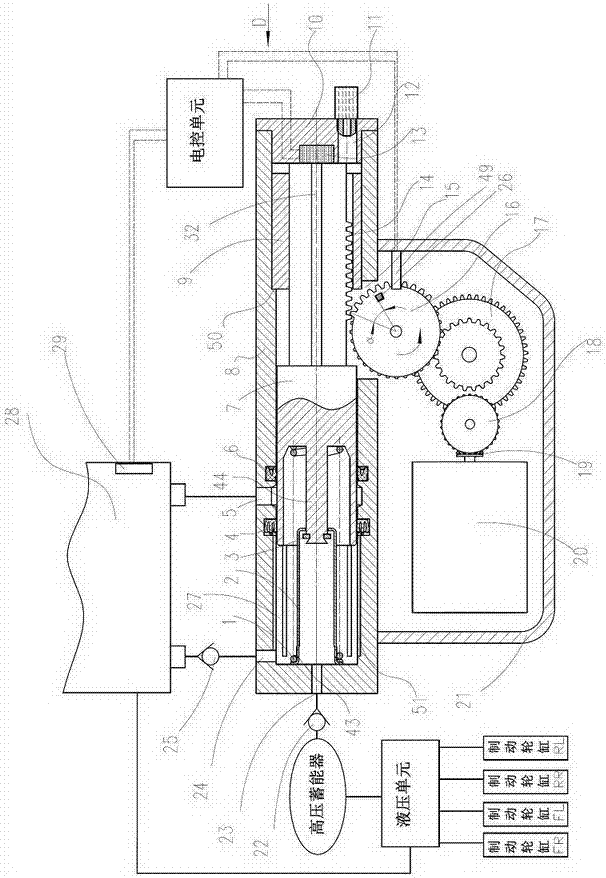

Electric pump for automobile drive-by-wire braking system

A technology of electric pumps and automobile lines, applied in the direction of brake transmissions, brakes, vehicle components, etc., can solve the problems of small volume of high-pressure brake fluid, fast wear of plunger pumps, low efficiency of high-pressure brake fluid, etc., and achieve reduction The effect of building pressure stroke, reliable operation and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

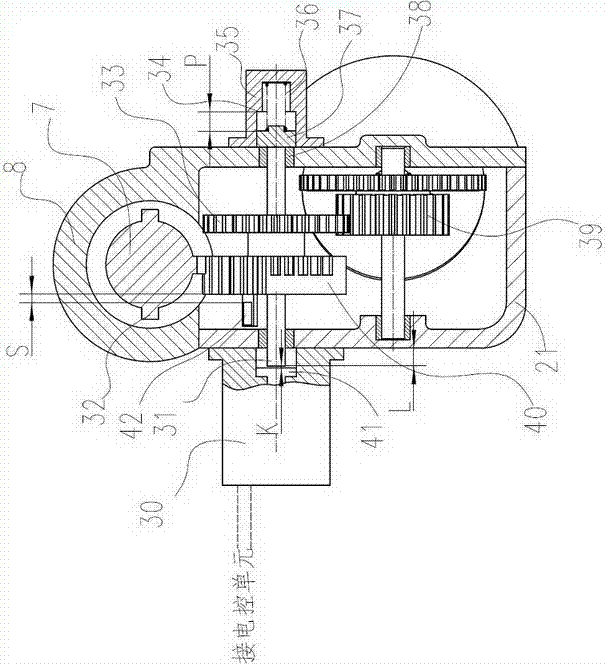

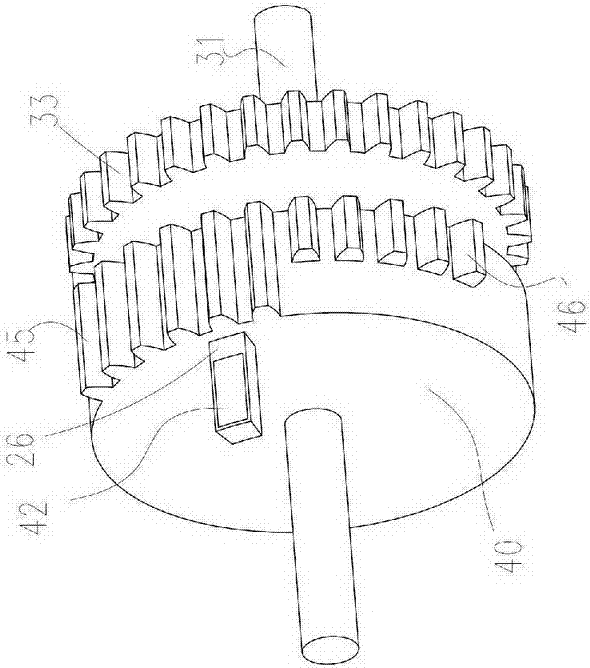

[0014]The guide sleeve 9 has an interference fit with the inner hole of the cylinder body 8, and one axial end is in contact with the limit step 50 of the inner hole of the cylinder body 8. The inner hole of the guide sleeve 9 is a cylindrical surface, and there are axial guide rail grooves 47 symmetrically on both sides of the cylindrical surface. There is an axial rack through groove 48 at the bottom of the cylindrical surface. One end of the piston 7 is a sealing cylindrical surface, and the other end is a guiding part. The diameter of the sealing cylindrical surface is larger than the diameter of the guiding part. There are bar-shaped protruding guide rails 32 symmetrically on both sides of the cylindrical surface in the axial direction, and a rack 14 in the bottom axial direction. The sealing cylindrical surface of the piston 7 is in clearance fit with the main hole of the cylinder body 8, and the guide part is in clearance fit with the cylindrical surface of the inner hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com