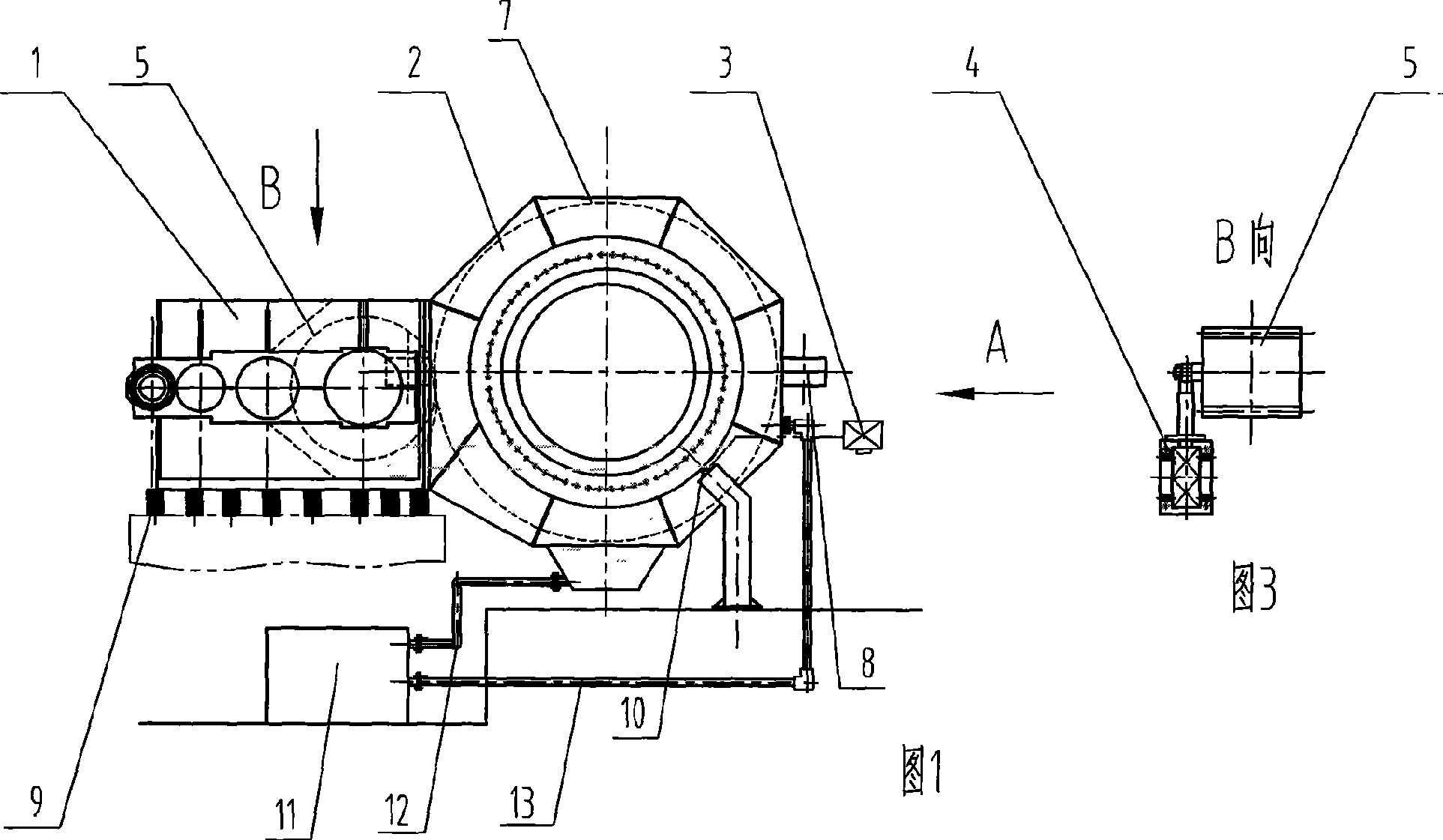

Gear box device for mixing machine

A technology for gear boxes and mixers, which is applied to mixers, mixers with rotating containers, mixer accessories, etc., and can solve problems such as unqualified gear contact pitting or toothing, gears that easily enter dust, and affect gear meshing, etc. , to achieve long service life, increase production efficiency and economic cost, and ensure normal meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

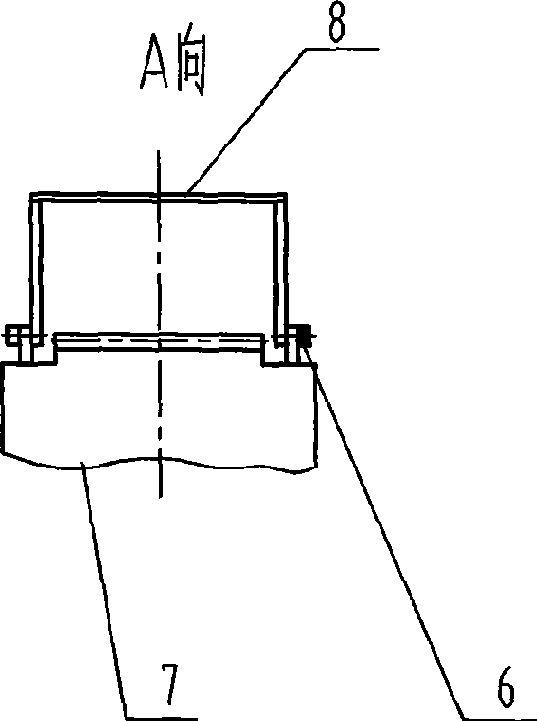

[0009] As shown in the figure: the gear box device for the mixer, the large gear 7 of the drum mixer meshes with the pinion 5, and the pinion 5 is connected to the output shaft of the gear box 1, and the drum bearing 10 is installed in the drum mixer, and the gear box 1 is installed on the elastic floating support base 9, and the hydraulic cylinder servo system 4 is assembled on the side of the gear box 1. The large and small gears 7 and 5 driven by the drum 2 of the drum mixer are installed in the closed box 8, and the drum of the drum mixer 2. The bottom and the side wall of the closed box 8 are respectively connected to the oil storage tank 11 through oil pipes 12 and 13. The closed box 8 is sealed with a sealing ring 6. The whole set of devices is equipped with a servo telecommunication encoder 3. The cylinder mixer pinion 5, when the cylinder of the cylinder mixer sinks due to long-term operation, the height and low adjustment of the gear box 1 is realized by the elastic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com