Patents

Literature

50results about How to "Avoid continuous heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

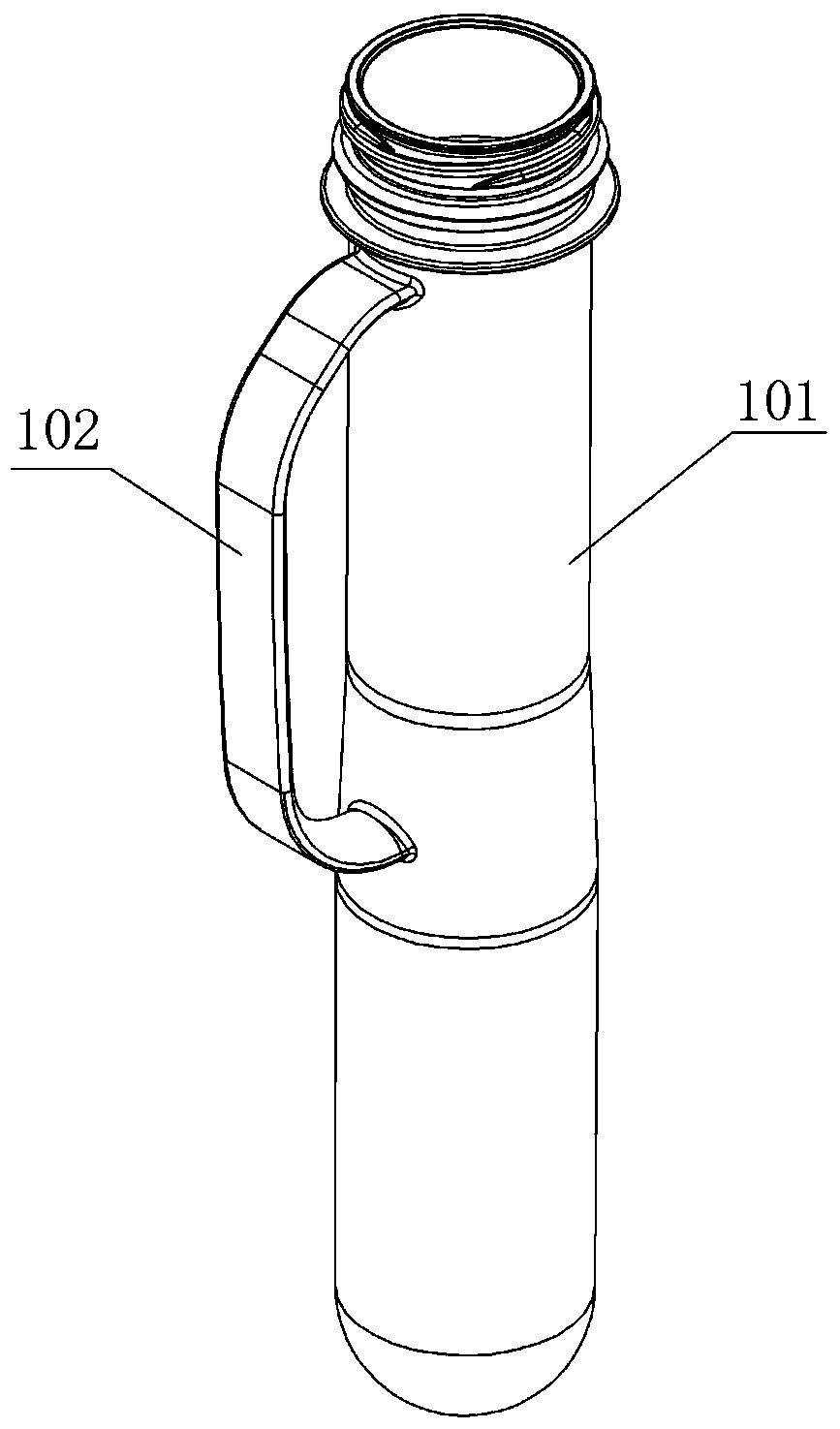

Overheating protection device for electronic cigarette and smoke cartridge

InactiveUS20140283856A1Avoid scalds and burnsImprove securityTobacco pipesTobacco devicesElectricityElectronic cigarette

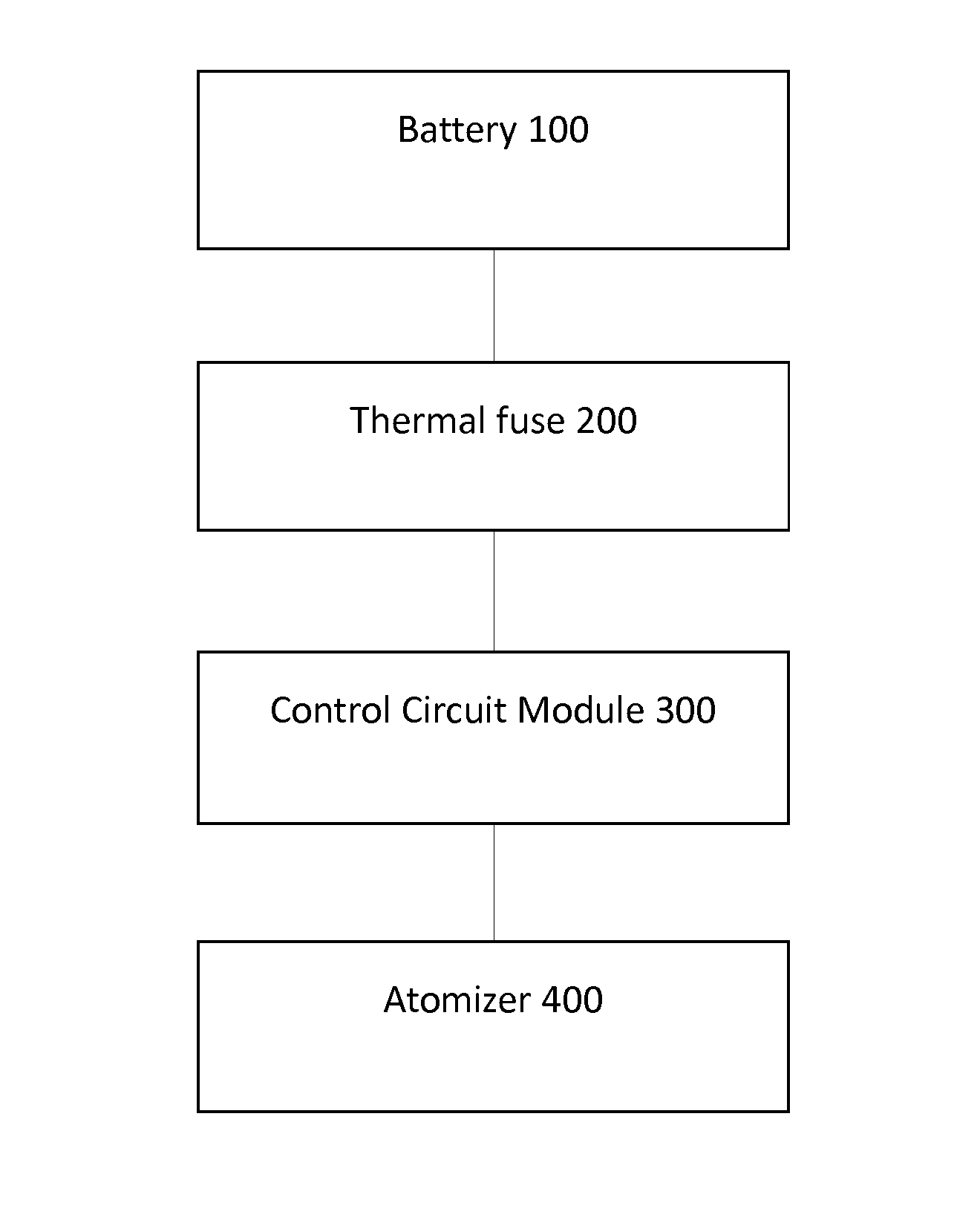

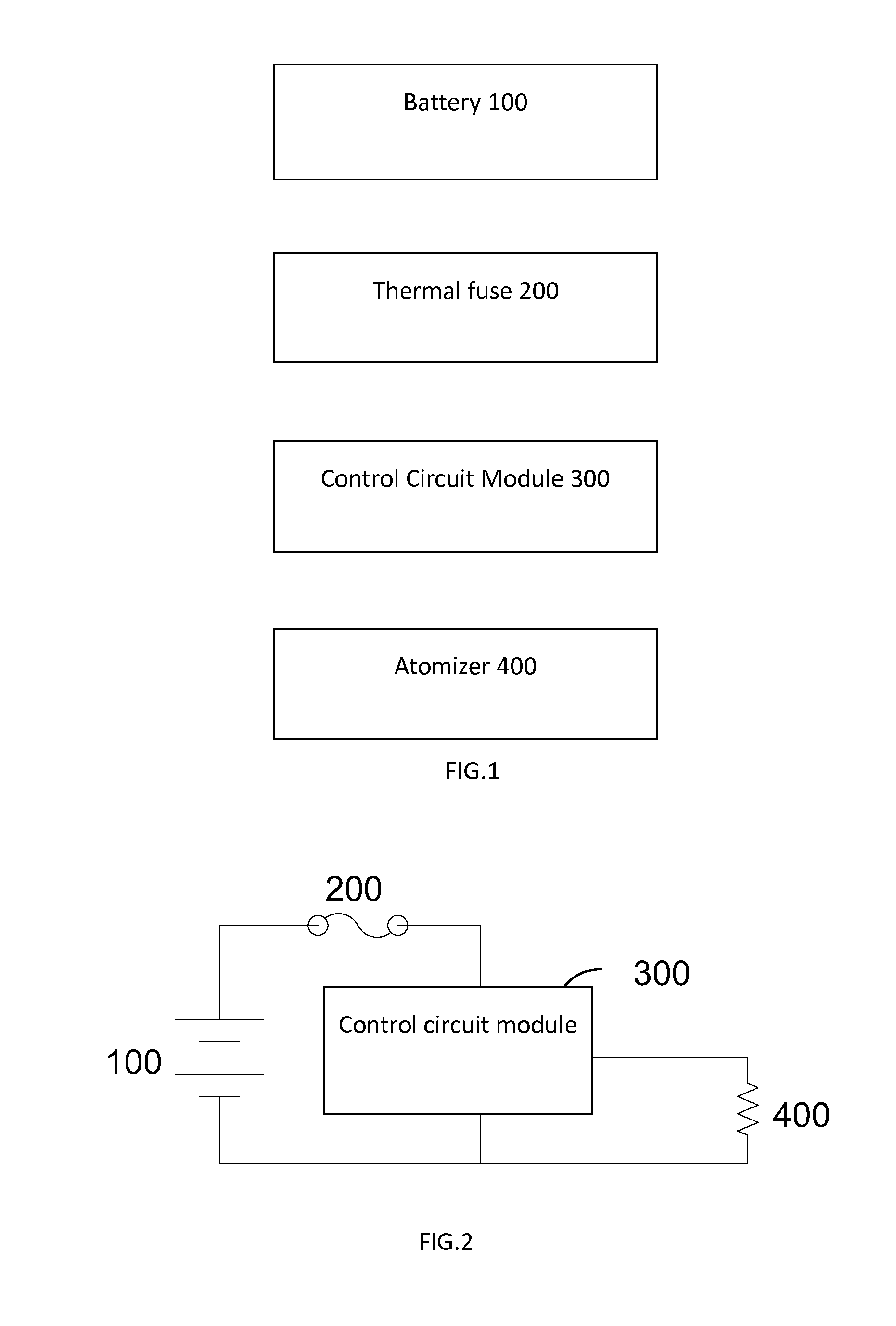

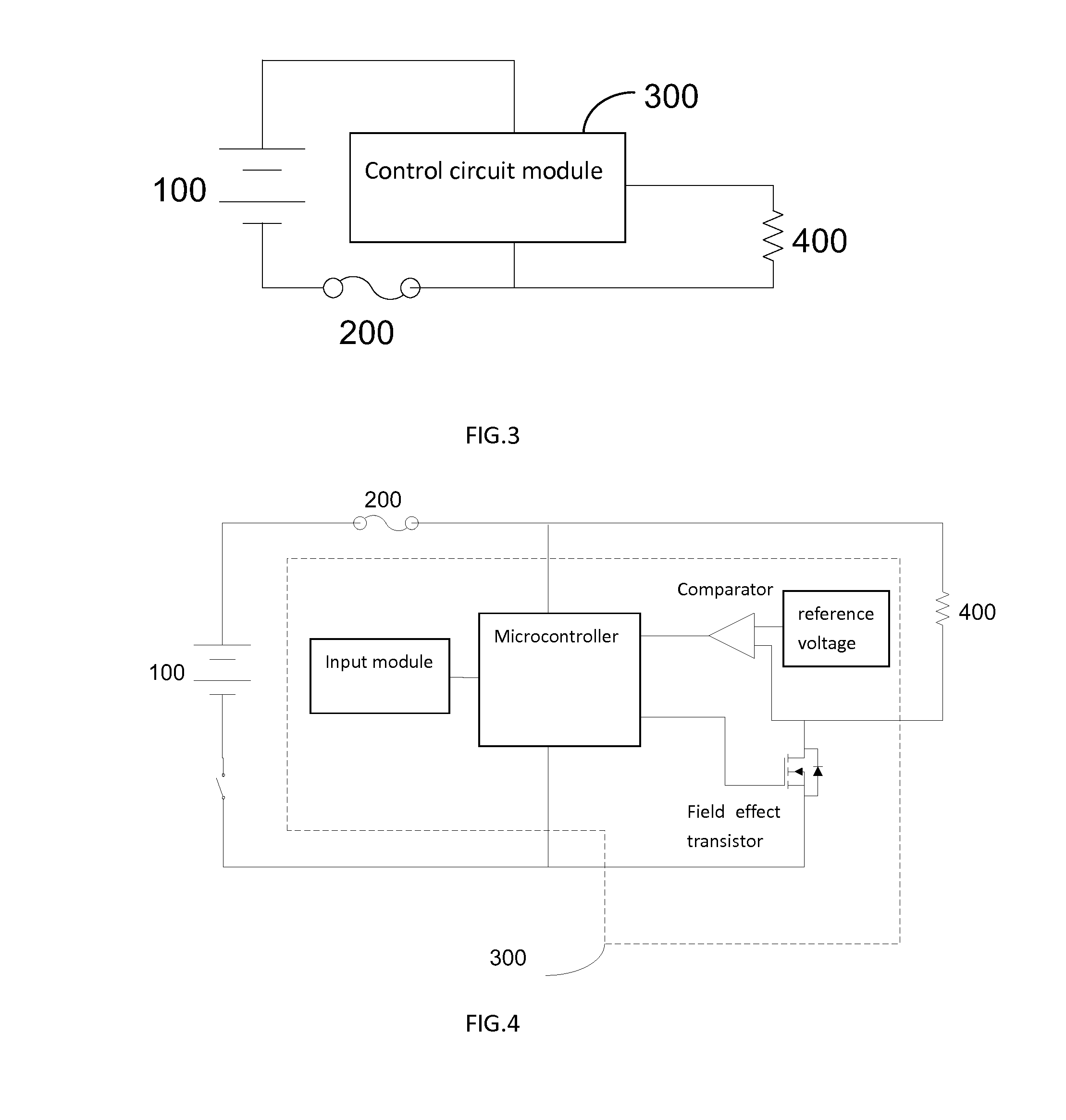

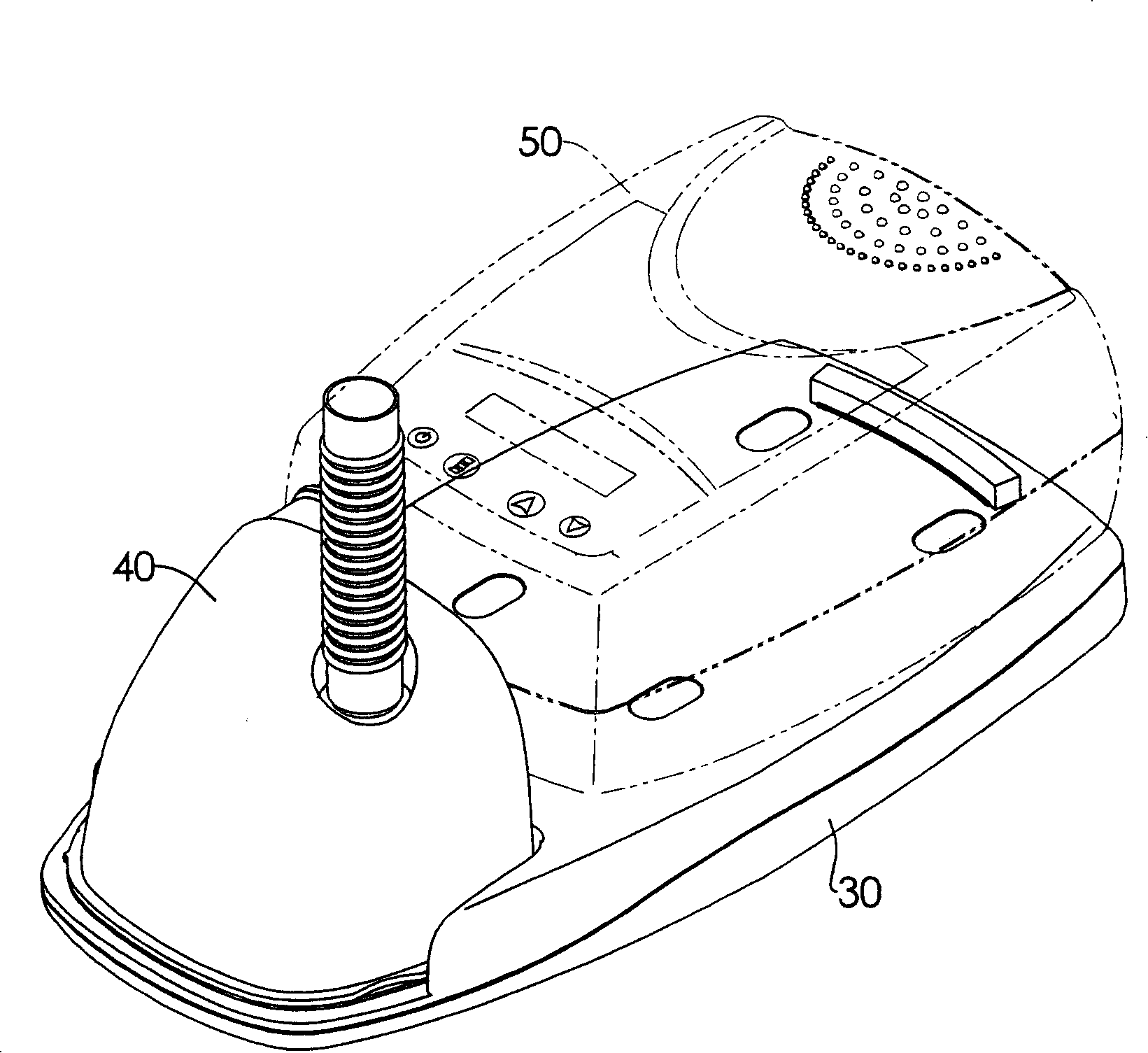

An overheating protection device for an electronic cigarette includes a battery for powering the electronic cigarette, an atomizer for vaporizing a tobacco flavored liquid by heating, and a control circuit module for controlling the atomizer to work. The battery, the control circuit module, and the atomizer are electrically connected one by one to define a heating circuit. The overheating protection device further includes a thermal fuse connected in series in the heating circuit. When environment temperature is overheat, the thermal fuse automatically blows to cut off the heating circuit, and the battery stops powering the atomizer. The overheating protection device is safe for smoker and the electronic cigarette.

Owner:KIMREE HI TECH

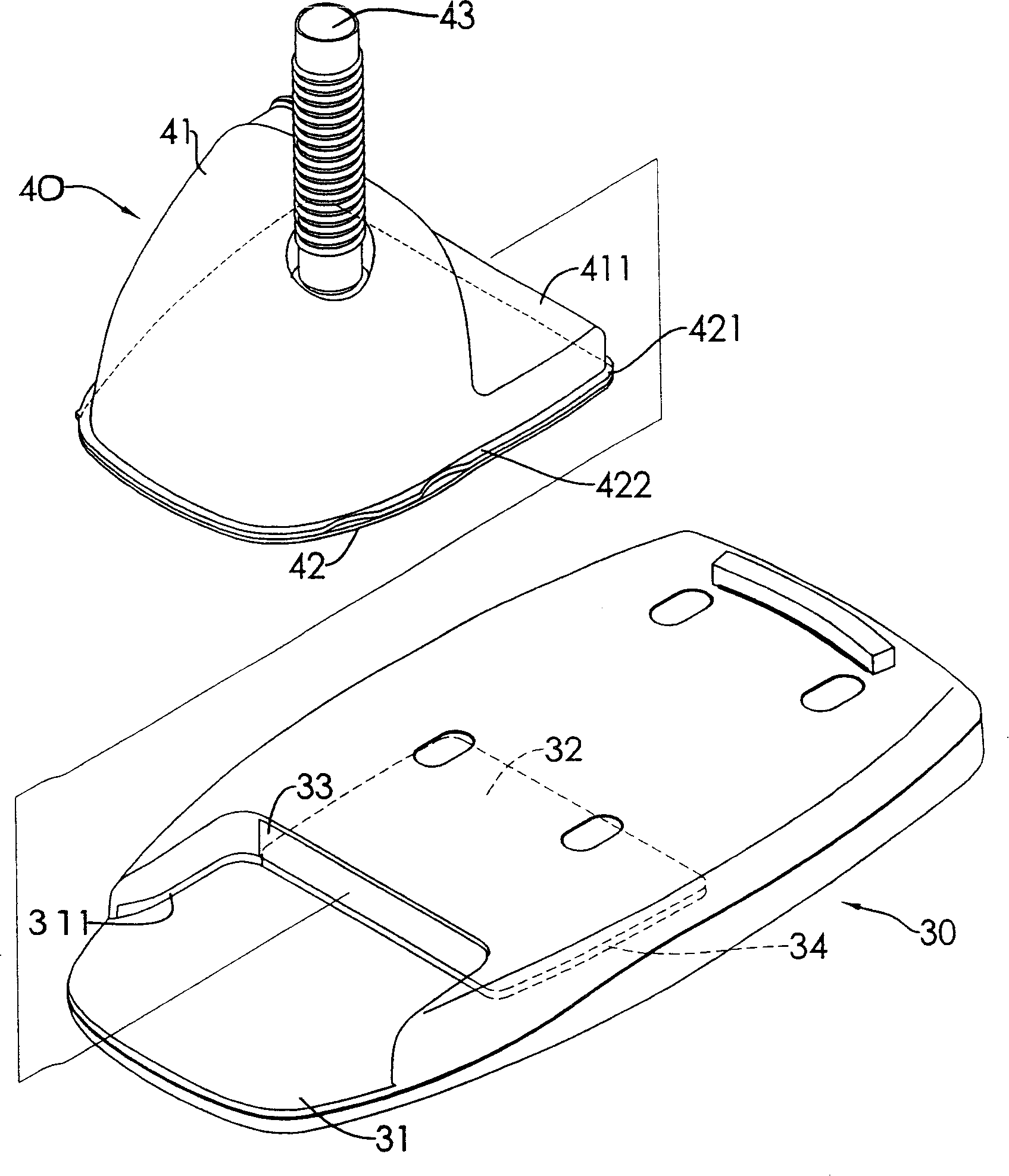

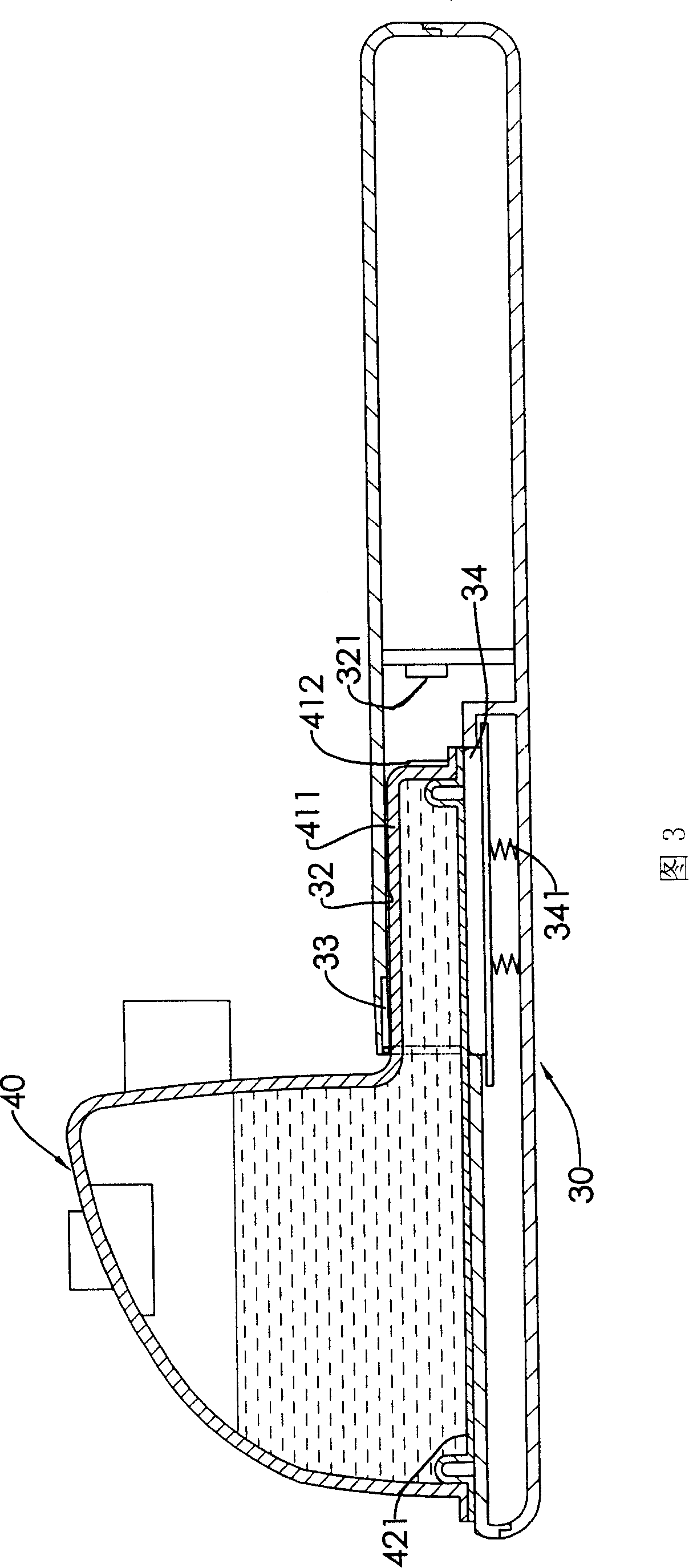

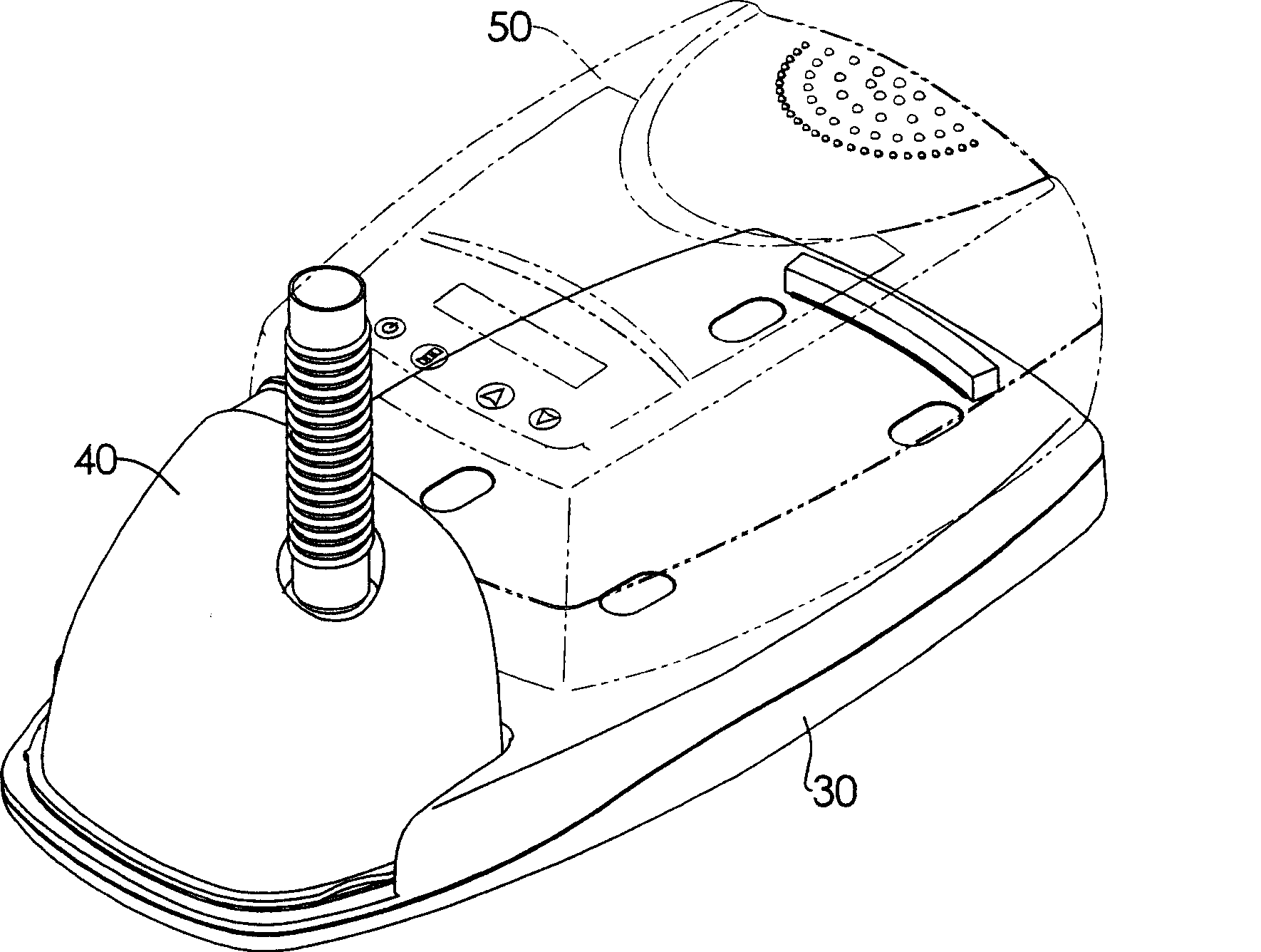

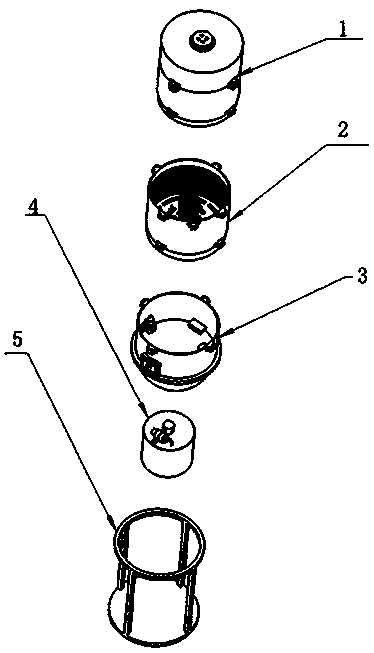

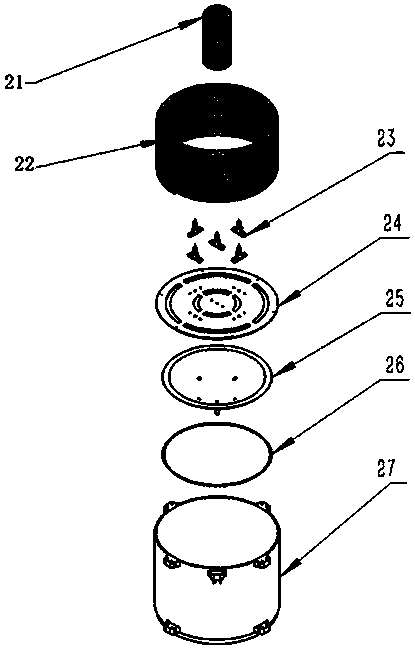

Warming disk assembly of respiration therapeutic equipment

The invention relates to a heating disk assembly used for a breathing therapy device, in particular to a heating disk assembly which can heat liquid water stored in a water tank to generate steam. The invention mainly comprises a main body, a heating plate and a water tank. The arrangement of the heating plate on the main body and a protection device on an outer side of the heating plate can protect and avoid a user from being scalded accidentally; simultaneously, a heat transmission plate which is corresponding to heating plate is arranged on the lower part of the water tank so as to quickly transmit the heat coming from the heating plate to the whole part of the heat transmission plate so as to achieve the effect of safe and quick heating.

Owner:APEX MEDICAL CORPORATION

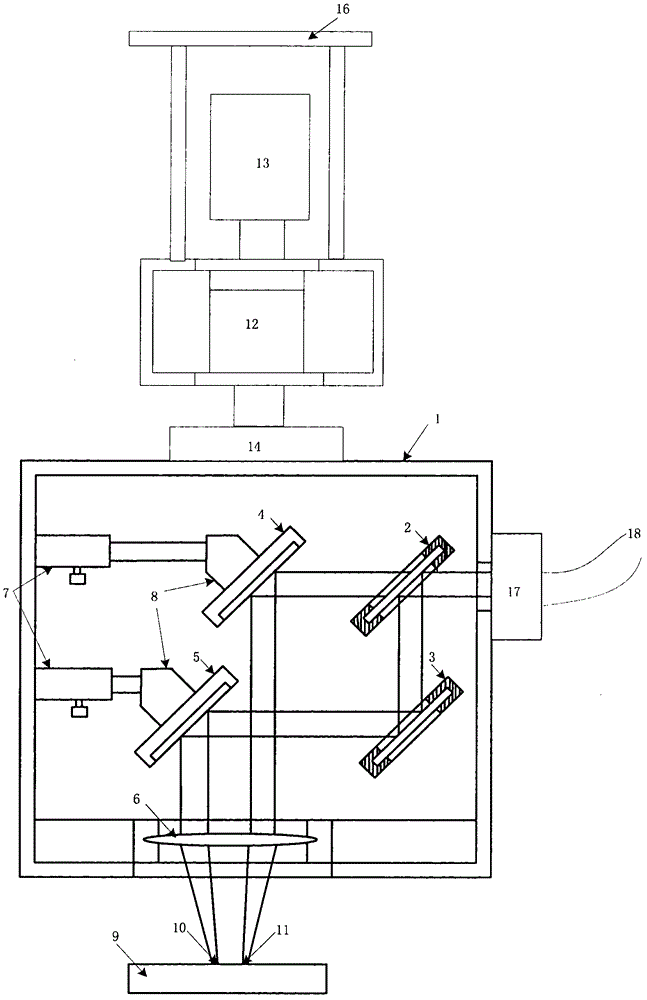

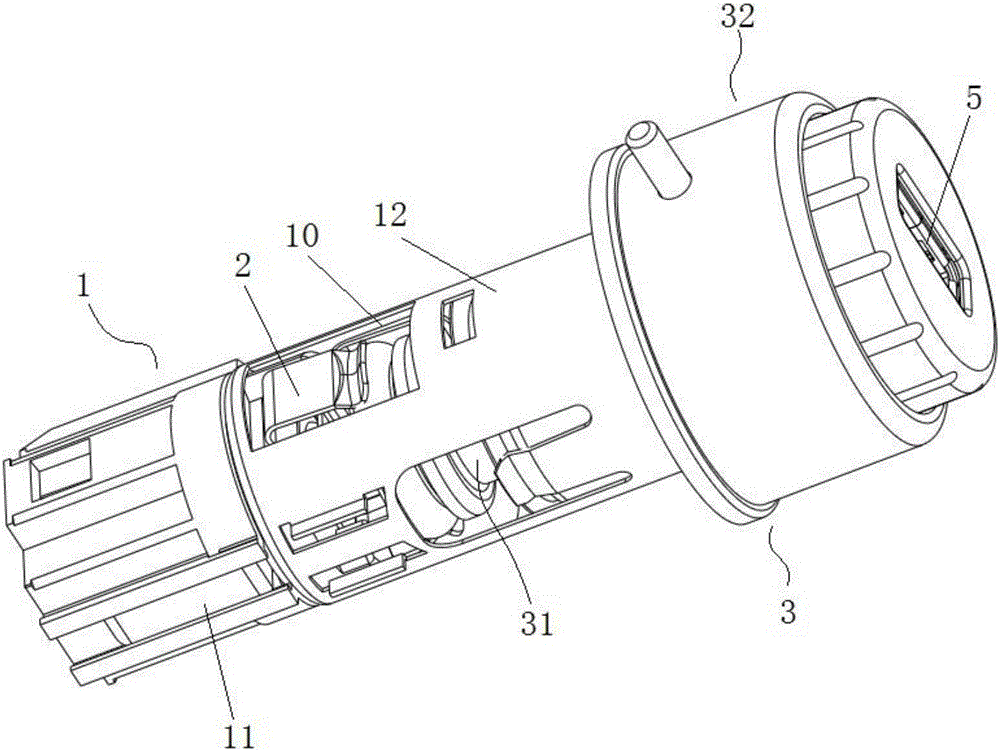

Beam splitting double-focus-point laser processing head

ActiveCN104801852ALower requirementMeets high energy density requirementsLaser beam welding apparatusLaser processingBeam splitting

The invention provides a beam splitting double-focus-point laser processing head, which comprises a light path cavity, a cavity connecting box, a servo motor and an external connecting flange, wherein the light path cavity is connected with an output shaft of the servo motor through a shaft coupler, a beam splitting mirror, a first reflecting mirror, a second reflecting mirror, a third reflecting mirror, a focusing mirror and two telescopic sleeves are arranged inside the light path cavity, the beam splitting mirror and the first reflecting mirror are respectively and fixedly arranged on the side wall of the light path cavity through a regulating mirror seat, the second reflecting mirror and the third reflecting mirror are respectively arranged on the telescopic ends of the two telescopic sleeves through a regulating mirror seat, and the fixing ends of the telescopic sleeves are arranged on the side wall of the light path cavity. The beam splitting double-focus-point laser processing head has the advantages that an incident laser beam is subjected to space beam splitting, the front focusing point and the back focusing point are realized, the relative space position between the double light beam focusing points is changed, the utilization efficiency of laser energy is improved, the laser welding plasma shielding effect can be effectively inhabited, the processing depth is improved, and the laser processing quality is improved.

Owner:WENZHOU UNIVERSITY

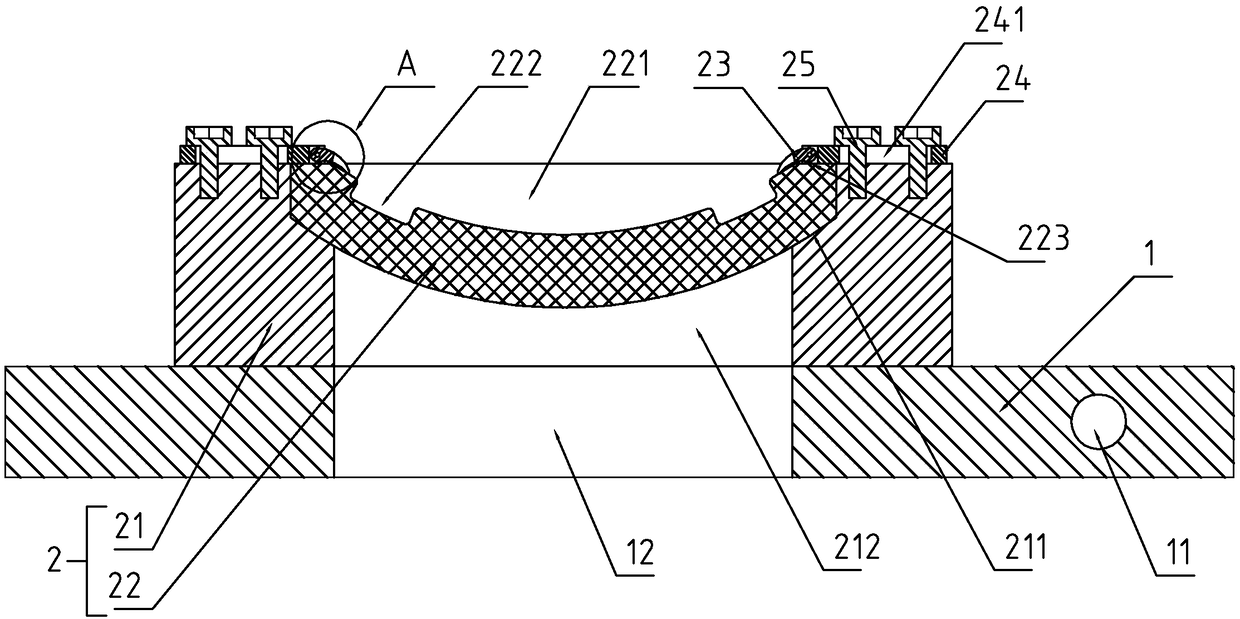

Warming disk assembly of respiration therapeutic equipment

The invention relates to a heating disk assembly used for a breathing therapy device, in particular to a heating disk assembly which can heat liquid water stored in a water tank so as to generate steam. The invention mainly consists of a main body, a heating plate and a water tank. The arrangement of the heating plate on the main body and a protection device on the outer side of the heating platecan protect and avoid a user from being scalded accidentally; simultaneously, a heat transmission plate corresponding to a heating plate is arranged on the lower part of the water tank so as to quickly transmit the heat coming from the heating plate to the whole part of the heat transmission plate, thus achieving the effect of safe and quick heating.

Owner:APEX MEDICAL CORPORATION

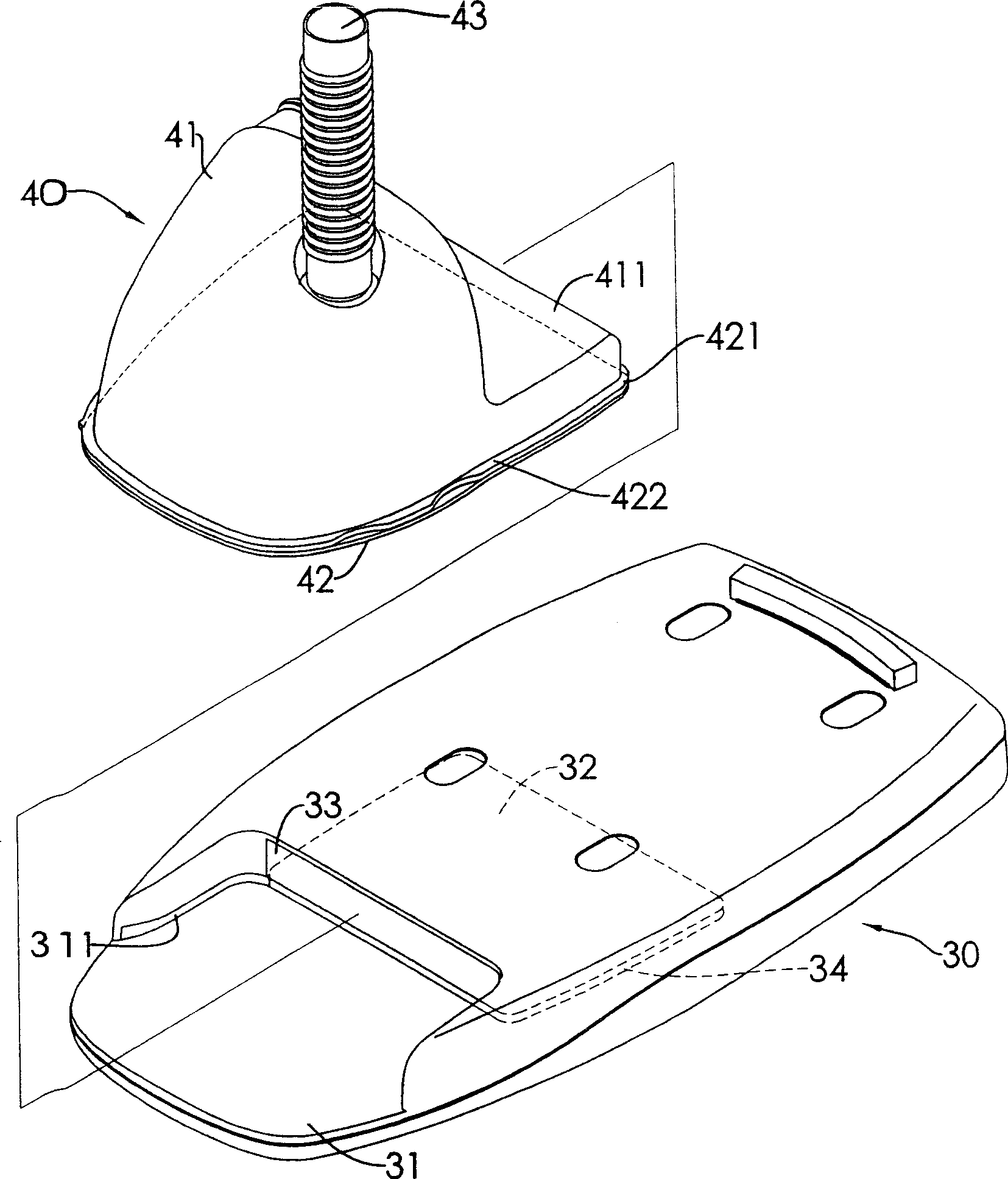

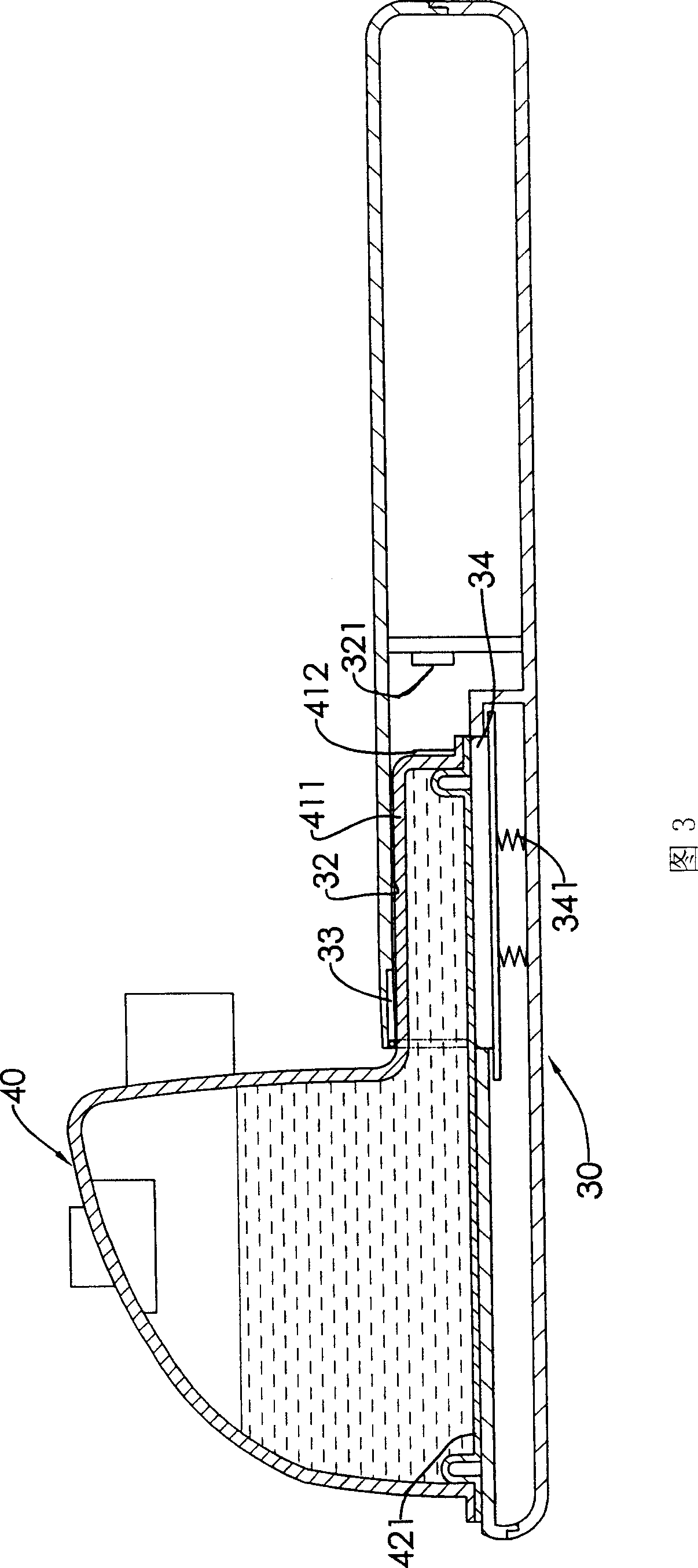

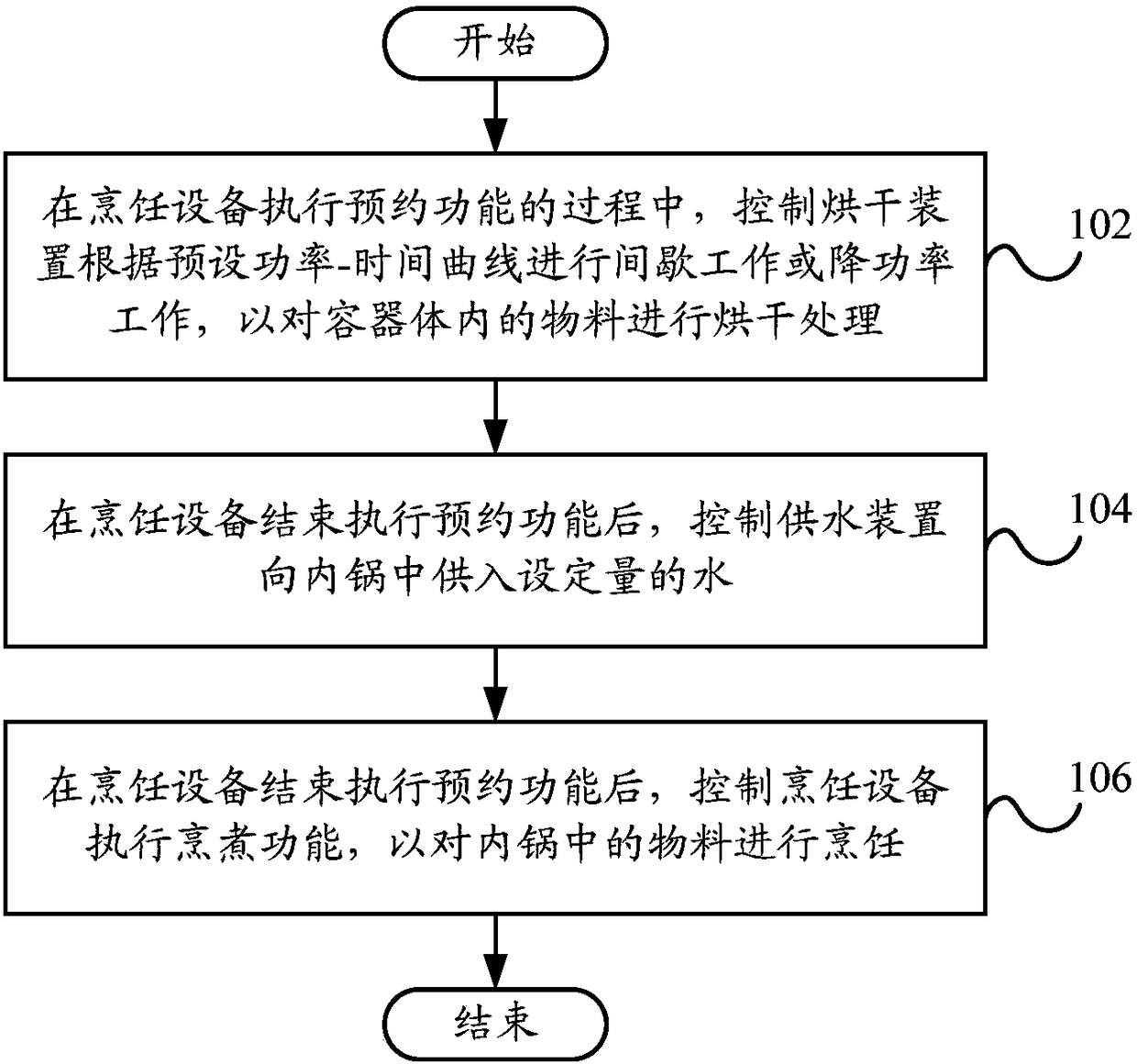

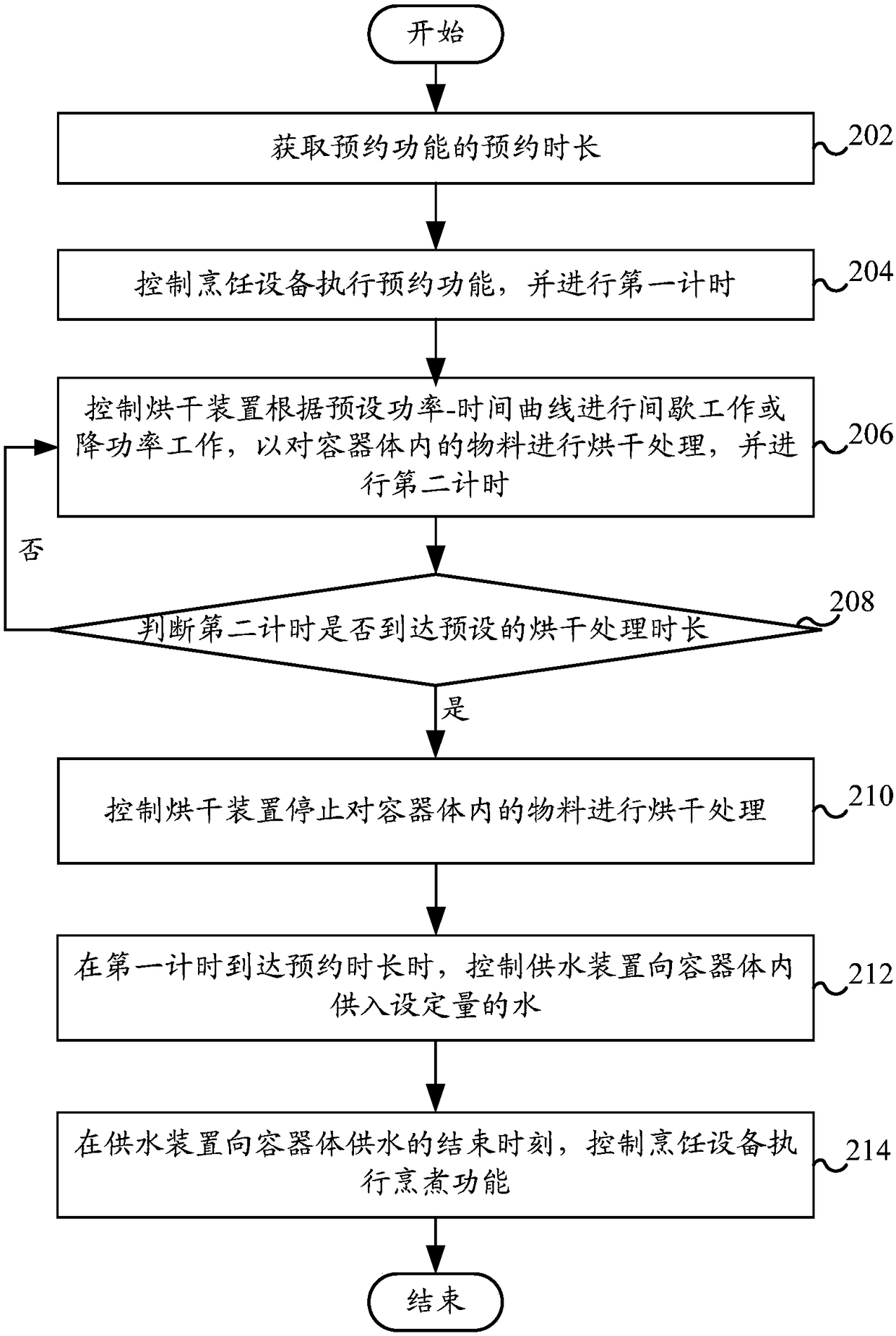

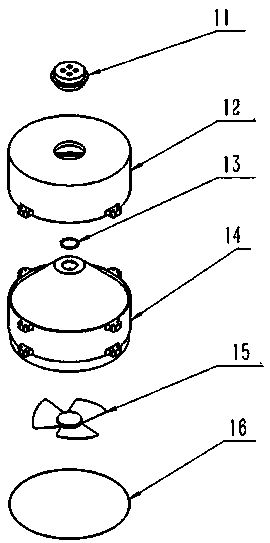

Cooking equipment and control method thereof

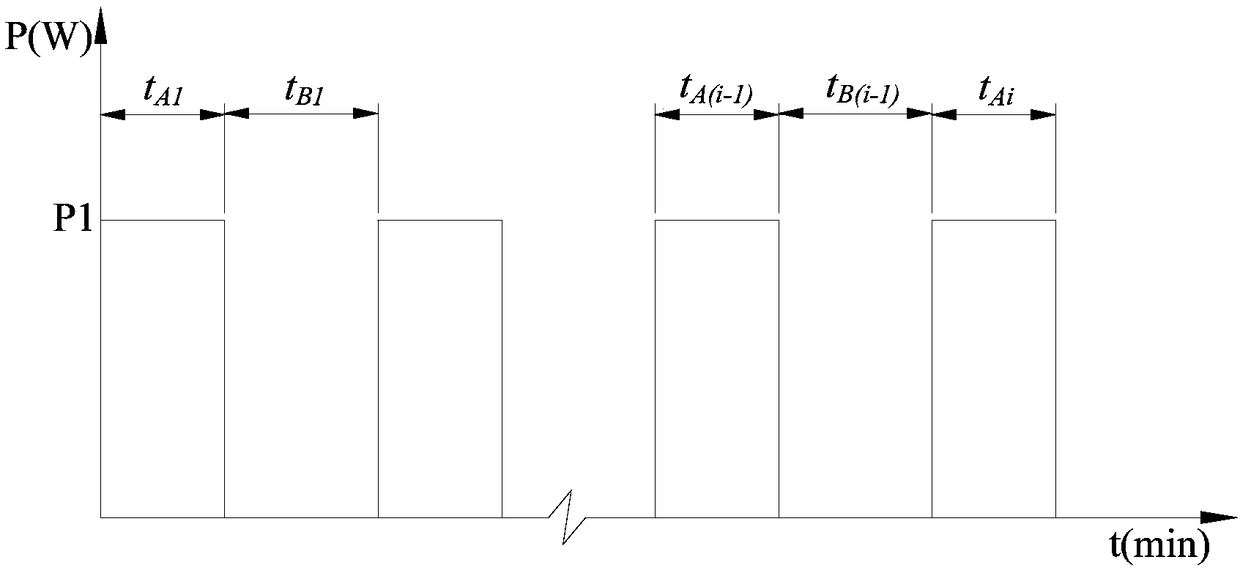

PendingCN108125570AAvoid continuous heatingInhibit ripeningBeverage vesselsPressure-cookersProcess engineeringTime curve

The invention provides cooking equipment and a control method thereof. The cooking equipment comprises a container body and a drying device. The control method of the cooking equipment comprises a drying step, wherein the drying device is controlled to perform intermittent operation or power-lowering operation according to a preset power-time curve to dry materials in the container body. Accordingto the method, by controlling the drying device to operate according to the preset power-time curve in the process that the cooking equipment perform a reservation function, the materials can be dried while the problem that the temperature of the drying device continues to rise is avoided, so that the problems that the materials are cured or gelatinized or the freshness is lowered in the drying process due to too high temperature of the drying device are avoided, and the cooking taste of the materials is ensured.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

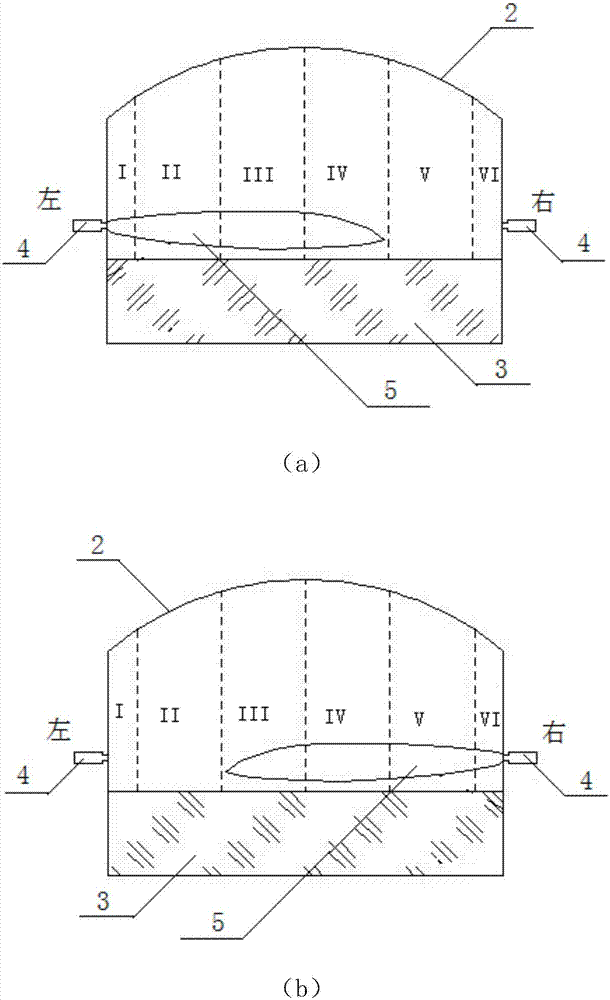

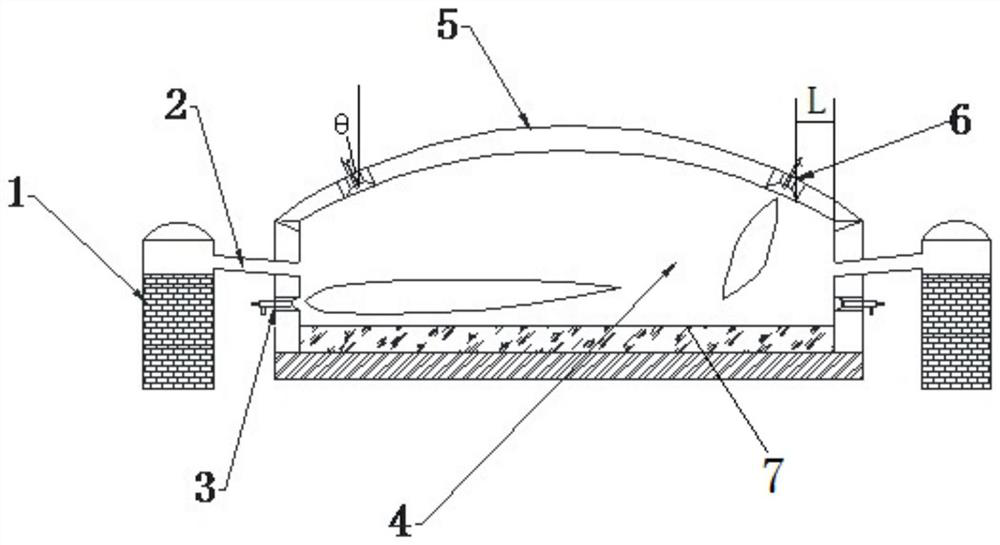

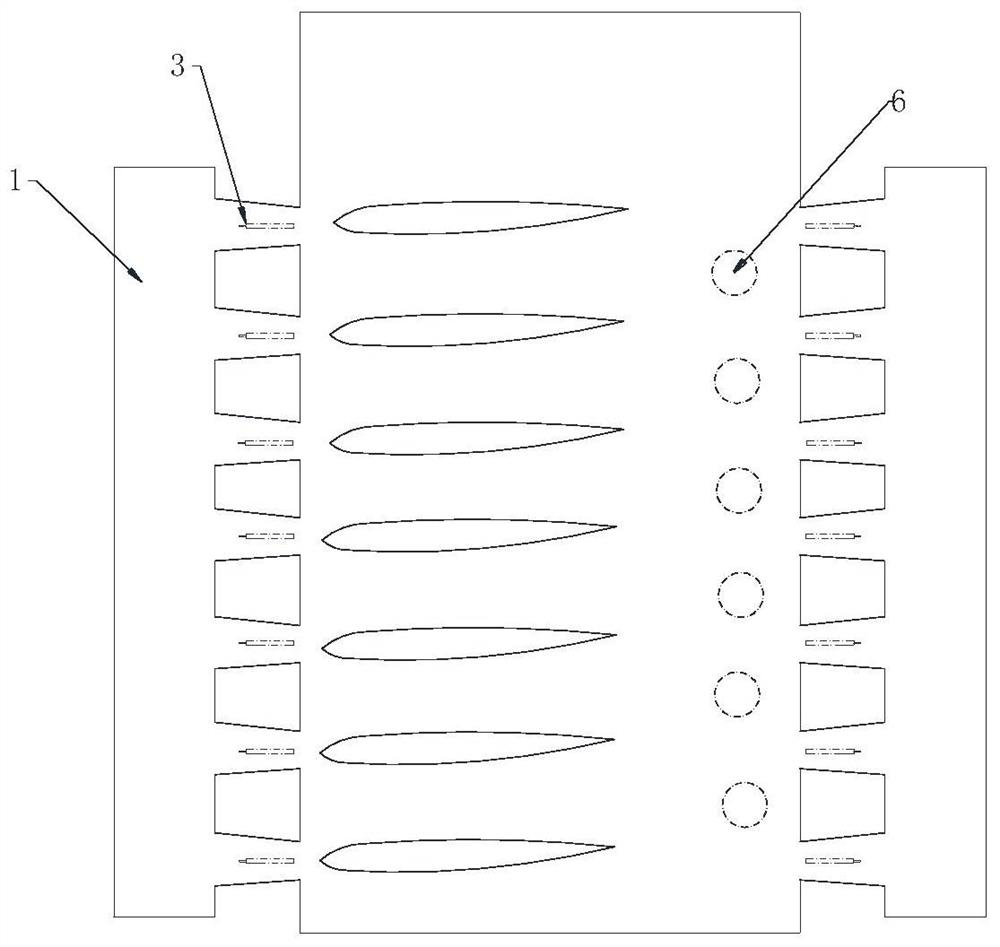

Spray guns for glass kiln and glass kiln combustion method based on spray guns

PendingCN107954591AAdjust the ejection speedThe adjustment rod assembly makes the adjustment piston slide in the gun chamber to change the ejection speedGlass furnace apparatusCombustionProcess engineering

The invention provides spray guns for a glass kiln and a glass kiln combustion method based on the spray guns. The spray guns are arranged at the two sides of the glass kiln and are communicated withan internal combustion area; each spray gun includes a gun body and a adjusting rod assembly, each gun body includes a gun chamber, an outer pipe and an inner pipe, one end of each gun chamber is provided with an opening, the outer pipes extend into and are fixed to the openings of the gun chambers, and the inner pipes penetrate through the outer pipes and extend into the gun chambers, the adjusting rod assemblies are slidably mounted on the inner pipes in a sleeving mode and extend out of the tail portions of the gun chambers, and a fuel inlet is formed in each gun body and is communicated with the interior of the corresponding gun chamber. According to the spray guns for the glass kiln and the glass kiln combustion method based on the spray guns, by pushing and pulling the adjusting rodassemblies, adjusting pistons slide in the gun chambers along the inner pipes, and therefore the purposes of changing the fuel spraying speed and adjusting the flame length are achieved; the purpose is achieved that flame ends alternately reach a specific combustion area, the situation is avoided that a middle combustion area is heated continually, and the discharging concentration and total discharging amount of NOx in glass kiln exhaust gas are obviously reduced. The spray guns for the glass kiln and the glass kiln combustion method based on the spray guns are easy to apply and popularize inthe field of all kinds of combustion kilns which use air for supporting combustion.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

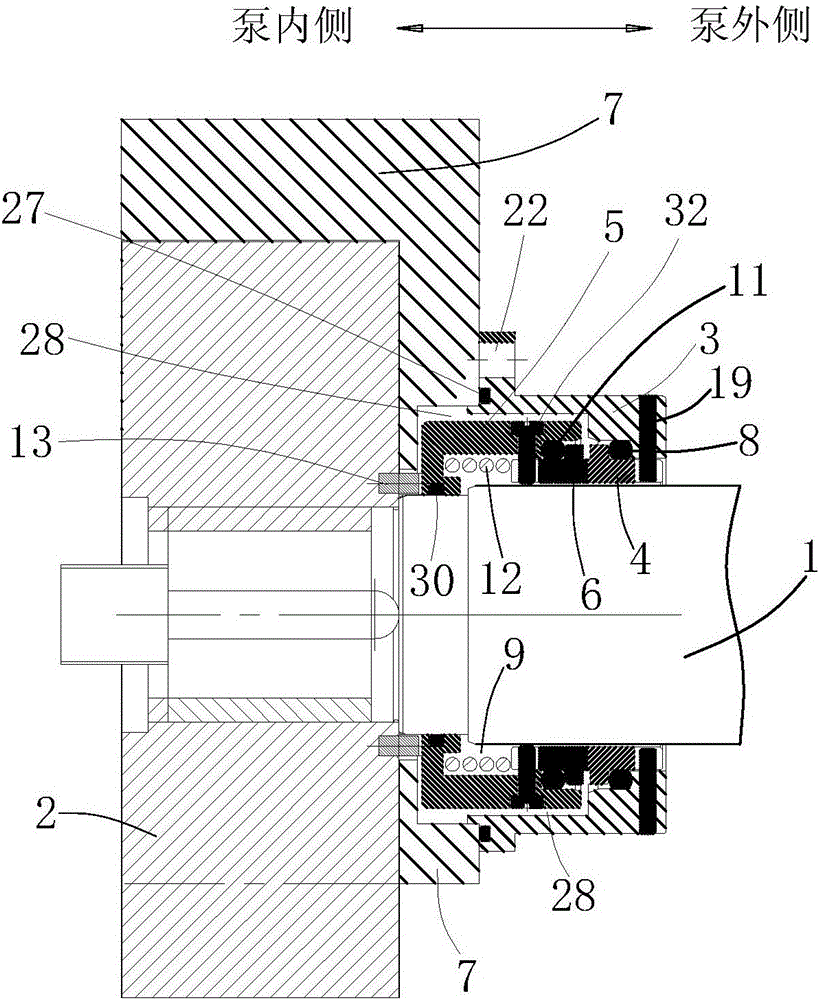

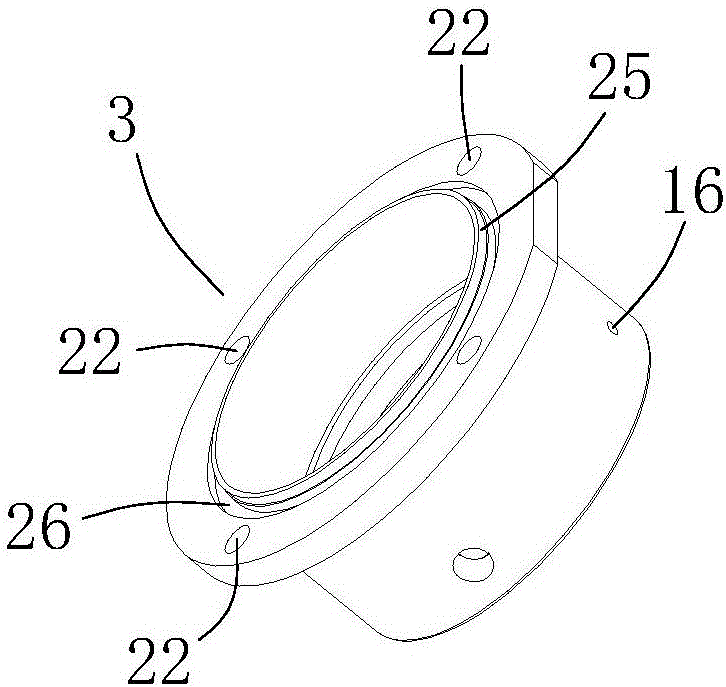

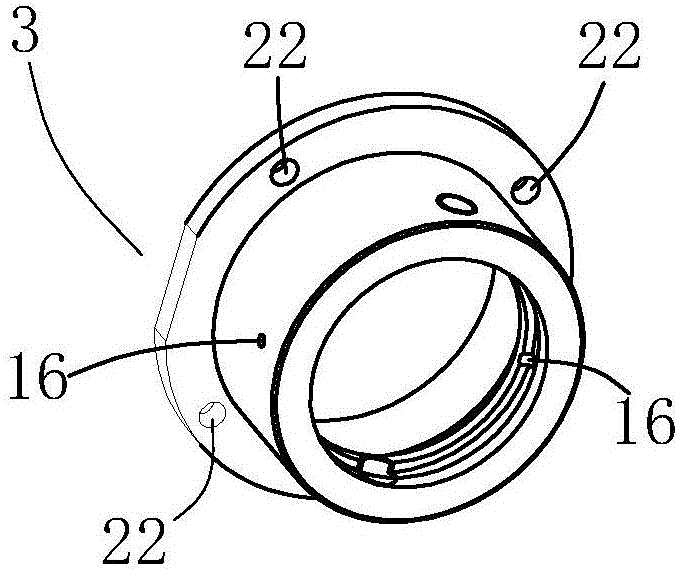

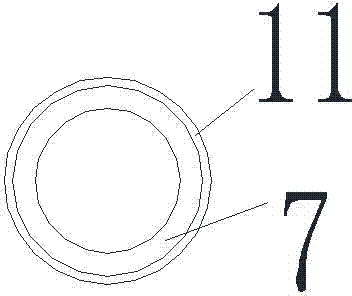

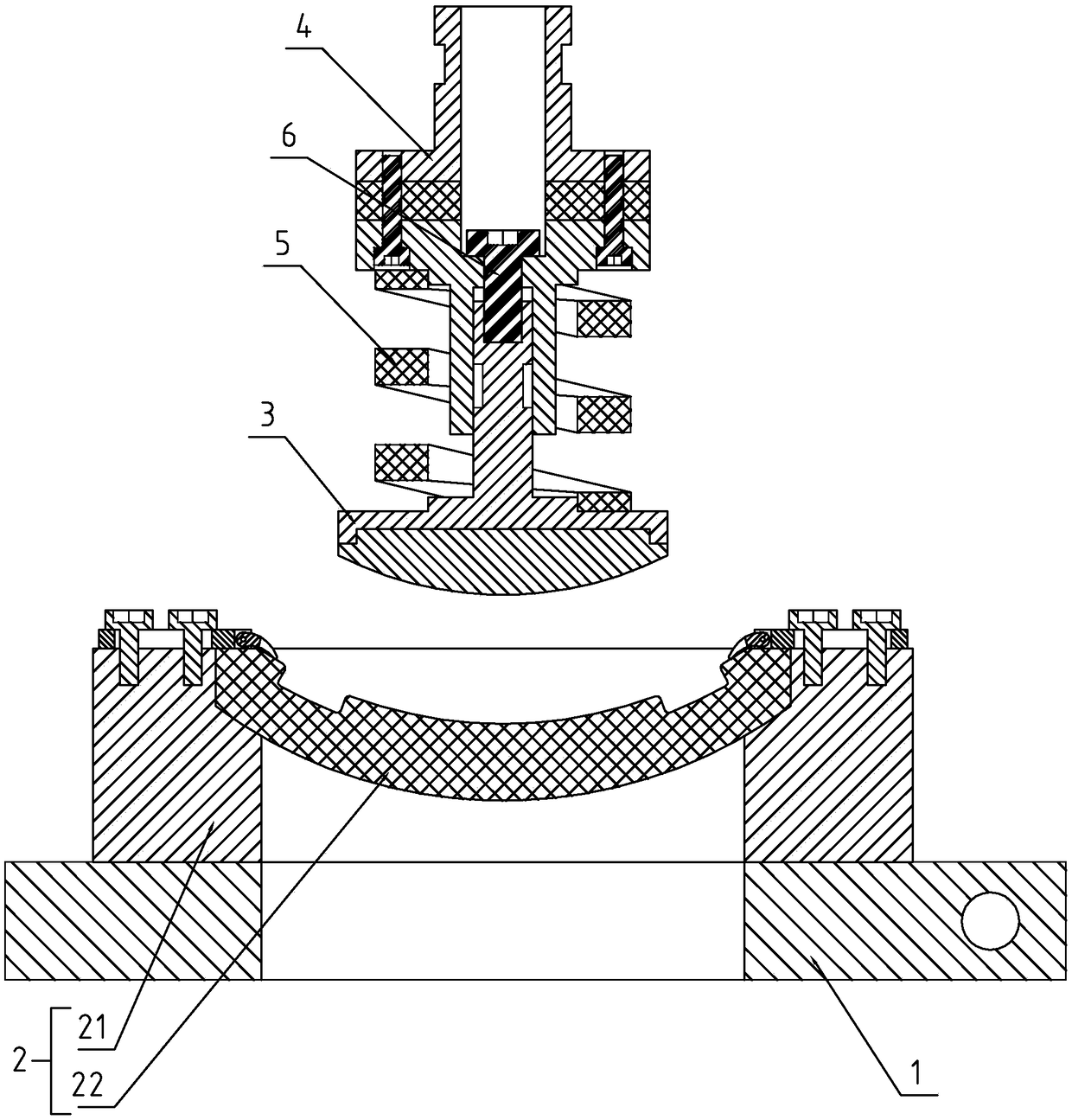

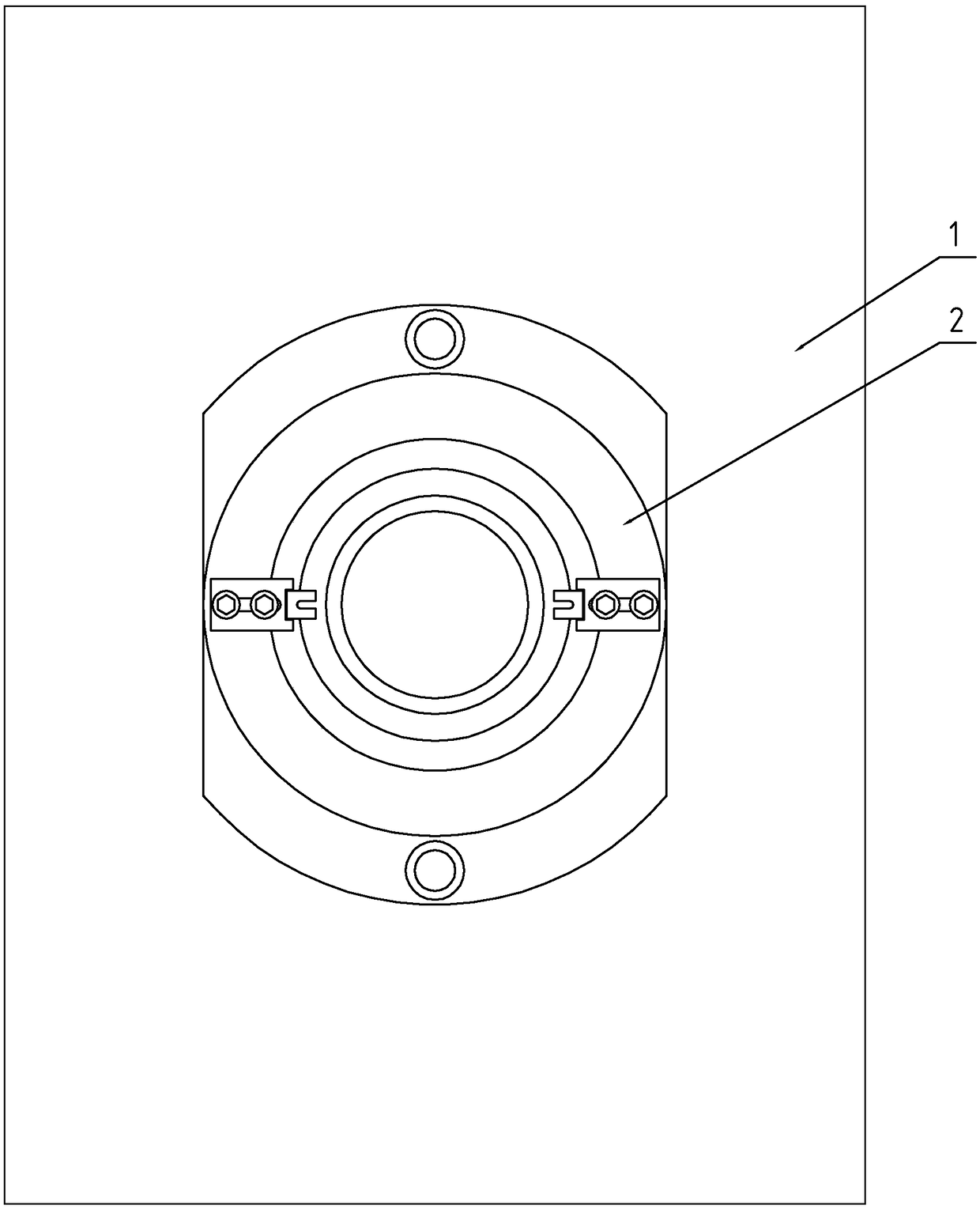

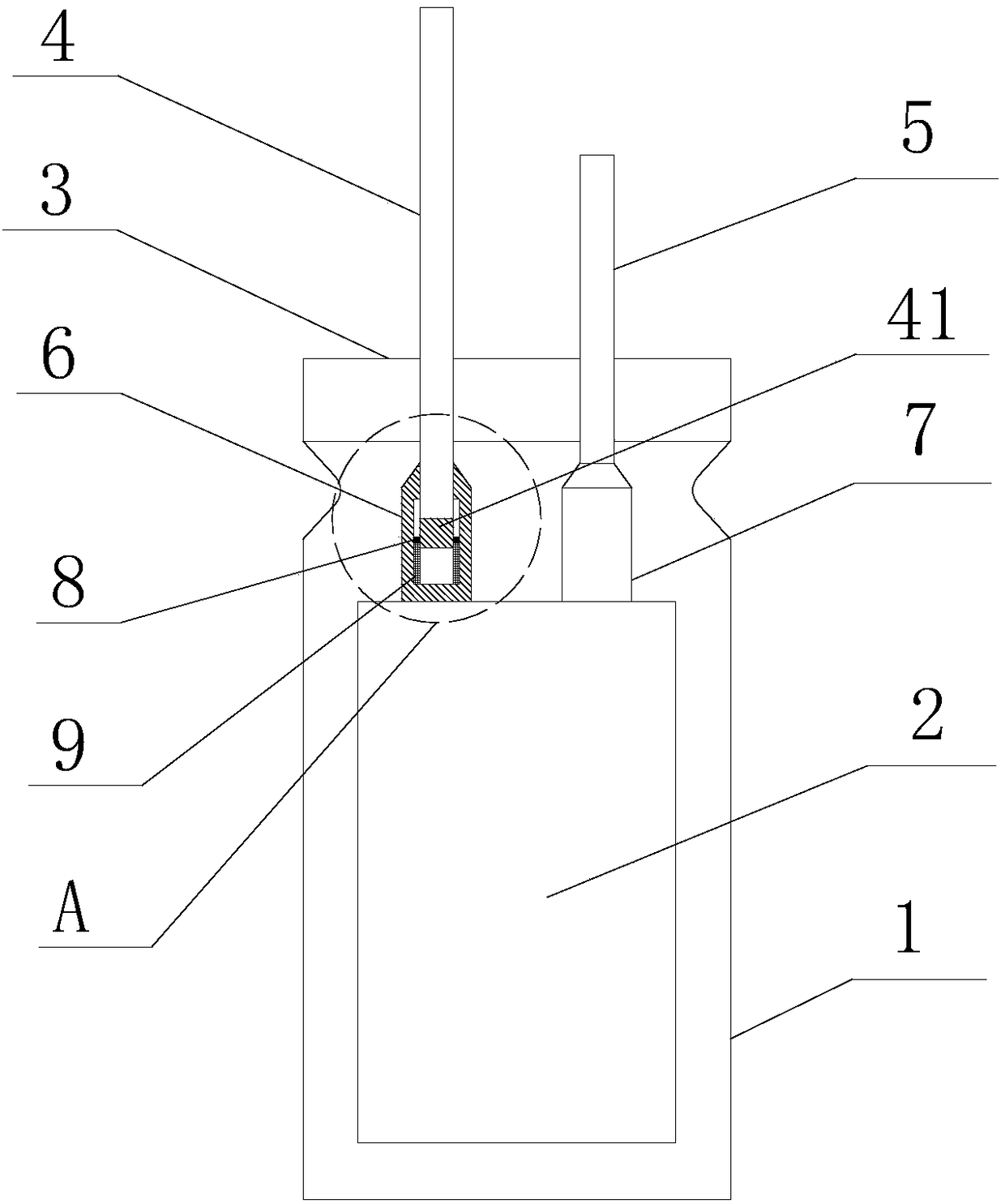

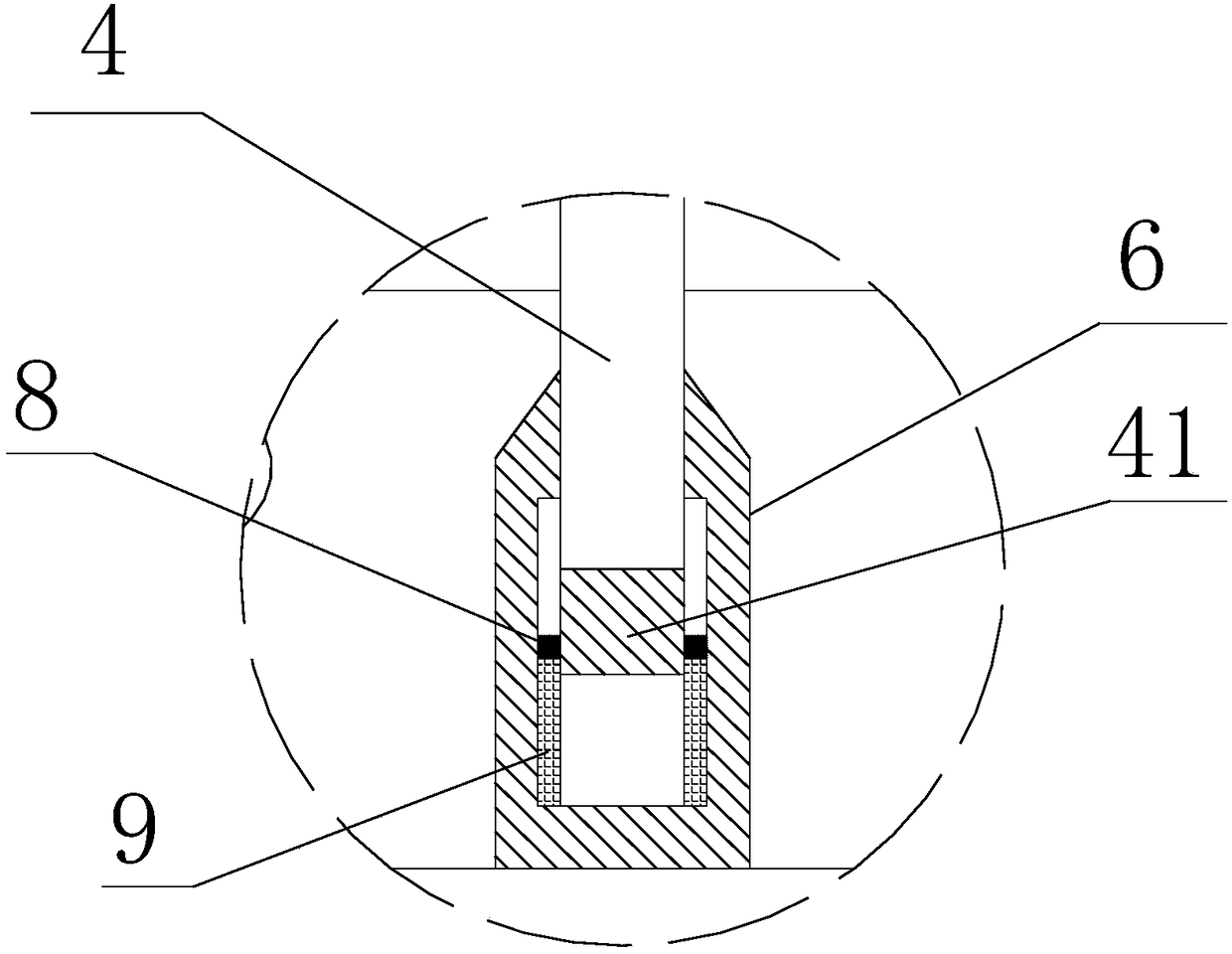

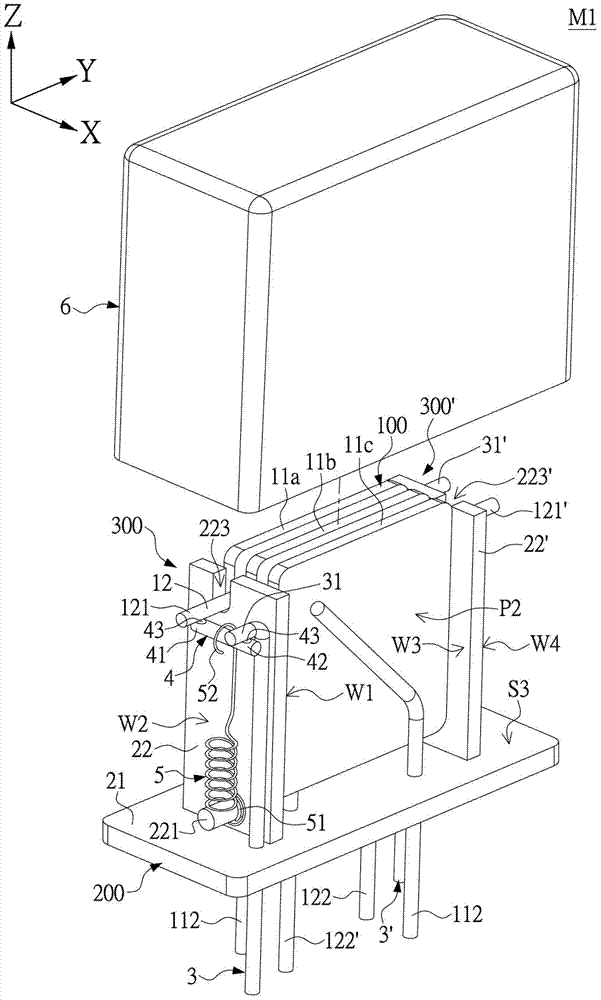

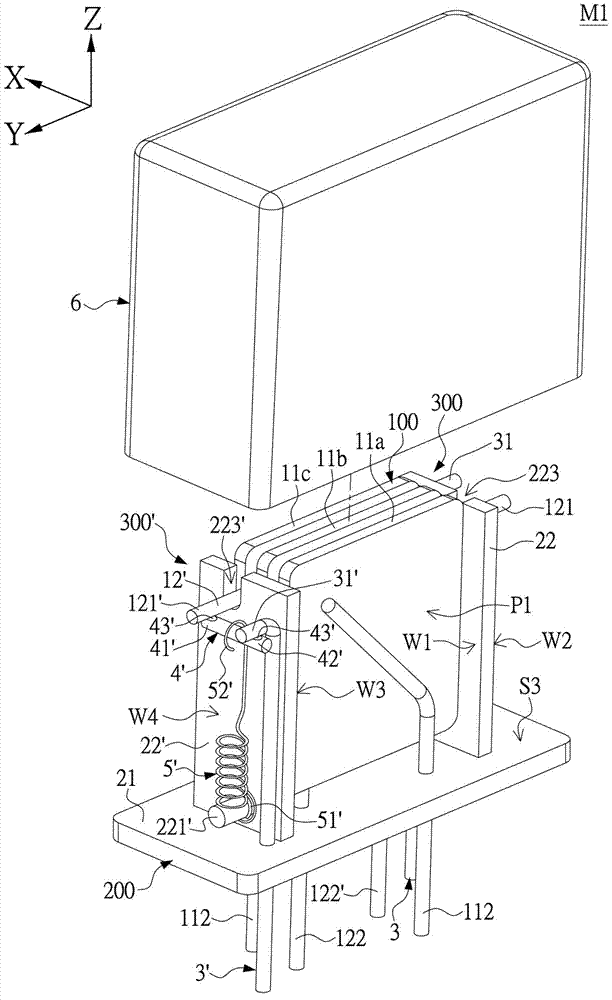

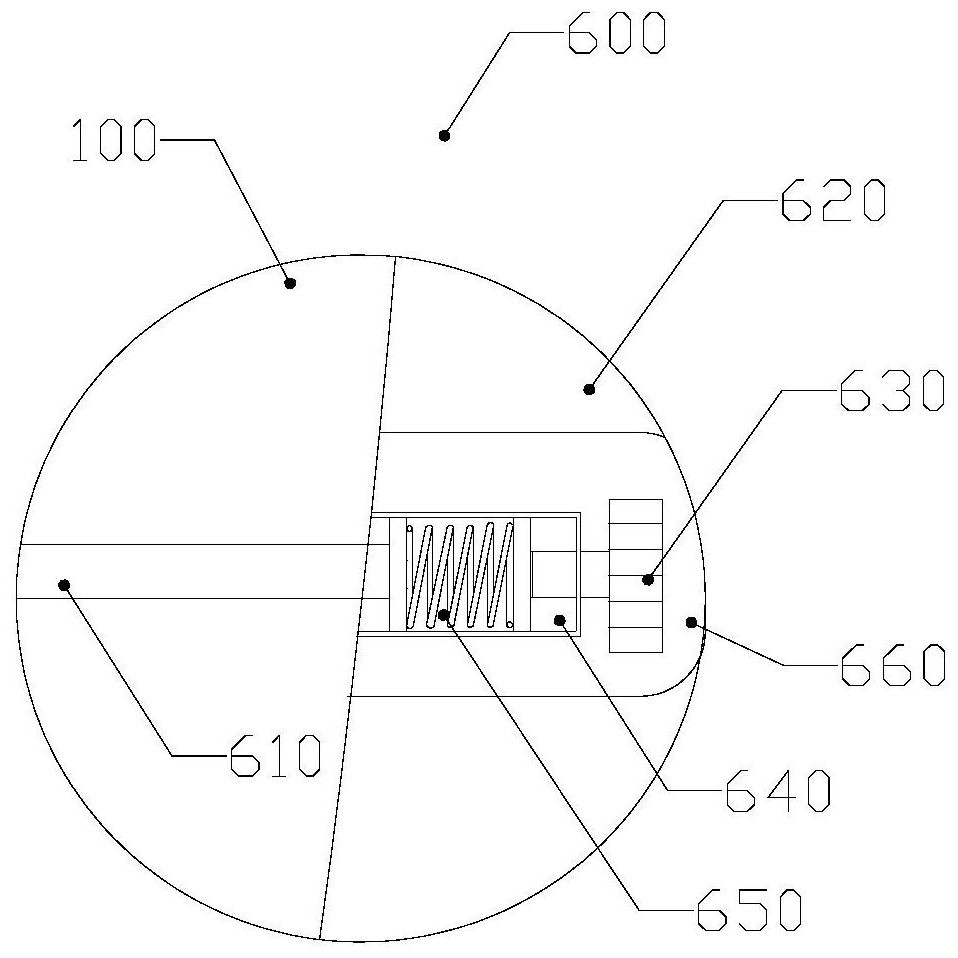

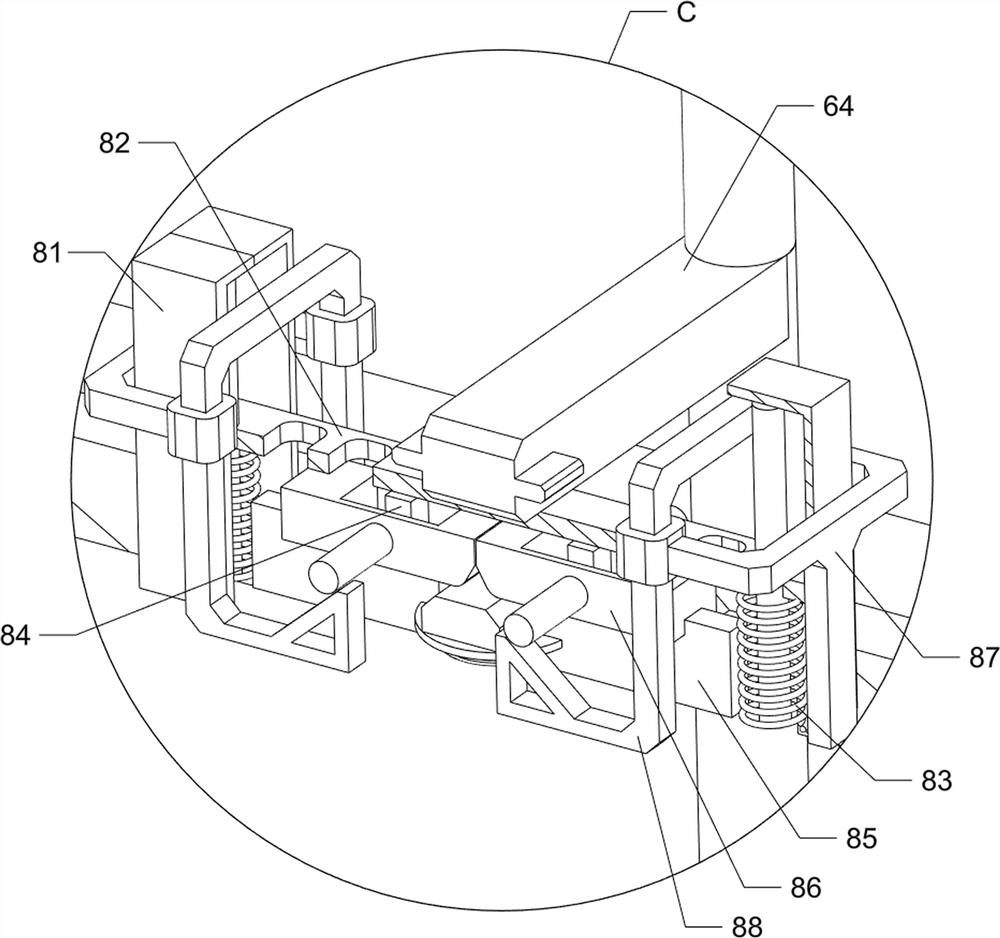

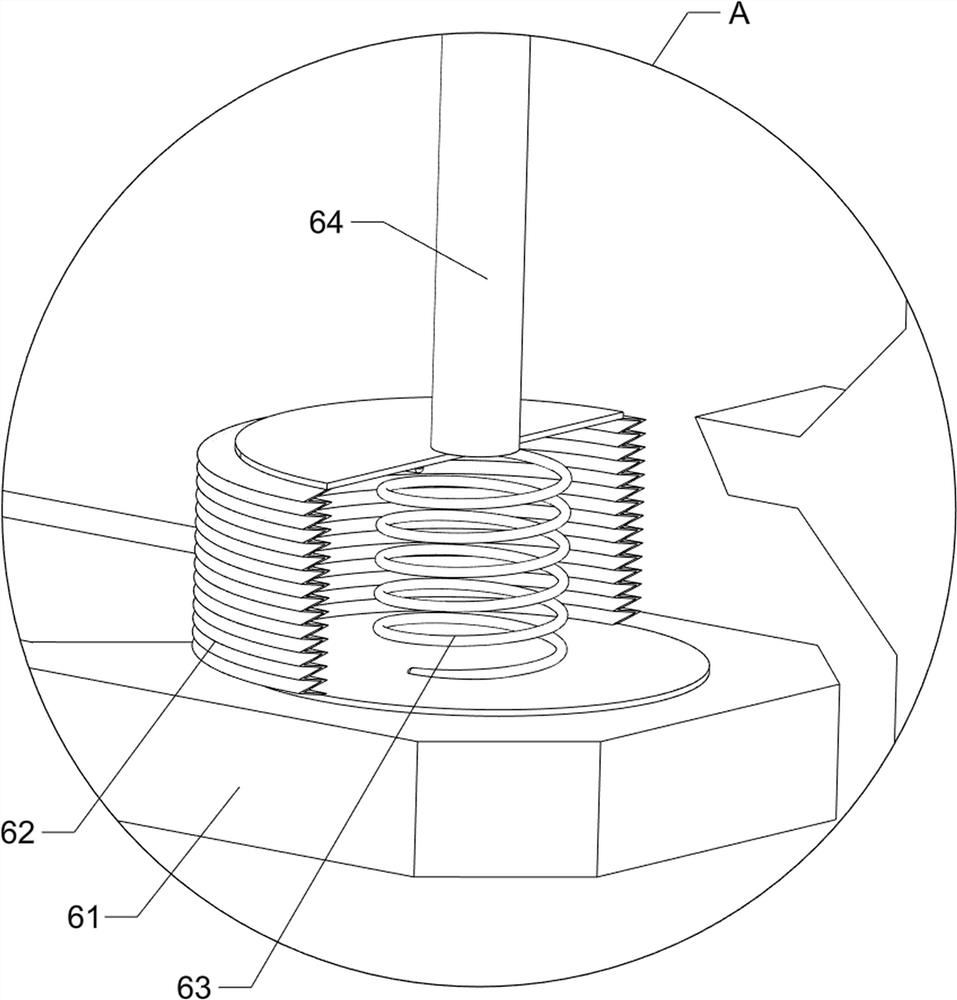

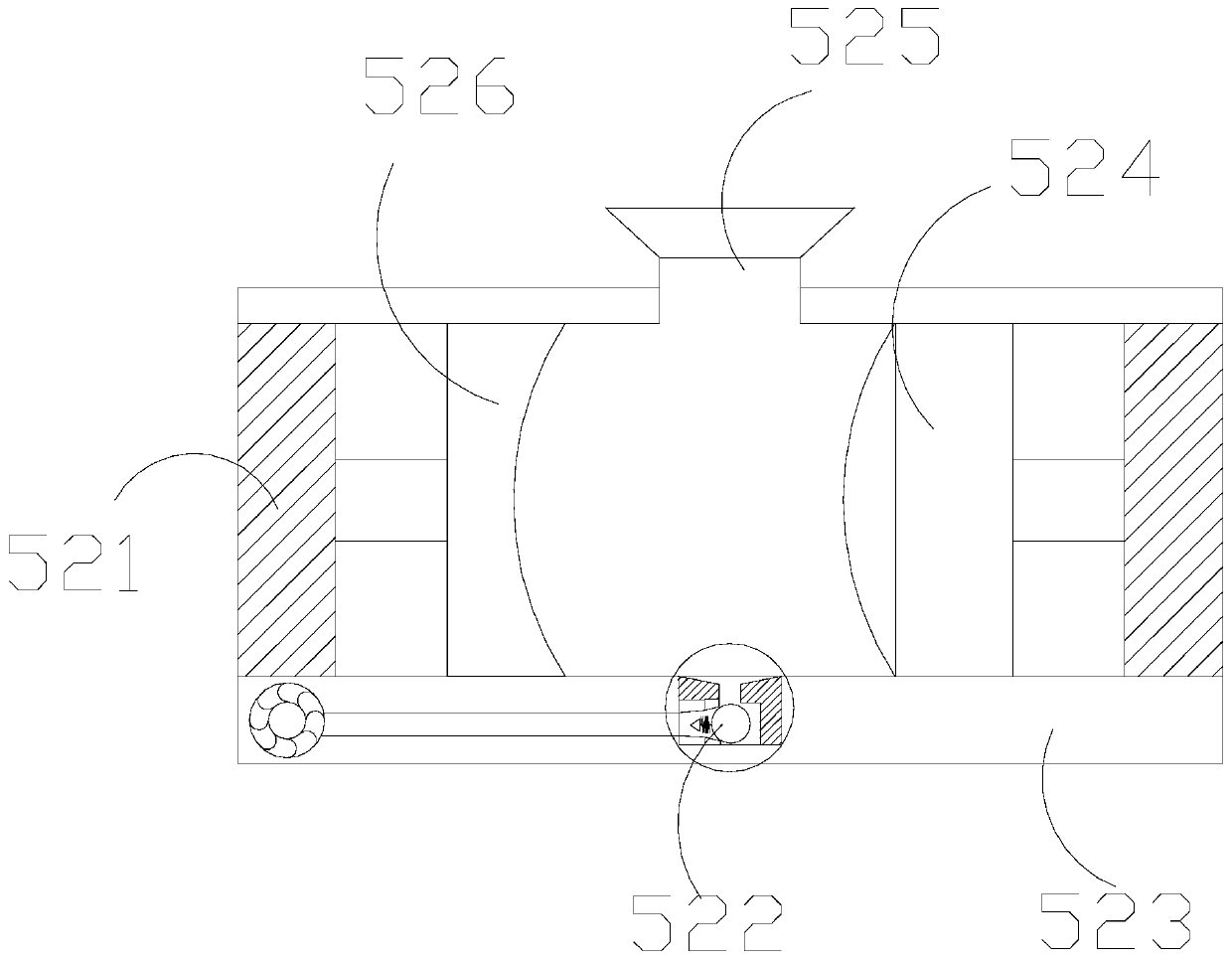

Shaft seal device of rotor pump

ActiveCN106286290AExtended service lifeAvoid continuous heatingMachines/enginesRotary/oscillating piston pump componentsImpellerClose contact

Provided is a shaft seal device of a rotor pump. The shaft seal device comprises a mechanical seal base (3), a fixed ring (4), a moving ring base (5) and a moving ring (6) driven by the moving ring base (5). A first O-shaped ring (8) is arranged in a slit between the fixed ring (4) and the mechanical seal base (3). A tube body of the moving ring base (5) extends into the inner cavity of the mechanical seal base (3), an inner cavity (9) of the moving ring base, which is closed, is formed between the tube body of the moving ring base (5) and a shaft (1), a second O-shaped ring (11) is arranged in a slit between the moving ring (6) and the moving ring base (5). A compressive spring (12) is arranged between a connected end of the moving ring base (5) and the moving ring (6), and the moving ring (6) is in close contact with the fixed ring (4). A third O-shaped ring (30) is arranged between a connected end of the moving ring base (5) and the shaft (1). The moving ring base (5) is connected with an impeller (2) through at least one drive pin (13); one end of each drive pin (13) is in close-fit connection and the other end thereof is in floating insertion. By the shaft seal device of the rotor pump, performance of the rotor pump is improved and service life thereof is prolonged effectively. The shaft seal device is particularly applicable to shaft sealing of hygiene-grade rotor pumps.

Owner:宁波邦威泵业有限公司

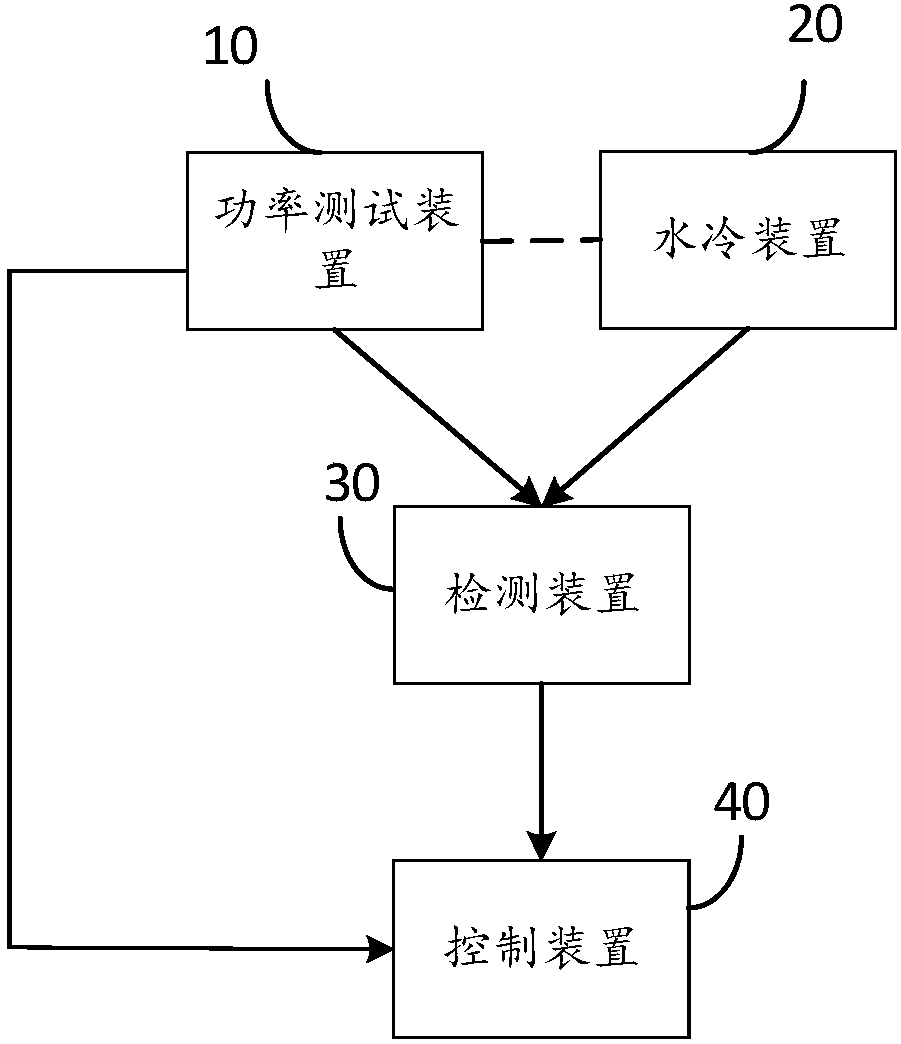

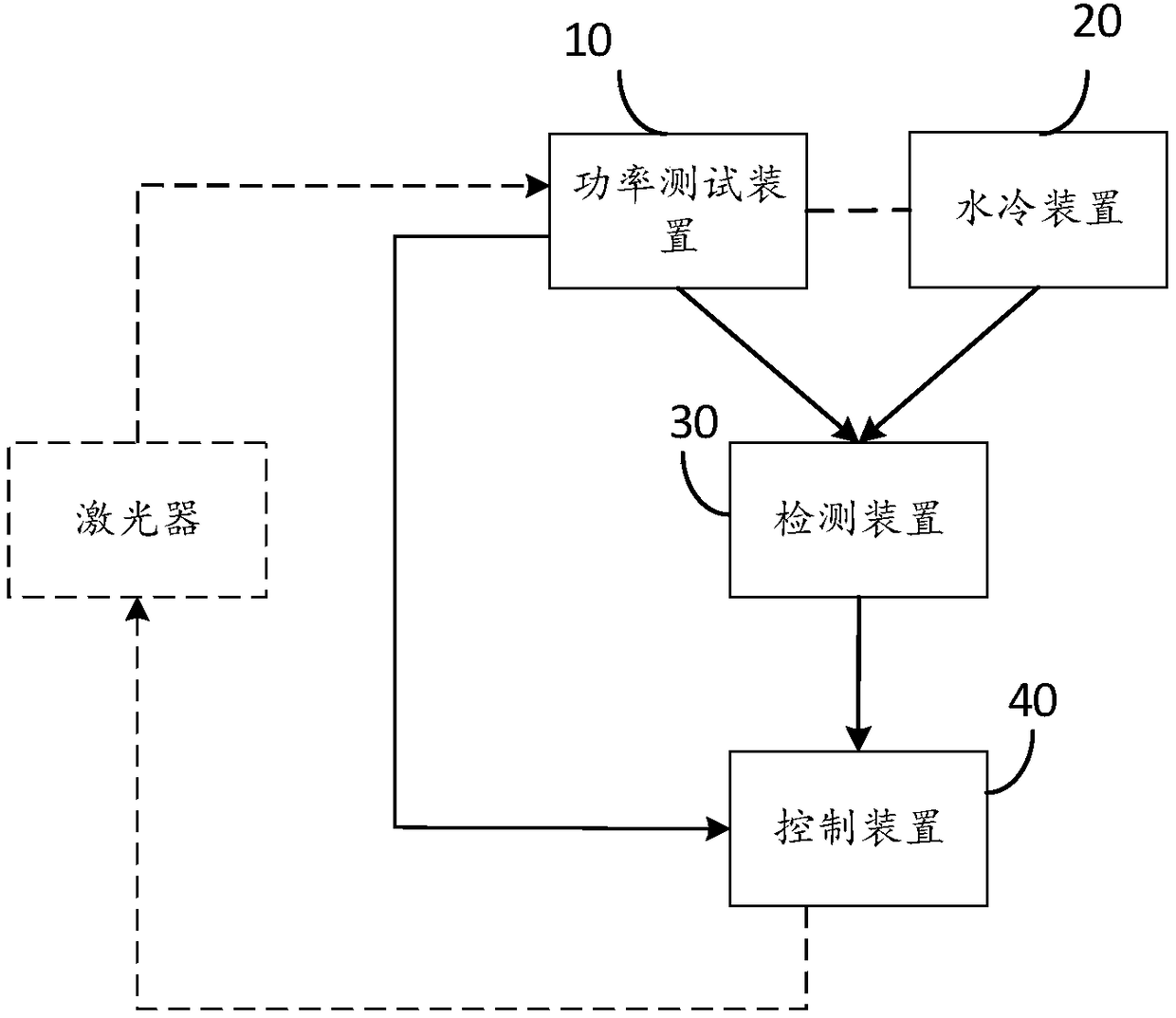

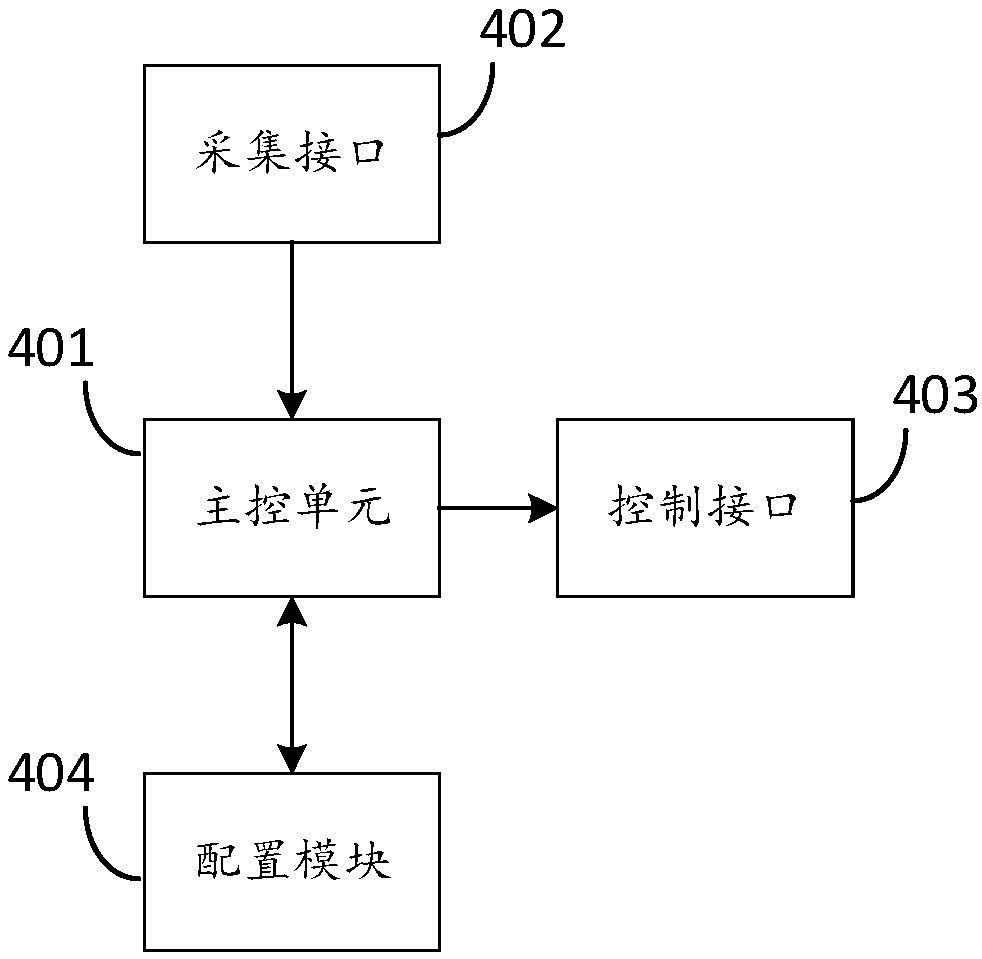

Laser power testing system and method and storage medium

ActiveCN108195463AAvoid continuous heatingGuaranteed stabilityPhotometryLaser power scalingWater cooling

An embodiment of the invention relates to a laser power testing system. The laser power testing system comprises a power testing device, a water-cooling device, a detecting device and a control device, wherein the water-cooling device is used for carrying out water-cooling heat dissipation on the power testing device; the power testing device is attached to the water-cooling device; the detectingdevice cooperates with the power testing device and / or the water-cooling device to acquire a working parameter of the power testing device and / or the water-cooling device; the power testing device andthe detecting device are connected with the control device; the control device controls the working state of a laser device by judging whether the working parameter of the power testing device or thewater-cooling device is abnormal or not. According to the scheme provided by the embodiment of the invention, stability of cooling of the system can be ensured, and equipment damage caused by over-high temperature of the laser power testing device is prevented. The embodiment of the invention further provides a laser power testing method applied to the system and a storage medium.

Owner:MAXPHOTONICS CORP

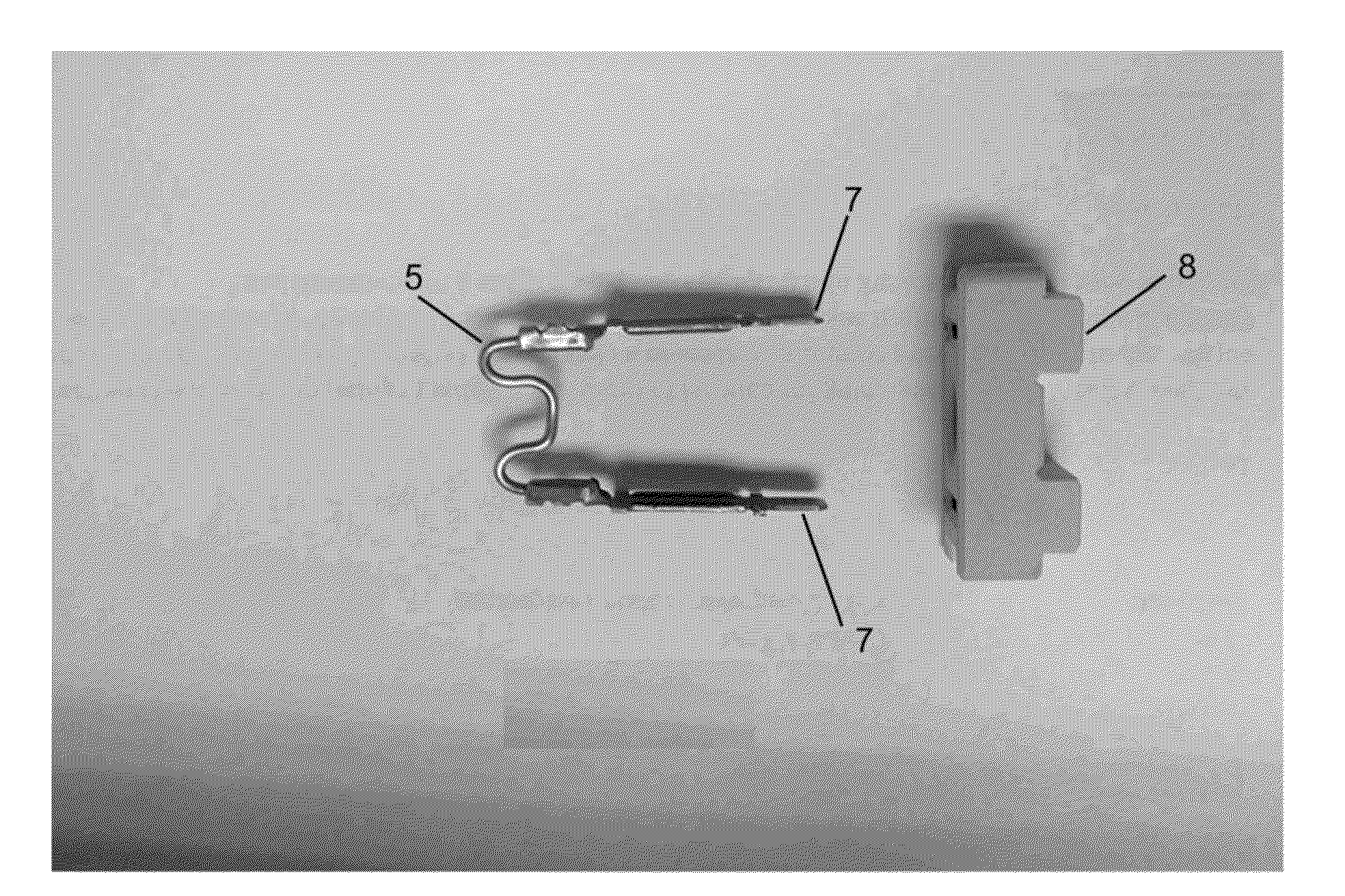

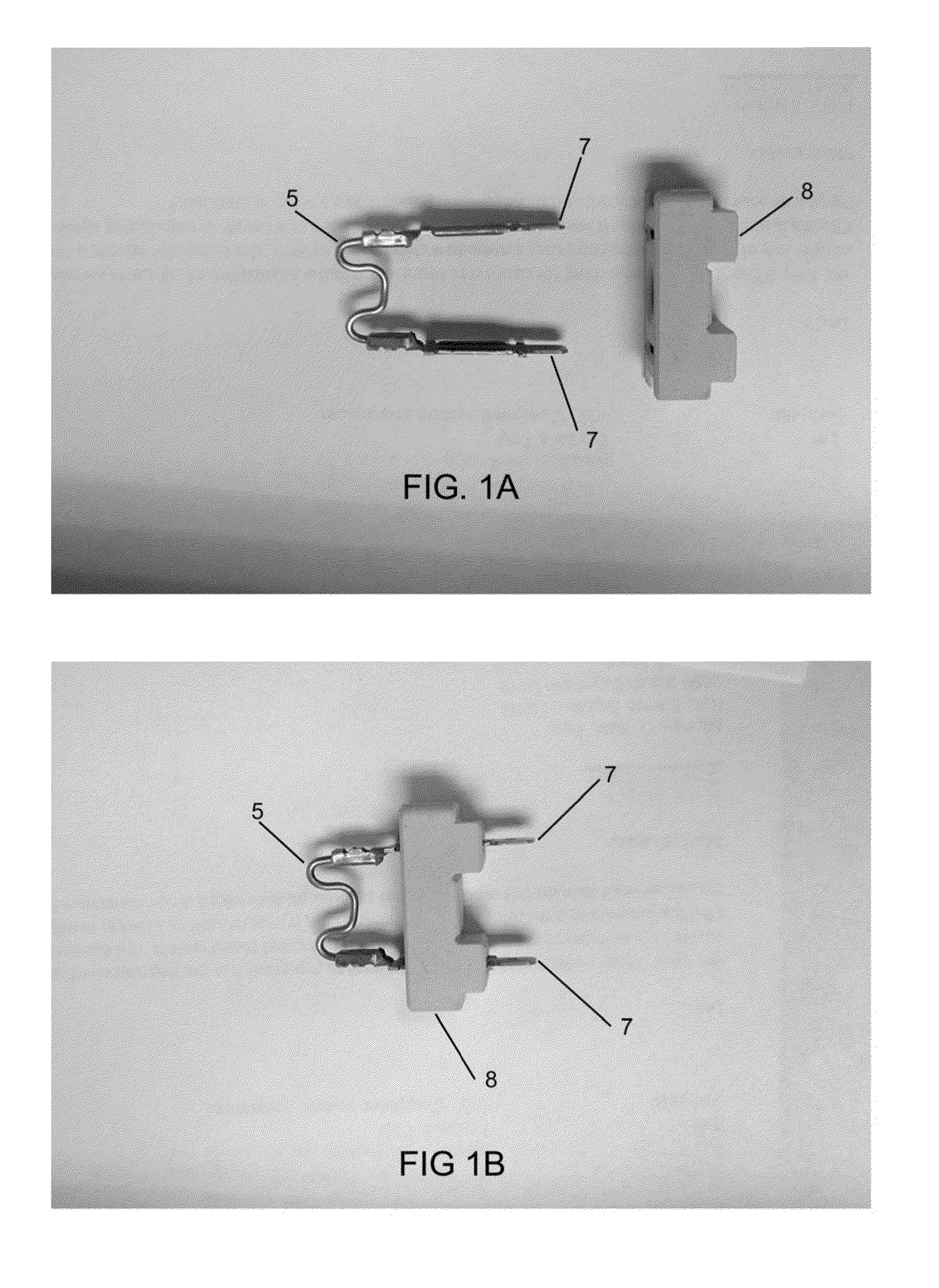

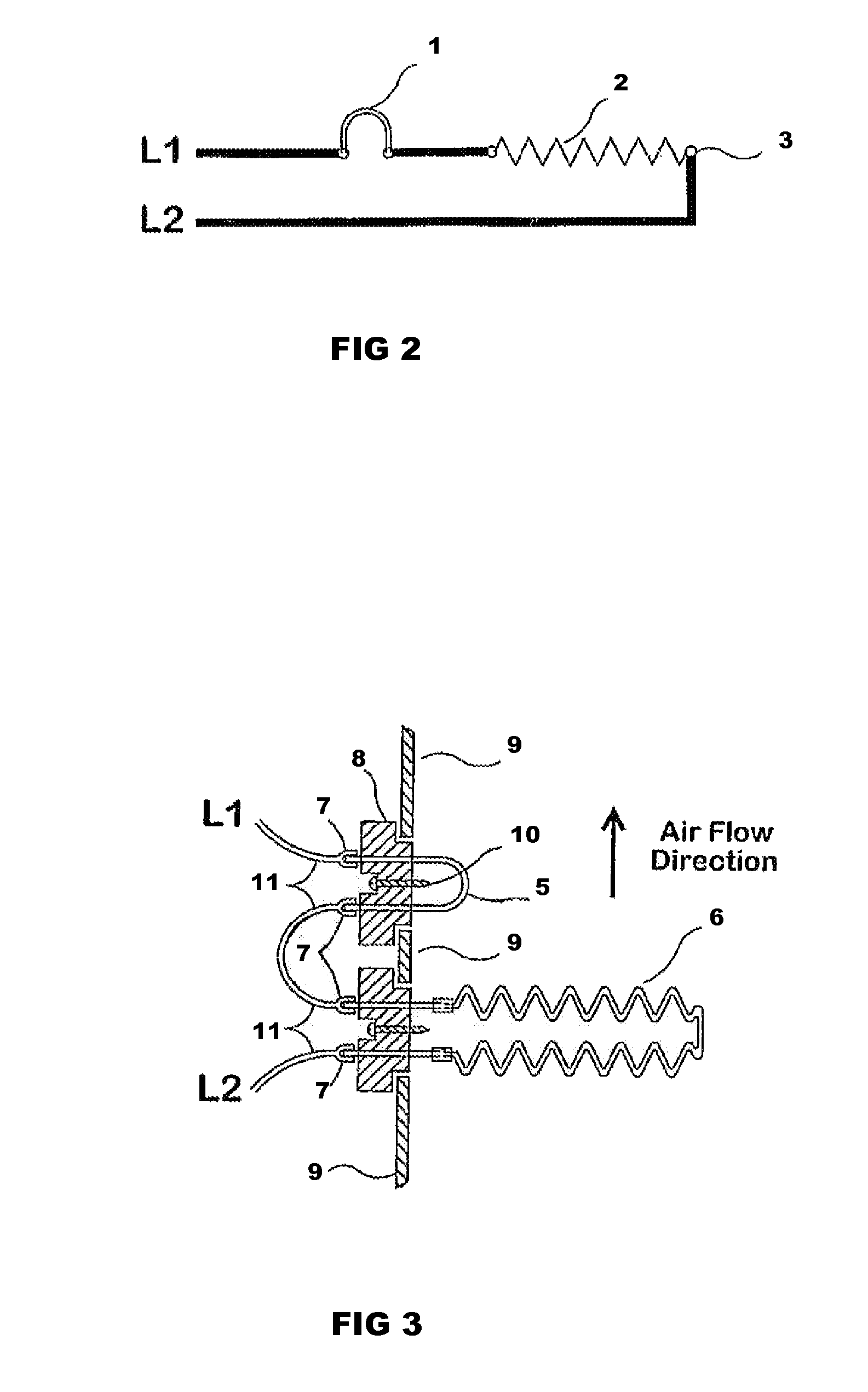

Thermal cutoff link safety fuse in HVAC system

InactiveUS20130162387A1Avoid continuous heatingReducing and eliminating risk of fireThermally actuated switchesEmergency protective devicesEngineeringThermal cutoff

The present invention relates to a thermal cut off link safety fuse for use in a HVAC system. The thermal cut off link safety fuse disconnects the electrical circuit from the HVAC system's heating element when the thermal cut off link safety fuse melts upon reaching a temperature that exceeds a set temperature. The use of the thermal cut off link safety fuse in a HVAC system helps prevent fires caused by blocked airflow, insufficient airflow or excessive heat within the HVAC system

Owner:KELLEY ROY

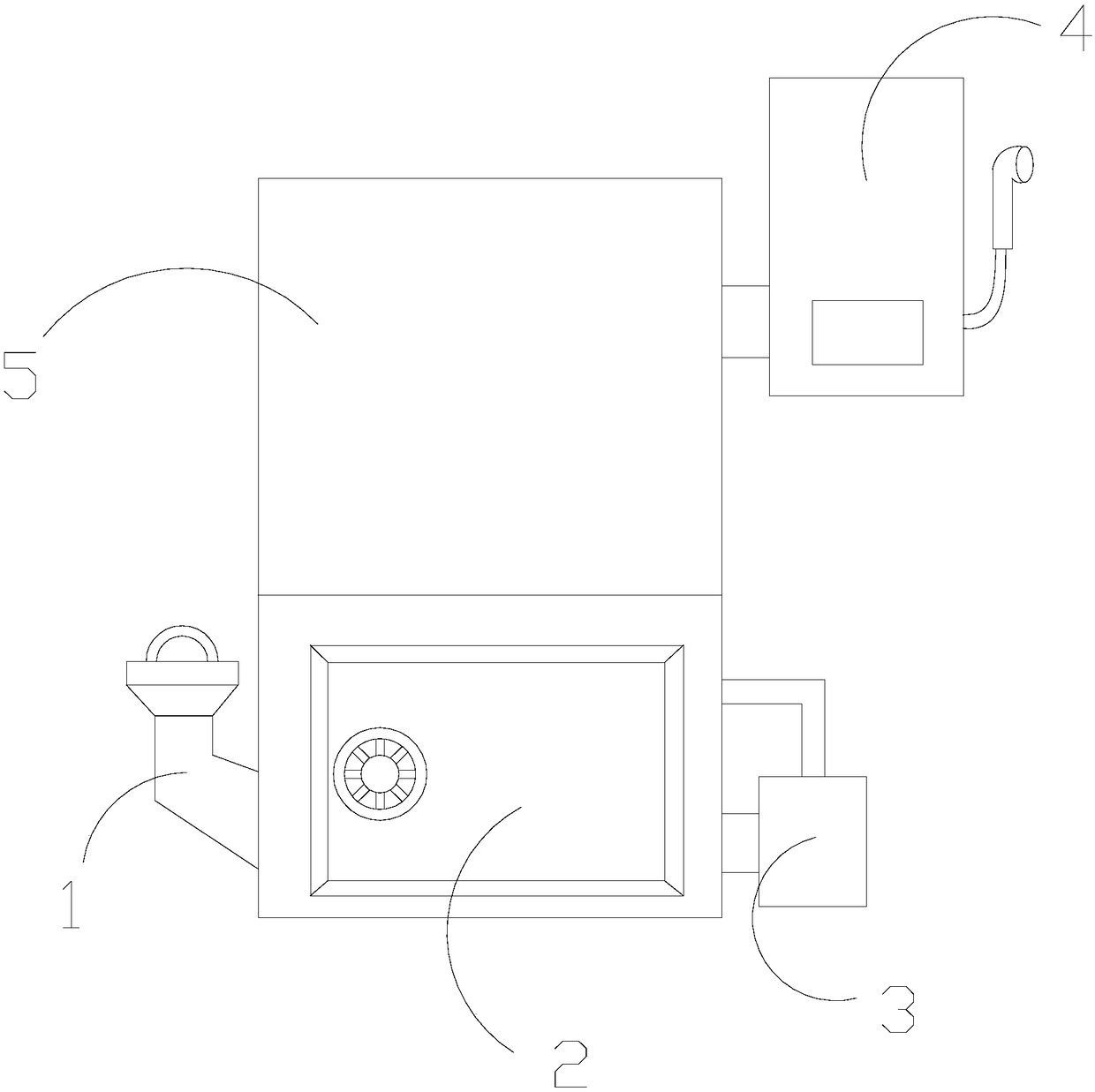

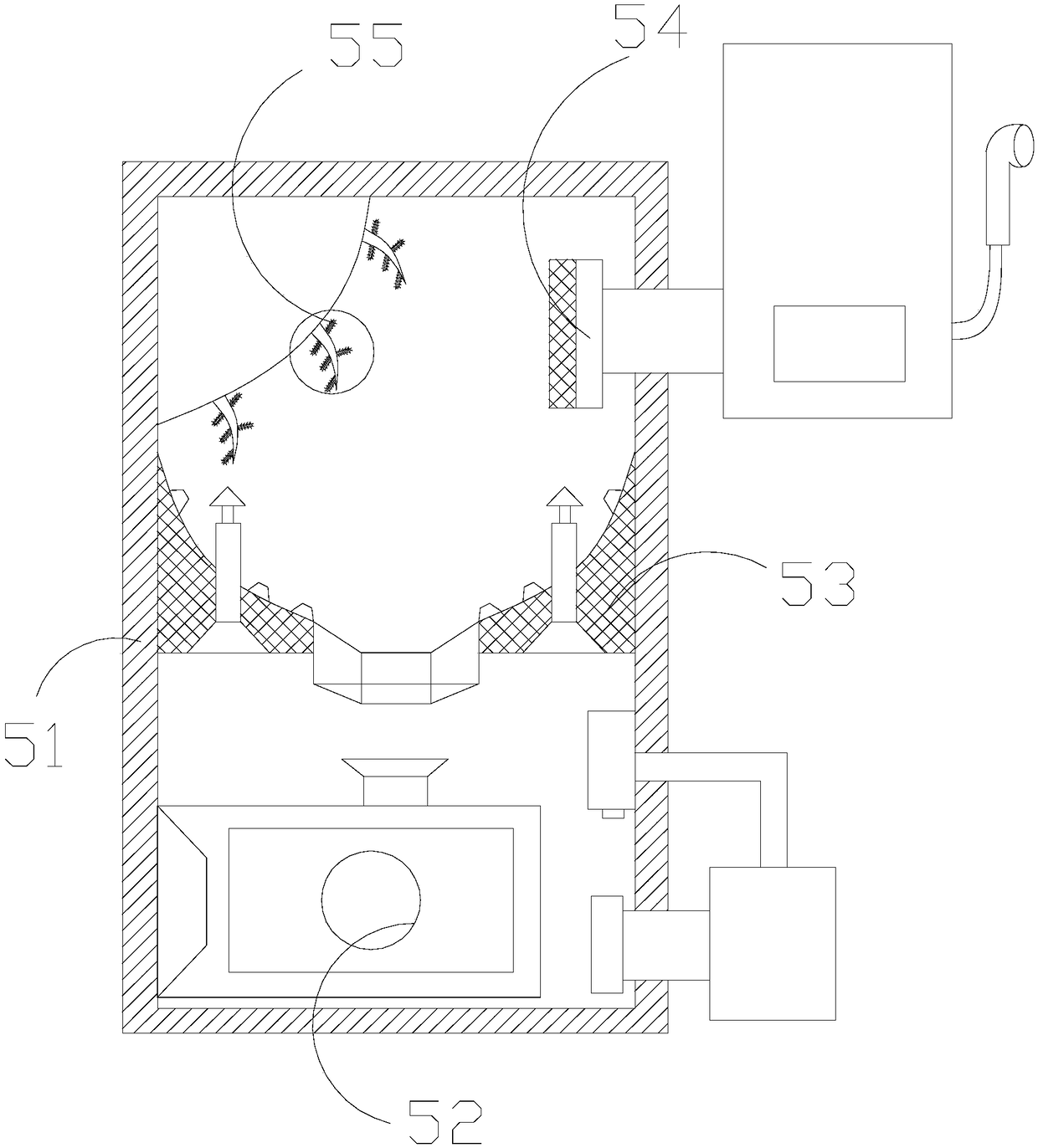

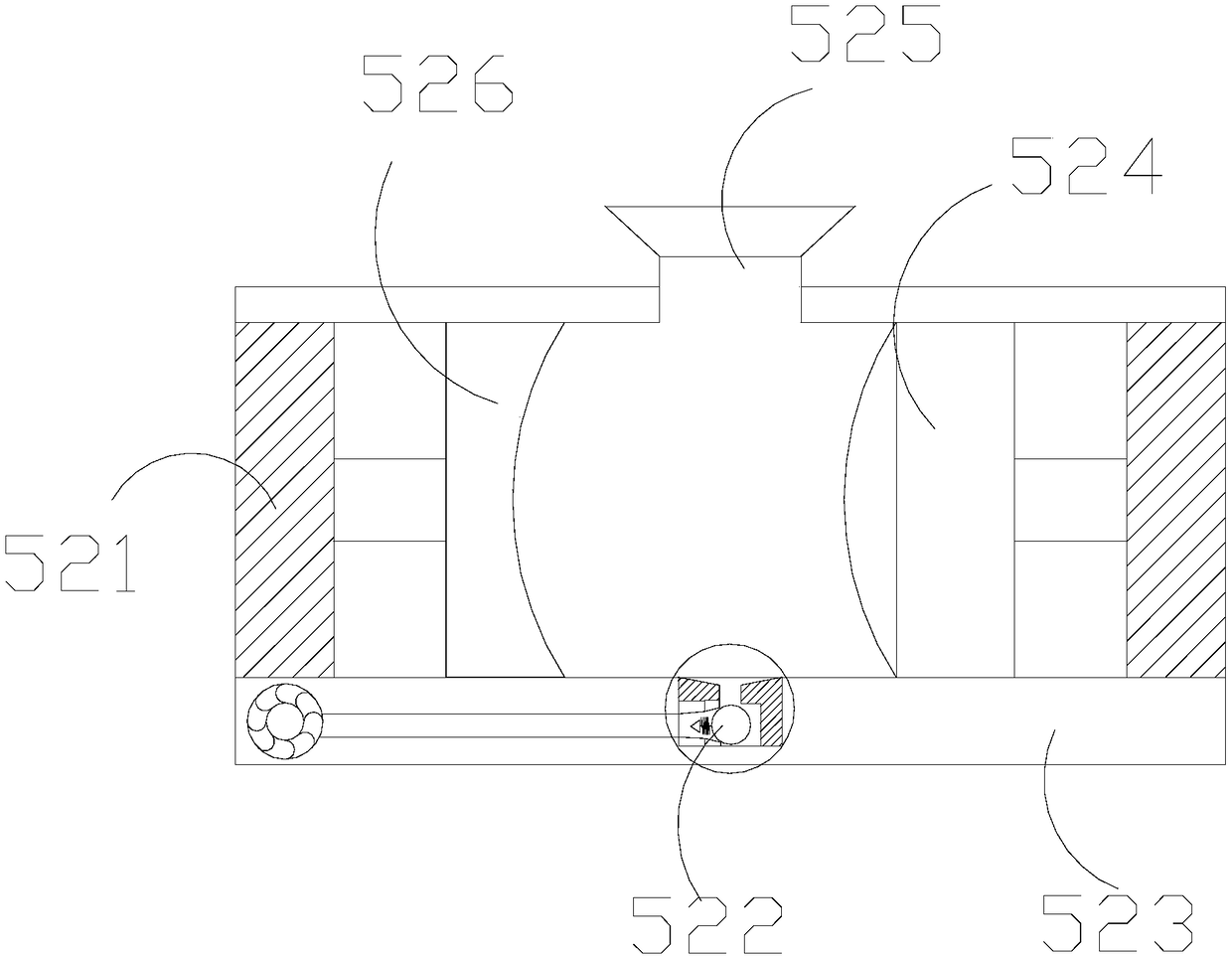

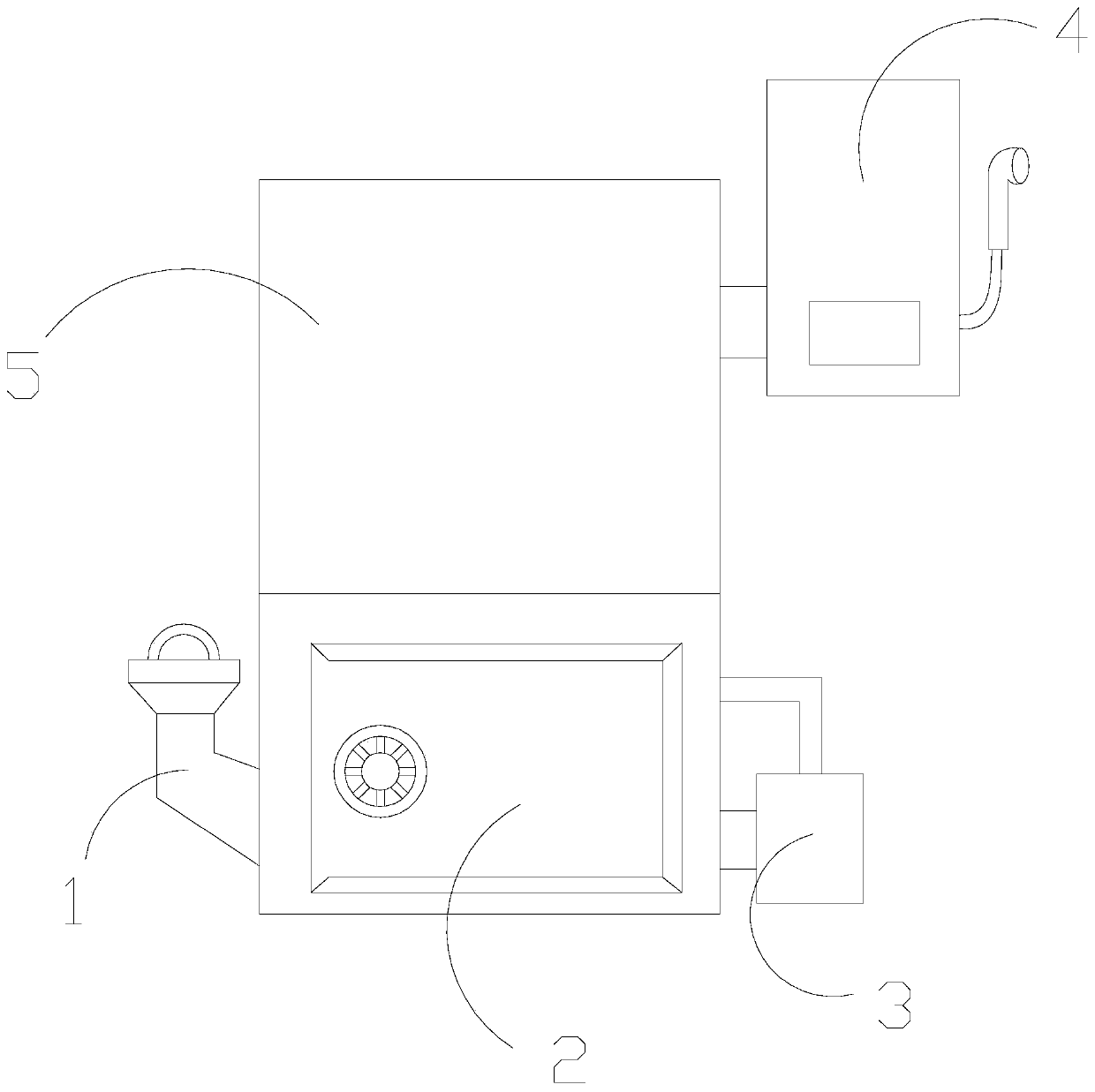

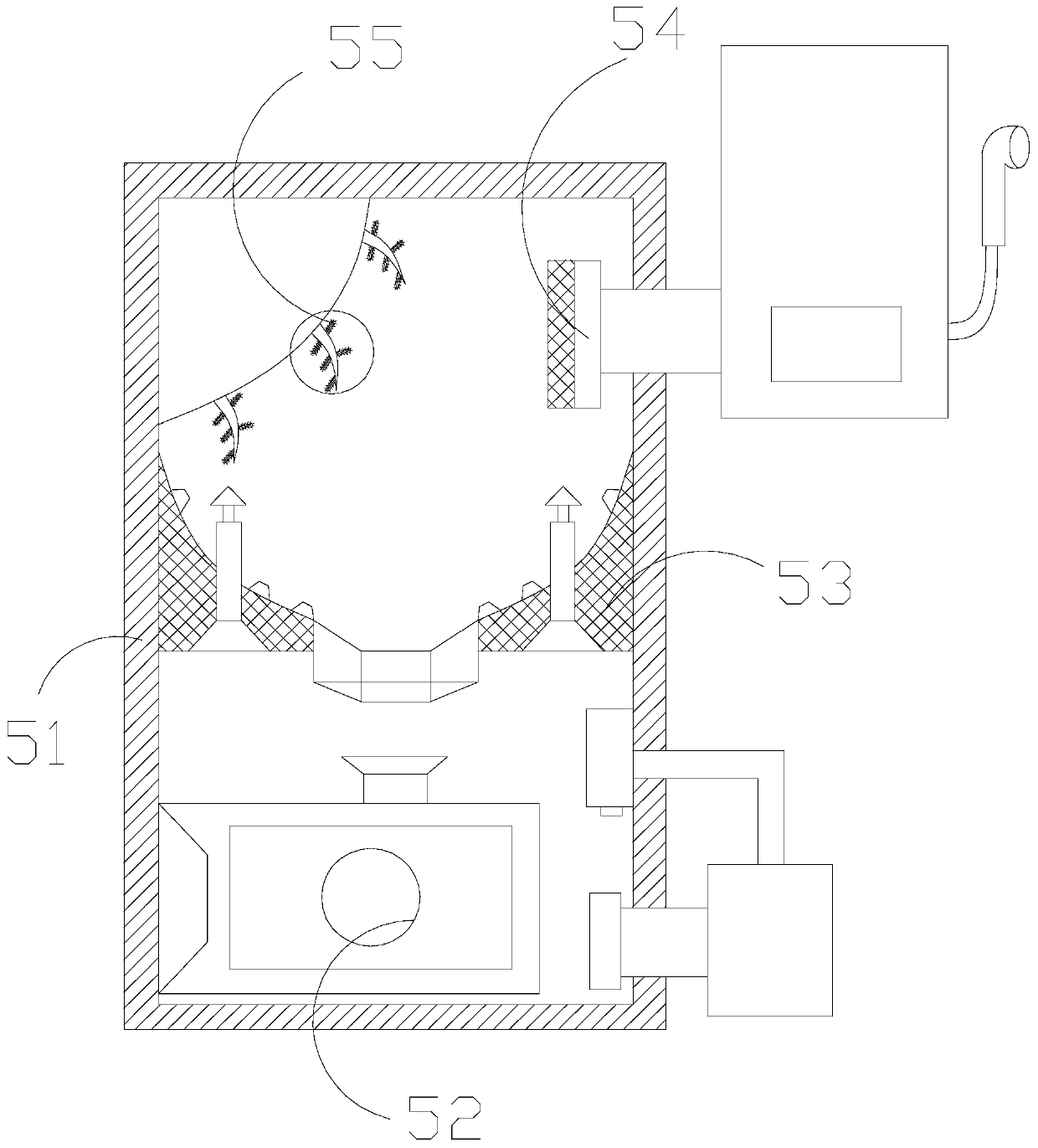

Electrostatic atomization intelligent fumigation instrument and fumigation method thereof

The invention relates to an electrostatic atomization intelligent fumigation instrument and a fumigation method thereof. The fumigation instrument comprises a support rack, a constant-temperature water tank, a liquid medicine container chamber, an atomization chamber and a steam chamber and is characterized in that the constant-temperature water tank is arranged on the support rack, the liquid medicine container chamber is located on the constant-temperature water tank, the constant-temperature water tank, the atomization chamber is arranged on the liquid medicine container chamber, and the steam chamber is communicated with the atomization chamber; a liquid medicine medium is sprayed out through high-voltage electrostatic atomizers and becomes fine vaporous charged drops in a high-voltageelectrostatic field; a large heat exchanging pipe and a small heat exchanging pipe are grounded and connected with the constant-temperature water tank through a water pipe, the fine vaporous chargeddrops are evenly attached to the surface of the large heat exchanging pipe and the small heat exchanging pipe under the effect of the electric field, the temperature of the large heat exchanging pipeand the small heat exchanging pipe is controlled through the temperature of heat exchanging media flowing in the large heat exchanging pipe and the small heat exchanging pipe to allow the liquid medicine attached to different positions of the large heat exchanging pipe and the small heat exchanging pipe to be evaporated at different temperature so as to achieve steam temperature adjustability andcontrollability and avoid continuous heating, energy consumption is lowered, and influence of the fumigation instrument on environment temperature is reduced; the fumigation instrument is simple in structure, easy to manufacture and promising in application prospect.

Owner:EAST CHINA UNIV OF TECH +1

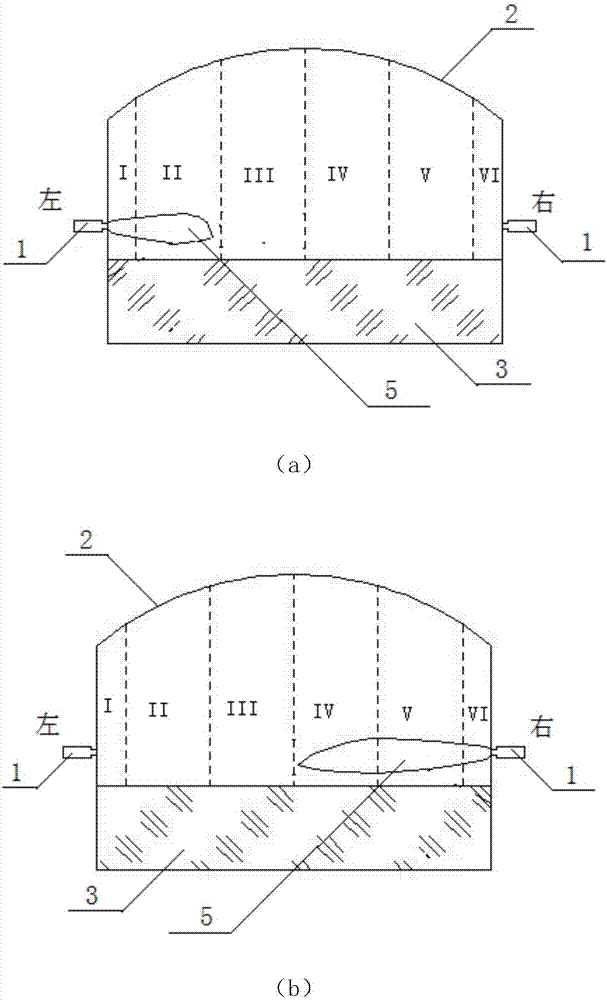

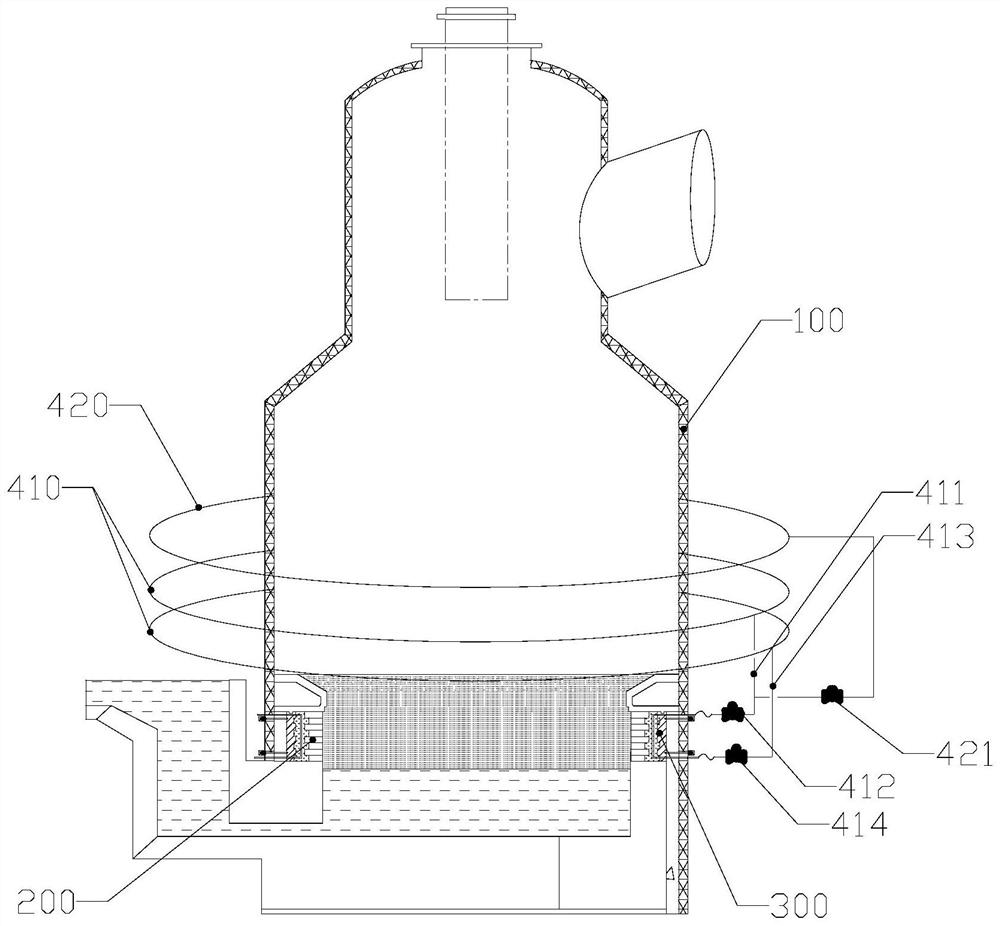

Glass kiln and method for heating glass batch

ActiveCN111908770ASimple structureStable structureGlass furnace apparatusTank furnacesMelting tankCombustion

The invention discloses a glass kiln and a glass batch heating method thereof. The glass kiln comprises kiln side walls, a melting tank and a crown located above the melting tank and used for formingthe top of the glass kiln, wherein side burning spray guns are arranged on the opposite side walls of the glass kiln, and a plurality of top burning spray guns are further arranged on the two sides ofthe top of the crown respectively. According to the glass kiln, the burning spray guns are additionally arranged on the crown top, so that the flame ends alternately reach the set combustion area andcover the whole glass liquid level, continuous heating of the center combustion area is avoided, the NOX emission concentration and the total emission amount in smoke of the glass kiln are remarkablyreduced, energy consumption is reduced, and environmental pollution is reduced. The glass kiln with the new combustion mode provided by the invention is simple and stable in structure, simple in transformation of an existing kiln, low in investment and easy to popularize and apply in various combustion kilns taking air as combustion-supporting gas.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

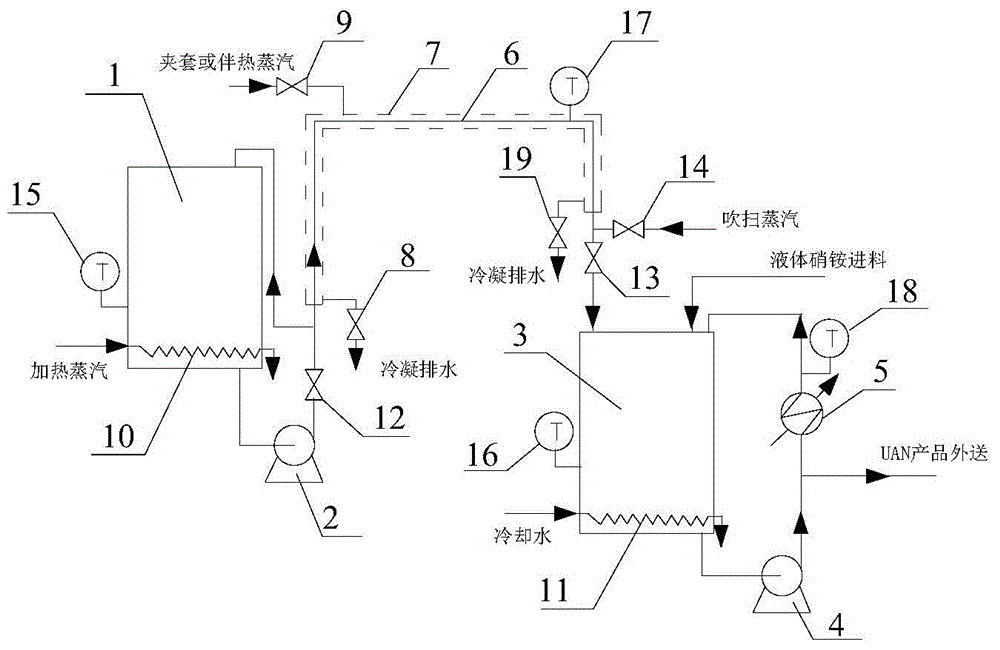

Device for reducing generation of biuret in urea ammonium nitrate solution industrial production process and application method thereof

InactiveCN104311163ANot prone to condensation reactionsReduce generationAmmonium nitrate fertilisersUrea compound fertilisersAmmonium nitrateChiller

The invention provides a device for reducing generation of biuret in a urea ammonium nitrate solution industrial production process, which comprises a urea solution tank, a urea solution pump, a urea ammonium nitrate preparation tank, a urea ammonium nitrate solution pump, a cooler and a delivery pipeline, wherein the bottom of the urea solution tank is connected with an inlet of the urea solution pump through a pipeline; the urea solution pump is connected with an inlet of the urea ammonium nitrate preparation tank through the delivery pipeline; a heat tracing pipeline is arranged outside the delivery pipeline; the bottom of the urea ammonium nitrate preparation tank is connected with an inlet of the urea ammonium nitrate solution pump through a pipeline; the urea ammonium nitrate solution pump is connected with an inlet of the cooler through a pipeline; the pipeline between the ammonium nitrate solution pump and cooler is connected with a urea ammonium nitrate solution product discharge pipeline; and the cooler is connected with a top inlet of the urea ammonium nitrate preparation tank through a pipeline. The device optimizes the production control, reduces the generation of biuret, and effectively improves the product quality. The invention also provides an application method of the device.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

Titanium sponge, zirconium sponge energy-saving reaction furnace

InactiveCN104764325AHigh control precisionReduce labor intensityFurnace typesFurnace coolingFrequency conversionThermal insulation

The invention discloses a titanium sponge, zirconium sponge energy-saving reaction furnace which comprises a furnace body, wherein a forced ventilation system is arranged at the upper end of the furnace body; a thermal insulation vacuum energy-saving system is arranged below the forced ventilation system; the forced ventilation system comprises a frequency conversion draught fan, a blast pipe and annular wind collecting belts; the annular wind collecting belts are arranged at the upper side and the lower side in a parallel mode at least and are respectively arranged inside the side wall of the furnace body; the outer side of each annular wind collecting belt is connected with the frequency conversion draught fan through the blast pipe, and an exhaust annular wind collecting belt for exhaust function is also arranged, the outer side of the exhaust annular wind collecting belt is connected with a wind collecting pipeline, and exhaust outlets are formed in the inner side of the exhaust annular wind collecting belt. The titanium sponge, zirconium sponge energy-saving reaction furnace is that the forced ventilation system is provided with the annular wind collecting belt and the exhaust annular wind collecting belt, so that inlet air and the outlet air are smooth under the power of the frequency conversion draught fan.

Owner:JIANGSU XINHUI TI ZR EQUIP CO LTD

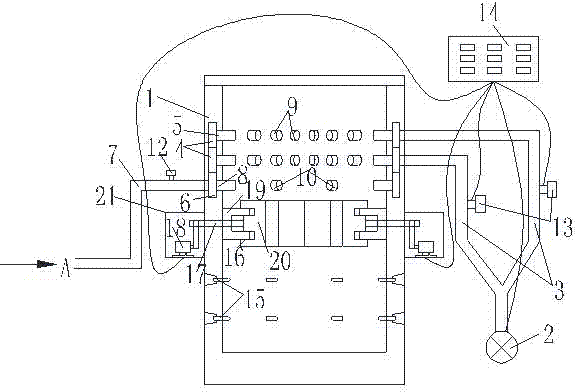

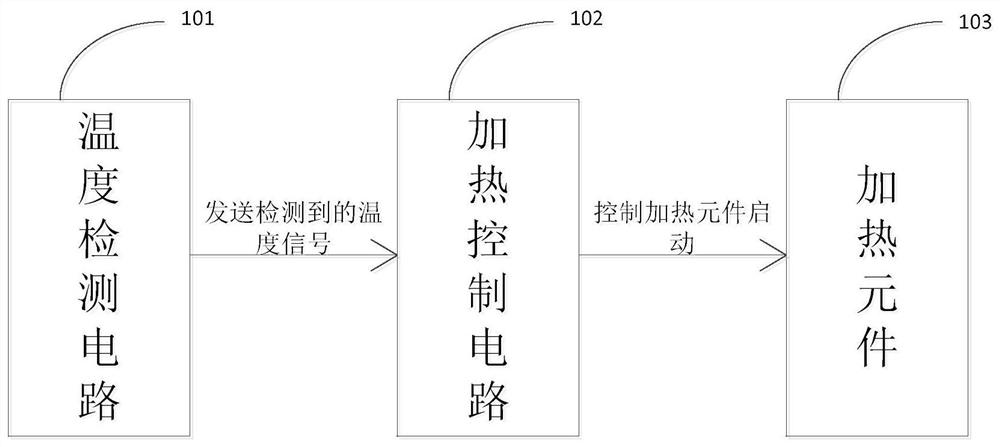

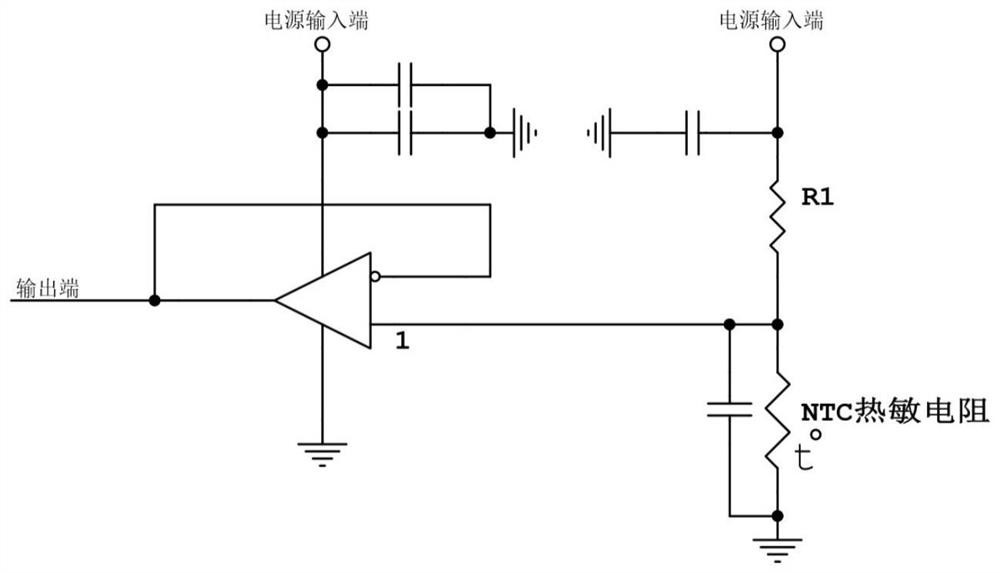

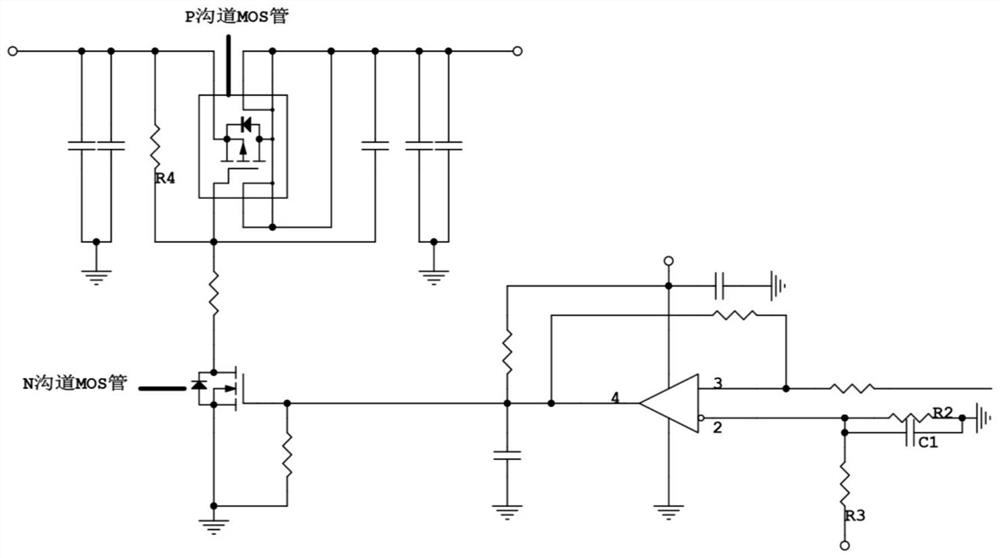

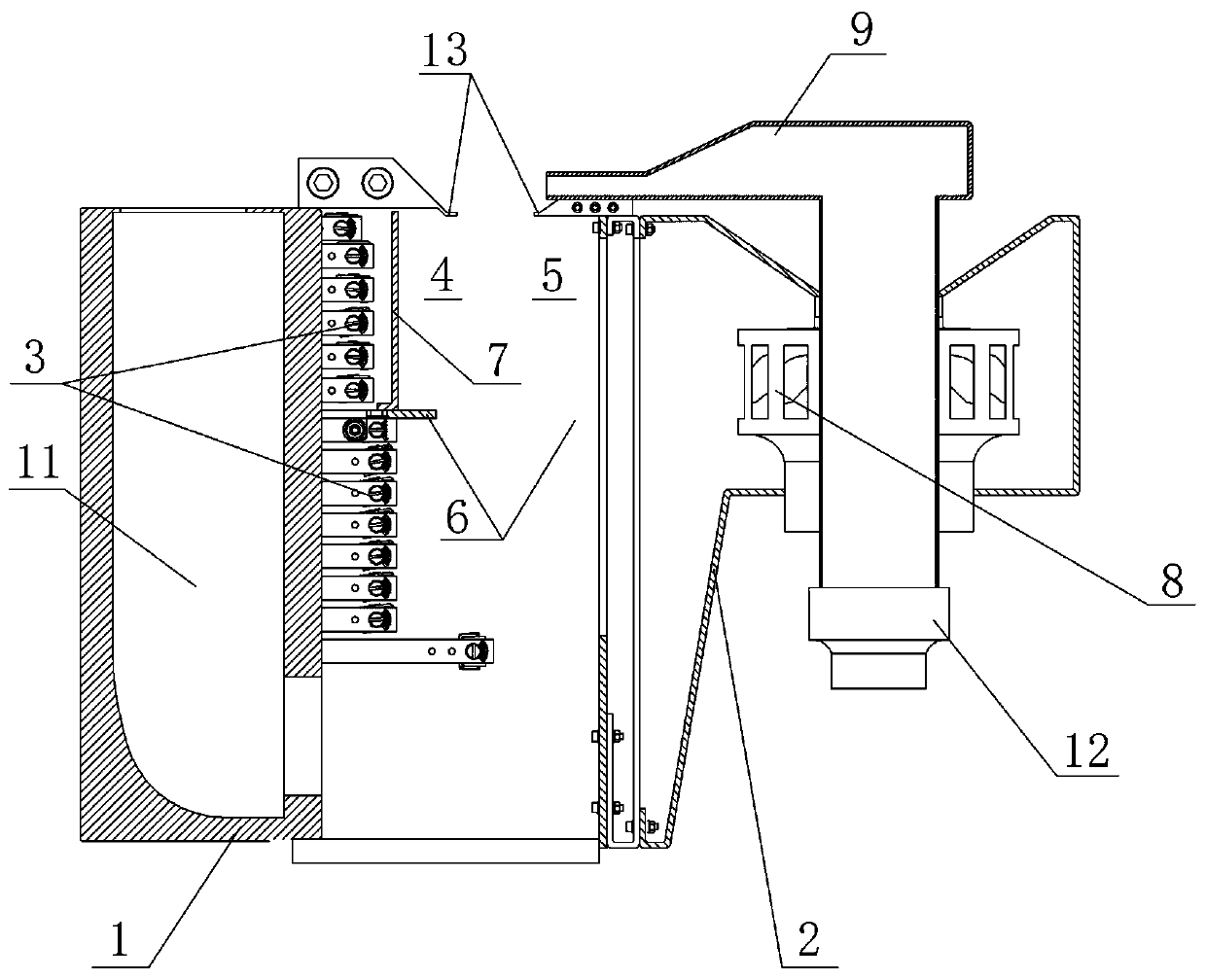

Heating system for low-temperature starting of electronic equipment

InactiveCN112346501AClear division of laborAvoid continuous heatingTemperatue controlProcess engineeringHeat control

The invention discloses a heating system for low-temperature starting of electronic equipment. The heating system comprises a temperature detection circuit, a heating control circuit and a heating element, the temperature detection circuit is used for detecting the temperature of the electronic equipment; and the heating control circuit is used for starting the heating element according to the temperature of the electronic equipment.

Owner:SENSCAPE TECH BEIJING CO LTD

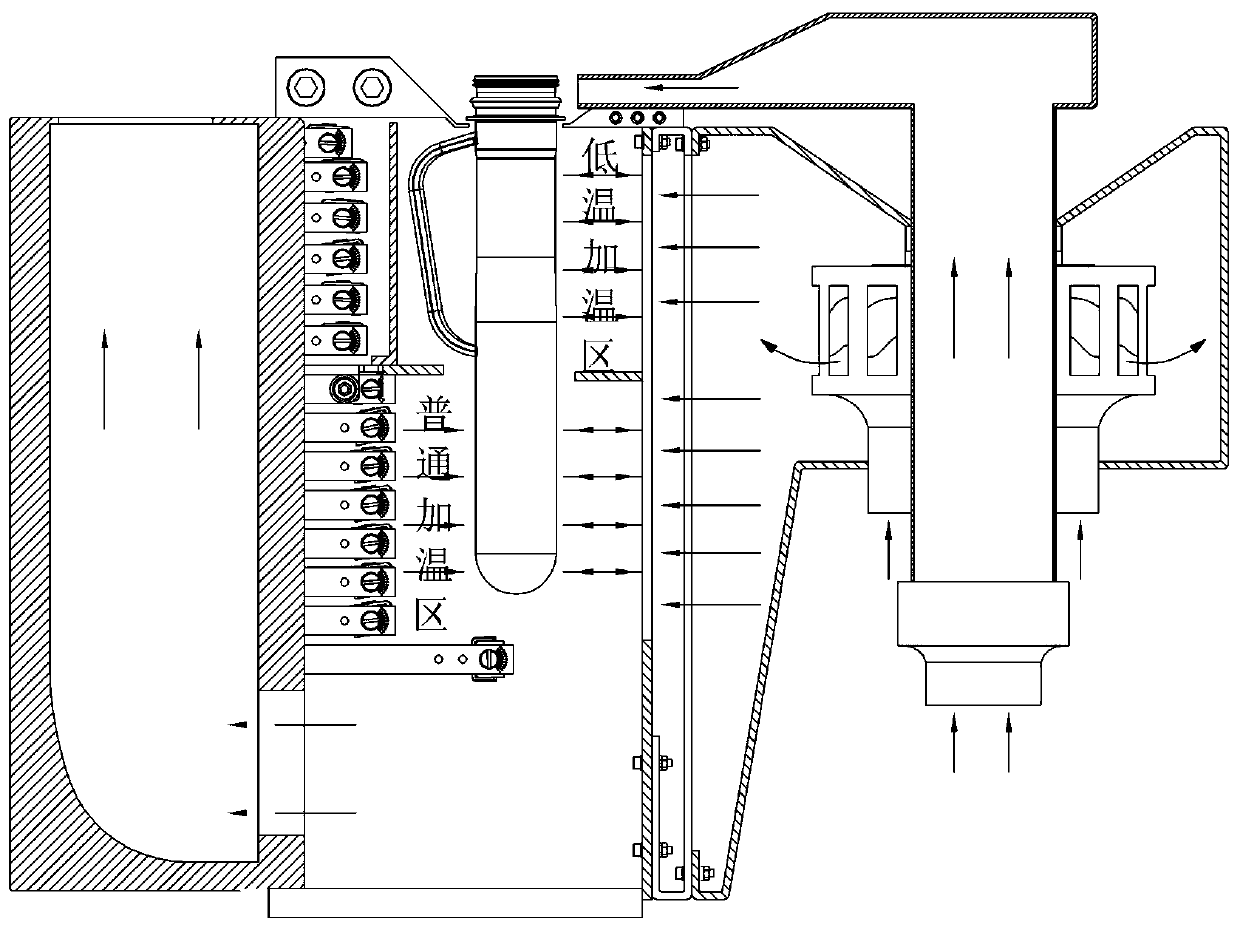

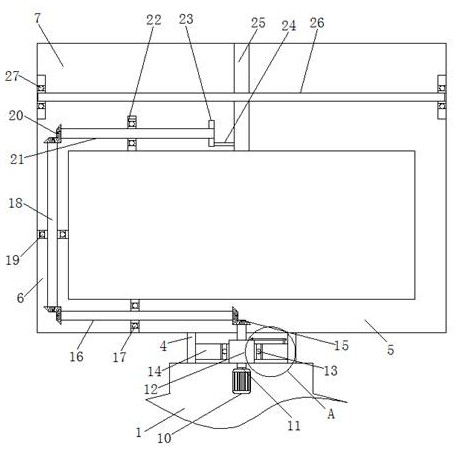

Heating device for blowing bottle preform with handle

The invention discloses a heating device for blowing a bottle preform with a handle. A partition is arranged at the middle parts of opposite heating areas of a heating box and a heating air channel separately; the positions of the partitions are adjacent to the tail end of the handle on the bottle preform, and shield plates are arranged on the partition at one side of the heating box at intervalsin the movement direction of the bottle preform; and the shield plates and the handle on the bottle preform rotate to be opposite to positions facing the heating areas. The bottle preform continuouslyrotates around an axis while moving along the heating areas in a heating area, and the bottle preform is shielded by the shield plates while rotating to be opposite to a heating component on the heating box, so that heat emitted by a heating lamp pipe cannot be directly transferred onto the handle. The heating device is extremely simple in structure, the heating areas are skillfully partitioned to adapt to blowing for the bottle preform, the handle is protected, and then a container bottle with a handle is smoothly produced by virtue of a PET bottle blowing machine, so that the production difficulty for the a PET container bottle with a handle is effectively reduced, the machining quality for the container bottle is improved, and the production efficiency for the container bottle is increased.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

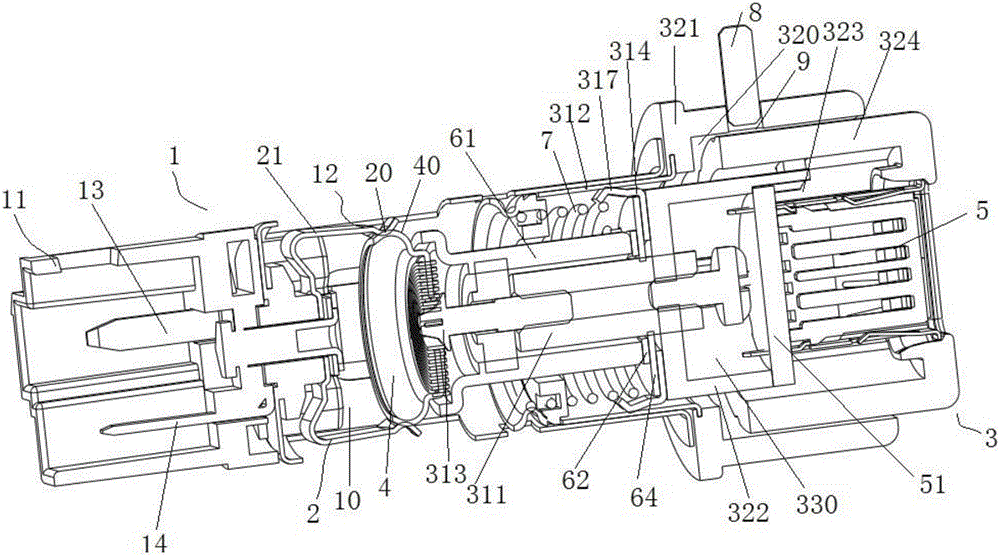

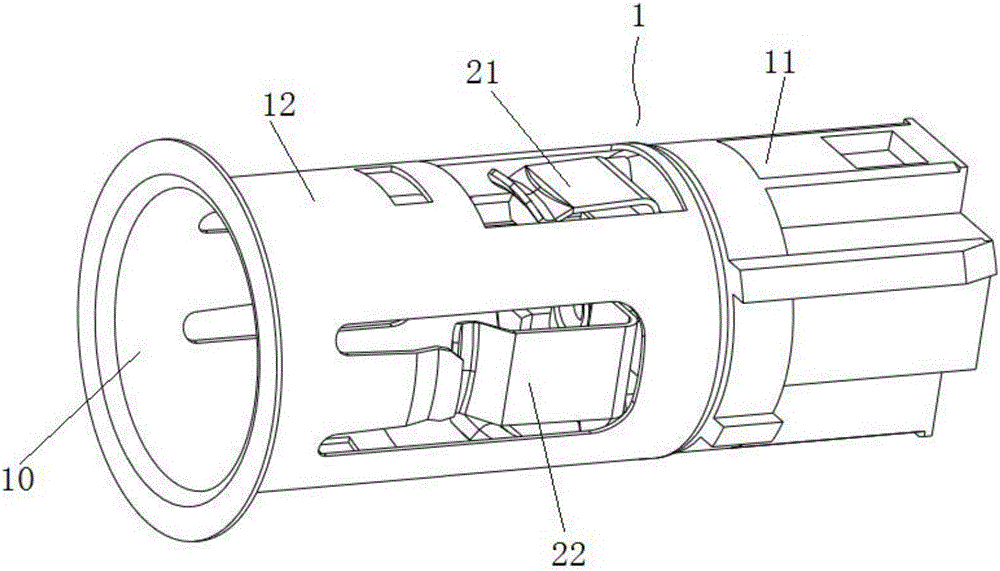

Cigarette lighter structure with charging function

ActiveCN106051818ANo collision damageEasy to useBatteries circuit arrangementsVehicle arrangementsElectricityElectrode

The invention provides a cigarette lighter structure with a charging function. The cigarette lighter structure comprises a base and a cigarette lighter, wherein a first electrode and a second electrode suitable for being electrically connected with a vehicle-mounted power supply are arranged on the base; an accommodating end is electrically connected with the first electrode; an electricity-taking sheet installed in an accommodating inner cavity of the accommodating end is electrically connected with the second electrode; the cigarette lighter is provided with a heating part, a charging part, a first electricity-taking structure and a second electricity-taking structure; one end of the first electricity-taking structure is electrically connected with a heating basin, the other end of the first electricity-taking structure is electrically connected with the accommodating end, one end of the second electricity-taking structure is electrically connected with the electricity-taking sheet, and the other end of the second electricity-taking structure is electrically connected with the accommodating end through a charging socket; when the heating part is located at a first plugging position, the electricity-taking sheet contacts with the heating basin, and at this moment, the cigarette lighter structure enters a cigarette lighting mode; and when the heating part is located at a second plugging position, the electricity-taking sheet contacts with the second electricity-taking structure, and at this moment, the cigarette lighter structure enters a charging mode. According to the cigarette lighter structure disclosed by the invention, the charging socket is integrated on the cigarette lighter; and the two working modes are provided, thus great convenience is brought to use of people.

Owner:浙江致威电子科技有限公司

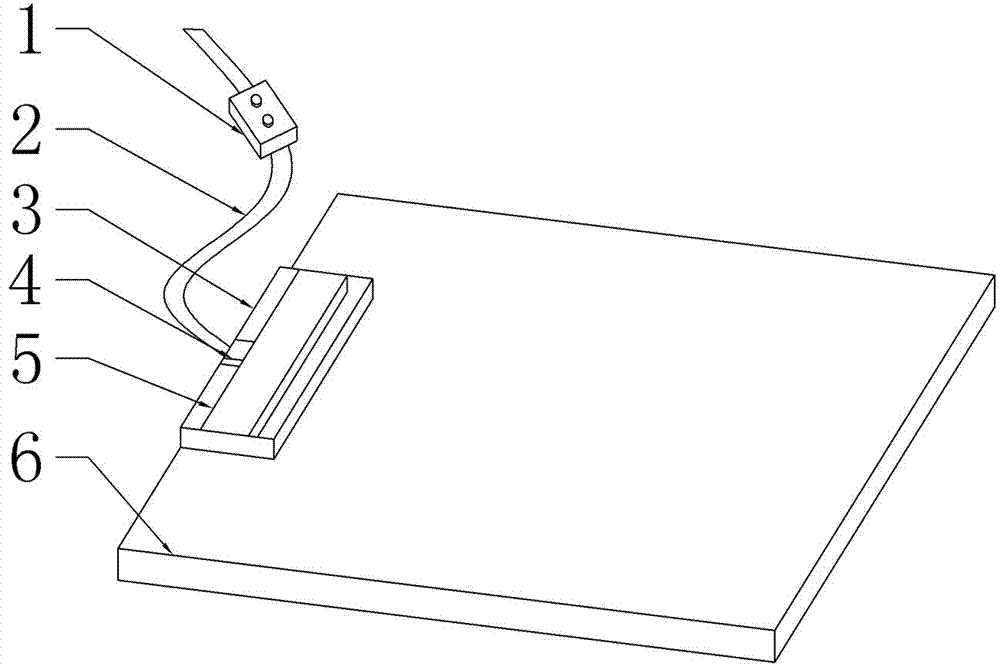

Stitching device for lens pad pasting

PendingCN109143419AImprove convenienceImprove placement efficiencyOptical elementsEngineeringContinuous operation

The invention discloses a stitching device for lens pad pasting. The stitching device is characterized by comprising a frame, a platform body, a stitching plug and a fixture body, wherein the fixturebody is provided with an accommodation cavity and a positioning block, the positioning block includes abutting positioning edges, when an outer side wall of the lens abuts each abutting positioning edge, the center of the lens can coincide with the center of the accommodation cavity, the stitching plug includes a plug body, a mounting base body and an elastic member, the plug body is slidably connected with the mounting base body, a limit structure used for limiting separation of the plug body and the mounting base body and the sliding stroke is mounted between the mounting base body and the plug body, the platform body is provided with a heat dissipation channel, and the heat dissipation channel includes an inlet end and an outlet end. The stitching device is advantaged in that the lens can be rapidly and accurately mounted in place, positioning accuracy requirements between upper and lower dies are effectively reduced, the effect of reducing manufacturing cost and use cost of the stitching device is achieved, and the shortcoming of continuous heating due to continuous operation of a workbench in the prior art can be overcome.

Owner:浙江宝乐维科技有限公司 +1

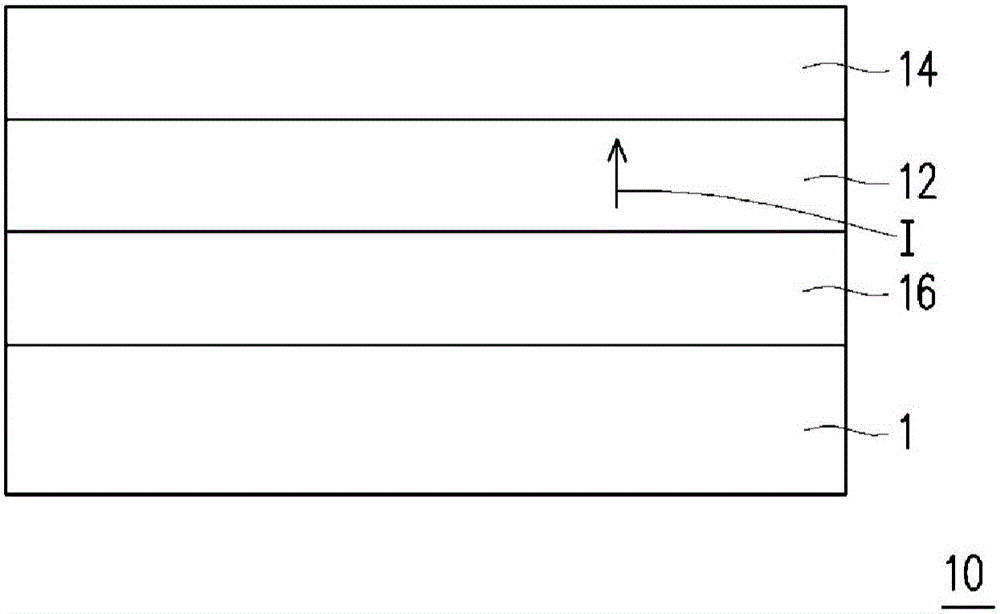

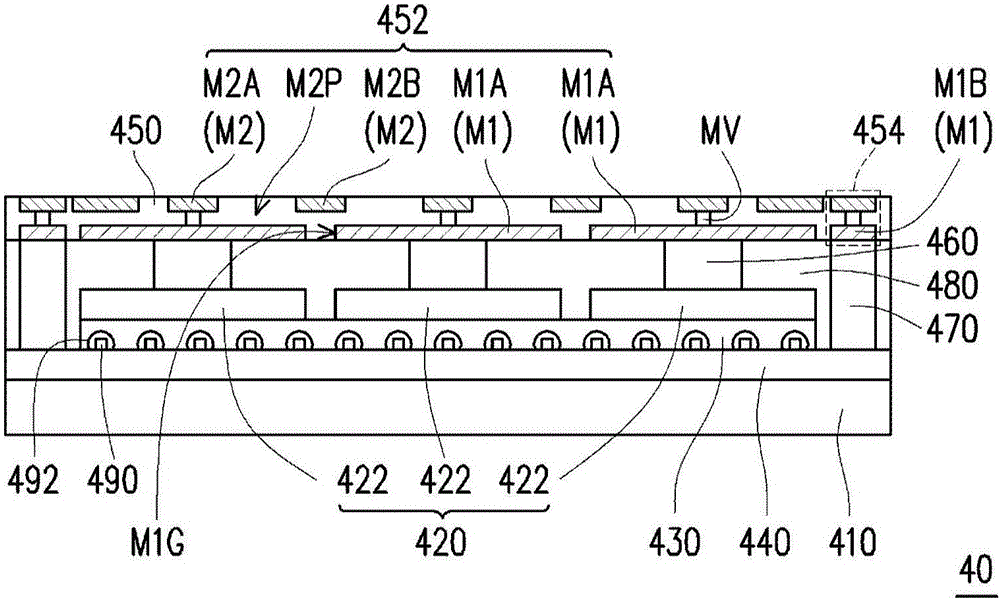

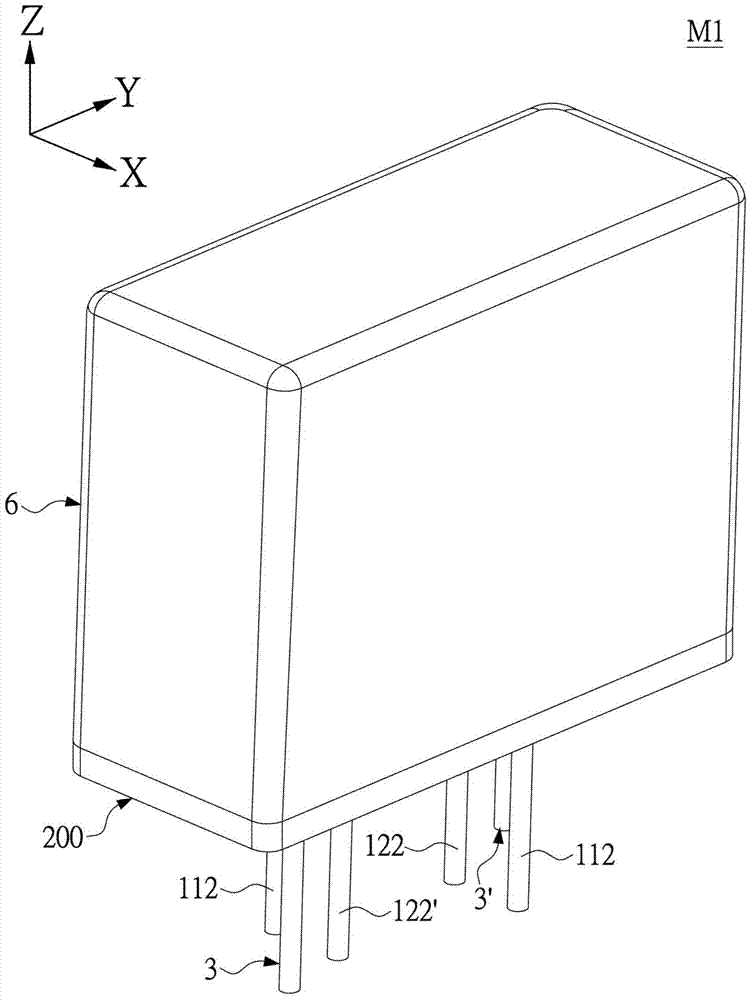

Organic light-emitting device

ActiveCN106505083AAvoid continuous heatingExtended service lifeSolid-state devicesSemiconductor devicesPhysicsElectrical and Electronics engineering

The invnetion provides an organic light-emitting device, which includes a first substrate, a light-emitting structure layer, a first electrode layer, a second electrode layer, a second substrate, first conduction members, a second conduction member and protection structures. The light-emitting structure layer is disposed on the first substrate. The first electrode layer is disposed on the light-emitting structure layer and includes pad-like patterns. The second electrode layer is disposed between the light-emitting structure layer and the first substrate. The second substrate is adhered on the first electrode layer and includes a first circuit and a second circuit. The first circuit includes a continuous pattern and contact portions. The first conduction members are connected between the first circuit and the first electrode layer. The second conduction member is connected between the second circuit and the second electrode layer. The protection structures respectively form open circuits or close circuits between the contact portions and the continuous pattern.

Owner:IND TECH RES INST

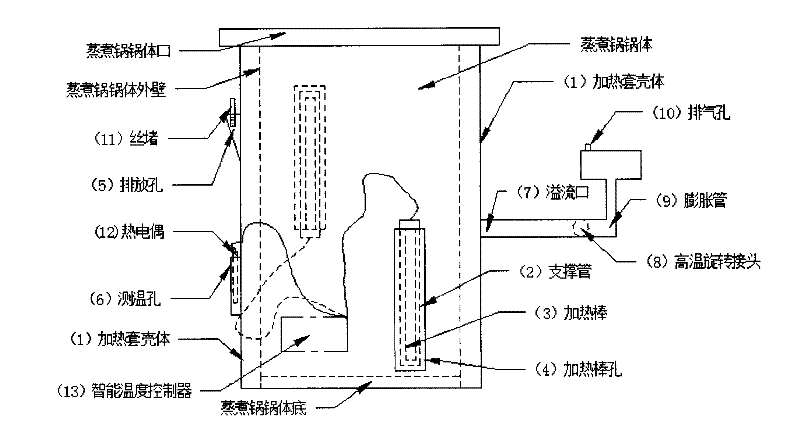

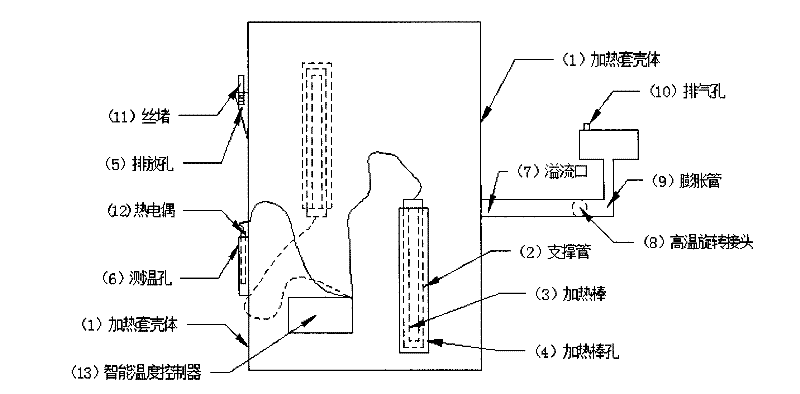

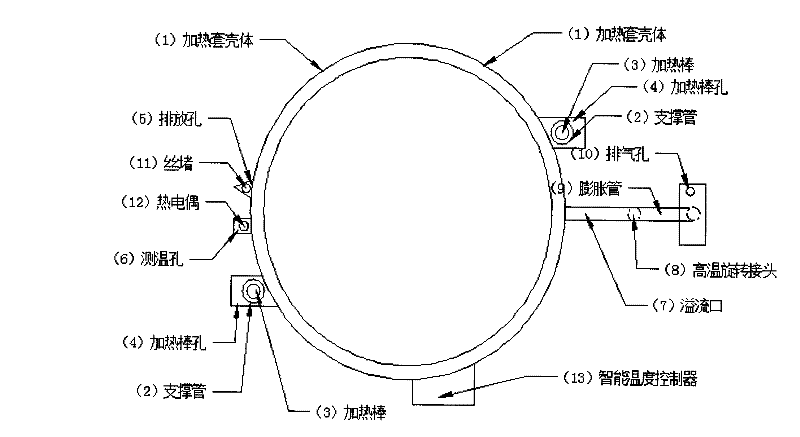

Heating device for cooking boiler

InactiveCN102517951AControllable heating temperatureHeating evenlyDigestersPaper material treatmentElectricityEngineering

The invention discloses a heating device for a cooking boiler. The device belongs to a heating jacket part of an experimental cooking boiler body, and is applied to heating the cooking boiler. A traditional heating manner for the cooking boiler comprises resistance trace heating and steam heating, and the temperature precision in the heating process is difficult to control. Electric heating is slow, thus a short circuit is easily caused; due to the high pressure, the steam heating process has hidden troubles and complex facilities are provided. The heating device heats up heat conduction liquid in a cavity which is formed between the heating device and the cooking boiler body, so that the cooking boiler body is heated up in an intermittent manner; the heat conduction liquid is integrally coated on the cooking boiler body, so that the cooking boiler is quickly, uniformly and stably heated up; the heating device is kept in the normal pressure the same as the atmosphere in the heating process, additional pressure is not applied, and external vapour is not accessed, thus the facilities are simple and the operation is safe; a rotary part is added to achieve the synchronous rotation of the cooking boiler and the heating device.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Pressure-trigger-type electric blanket

This proposal discloses a pressure-triggered electric heating blanket in the field of household daily necessities, including a blanket, a manual switch and a kneading cable-type electric heating element woven into the blanket in the shape of a snake; one end of the blanket is provided with a pressure trigger, and the The pressure trigger includes a boss, a pressure trigger switch and a movable switch arranged in the boss; one end of the manual switch is connected to an external power supply, the other end of the manual switch is movably connected to one end of the movable switch, and the movable switch The other end of the movable switch is connected to the pressure trigger switch, and the other end of the movable switch is also connected to the electric heating element; a spring is connected between the pressure trigger switch and the bottom of the boss. In this invention, when a person falls asleep, the head is just at the position of the boss, the gravity of the head and the state of no one falling asleep make the spring in the boss compress and stretch, so as to realize the connection and disconnection of the electric heating element and the power supply, and then control Heated and unheated blankets.

Owner:GUIZHOU LITIAN TECH DEV CO LTD

Vertical, automatic-cutoff and explosion-proof capacitor

ActiveCN108198688ASolve the phenomenon of high temperature explosionAvoid continuous heatingCapacitorsInsulation layerThermal expansion

The invention discloses a vertical, automatic-cutoff and explosion-proof capacitor. The vertical, automatic-cutoff and explosion-proof capacitor comprises an outer shell, a core, a sealant cover, a first lead and a second lead, wherein the sealant cover is matched with the outer shell and is used for packaging the core in the outer shell, the core is provided with a first electrode post and a second electrode post, a hole passage is arranged in the first electrode post, a conductive sleeve and an expansion sleeve are arranged in the hole passage, the conductive sleeve is made of a conductive material, the expansion sleeve is made of a thermal expansion material, an insulation layer wraps a peripheral surface of the first lead and is arranged between two ends of the first lead, one end of the first lead penetrates through the sealant cover, the first lead and the insulation layer extend into the hole passage, the conductive sleeve is arranged at one side of the insulation layer and sleeves the first lead, the expansion sleeve is arranged at one side, far away from the insulation layer, of the conductive sleeve and sleeves the first lead, and one end of the second lead penetrates through the sealant cover, extends into the outer shell and is fixed with the second electrode post. By the vertical, automatic-cutoff and explosion-proof capacitor, the phenomenon of high-temperature explosion of the capacitor is effectively solved, and the application safety of the capacitor is improved.

Owner:宁国市裕华电器有限公司

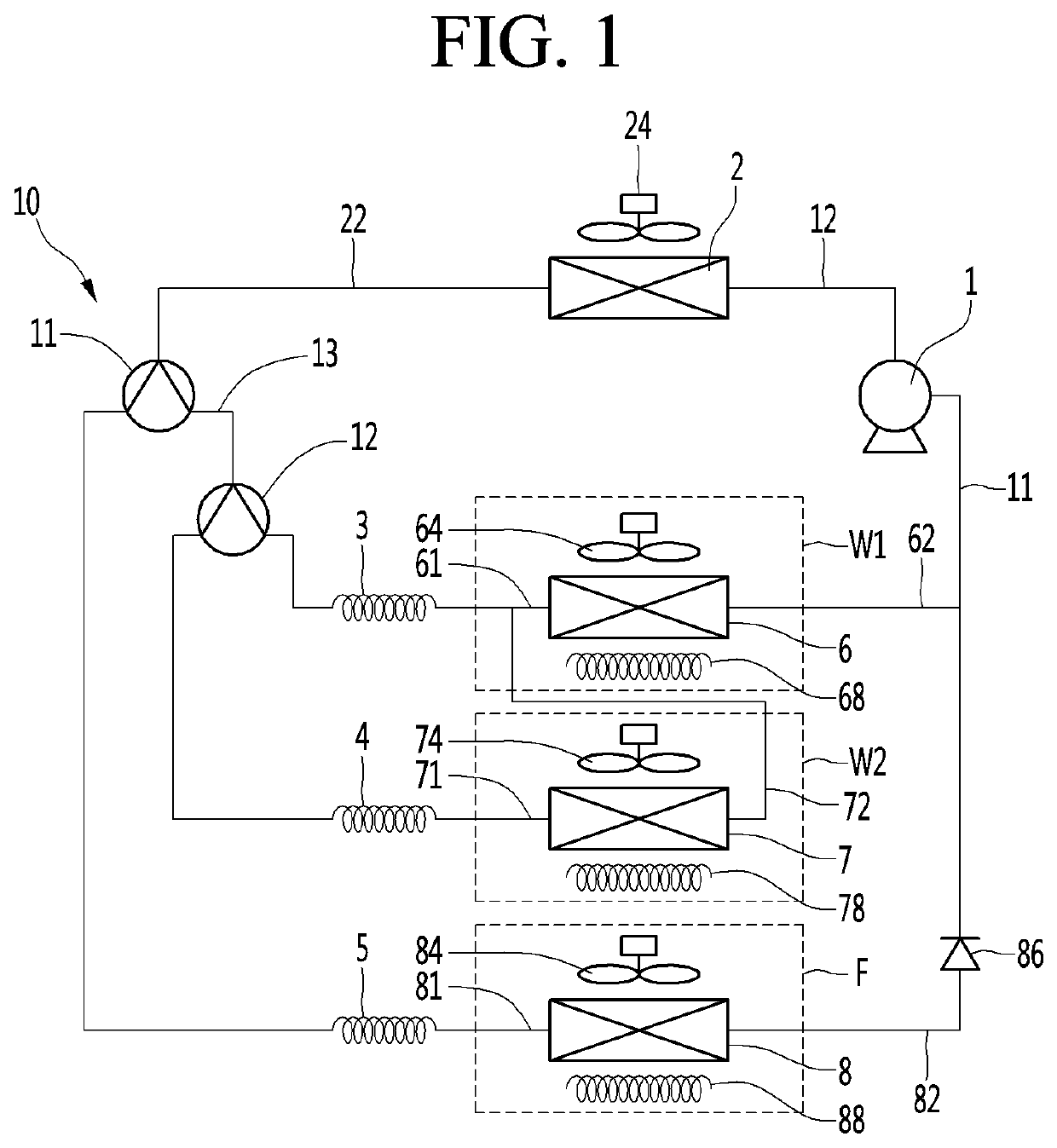

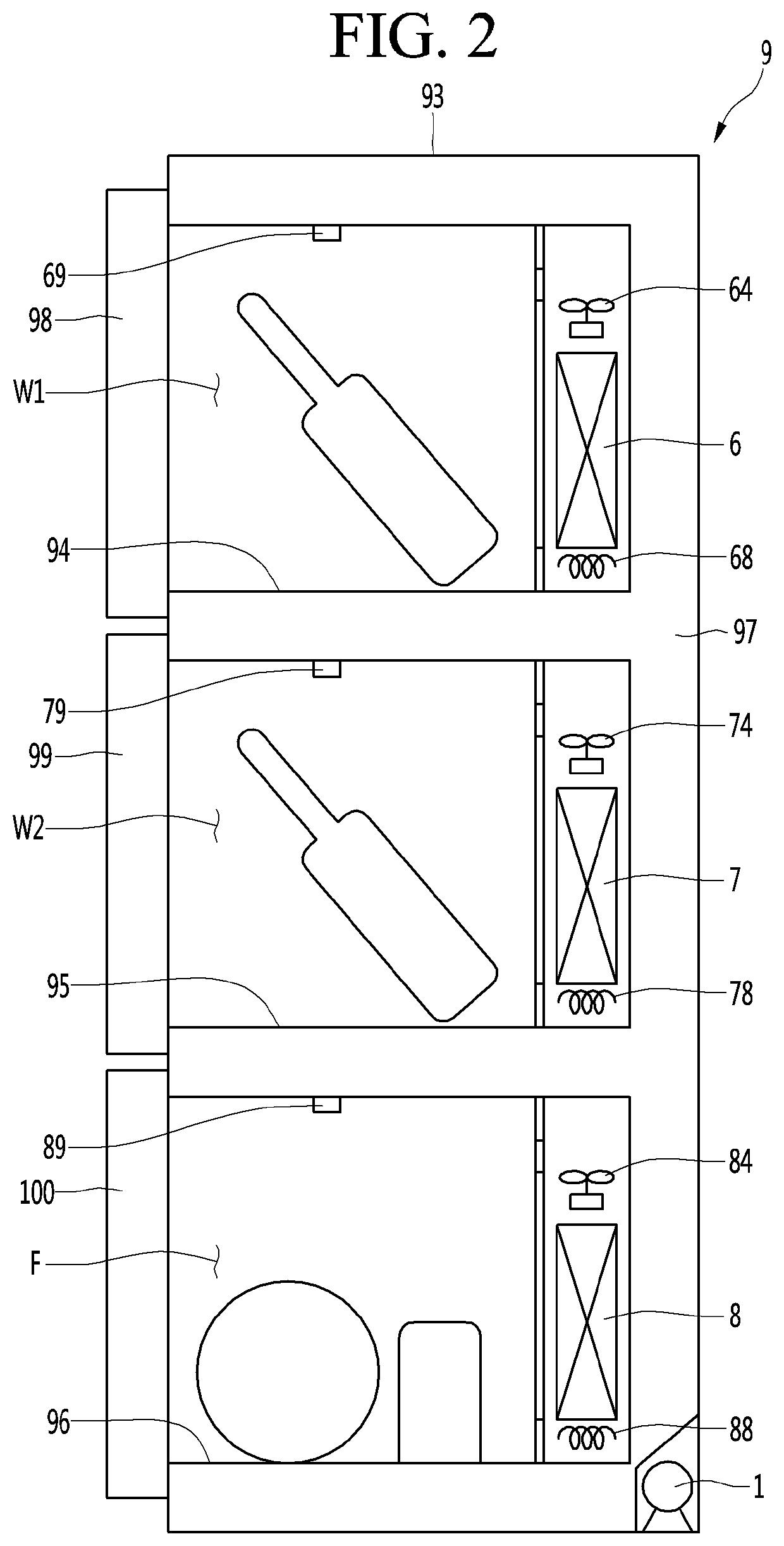

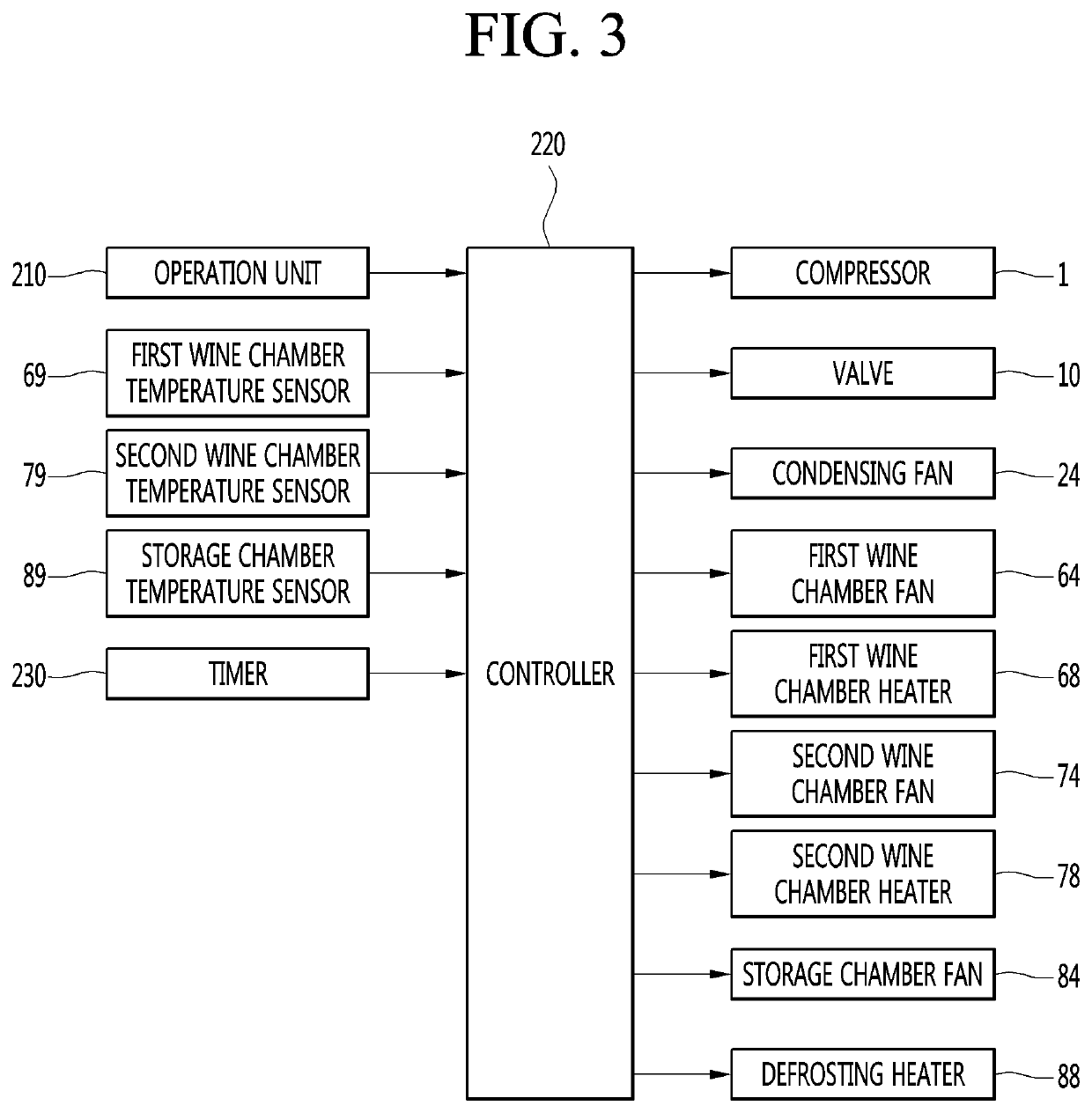

Refrigerator

ActiveUS10928126B2Preventing a wine chamber from being overheatedMinimize quality deteriorationMechanical apparatusDomestic refrigeratorsIceboxEngineering

A refrigerator includes a wine chamber, a wine chamber evaporator, a compressor, a wine chamber heater, a valve, a wine chamber temperature sensor, and a controller. The controller selectively performs a cooling mode and a heating mode.

Owner:LG ELECTRONICS INC

Fuel water heater utilizing water vapor generated in straw gasification to repeat reaction

The invention discloses a fuel water heater utilizing water vapor generated in straw gasification to repeat a reaction. The structure of the fuel water heater comprises a feeding funnel, a box door, an inductive oxygen extractor, a fuel water heater and a biomass reactor. Needles are very fine needles, and can centralize water vapor generated in the reaction in order to form water drops, a water collecting rod has an inclination to facilitate the dropping of the water drops, water drainage bumps cooperate with a flow guiding plate while centralizing the water drops in order to guide the waterdrops to a water drainage tank, and the water drops are added into the reaction through a gas discharging tube. Loss of water in the heating environment is easy, so the water vapor is fully used to make the reaction sufficient, the material is fully used to make straws reacted to generate methane, a pump slightly delivers a gas, a valve ball overcomes that a spring slides to the right, and the gasis jetted upwards by a nozzle frame to keep the temperature in a compression reactor, prevent continuous heating and accelerate the upward flowing of methane and the water vapor in order to prevent the too long stagnation of the methane generated in the reaction in the heating environment and avoid the heating and spontaneous combustion of the methane.

Owner:宿州市徽腾知识产权咨询有限公司

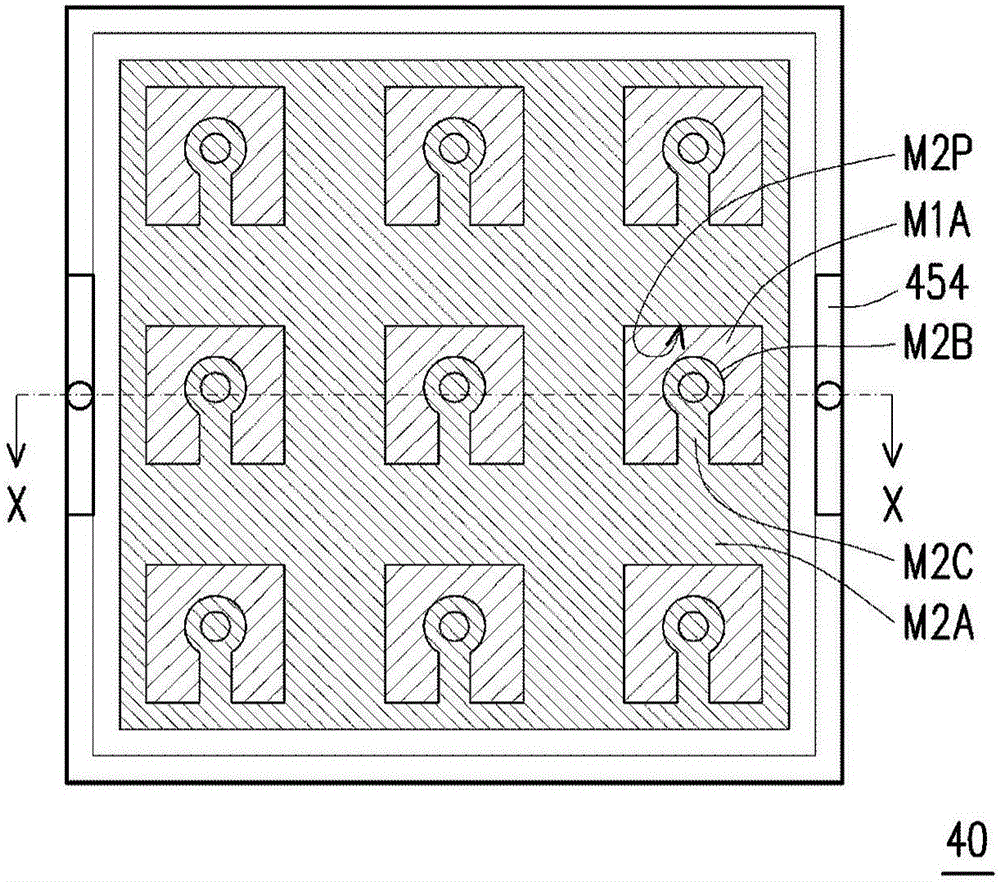

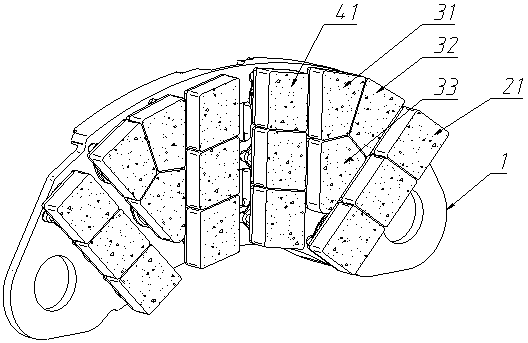

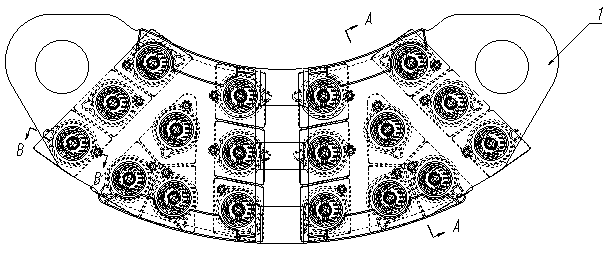

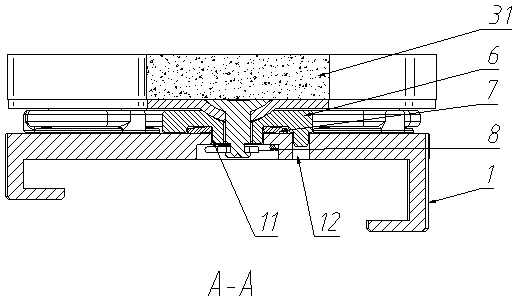

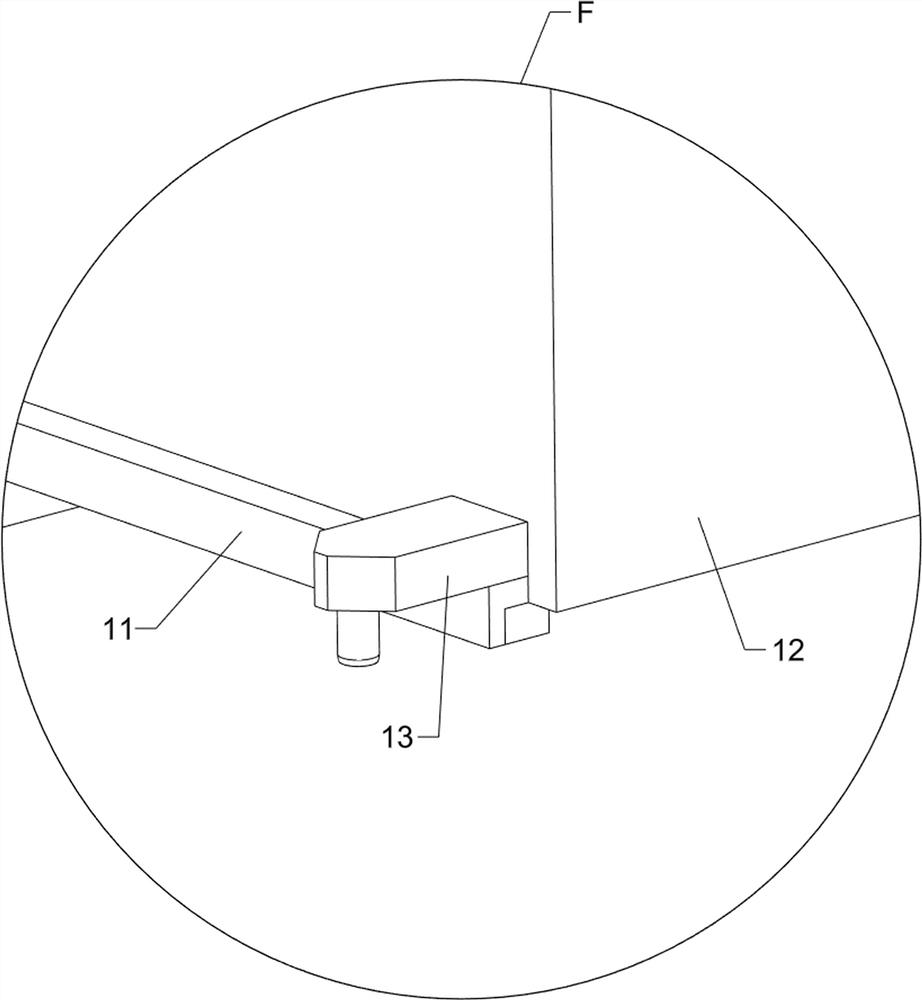

A powder metallurgy brake pad for a train

ActiveCN105840700BEliminate abnormal wearEliminate premature failureFriction liningActuatorsEngineeringBrake pad

A powder metallurgy brake pad for a train comprises a steel backing, a plurality of friction block units I, a plurality of friction block units II and a plurality of friction block units III; the friction block units I, the friction block units II and the friction block units III are mounted on the steel backing; the friction block units I are in a strip shape; the friction block units II are in a triangular shape; the friction block units III are in a strip shape; the friction block units II are arranged between the friction block units I and the friction block units III; and the friction block units I, the friction block units II and the friction block units III are arranged in a radiation shape in the radial direction of the steel backing. Abrasive dust cannot be stored up in the brake pad, and even if the brake pad is used in the cold environment, the phenomenon that due to ice blocks formed by condensing of the abrasive dust, rain and snow, a brake disc is scratched, and normal braking is affected cannot appear.

Owner:HUNAN DINGMAO TECH CO LTD

Integrated surge-absorbing device

InactiveCN104716627AAvoid continuous heatingTo achieve the effect of double protectionSpark gap detailsEmergency protective arrangements for automatic disconnectionMetallic materialsAlloy

An integrated surge-absorbing device includes a surge-absorbing unit and a first external lead structure. The surge-absorbing unit includes a plurality of varistors stacked with together and a first metal lead, which is disposed between two of the neighboring varistors and has a first end protruding toward a first side edge of the varistors. A first end of the conductive rod of the first external lead structure is connecting to the first end of the first lead through a first low-melting-point metallic material. The first external lead structure applies a first resilient force to the first conductive rod.

Owner:POWERTECH INDAL

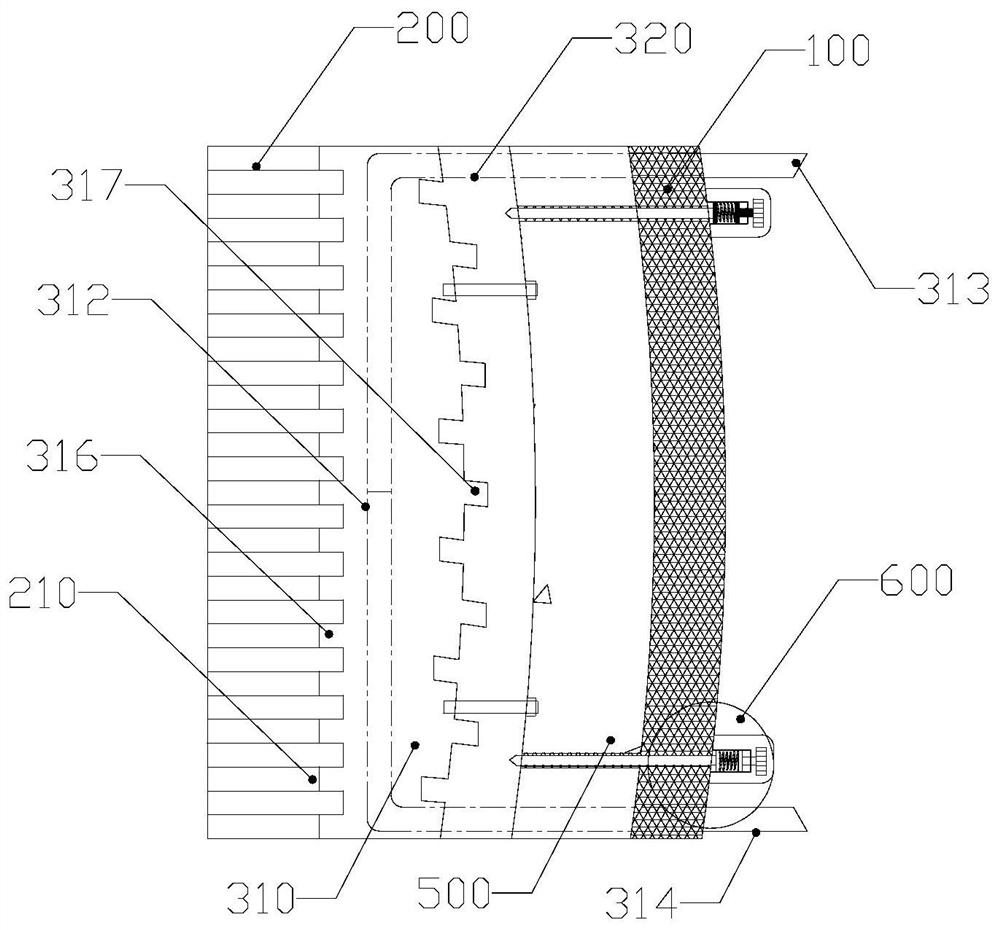

Cooling device for transition area of smelting reduction furnace

PendingCN113390266AReduce the temperaturePrevent peelingCharge treatment typeFurnace coolingSurface coolingCold side

The invention provides a cooling device for a transition area of a smelting reduction furnace. The cooling device is set to be of a layered structure and comprises a hot surface cooling layer and a cold surface protection layer. The hot surface cooling layer is attached to a refractory layer, and comprises a first metal shell and a cooling pipeline arranged inside the first metal shell, wherein the cooling pipeline penetrates out of the first metal shell and extends to form a liquid inlet pipe and a liquid outlet pipe. The cold surface protection layer is attached to the hot surface cooling layer, and the cold surface protection layer and the refractory layer jointly clamp the hot surface cooling layer. The cold surface protection layer comprises a second metal shell, a liquid inlet through hole and a liquid outlet through hole, wherein the liquid inlet through hole and the liquid outlet through hole penetrate through the second metal shell, the liquid inlet pipe penetrates through the liquid inlet through hole, and the liquid outlet pipe penetrates through the liquid outlet through hole. The cooling device is arranged in the transition area of the smelting reduction furnace, and therefore the cooling device can reduce the surface temperature of the refractory layer, a stable slag iron solidification layer can be formed on the surface of the refractory layer in the transition area to protect the refractory layer, and the service life of the smelting reduction furnace is prolonged.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

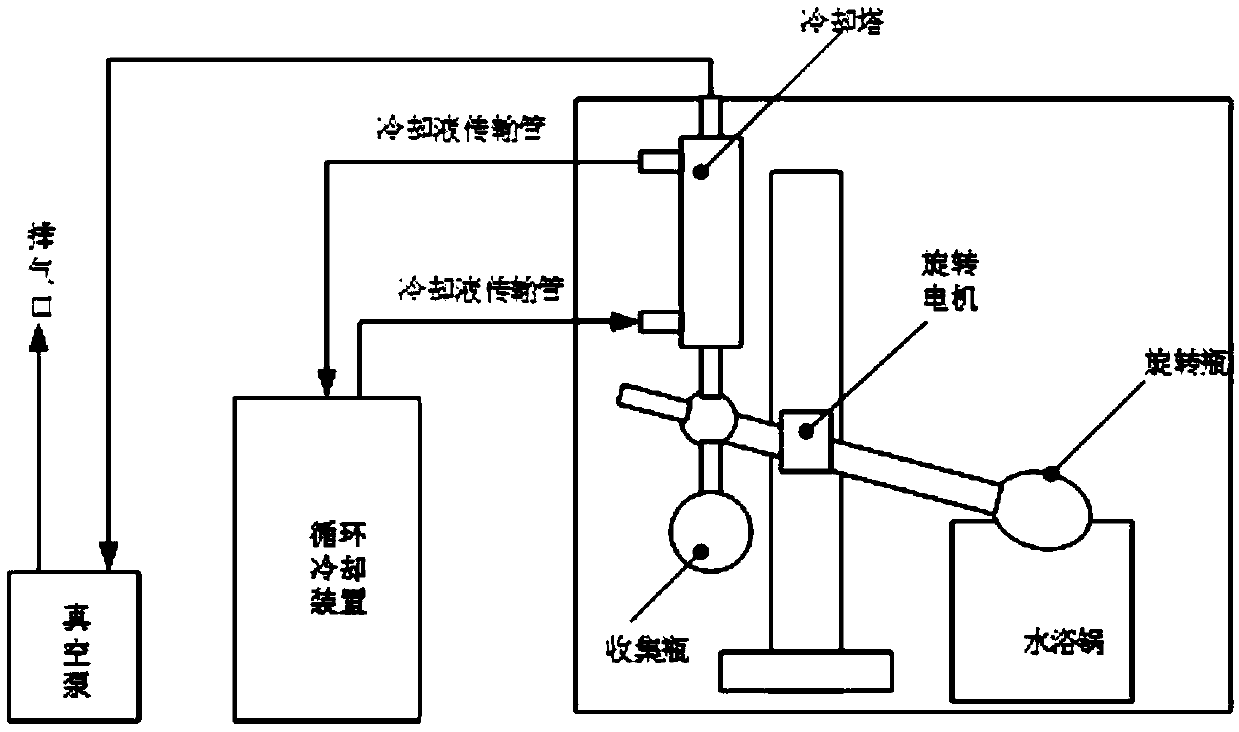

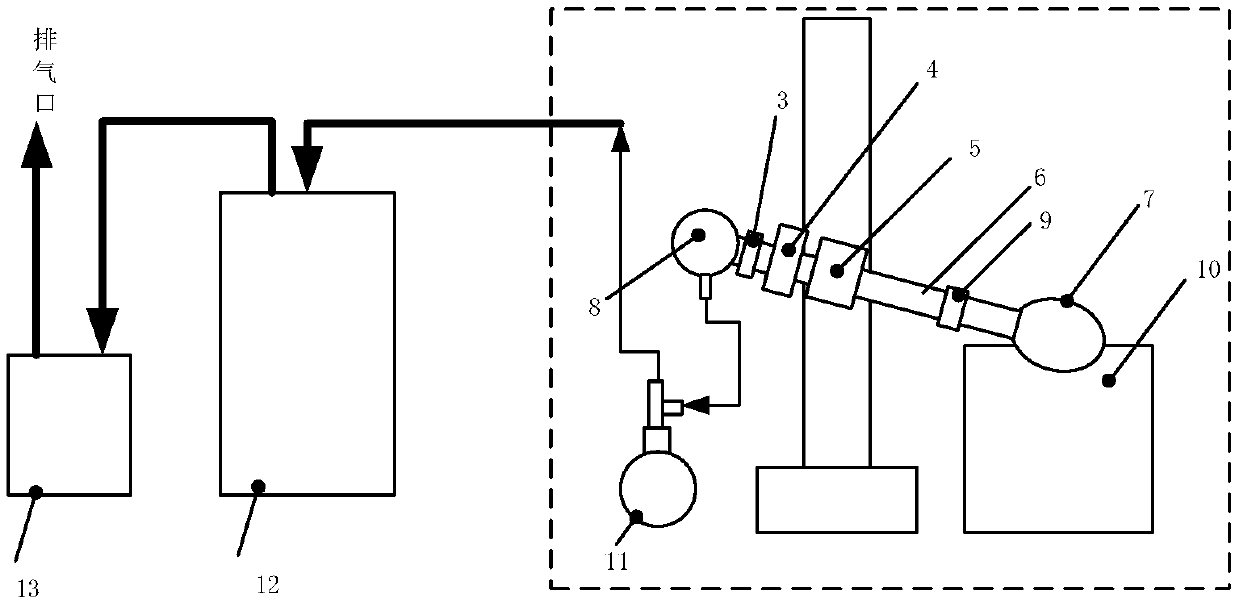

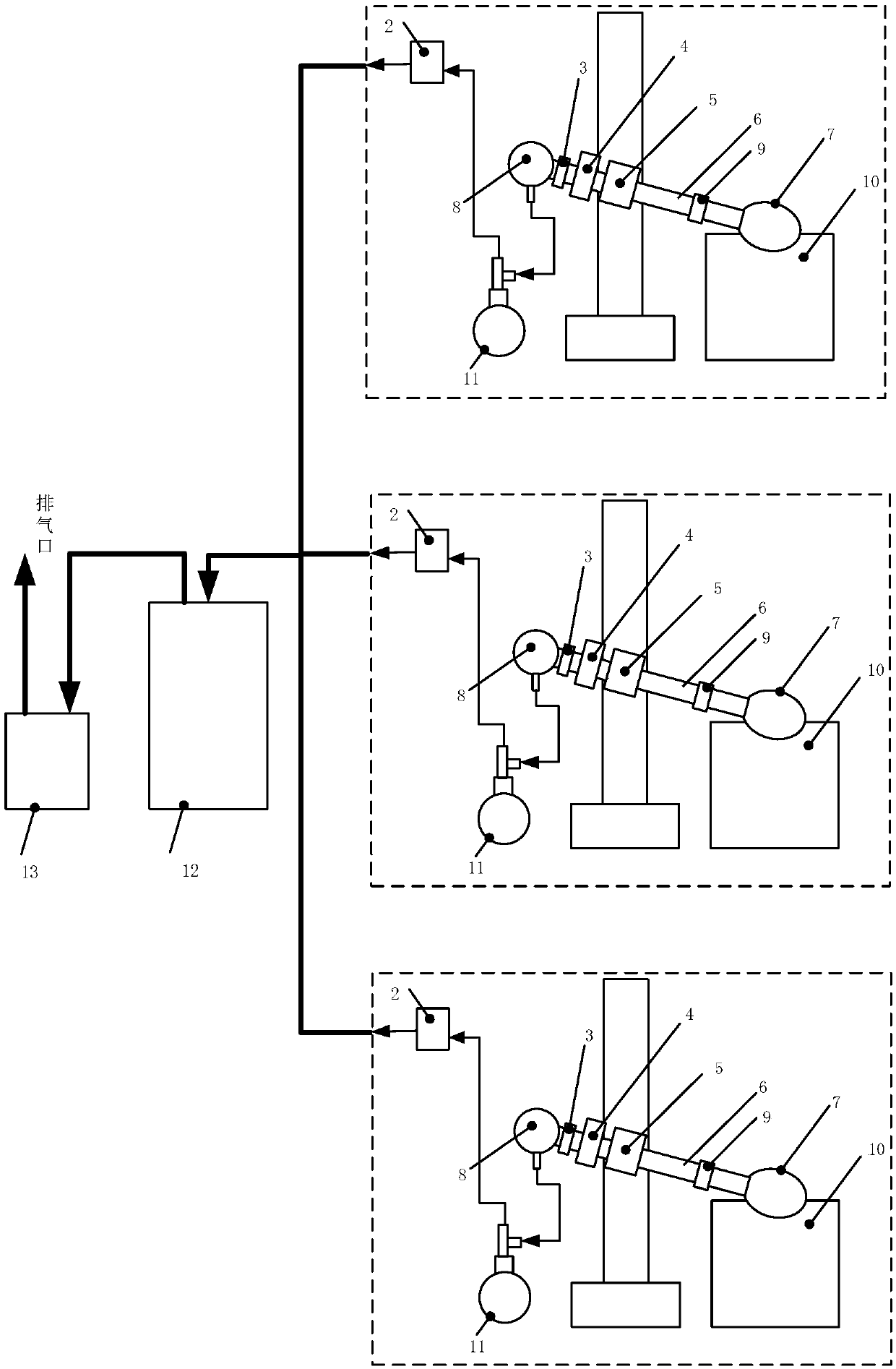

Rotary evaporation system based on cold trap

PendingCN109529391AImprove liquefaction recovery efficiencyNormal work does not affectSolidificationLiquefactionCooling towerRotary evaporator

The invention belongs to the technical field of analytical tests, and particularly relates to a rotary evaporation system. The rotary evaporation system based on the cold trap comprises a rotary evaporator, a vacuum pump and the cold trap; the rotary evaporator comprises a heating device, a rotary motor, a rotary bottle, a buffer bottle and a hollow bottle; the output end of the rotary motor is connected to a rotary hollow shaft; one end of the rotary hollow shaft is connected to the rotary bottle through a second connector; the other end of the rotary hollow shaft is inserted into a sealing connector; the hollow bottle is connected to the sealing connector, the buffer bottle and a gas inlet of the cold trap; a gas outlet of the cold trap is connected to a gas inlet of the vacuum pump; a gas outlet of the vacuum pump is communicated with the atmosphere; the rotary bottle is arranged in the heating device; and a switch valve communicated with the atmosphere is further arranged at the position of the hollow bottle. According to the system, the cold trap is adopted to replace a cooling circulation device, solvent steam is introduced into the cold trap and then is liquefied and collected, a cooling tower and cooling fluid are not required to be transmitted, and therefore the liquefaction recovery efficiency of the solvent steam is improved.

Owner:北京澳维仪器有限公司

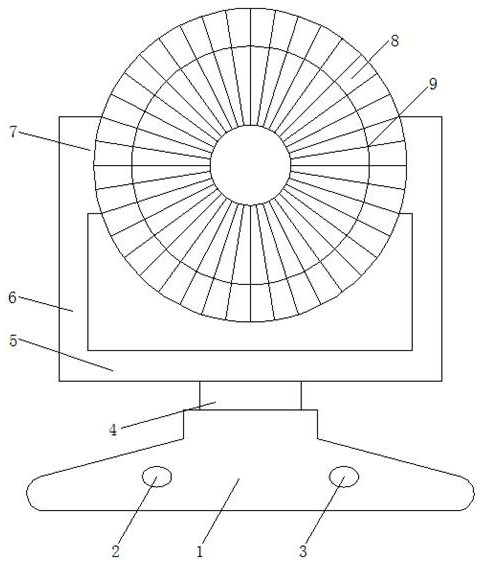

Essential oil electric heating device capable of rotating in multiple directions, preventing objects from falling and continuously heating

InactiveCN112824763AAvoid continuous heatingTo achieve the effect of shaking the head up and downLighting and heating apparatusElectric heating systemCrankElectric machine

The invention relates to the technical field of heating devices, and discloses an essential oil electric heating device capable of rotating in multiple directions, preventing objects from falling and continuously heating. The essential oil electric heating device comprises a base, wherein a motor is arranged in the base, the exterior of a first rotating rod is connected with a first rotating disc, the exterior of a first bearing is connected with a second rotating disc, the top of the first rotating rod is connected with a first bevel gear, the right end of a second rotating rod is connected with the second rotating disc, the right end of a first connecting rod is connected with a fourth rotating disc, the top of the first rotating disc is connected with a second connecting rod, and the interior of a crank is connected with a third connecting rod. According to the essential oil electric heating device capable of rotating in multiple directions, preventing objects from falling and continuously heating, through cooperative use of the first rotating disc, the second rotating disc, the second connecting rod, the third connecting rod and the crank, the effect that the electric heating device can rotate leftwards and rightwards is achieved, one fixed part can be prevented from being continuously heated, and through cooperative use of the third rotating disc, the fourth rotating disc and the first connecting rod, the effect that the electric heating device shakes up and down is achieved, when a falling object exists, the falling object can be shaken off, and danger is avoided.

Owner:HUNAN UNIV OF TECH

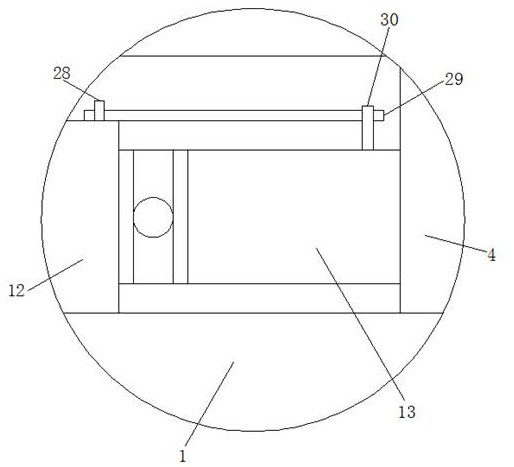

Energy-saving heat-preservation water storage equipment of heating system

The invention relates to water storage equipment, in particular to energy-saving heat-preservation water storage equipment of a heating system. The energy-saving heat-preservation water storage equipment for the heating system which eliminates potential safety hazards, enhances comfortable use feeling, is low in power consumption, can meet the green and environment-friendly use requirement, and meets the requirement on intelligent control of the equipment is provided. According to the technical solution, the energy-saving heat-preservation water storage equipment of the heating system comprises a one-way water outlet arranged on one part of a water storage tank, an one-way water inlet arranged on one part of the water storage tank, a U-shaped connecting plate arranged at the top of the water storage tank, a fixing plate arranged at one part of the water storage tank, a control assembly arranged between the water storage tank and the U-shaped connecting plate, and a heating assembly arranged at one part of the water storage tank. Through the action of a reset assembly, the equipment can be easily started through simple operation, and cold water is heated.

Owner:高涛则

A fuel water heater using straw gasification water vapor repeated reaction

The invention discloses a fuel water heater utilizing water vapor generated in straw gasification to repeat a reaction. The structure of the fuel water heater comprises a feeding funnel, a box door, an inductive oxygen extractor, a fuel water heater and a biomass reactor. Needles are very fine needles, and can centralize water vapor generated in the reaction in order to form water drops, a water collecting rod has an inclination to facilitate the dropping of the water drops, water drainage bumps cooperate with a flow guiding plate while centralizing the water drops in order to guide the waterdrops to a water drainage tank, and the water drops are added into the reaction through a gas discharging tube. Loss of water in the heating environment is easy, so the water vapor is fully used to make the reaction sufficient, the material is fully used to make straws reacted to generate methane, a pump slightly delivers a gas, a valve ball overcomes that a spring slides to the right, and the gasis jetted upwards by a nozzle frame to keep the temperature in a compression reactor, prevent continuous heating and accelerate the upward flowing of methane and the water vapor in order to prevent the too long stagnation of the methane generated in the reaction in the heating environment and avoid the heating and spontaneous combustion of the methane.

Owner:宿州市徽腾知识产权咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com