Heating device for cooking boiler

A technology of heating device and cooking pot, which is applied in the direction of cooking device, textile and paper making, fiber raw material processing, etc. It can solve the problems of cumbersome heating device, dangerous operation, uniform cooking, etc., achieve uniform heating process, prevent continuous heating, and heat temperature easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

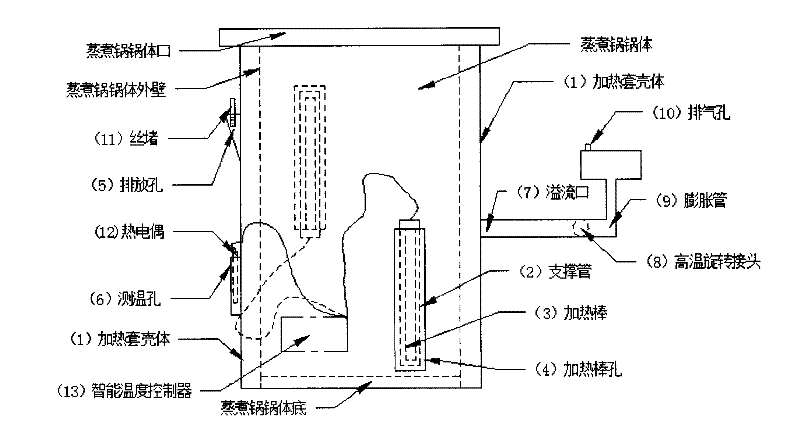

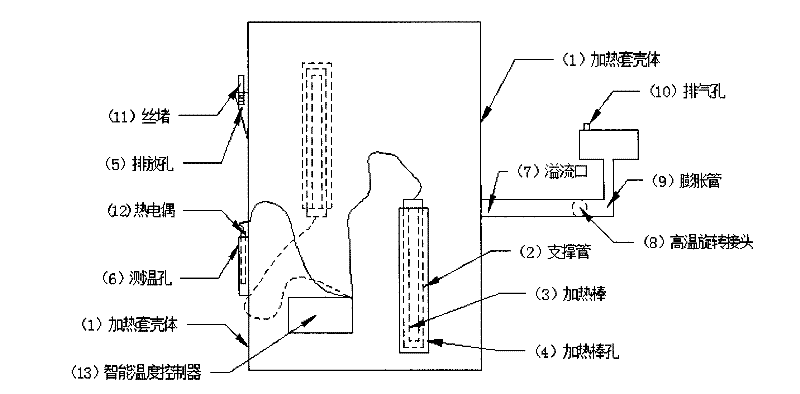

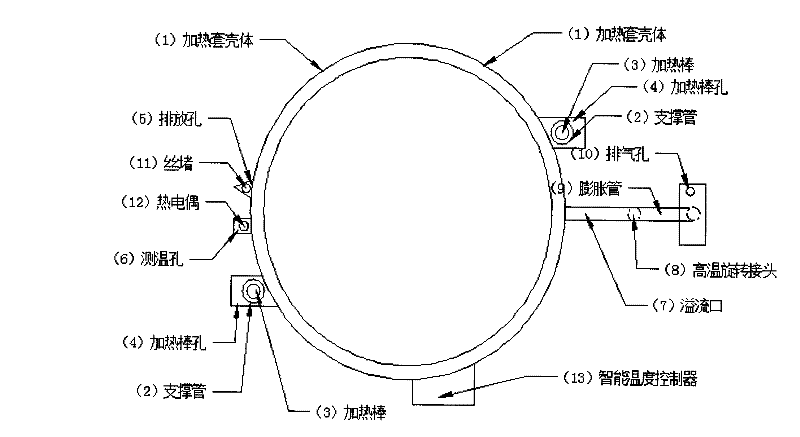

[0022] The device of the invention is suitable for heating test cooking pots in pulp and paper industry, chemical fiber industry, textile industry and chemical industry. The present invention will be further described below in conjunction with the embodiment shown in the accompanying drawings:

[0023] figure 1 It is a diagram of the cooperation of the device of the present invention with the body of the cooking pot. First install and fix the support pipe (2) in the heating jacket housing (1) of the device of the present invention, the pot body of the cooking pot passes through the middle of the heating jacket housing (1) on which the support pipe (2) has been installed, and heat The two ends of the casing (1) are welded together with the body of the cooking pot, and the heating casing and the outer wall of the cooking pot form a cavity, and a heating rod is installed at the heating rod hole (4) on the heating casing (3) At the same time, cover the plug of the discharge hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com