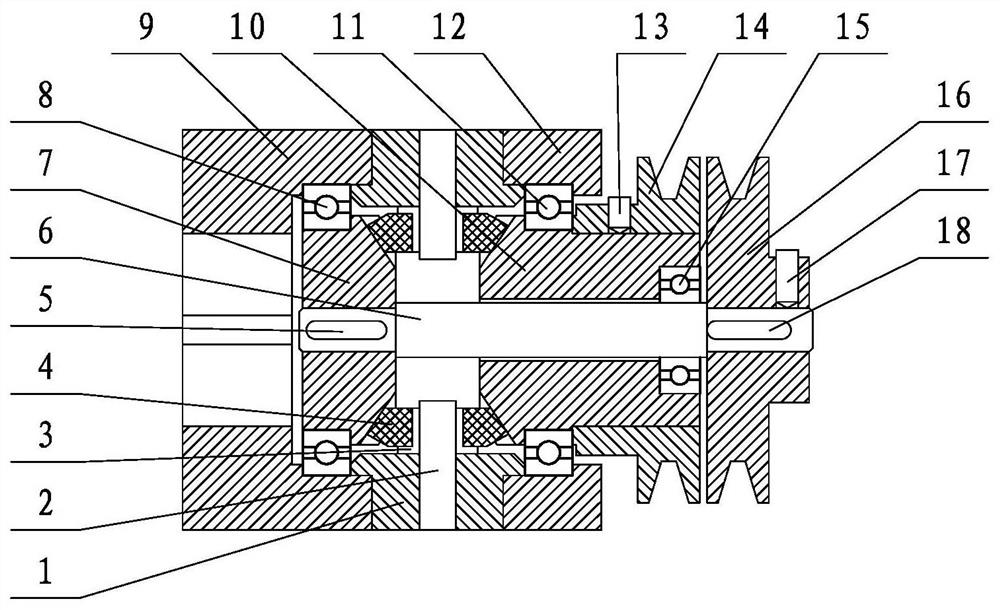

[0048] The present invention is further described below in conjunction with accompanying drawing.

[0049] refer to Figure 1 to Figure 4 , the reducer includes an output flange part, a planet carrier part, a pressure sleeve part, and a linkage shaft part. The output flange components include an output flange 9, a bevel gear II 7 and a bearing II 8. The planet carrier components include a planet carrier 1 , a planet shaft 2 , a planet sleeve 3 and a planet bevel gear 4 . Press sleeve parts comprise press sleeve 12, bevel gear one 10, bearing one 11, bearing three 15, pulley one 14, set screw one 13, key bar three 19, set screw 20. The linkage shaft parts include linkage shaft 6, key bar one 18, key bar two 5, belt pulley two 16, set screw two 17. The output flange parts, planetary support parts, and pressure sleeve parts are arranged in sequence along the axial direction, and the output flange parts, planetary support parts, and pressure sleeve parts are connected and fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com