Combined clutch of automotive AMT (Automated Mechanical Transmission)

A combined clutch and automatic transmission technology is applied in the field of clutches to achieve the effects of improving driving safety, eliminating shifting shocks and reducing energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

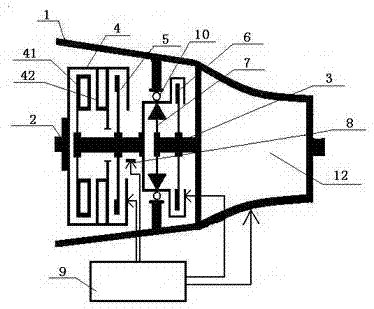

[0020] Embodiment 1: A combined clutch of an automobile AMT automatic transmission, comprising a housing 1, an engine power output shaft 2, a gear box input shaft 3, a fluid coupling 4 and a one-way clutch 7, the one-way clutch 7 The clutch 7 is installed on the input shaft 3 of the gear box through the bearing 10, and the power output shaft 2 of the engine is connected with the casing of the fluid coupling 4, that is, the power output shaft 2 of the engine is connected with the pump wheel I42 of the fluid coupling 4 The turbine I 41 of the fluid coupling 4 is connected to the outer ring of the one-way clutch 7 , and the inner ring of the one-way clutch 7 is connected to the input shaft 3 of the gear box. The fluid coupling 4 is equipped with a friction clutch A5 that can lock the pump wheel I42 and the turbine I41 of the fluid coupling 4 into one body. The friction clutch A5 is installed on the shell of the fluid coupling 4. The pressure plate of the friction clutch A5 is fix...

Embodiment 2

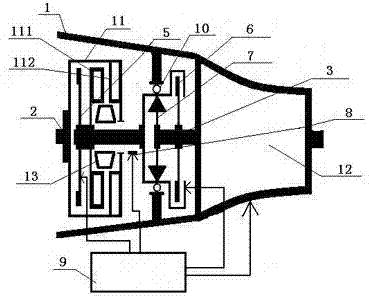

[0021] Embodiment 2: A combined clutch of an automobile AMT automatic transmission, including a housing 1, an engine power output shaft 2, a gear transmission input shaft 3, a hydraulic torque converter 11 with a locking device, and a one-way clutch 7 , the one-way clutch 7 is installed on the gear box input shaft 3 through the bearing 10, the locking device in the hydraulic torque converter 11 is controlled by the pressure oil provided by the oil pump, and the pressure oil An oil cooling device is installed in the pipeline, and the engine power output shaft 2 is connected to the casing of the torque converter 11, that is, the engine power output shaft 2 is connected to the pump wheel II 112 of the torque converter 11, and the The turbine II 111 of the hydraulic torque converter 11 is connected to the outer ring of the one-way clutch 7 , and the inner ring of the one-way clutch 7 is connected to the input shaft 3 of the gear box. The one-way clutch 7 is equipped with a frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com