Patents

Literature

32 results about "Trace heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric heat tracing, heat tape or surface heating, is a system used to maintain or raise the temperature of pipes and vessels using heat tracing cables. Trace heating takes the form of an electrical heating element run in physical contact along the length of a pipe. The pipe is usually covered with thermal insulation to retain heat losses from the pipe. Heat generated by the element then maintains the temperature of the pipe. Trace heating may be used to protect pipes from freezing, to maintain a constant flow temperature in hot water systems, or to maintain process temperatures for piping that must transport substances that solidify at ambient temperatures. Electric trace heating cables are an alternative to steam trace heating where steam is unavailable or unwanted.

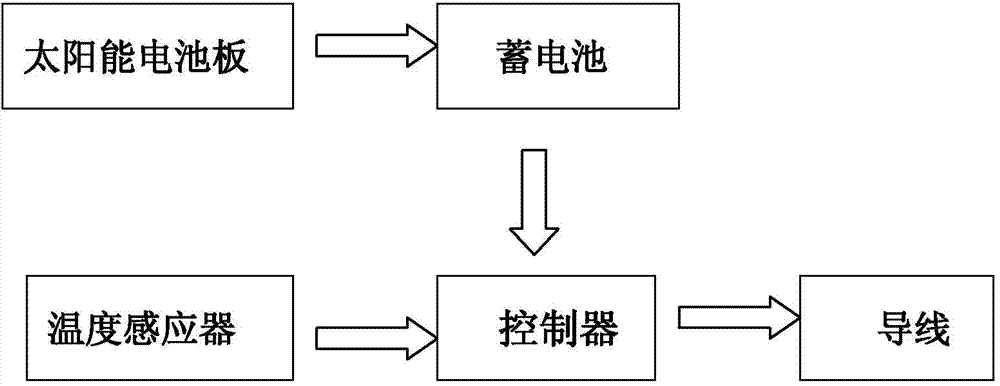

Anti-freezing electric tracing heating system for solar pipeline

InactiveCN103759440ASolve freezing problemsGuaranteed supplySolar heat devicesPipe heating/coolingAnti freezingSolar water

The invention discloses an anti-freezing electric tracing heating system for a solar pipeline. The anti-freezing electric tracing heating system for the solar pipeline comprises an electric tracing heating band core which is wound on a solar water supply pipeline, wherein the electric tracing heating band core comprises a lead which is embedded in an electric tracing heating layer, and the electric tracing heating layer is made of PTC material and is located between a cover layer and an inner layer; a temperature sensor is packaged in an insulating layer of the water supply pipeline of a water heater and is connected with the lead; the temperature sensor sends temperature signals to a controller through wires; the lead is connected with a rechargeable battery through the controller; the rechargeable battery is connected with a solar panel; the controller transmits the electric energy of the rechargeable battery to the lead through wires. The anti-freezing electric tracing heating system for the solar pipeline enables the electric tracing heating band to generate heat by means of the power generation of the solar panel, and accordingly the pipeline freezing of the solar water heater is avoided, and the freezing and the fracture of the solar water supply pipeline are avoided effectively.

Owner:ANHUI PRINTING MECHANICAL & ELECTRICAL

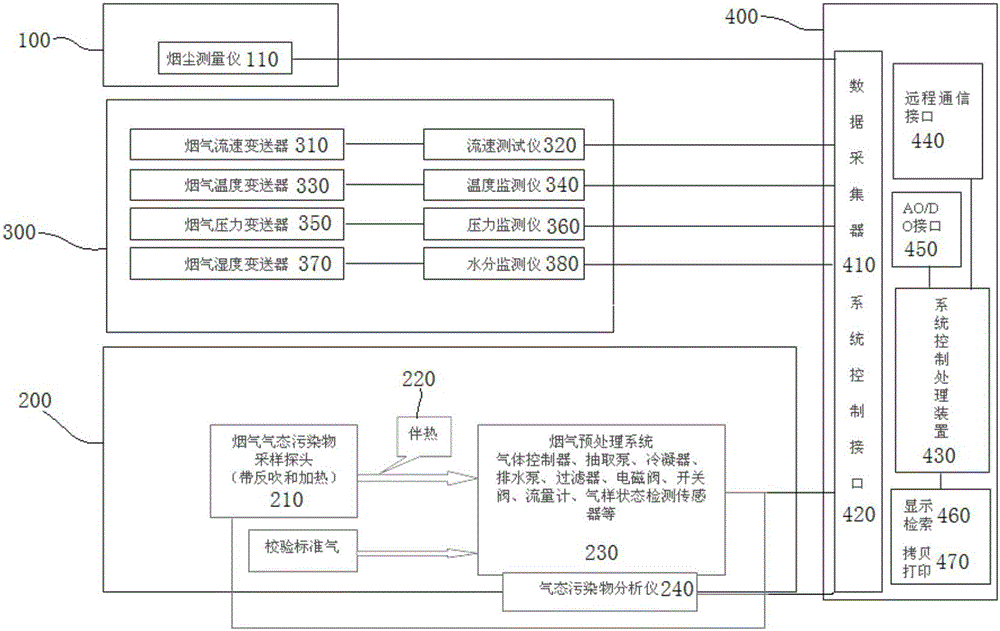

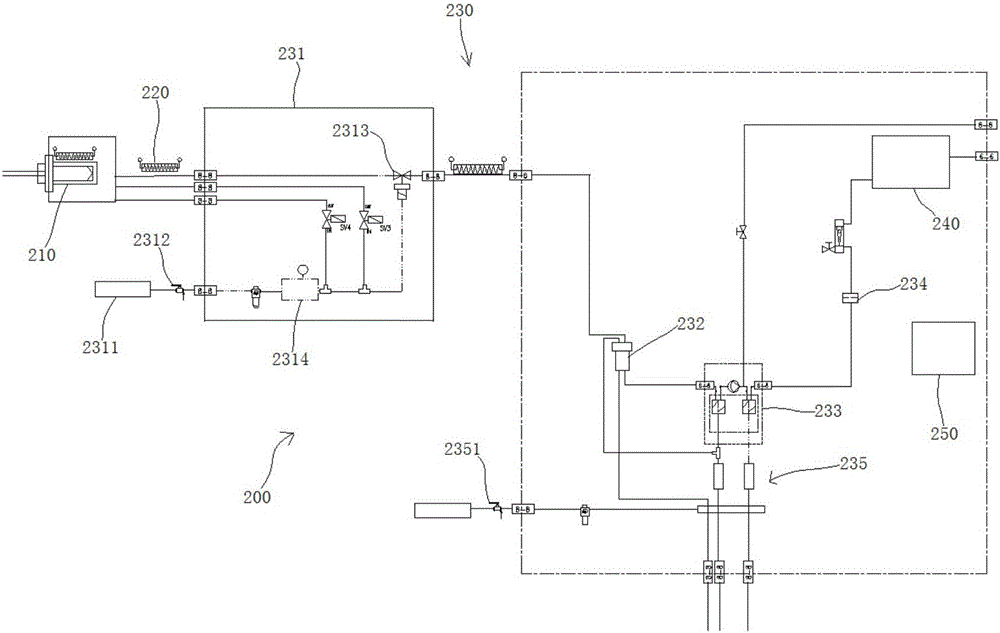

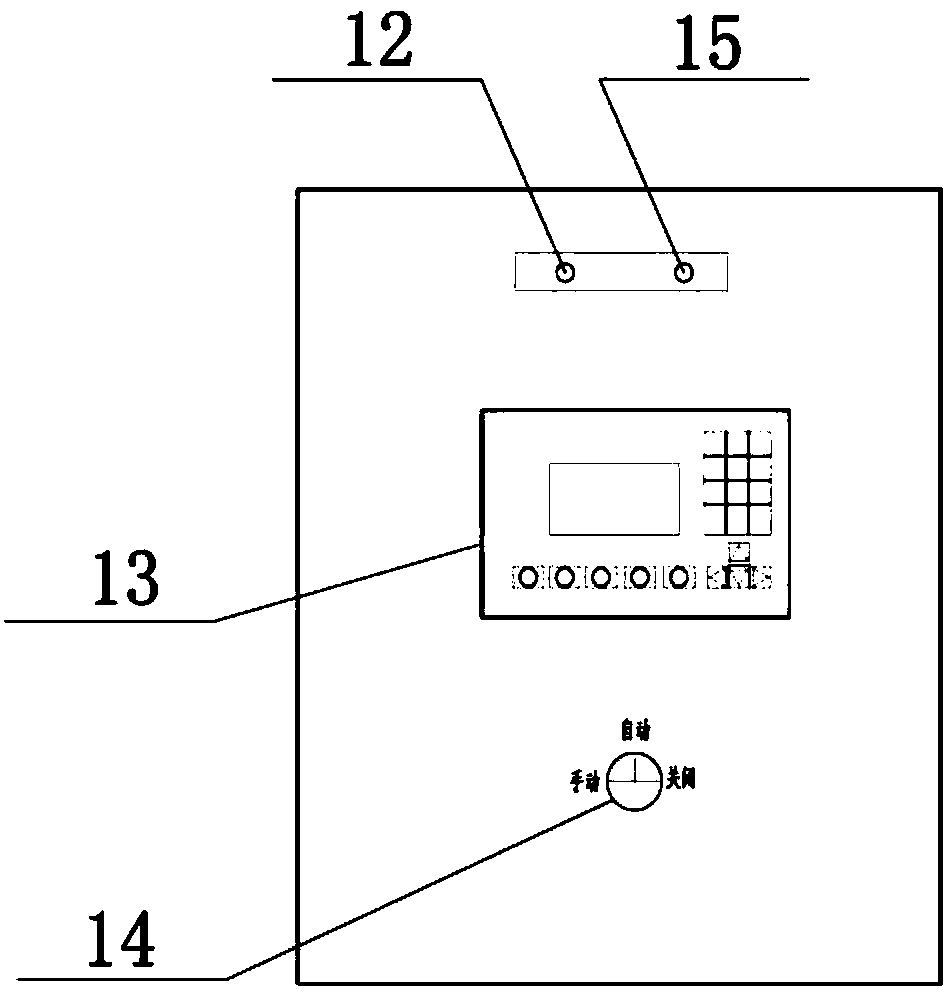

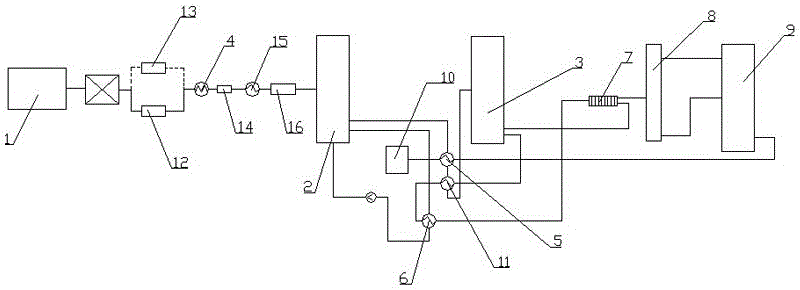

Continuous online emission monitoring system

PendingCN106840264AImpact monitoring concentrationWith remote fault diagnosisMeasurement devicesWater filterData acquisition

The invention discloses a continuous online emission monitoring system which comprises the components of a solid particle continuous monitoring subsystem, a gaseous pollutant continuous monitoring subsystem and an emission parameter continuous monitoring subsystem, wherein the solid particle continuous monitoring subsystem, the gaseous pollutant continuous monitoring subsystem and the emission parameter continuous monitoring subsystem are mounted in a chimney or a flue channel. The solid particle continuous monitoring subsystem, the gaseous pollutant continuous monitoring subsystem and the emission parameter continuous monitoring subsystem are connected with a data processing and remote communication system. The gaseous pollutant continuous monitoring subsystem comprises a sampling probe with a backflow function and a heating function, a trace heating tape, an emission preprocessing system and an infrared gas analyzer, wherein the sampling probe, the trace heating tape, the emission preprocessing system and the infrared gas analyzer are successively connected. Functions such as gas sampling, backflowing, dust filtering and water filtering in the gaseous pollutant continuous monitoring subsystem are controlled through a PLC control system. According to the continuous online emission monitoring system, through monitoring the solid particle, the gaseous pollutant and the emission parameter, by means of remote communication and a data acquisition unit, the continuous online emission monitoring system realizes advantages of remote fault diagnosis, strong software function, high flexibility in use, etc.

Owner:上海宝英光电科技有限公司

Electric tracing heat preservation device for cold region underground pipeline device

ActiveCN103867846APlay the role of thermal protectionGuaranteed safe operationThermal insulationPipe heating/coolingElectricityElectrical resistance and conductance

The invention discloses an electric tracing heat preservation device for a cold region underground pipeline device. The electric tracing heat preservation device comprises electric tracing heating cables, a heat preservation protective layer and a temperature monitoring system. The electric tracing heating cables are laid along a pipeline, the heat preservation protective layer is arranged on the outer side of the pipeline, the temperature monitoring system is connected with the electric tracing heating cables, and temperature sensors of the temperature monitoring system are tightly attached to the outer wall of the pipeline. The heat preservation protective layer is composed of a composite silicate heat insulating layer, a glass cloth composite aluminum foil damp-proof layer and an aluminum alloy sheet protective layer. The temperature monitoring system comprises the temperature sensors and a comprehensive control device. The temperature sensors are connected with the comprehensive control device through connection terminals. Thermistors serve as the temperature sensors and are tightly attached to the outer wall of the pipeline, and each electric tracing heating cable is matched with two temperature sensors. The temperature monitoring system achieves remote monitoring, any failure of the electric tracing heat preservation device is found in time, and safety running of the cold region underground pipeline device is ensured.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Electric trace heating band for melting snow and ice on road

InactiveCN106677004AImprove thermal conductivityAvoid lossPaving detailsThermal insulationHeat losses

The invention discloses an electric trace heating band for melting snow and ice on road. The electric trace heating band comprises a heating cable core, and an outer peripheral face of the heating cable core comprises a first external surface and a second external surface, wherein the first external surface and the second external surface are oppositely arranged at double sides of an axial lead of a heating cable core, the first external surface is covered by a heat conduction layer, and the heat conduction layer is prepared by a heat conduction material; the second external surface is covered by a thermal insulation layer, and the thermal insulation layer is prepared by a heat conduction material; the heating cable core is externally extruded by a sheath layer for coating the heat conduction layer and the thermal insulation layer. The heat conduction layer has heat conduction effects, in order to accelerate heat exchange speed; the heat insulation effects of the thermal insulation layer are utilized, so that heat loss is blocked, heat generated by the heating cable core is transmitted to a product to be heated from the heat conduction layer direction to the largest extent, and heat loss is effectively avoided.

Owner:ANBANG ELECTRICAL GRP

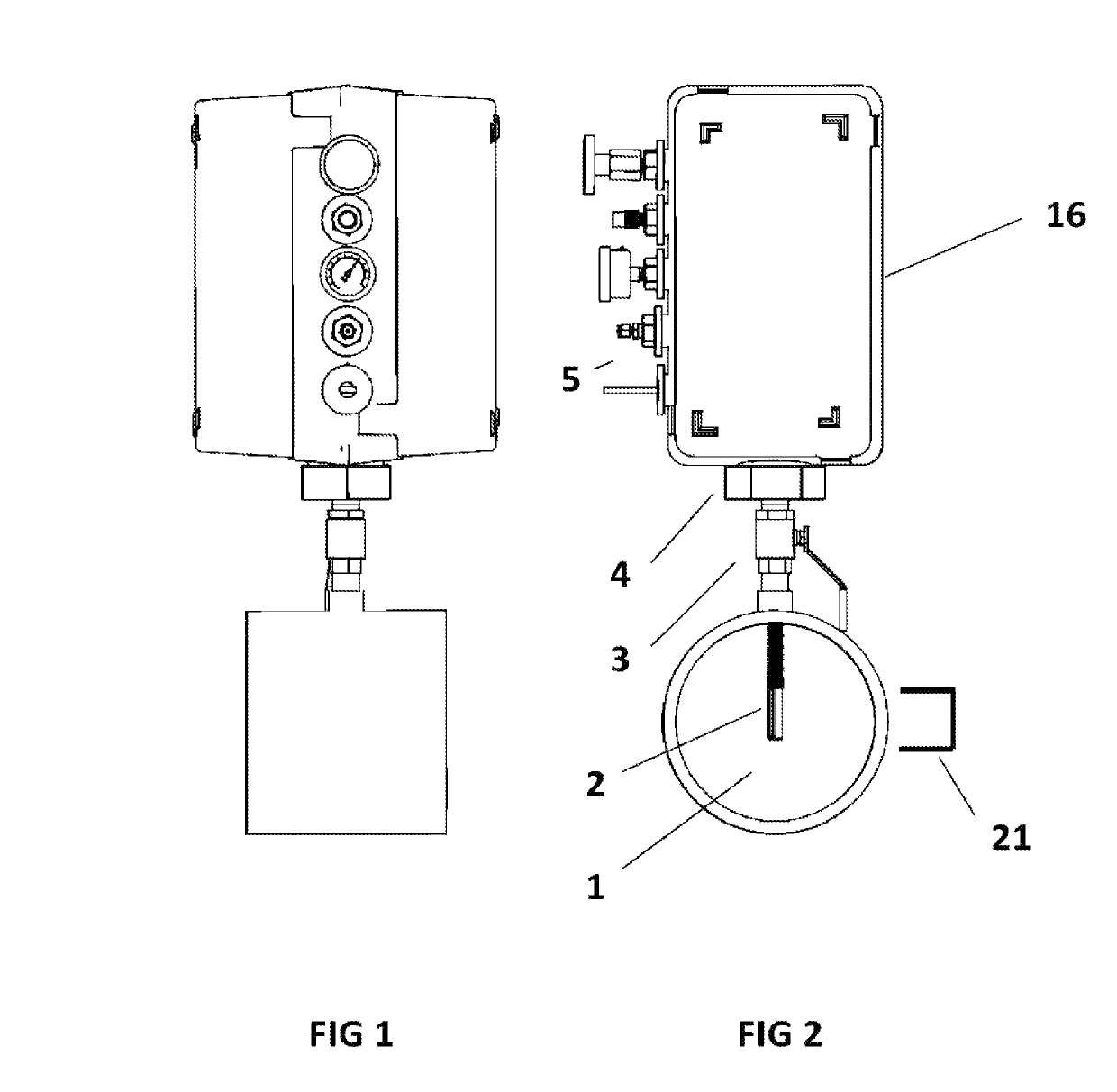

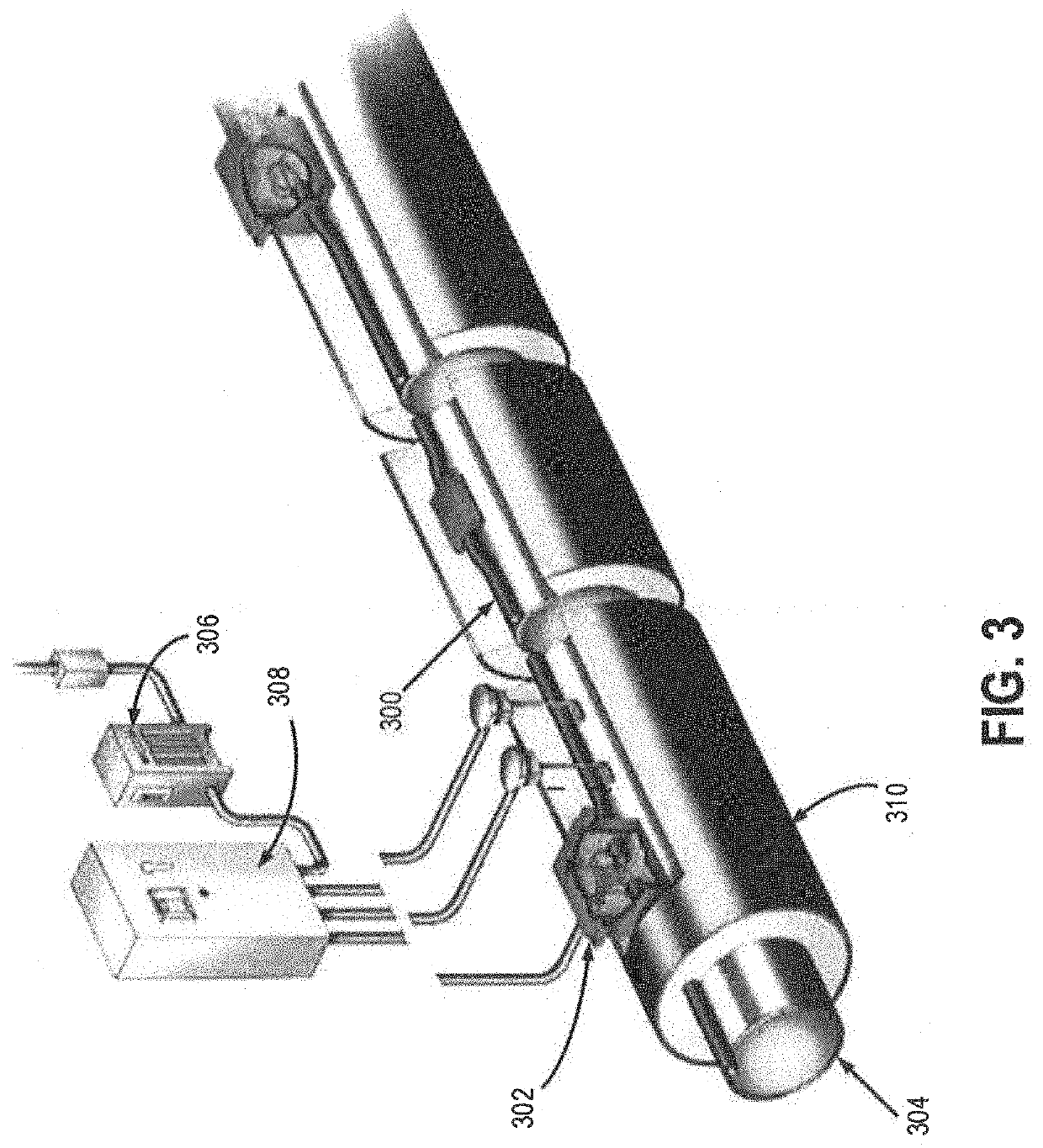

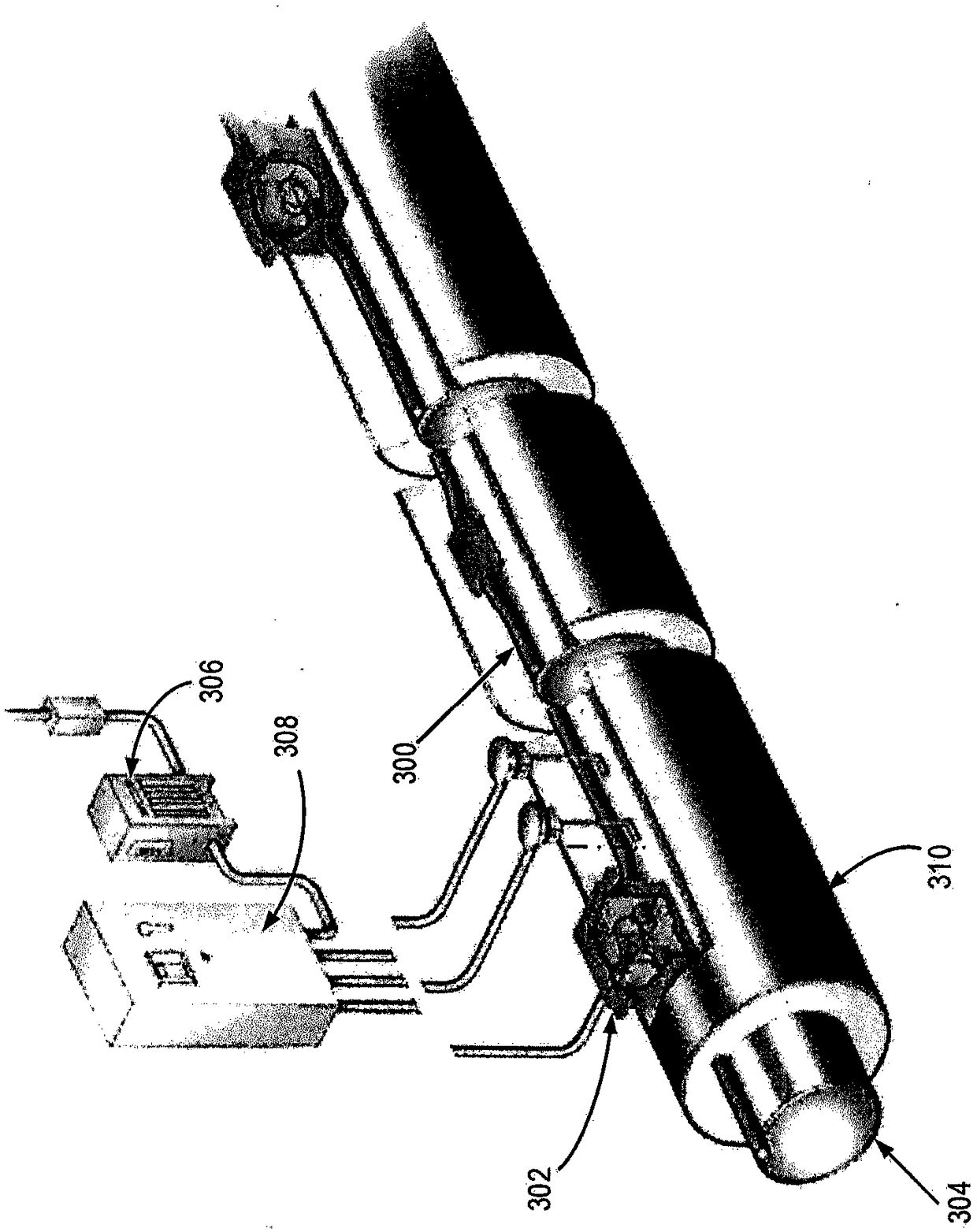

Wet gas sample system

ActiveUS10436678B1Facilitates % accessEasily and completely removedComponent separationWithdrawing sample devicesProcess engineeringCapillary action

A system for on-stream sampling of pressurized process gas such as natural gas or the like, said system optimized for use with pressurized process gas having liquid entrained therein, or otherwise referenced as “wet”. In the preferred embodiment, a probe and method of sampling is contemplated to provide linear sample of fluids from a predetermined of said fluid stream. Further taught is the method of preventing compositional disassociation of a gas sample having entrained liquid utilizing a probe having a passage formed to facilitate capillary action in fluid(s) passing therethrough. The present system further contemplates a heated pressure regulator or adapter formed to thermally engage a heat trace via conducting plates and heat pipes, in order to dispense with the need for an external power source for heating. Finally, the present system further contemplates a vaporizer system or adapter therefore utilizing heat trace heating via conductor plates in lieu of a conventional internal electric-powered heat source.

Owner:MAYEAUX HLDG

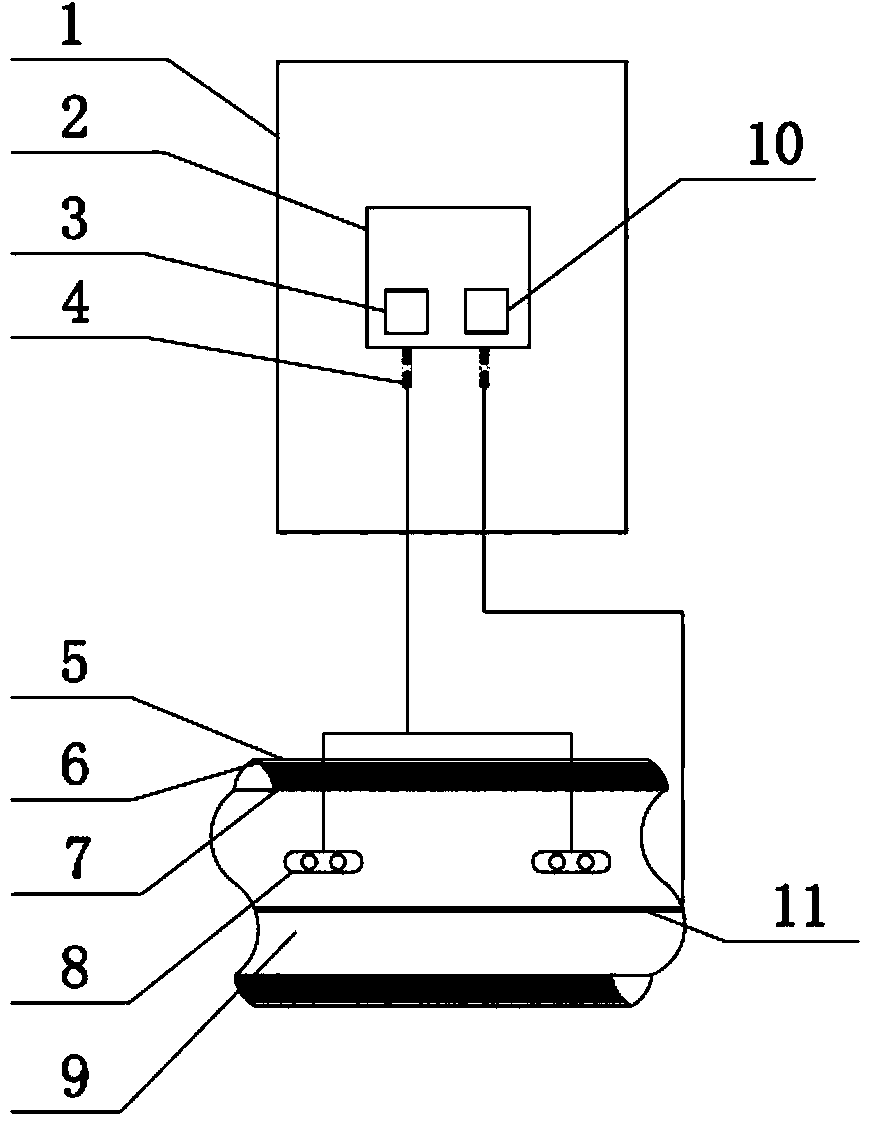

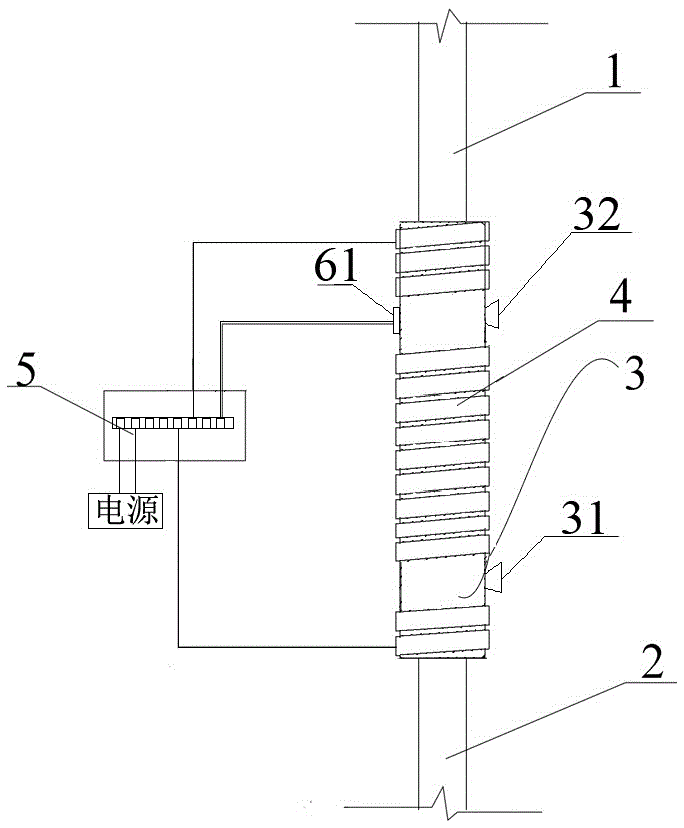

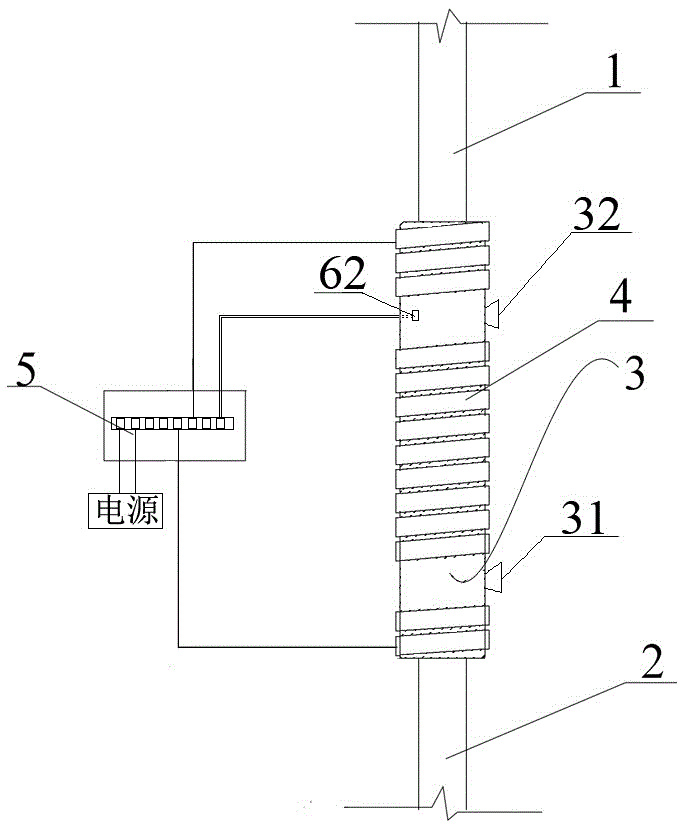

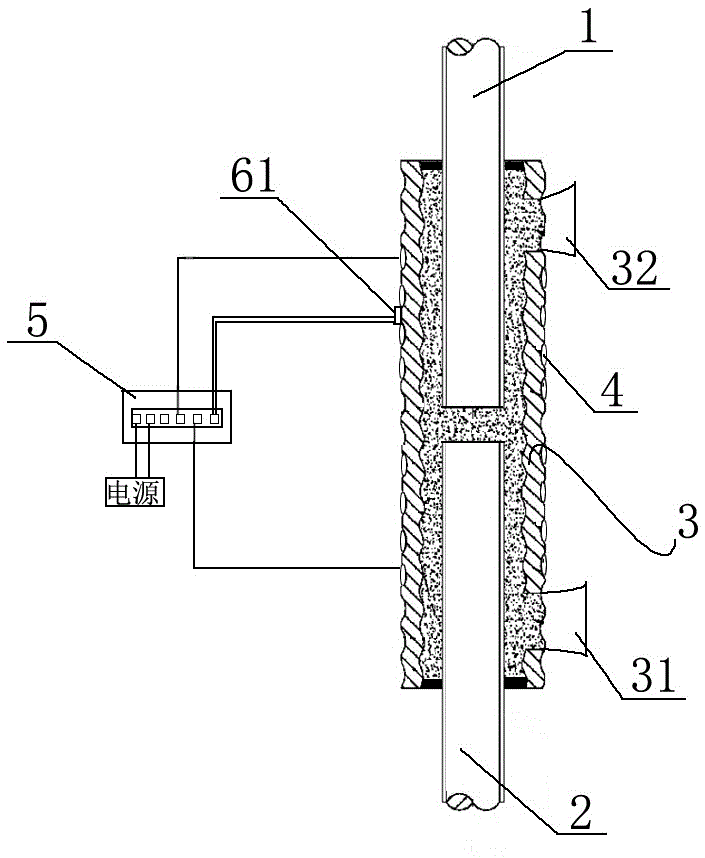

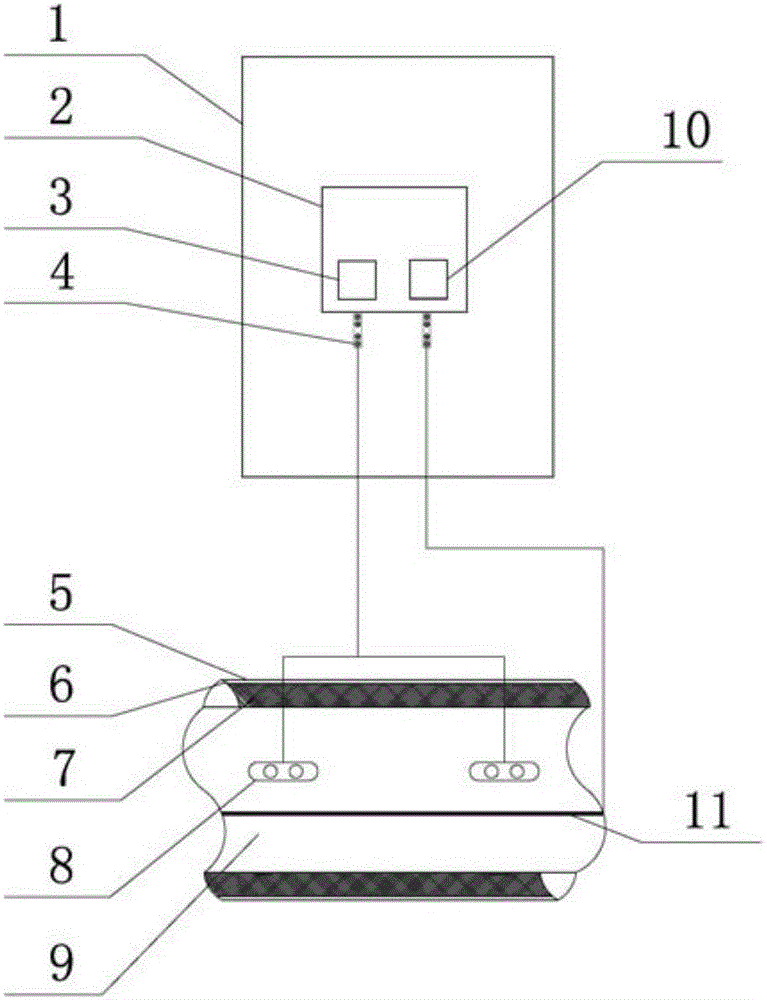

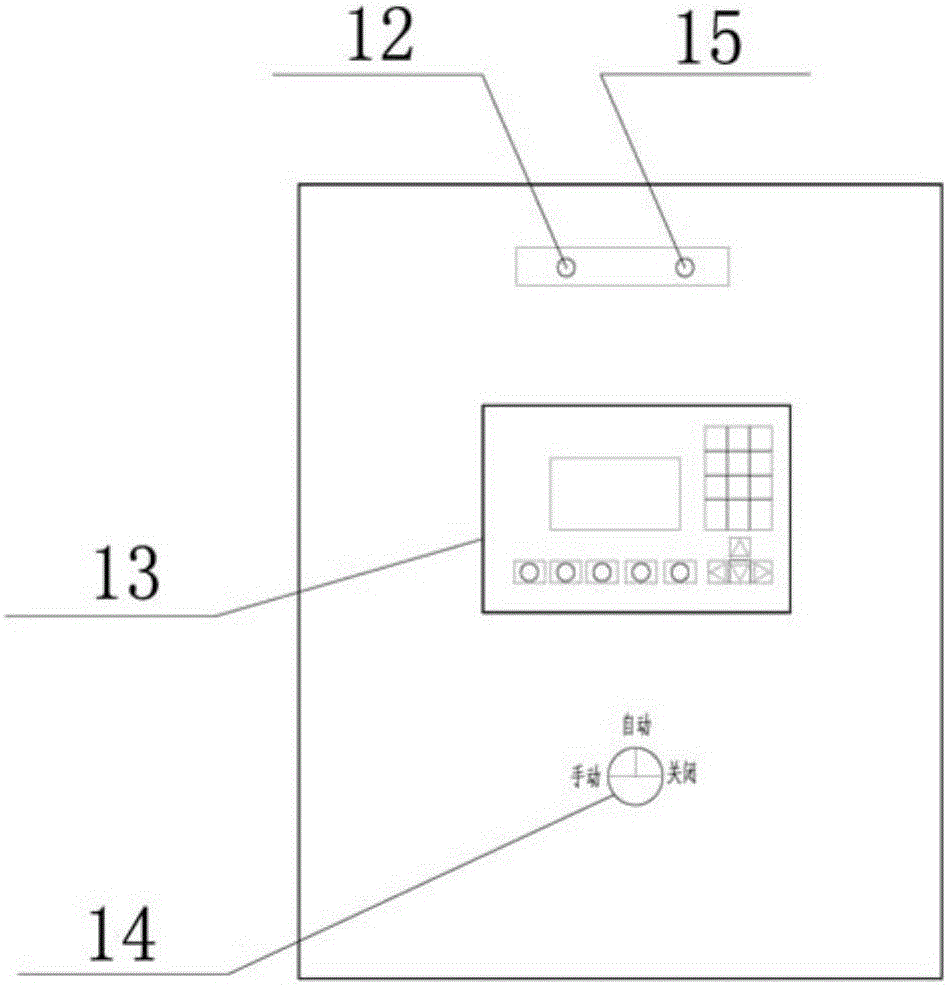

Assembly type prefabricated vertical member sleeve electric tracing heating system and using method thereof

InactiveCN106382738ABreak through the technical barriers that cannot be constructed normallyImprove collection efficiencyWater heatersBuilding reinforcementsSlurryEngineering

The invention discloses an assembly type prefabricated vertical member sleeve electric tracing heating system and a using method thereof. The assembly type prefabricated vertical member sleeve electric tracing heating system comprises a sleeve which is abutted to a steel bar which is arranged in an upper prefabricated member and extends outside downward and a steel bar which is arranged in a lower prefabricated member and extends outside upward; a grouting hole is formed in the lower half part of the sleeve; a slurry overflow hole is formed in the upper half part of the sleeve; the sleeve is provided with an electric tracing heating device which is composed of an electric heating element, a temperature sensor and a temperature controller which is connected with the electric heating element and the temperature sensor simultaneously; the electric heating element are wound on the outer surface of the sleeve to form a thermal resistance heat strip which is composed of two parallel metal wires, conductive plastic wrapping the two parallel metal wires and an external insulating layer wrapping the conductive plastic; and a probe of the temperature sensor measures current temperature of the sleeve or concrete in the sleeve and outputs the current temperature to the temperature controller. According to the assembly type prefabricated vertical member sleeve electric tracing heating system and the using method, the sleeve grouting technology can normally carry out construction at negative temperature, and the technical barrier that a prefabricated vertical member cannot carry out normal construction in winter is broken through.

Owner:北京住总集团有限责任公司

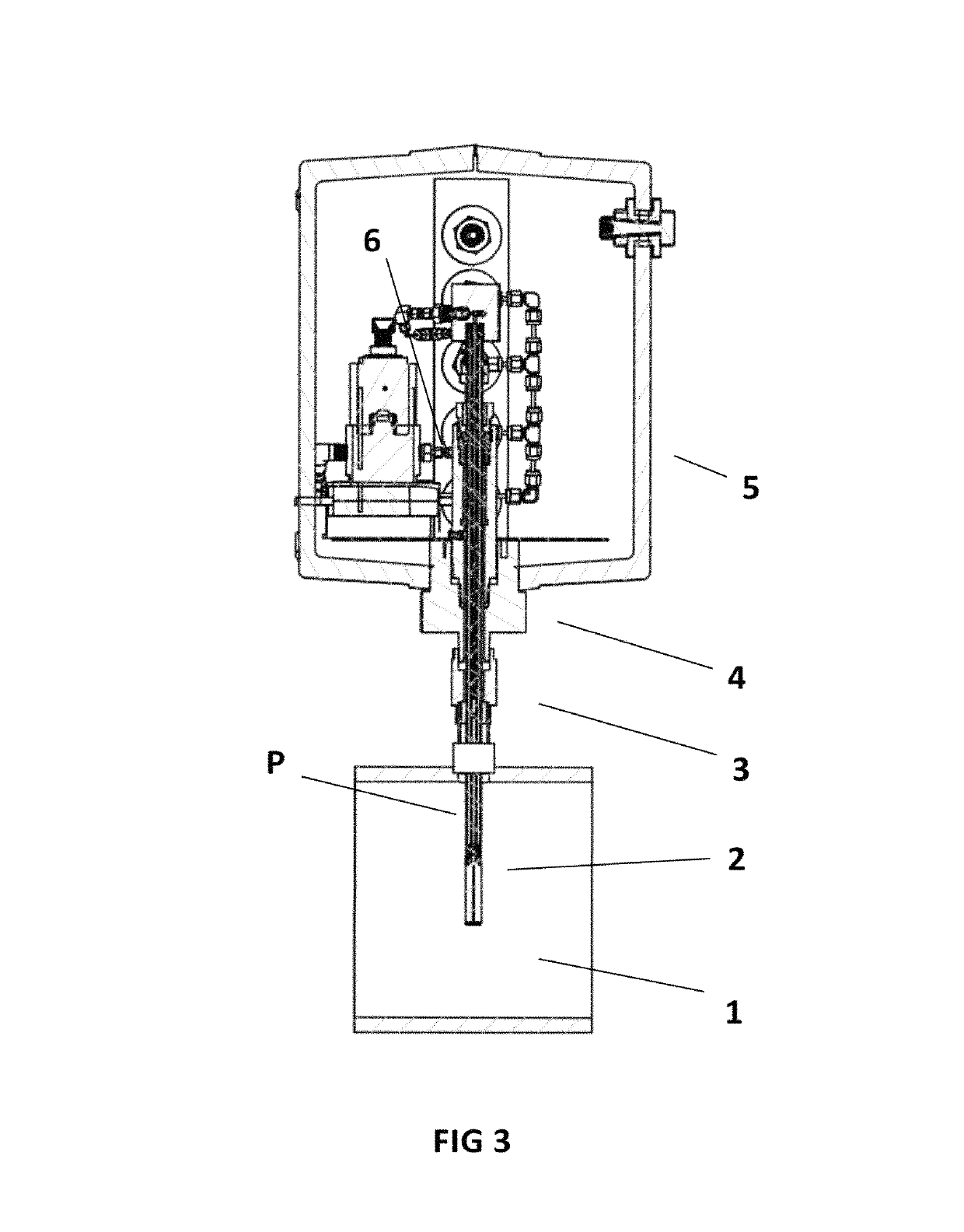

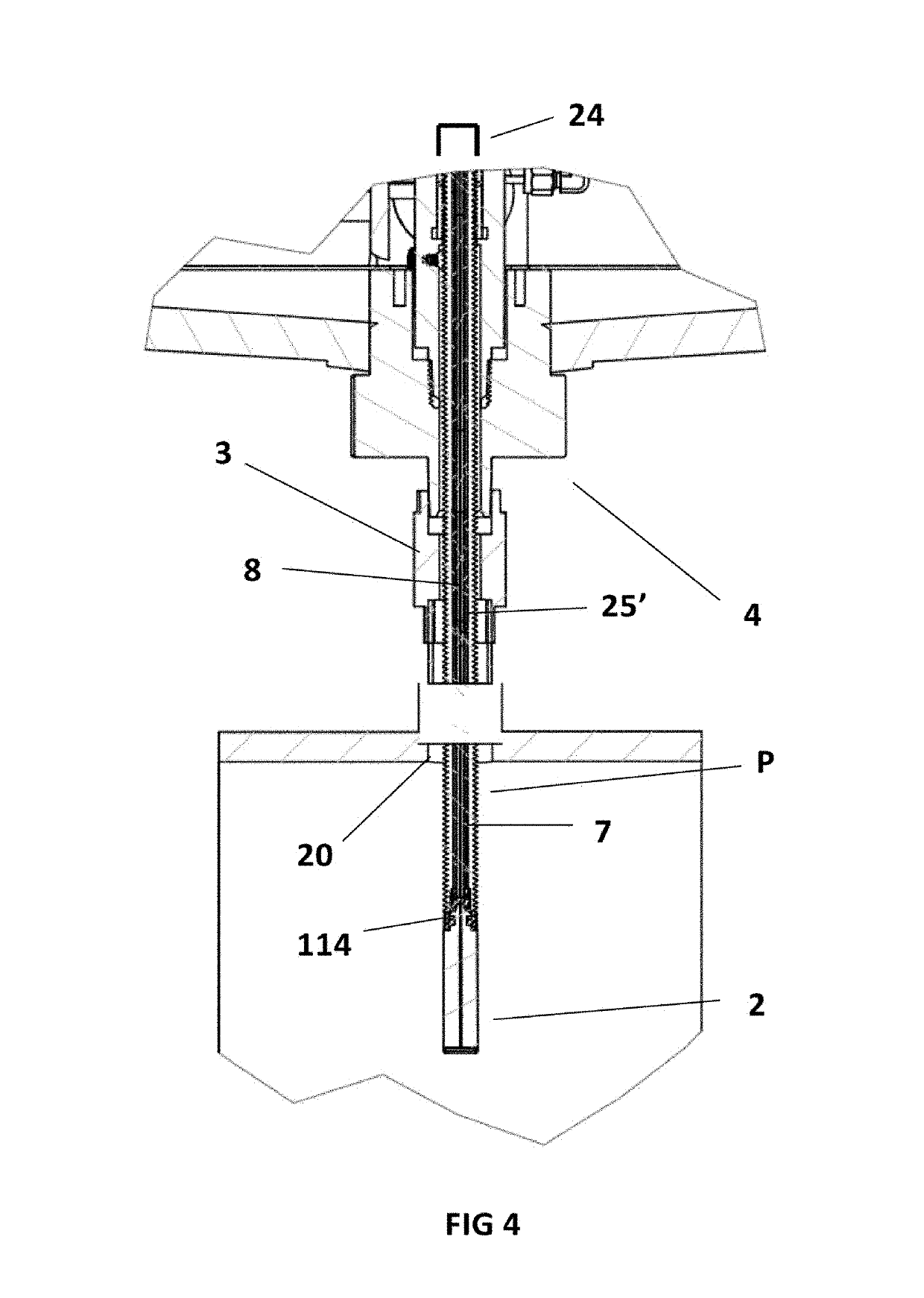

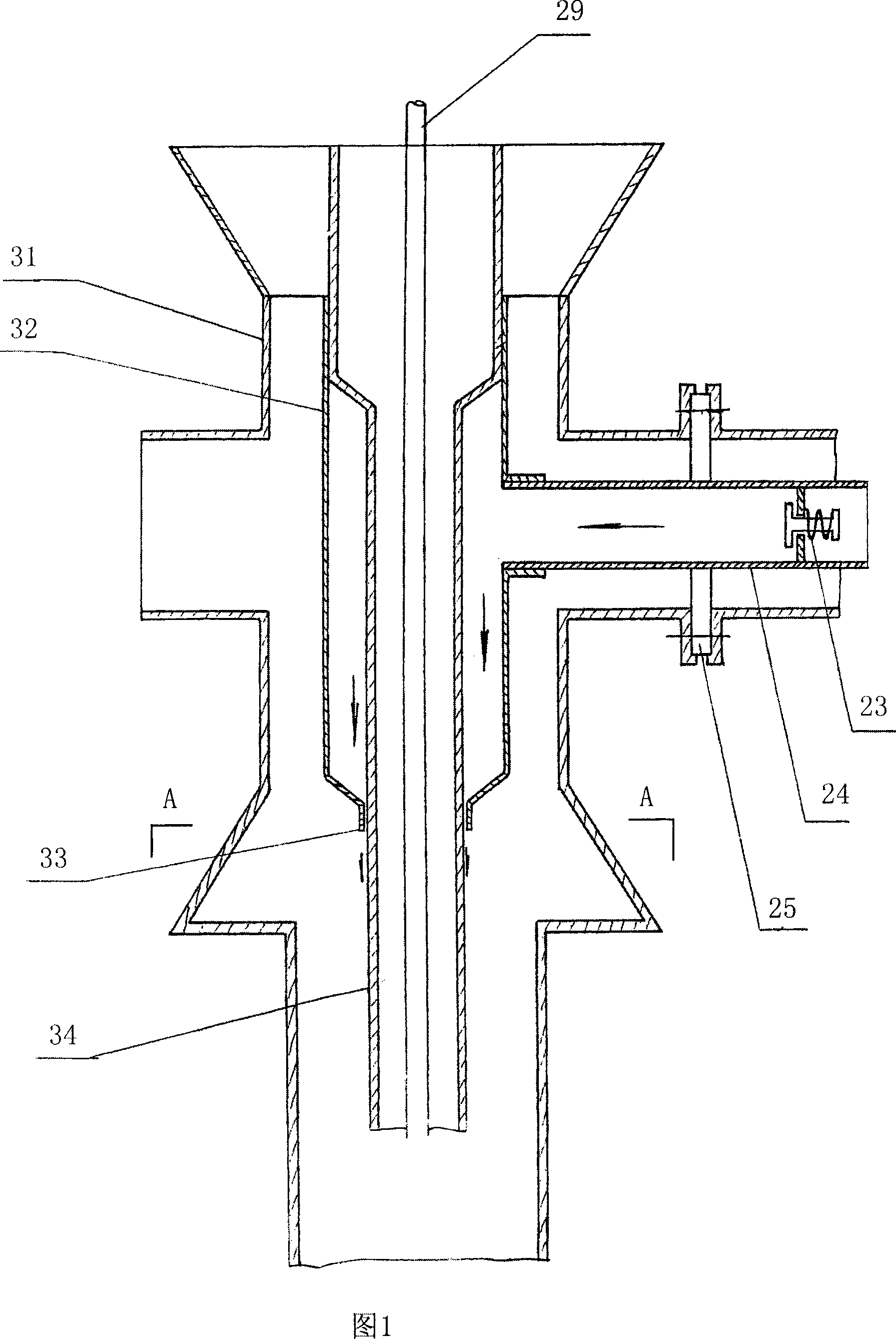

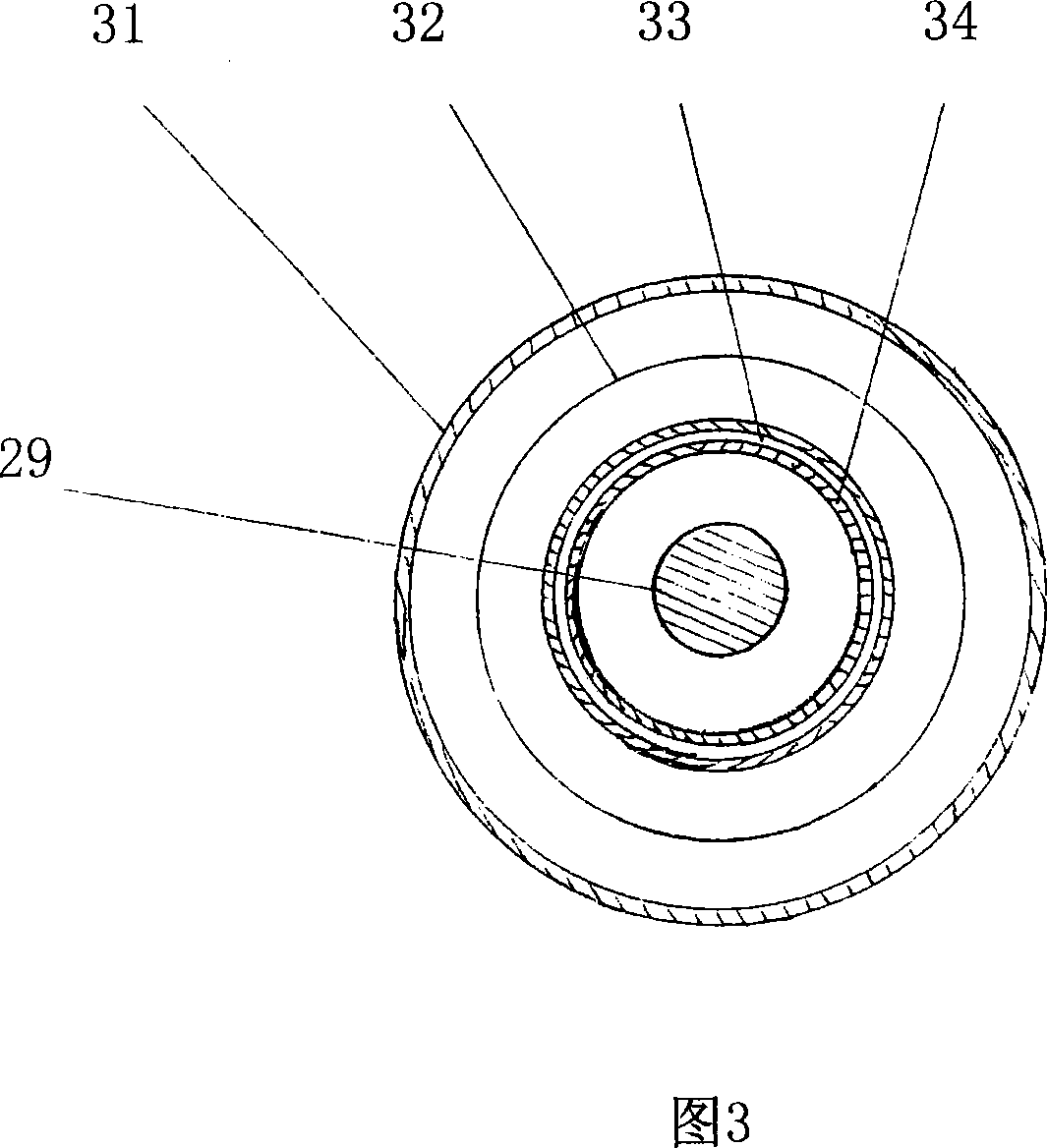

Trace heating for oil well viscosity,coagulation reduction and dewaxing

The invention relates to an oil pumping subordinate device, in particular to a heater for reducing stickiness and concretion, and dewaxing of an oil well, which is a preferred heater for the pumping of an oil well with high-concreted oil, high wax content and heavy oil. The invention consists of a sucker rod, a large cross joint, an oil pipe and a sleeve. A buffer passes into a main cavity of the large cross joint and is arranged on the periphery of the upper part of the oil pipe; the upper end of the buffer is tightly combined with the outer wall of the corresponding part of the oil pipe; an outflow clearance is arranged between the inner wall of an outlet of the lower end of the buffer and the outer wall of the oil pipe; one side of the buffer is provided with an interface connected with an inlet branch of hot water; the inlet end of the inlet branch of hot water is connected with a hot water circular pipeline of a well station. In the invention, a line is connected with the prior hot-water circular system of the well station, above 95 DEG C hot water is extracted, 2-3 m<3> hot water is consumed every 24 hours, the effects of dewaxing and concretion reduction are good, the effects are better if little pour point depressant is added; the extraction cost of thick oil with high wax content is decreased; the thermal source in the prior hot-water circular system of the well station is adopted; a water-can inner fuel can also be used for heating or supplementary heating. The invention is of easy implement and low cost.

Owner:姜永民

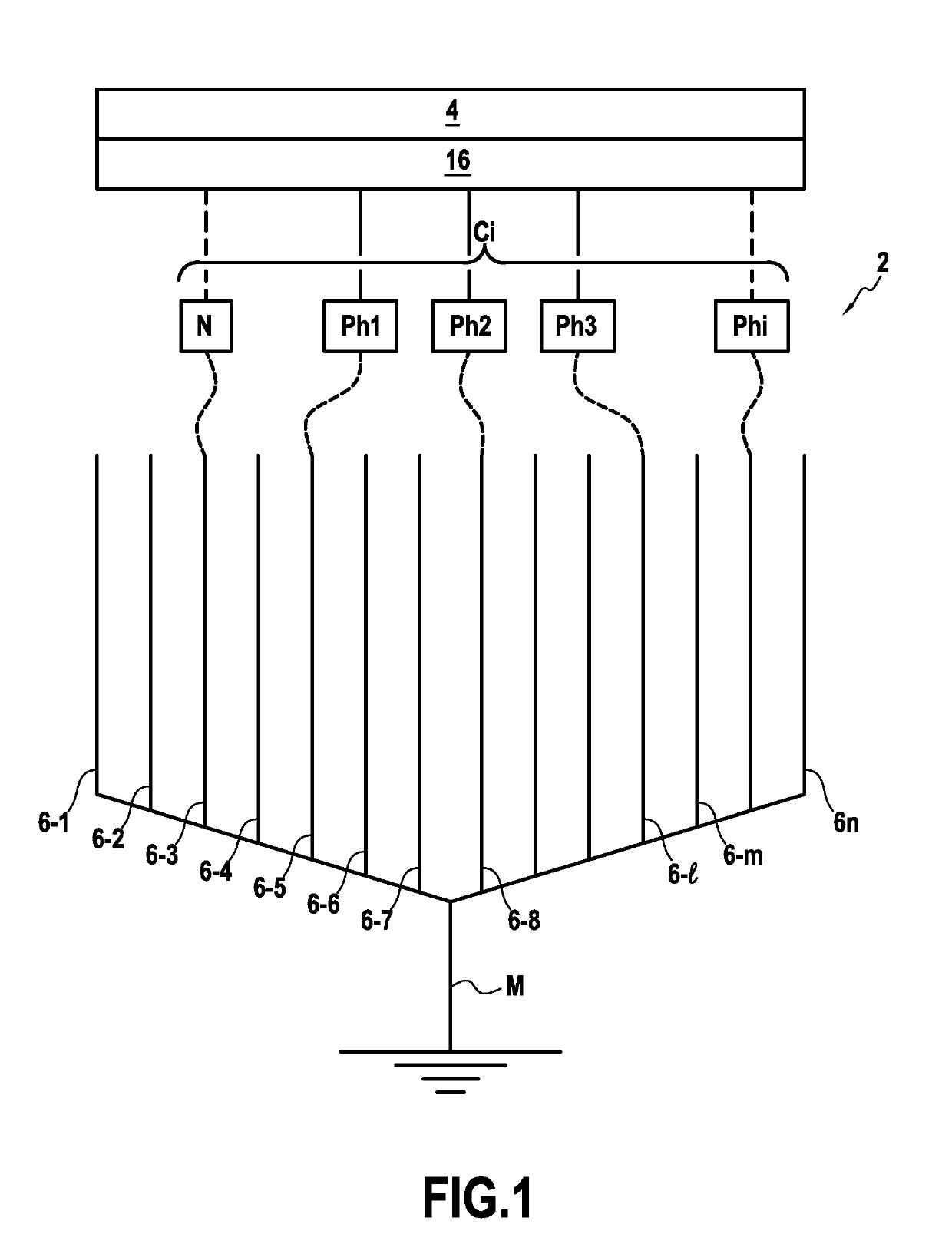

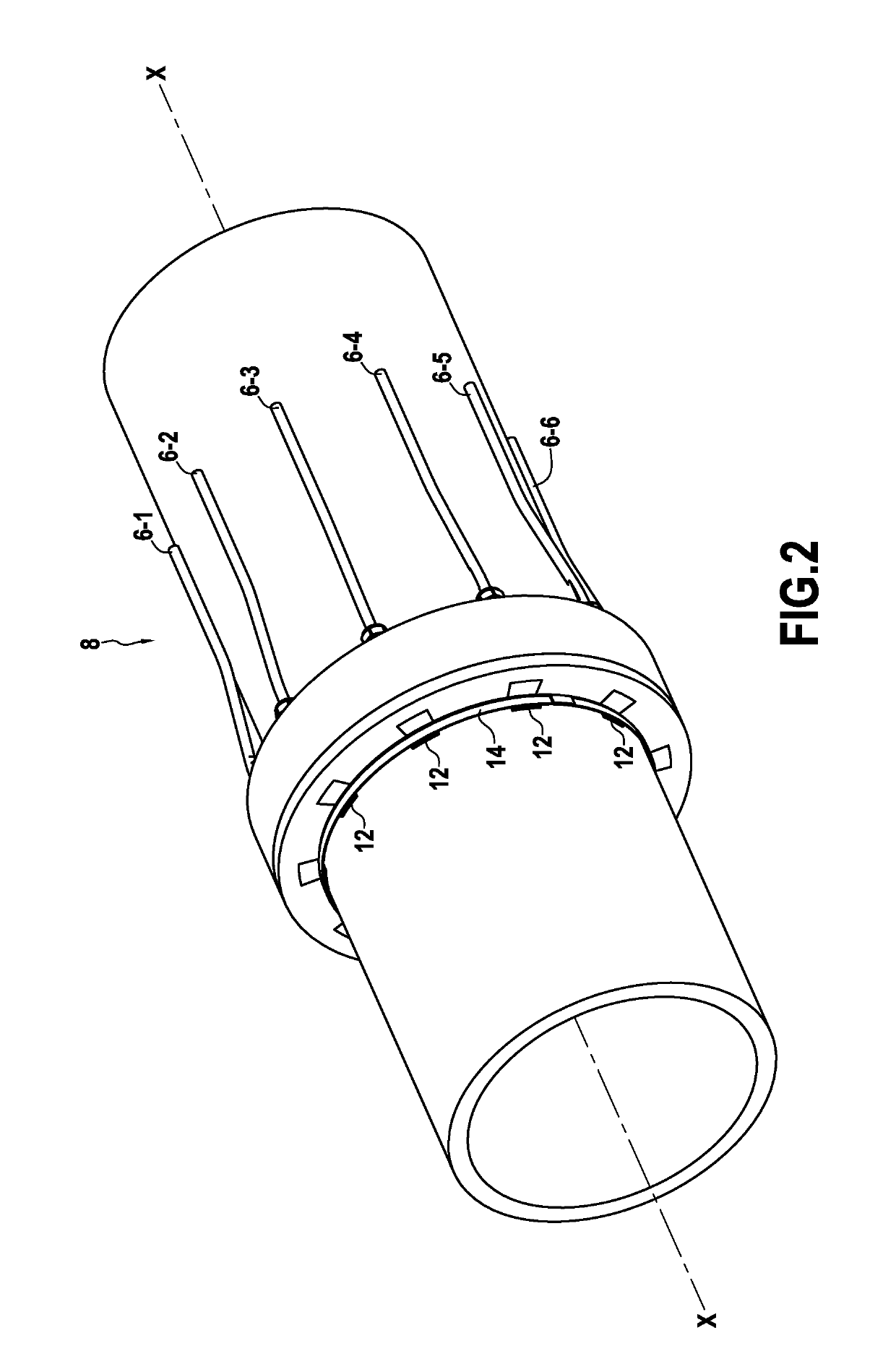

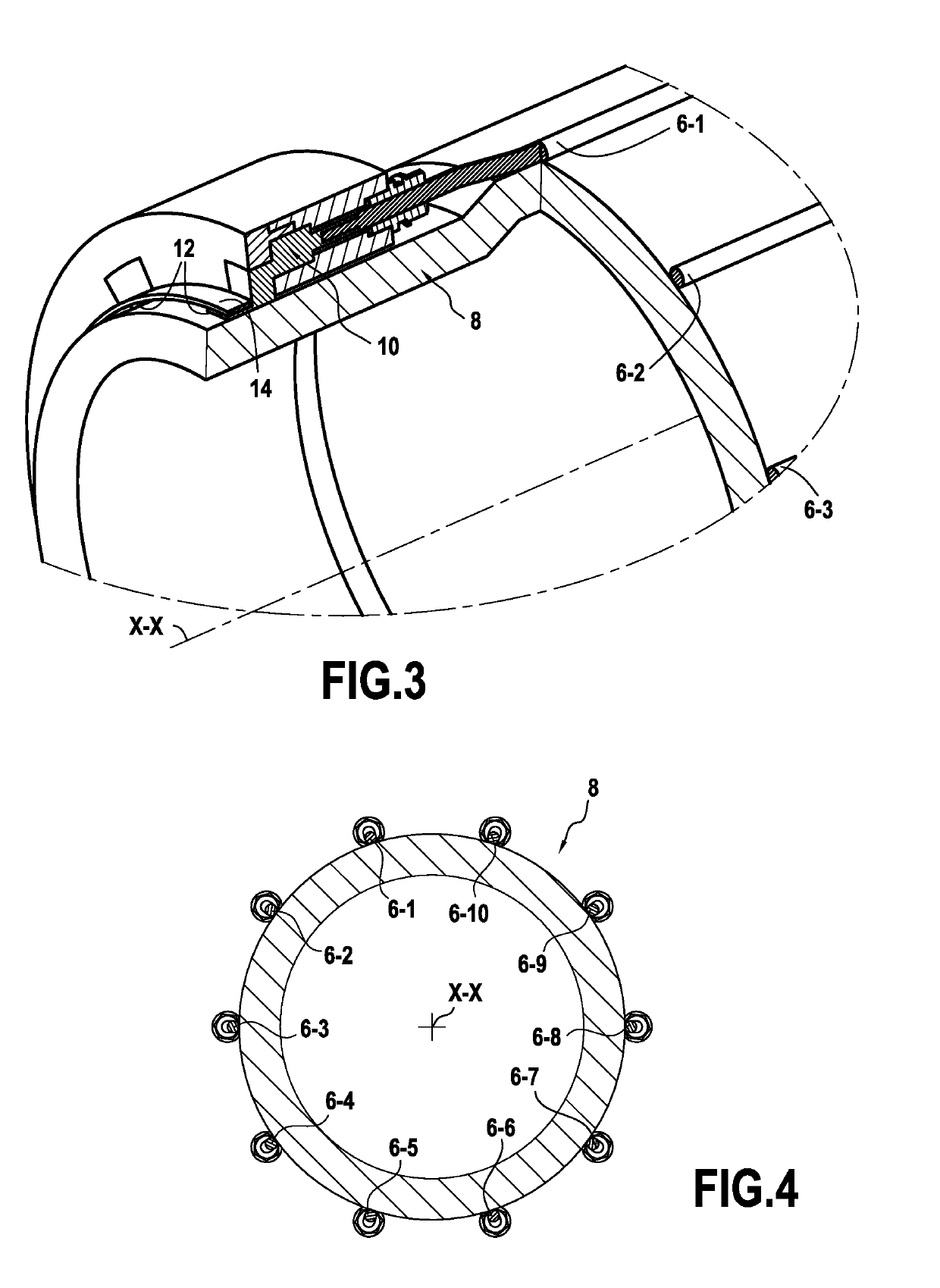

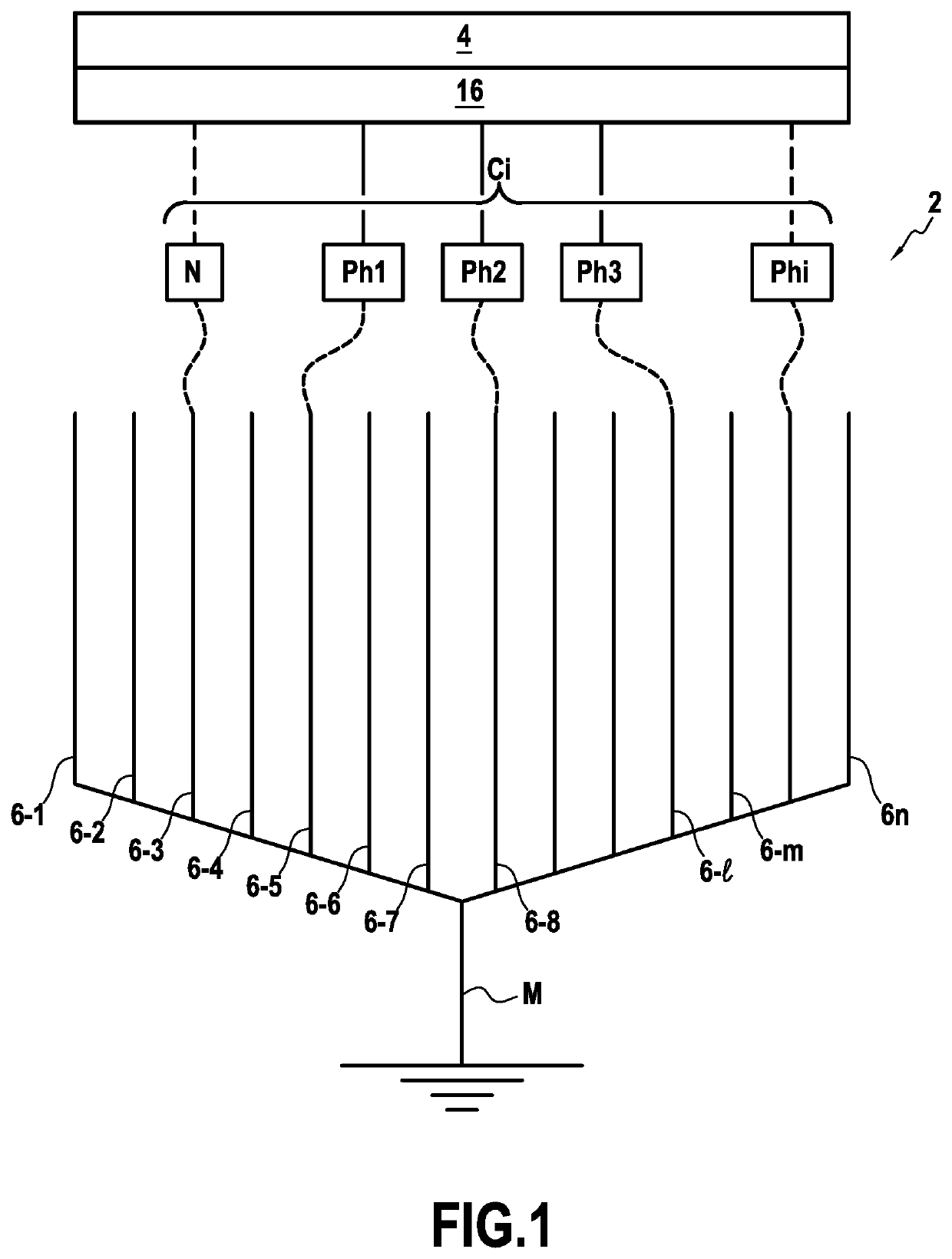

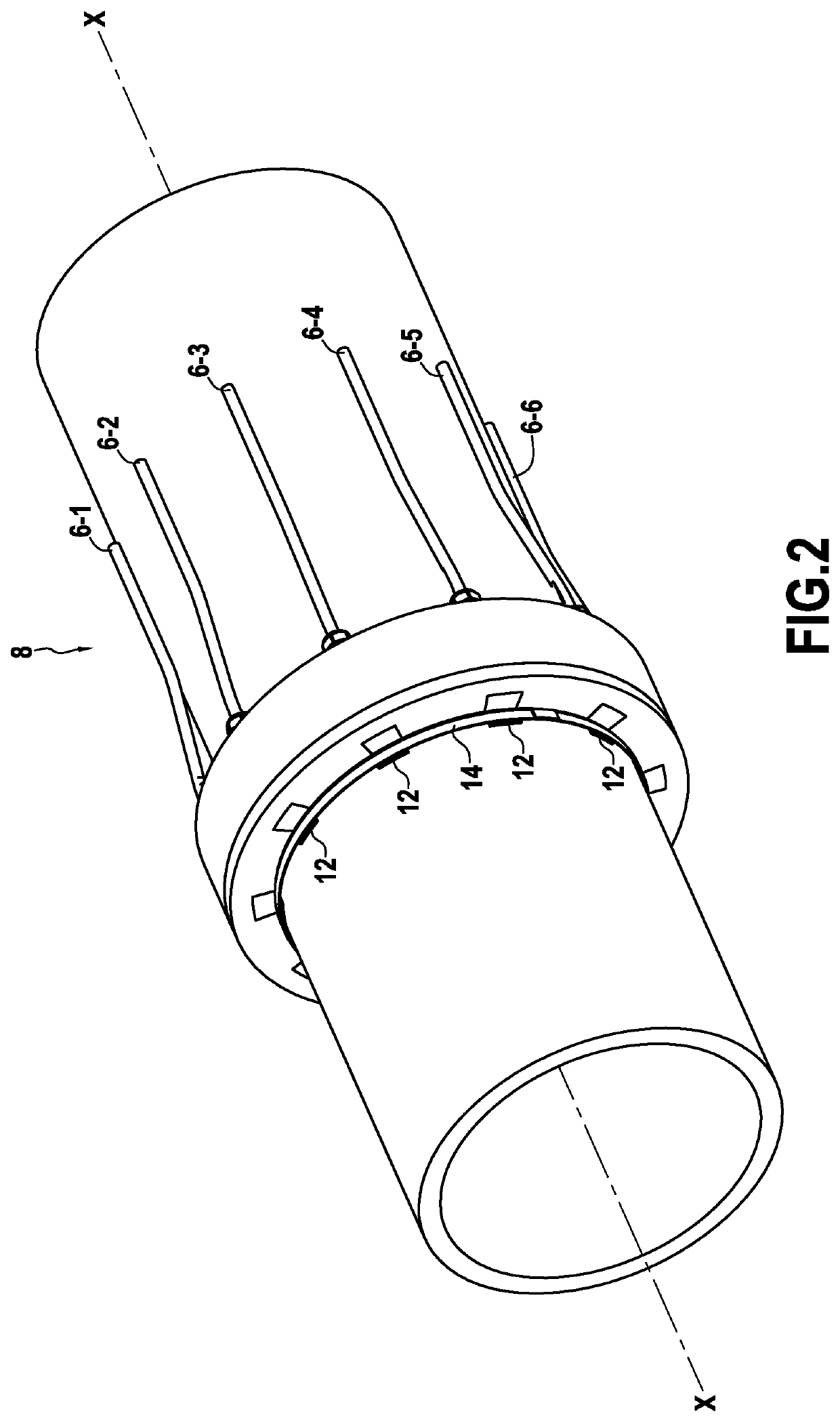

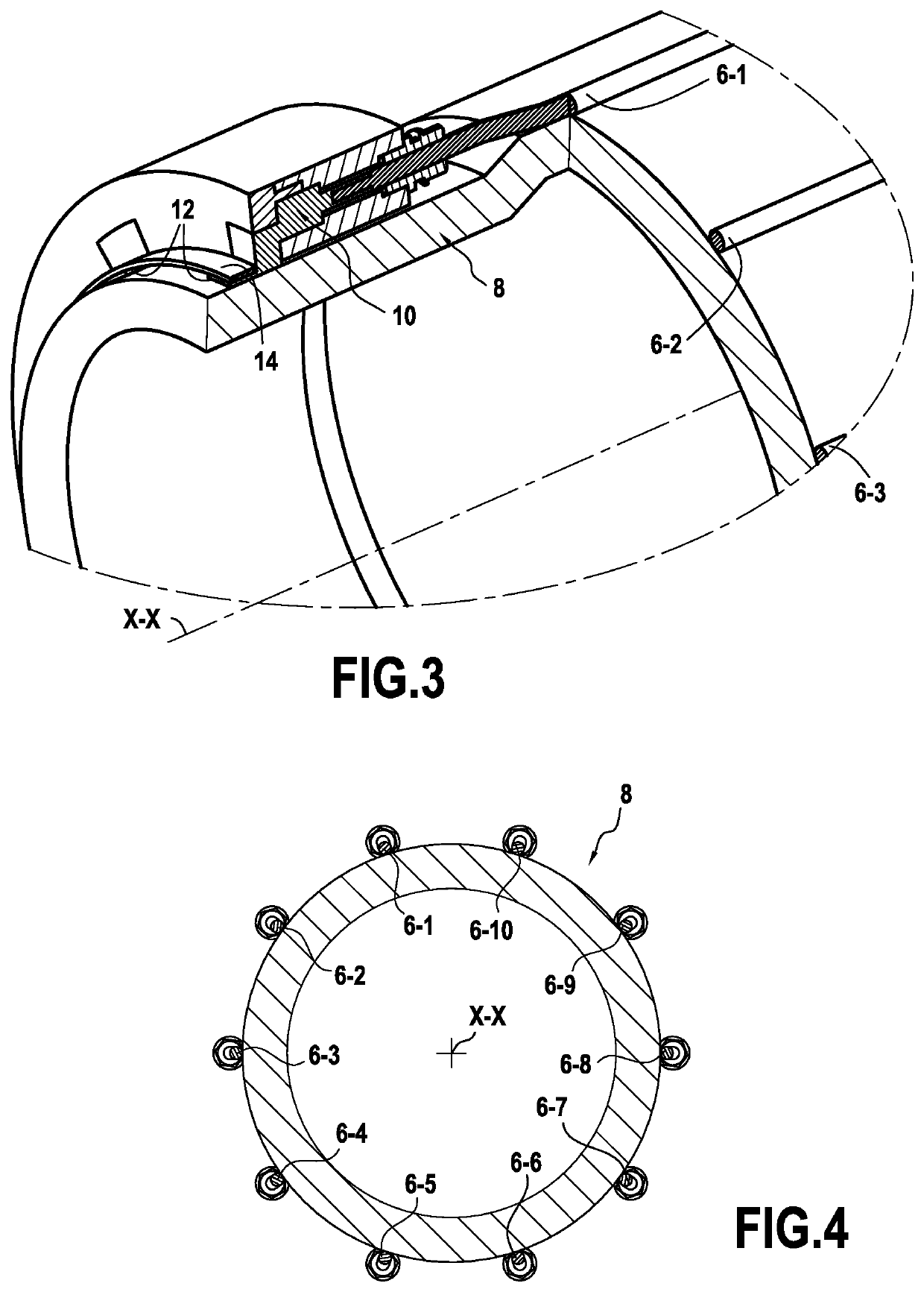

Electrical Installation For An Electric Trace Heating System For A Metal Pipe For Transporting Fluids And Electric Trace Heating Method For Such A Pipe

ActiveUS20190128461A1Mitigate such drawbackReduce in quantityPipe heating/coolingFault location by conductor typesFluid transportElectric cables

An electrical installation for an electrical system for trace heating a fluid transport pipe (8) made of metal, at least one polyphase circuit having three main electric cables (6-1, 6-4, and 6-7) in a star connection, and one additional electric cable (6-2, 6-3, 6-5, 6-6, 6-8, and 6-9), the main cables and the additional cable positioned around the pipe and connected at the pipeline end to a common connection ring (10) forming a point of zero electric potential, and detector for detecting a failure, if any, of the polyphase circuit to identify a failed main cable in order to replace it with the additional cable.

Owner:SAIPEM SA

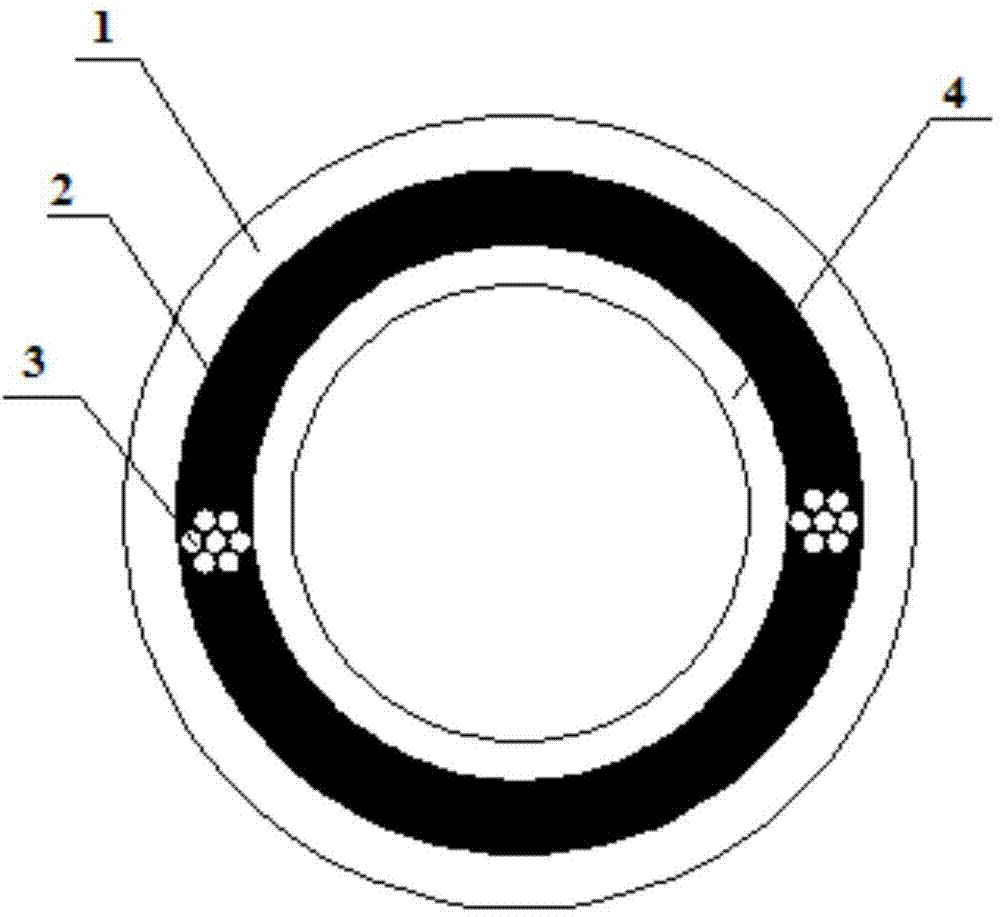

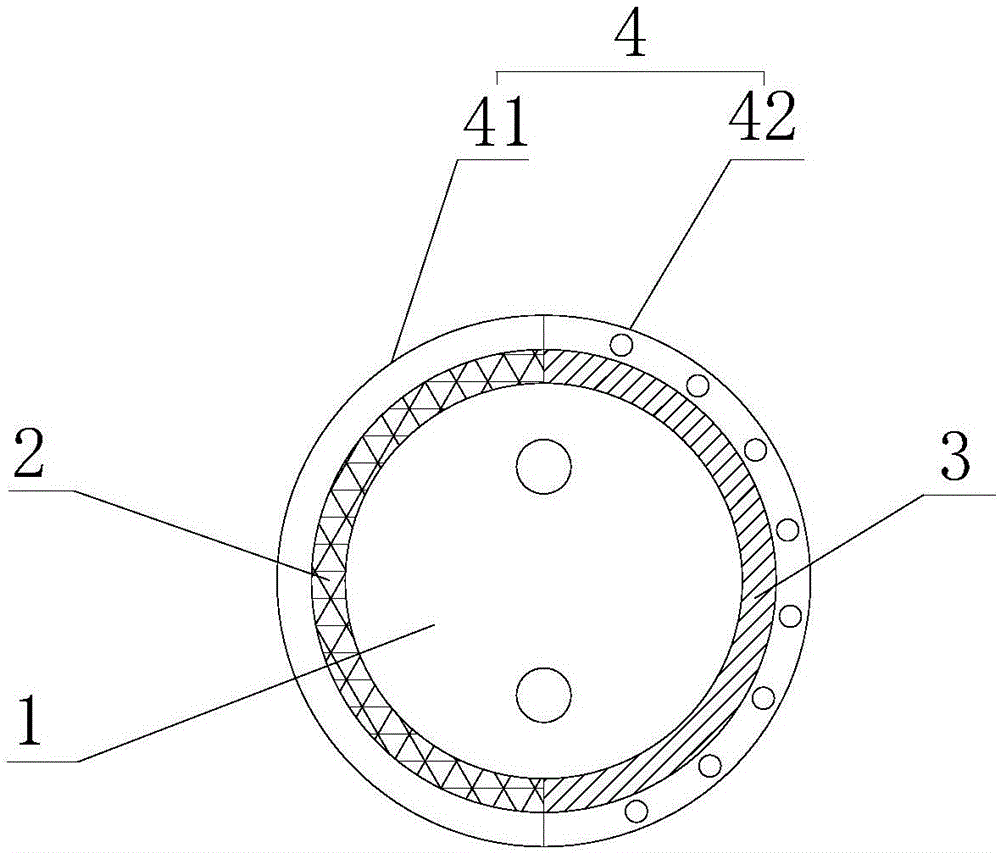

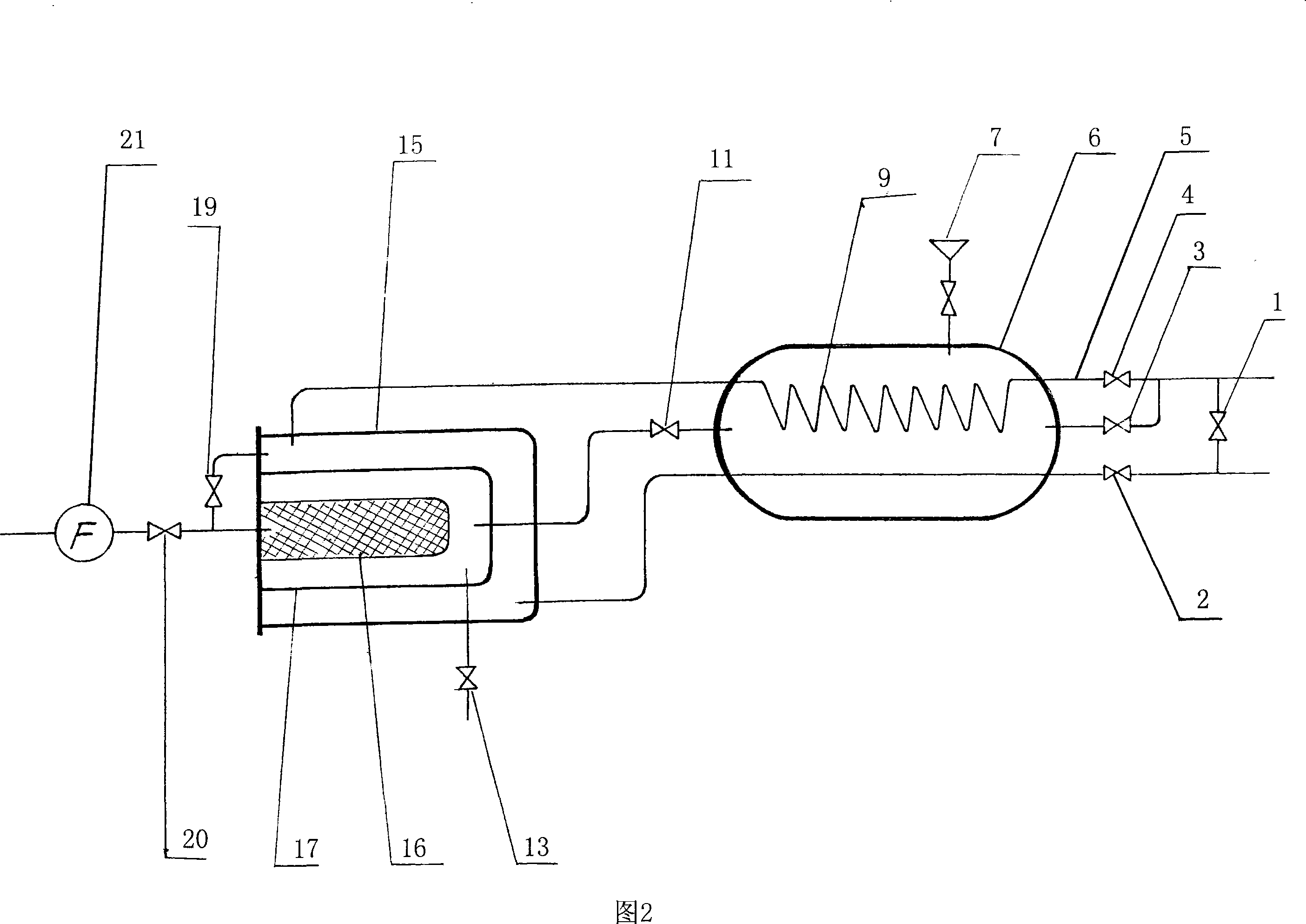

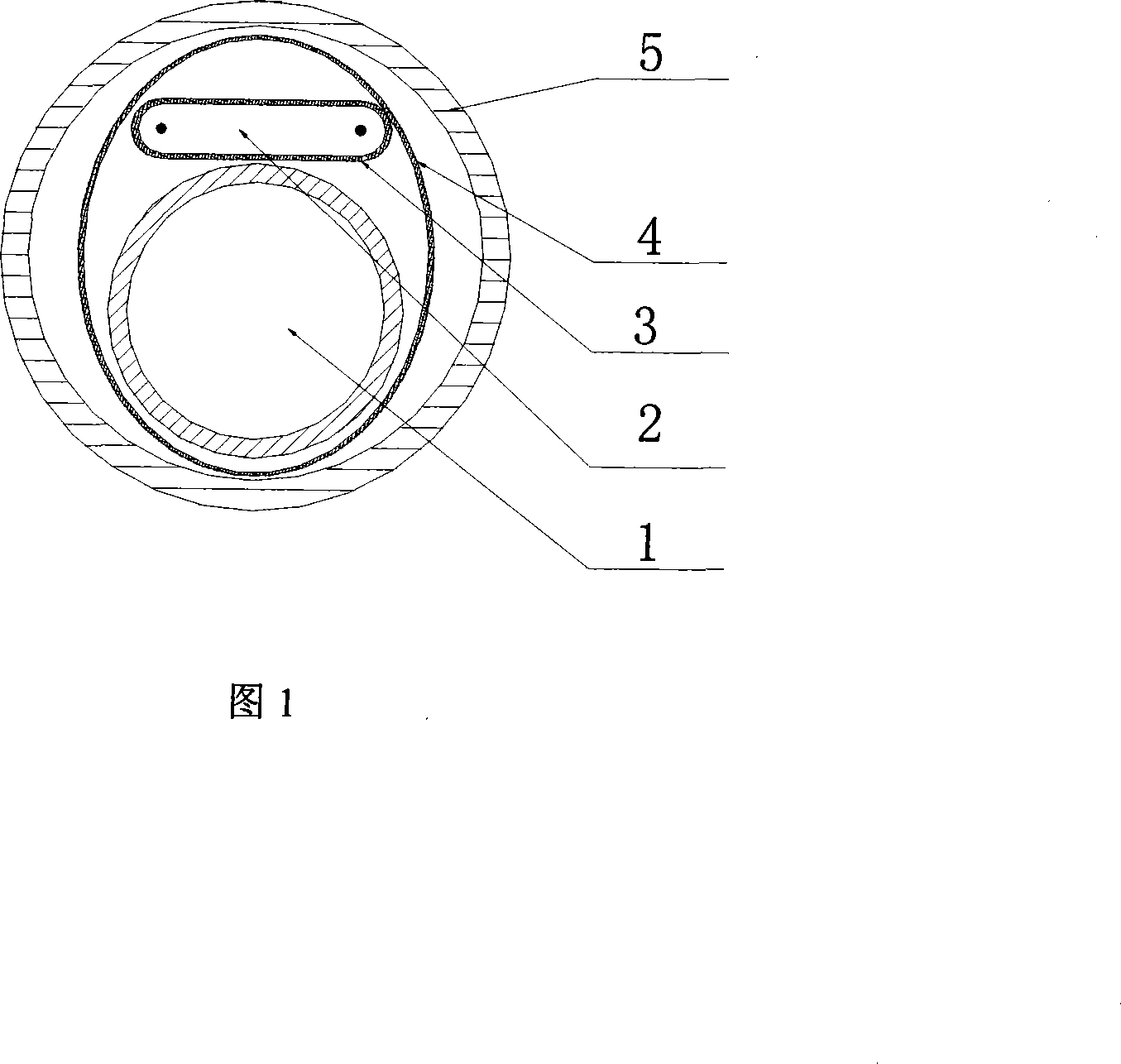

Self-temperature controlling water-electricity dual-purpose composite pipes

InactiveCN101235931AStart fastAvoid harmPipe heating/coolingCorrosion preventionGeothermal heatingEnergy conservation

The invention discloses a self-controlling-temperature water electric dual-purpose composite pipe, which is fabricated by that a self temperature control heating tape added by a metal wire braid layer is attached to the outer wall of a plastic flexible pipe, then metal shielding radiation membranes are wrapped outside the plastic flexible pipe and the self temperature control heating tape, and a reinforced sheath is extruded on the shielding radiation membranes. The self-controlling-temperature composite pipe can provides two modes of heat supply, which are water heating mode and electric trace heating mode, inner circulation hot-water of the plastic flexible pipe primarily supplies heat, and the self temperature control heating tape is in auxiliary heat supply. The self-controlling-temperature composite pipe can be used as a terminal of geothermal heating, which resolves the problem that when renewable energy green resources, such as solar heat collecting, air source heat pump systems and the like, are used in construction heating in winter, the existing water coils can not meet heating requirements under condition of unstable hot-water temperature or relatively low water temperature, and has the advantages of energy conservation, safety and reliability, low operation costs, environmental friendliness and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

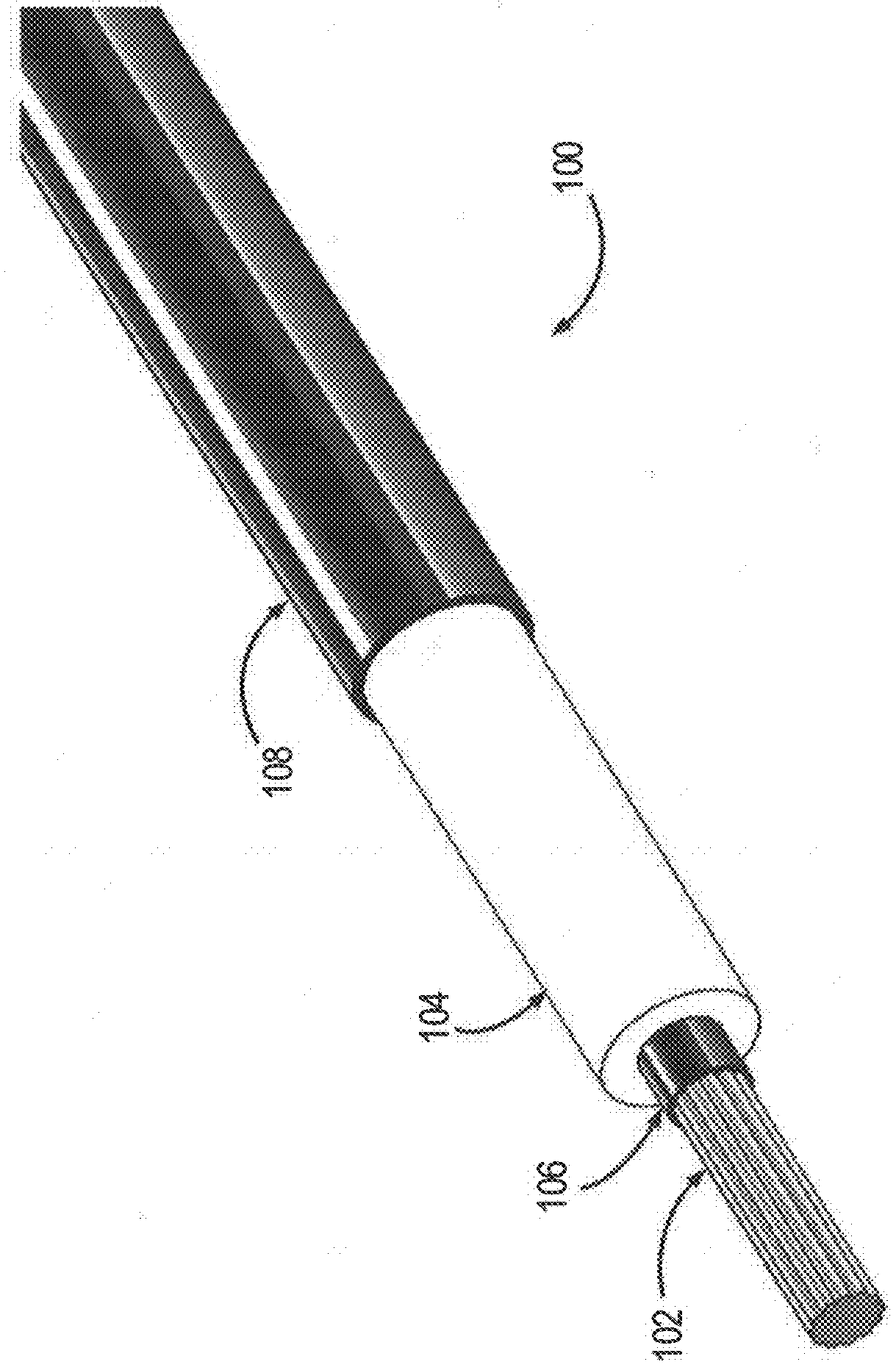

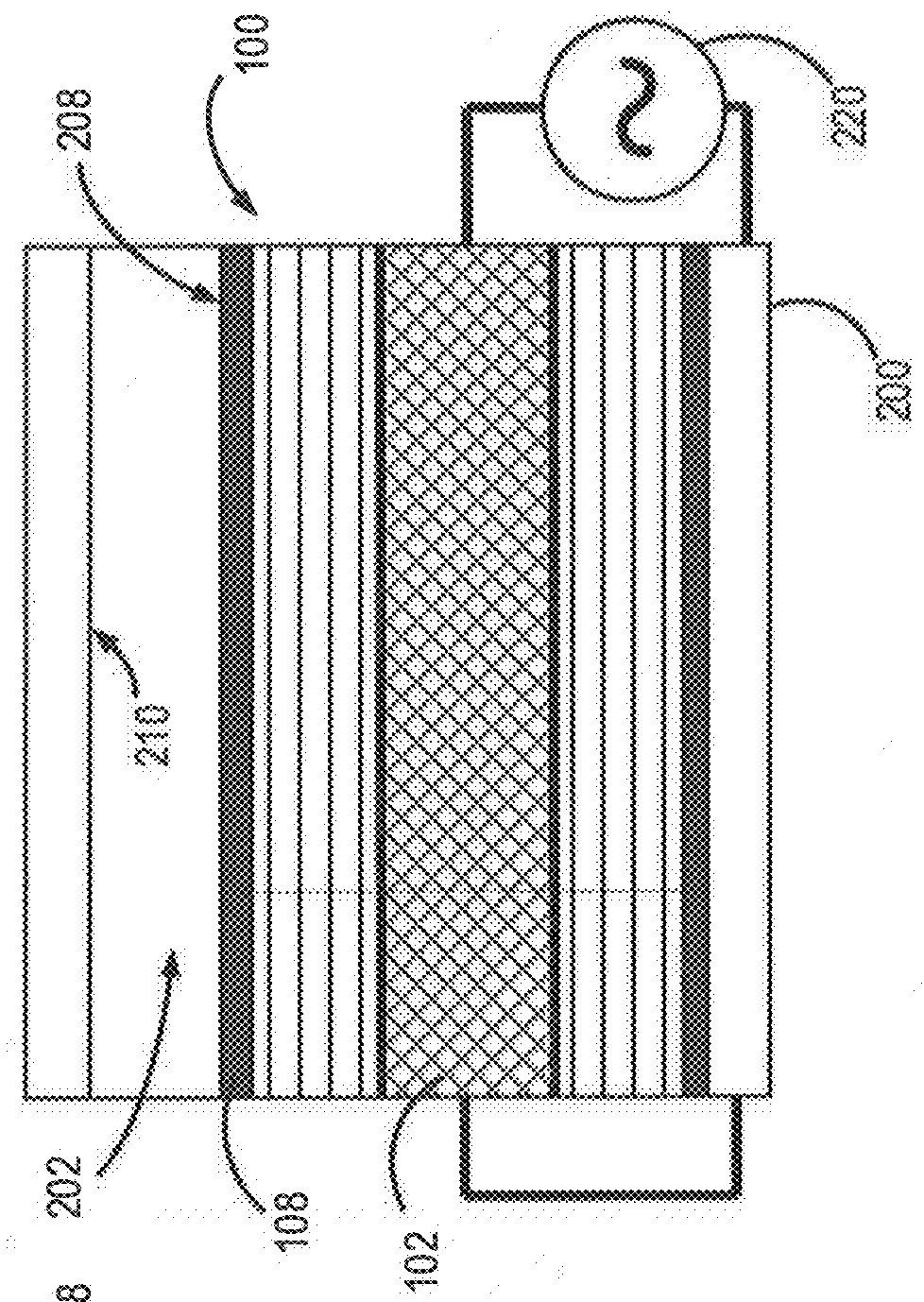

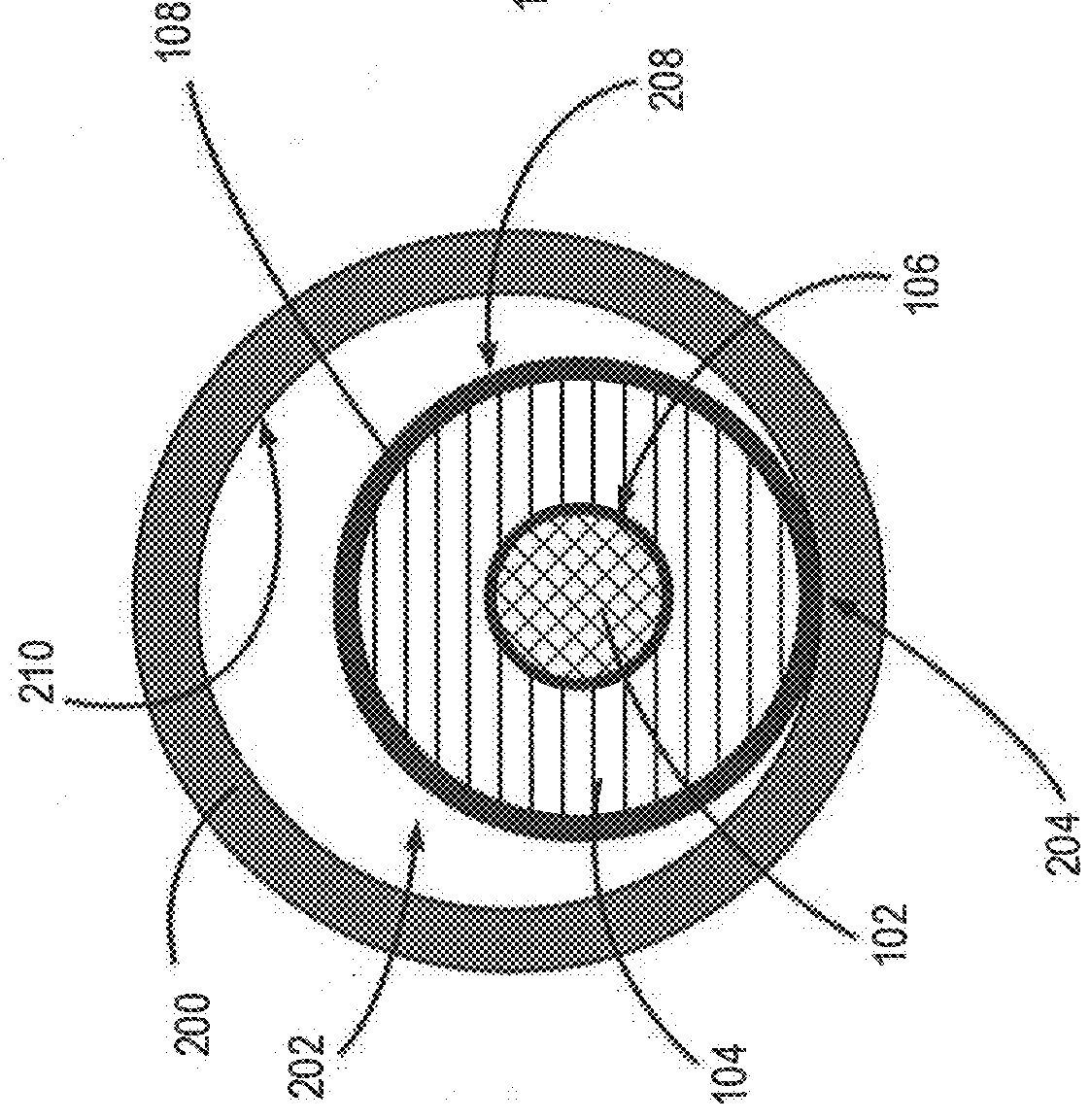

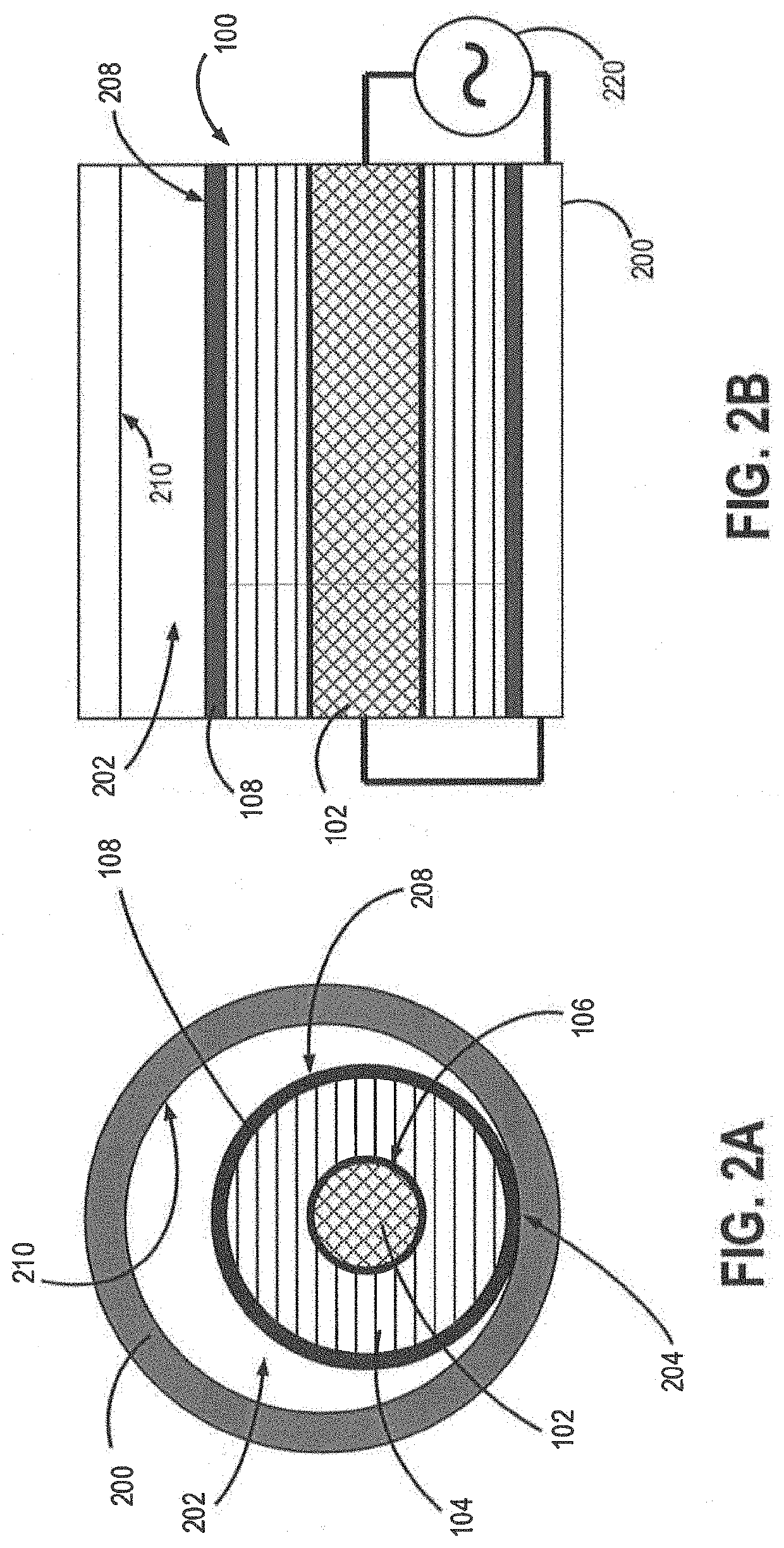

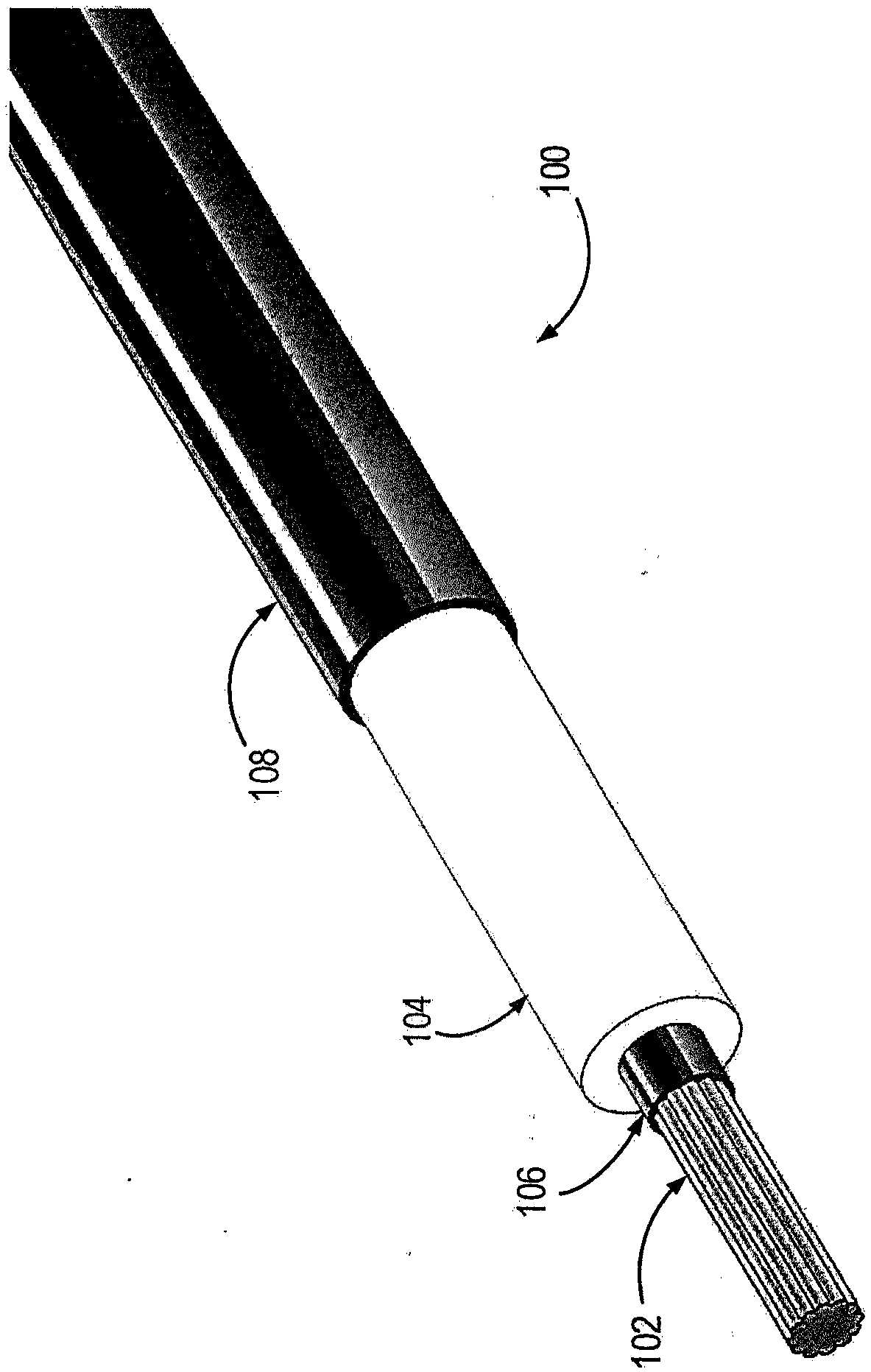

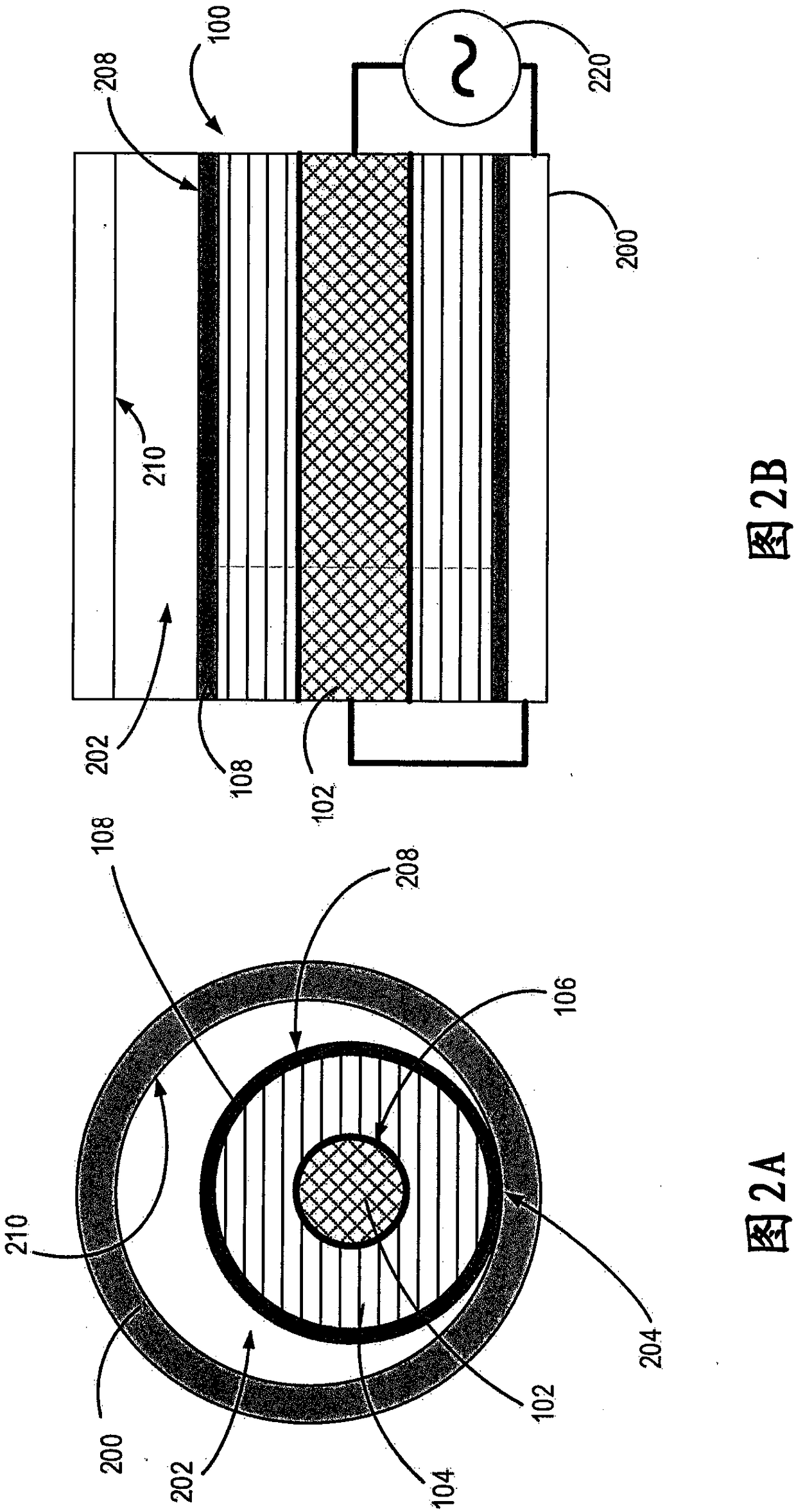

Shielded Fluoropolymer Wire for High Temperature Skin Effect Trace Heating

ActiveUS20180184487A1Minimize the numberHigh voltagePipe heating/coolingInsulated cablesPower flowReturn current

A skin effect heating system for long pipelines includes a heater cable disposed in a ferromagnetic or other conductive heat tube. A semiconductive jacket contacts the inner surface of the heat tube, where the charge density of the return current carried by the heat tube is at its highest. The semiconductive jacket material has a resistivity that is sufficiently low to reduce or eliminate arcing events such as corona discharge by allowing accumulated charge on the heat tube to dissipate. The resistivity is also high enough to prevent the return current from flowing into or through the semiconductive outer layer, so that heat production capacity of the system is maximized.

Owner:NVENT SERVICES GMBH

Electrical installation for an electric trace heating system for a metal pipe for transporting fluids and electric trace heating method for such a pipe

ActiveUS10704727B2Mitigate such drawbackReduce in quantityPipe heating/coolingFault location by conductor typesFluid transportHemt circuits

An electrical installation for an electrical system for trace heating a fluid transport pipe (8) made of metal, at least one polyphase circuit having three main electric cables (6-1, 6-4, and 6-7) in a star connection, and one additional electric cable (6-2, 6-3, 6-5, 6-6, 6-8, and 6-9), the main cables and the additional cable positioned around the pipe and connected at the pipeline end to a common connection ring (10) forming a point of zero electric potential, and detector for detecting a failure, if any, of the polyphase circuit to identify a failed main cable in order to replace it with the additional cable.

Owner:SAIPEM SA

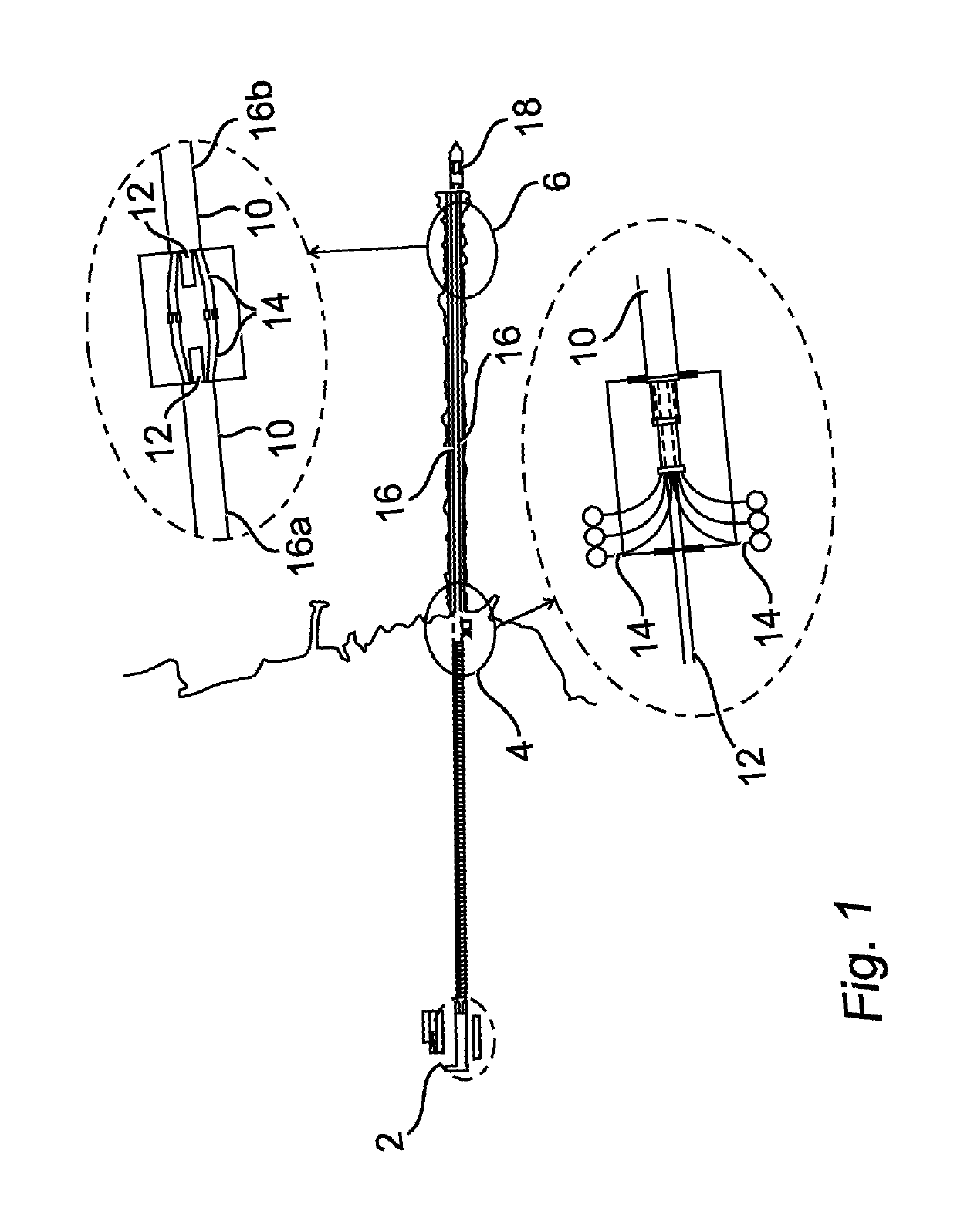

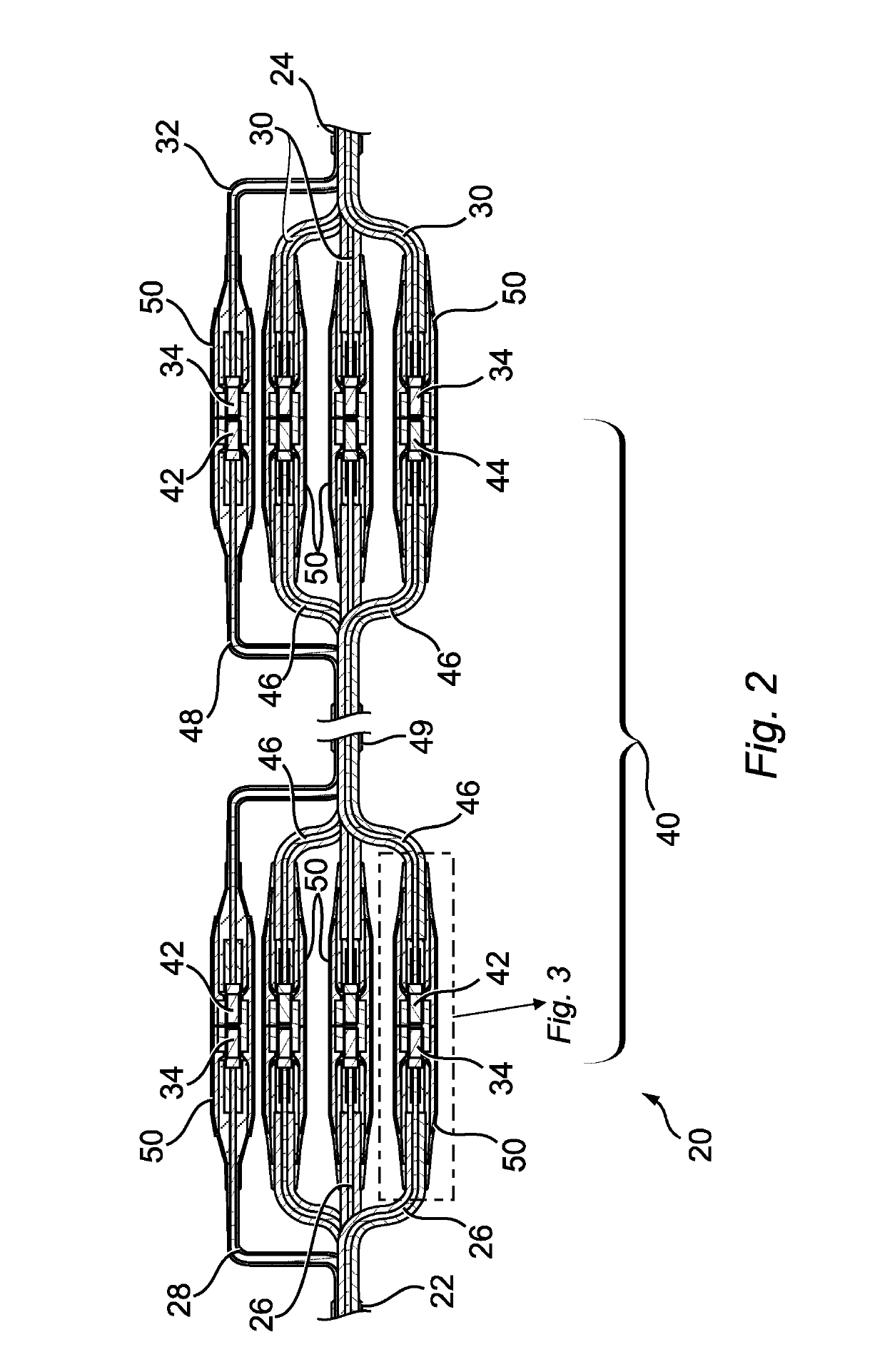

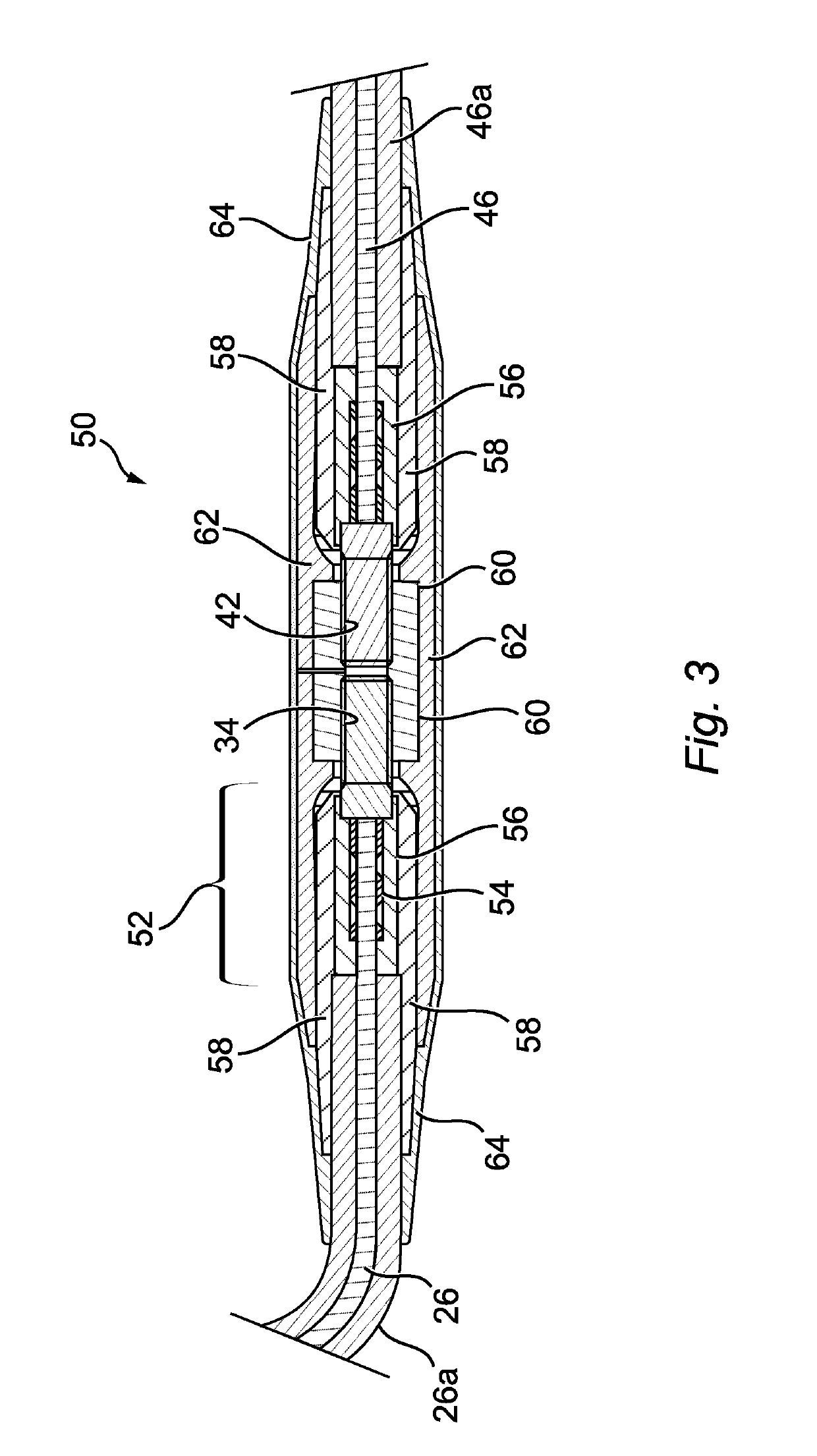

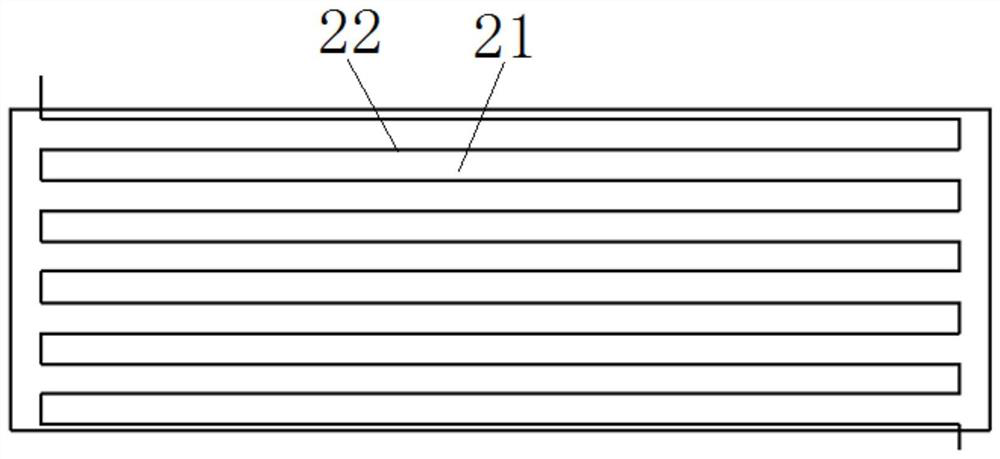

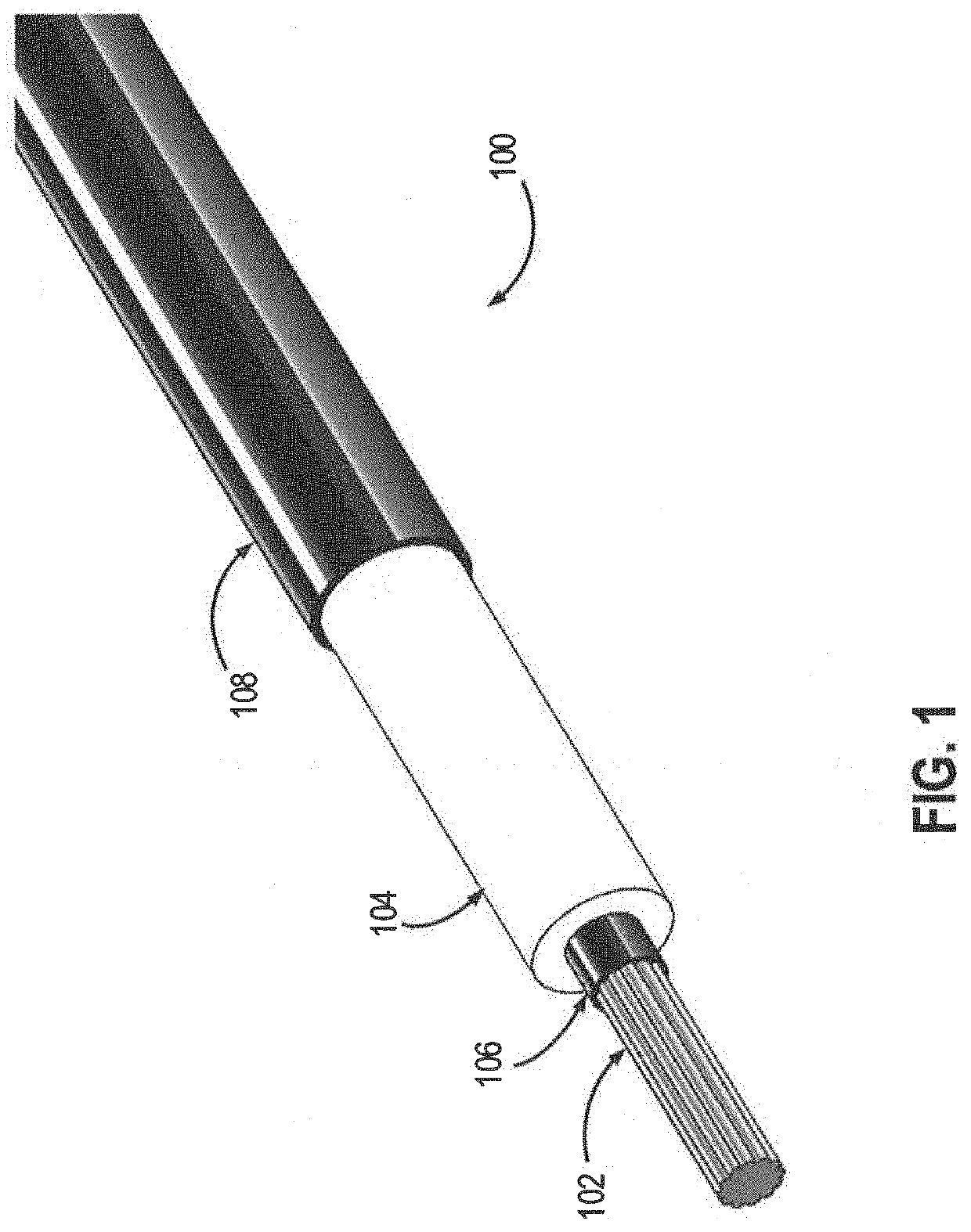

PIP trace heating connection assembly

ActiveUS10350716B2Engagement/disengagement of coupling partsPipe laying and repairElectricityTrace heating

A PIP Trace Heating Connection Assembly A pipe-in-pipe (PIP) trace heating connection assembly in the annulus of a PIP pipeline comprising at least first and second conjoined PIP stalks having inner and outer pipes and the annulus thereinbetween, the first PIP stalk having a first trace heating cable (22) located along its inner pipe, and the second PIP stalk having a second trace heating cable (24) located along its inner pipe, the first and second heating cables have cable ends and heating cable terminals on the cable ends, and a flexible intermediate connecting cable (40) having first and second intermediate terminals secured to, the heating cable terminals of the first and second trace heating cables respectively to form a secured electrical pathway between the first and second trace heating cables. In this way, securing the heating cable terminals with the intermediate connecting cable significantly reduces the time required to form a secured electrical pathway between the trace heating cables of each PIP stalk.

Owner:TECH FRANCE SA

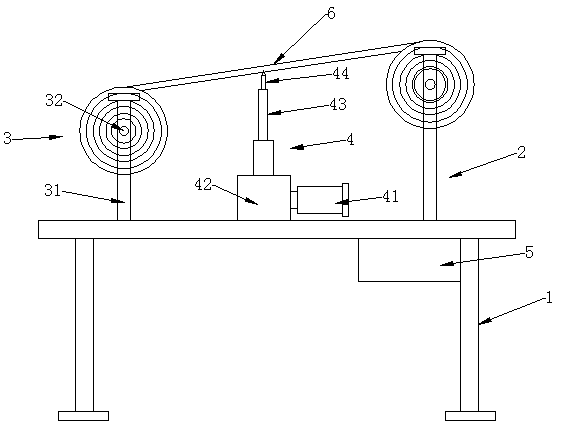

Novel anti-declining trace heating tape bundling machine

PendingCN107658069ARealize unloadingSimple structureManufacturing wire harnessesElectric machineProcess engineering

The invention provides a novel anti-declining trace heating tape bundling machine comprising a rack, a bundling mechanism, an unreeling mechanism, a cutting mechanism and a motor. The bundling mechanism is fixed on the rack. The unreeling mechanism is arranged on one side of the bundling mechanism. The cutting mechanism is arranged between the bundling mechanism and the unreeling mechanism. The motor is connected with the bundling mechanism and the cutting mechanism through lines. The novel anti-declining trace heating tape bundling machine is provided with a second support which is provided with support holes. An external rotating shaft can be separated from the second support after completion of bundling through design of the support holes so that the operability can be enhanced.

Owner:天津德尔泰热控系统有限公司

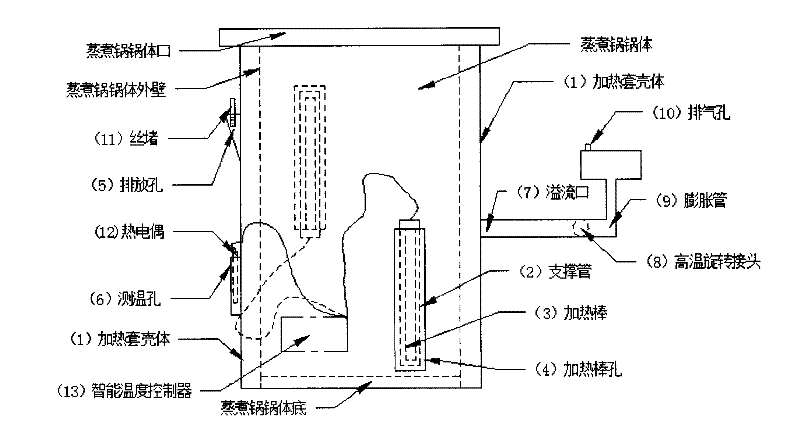

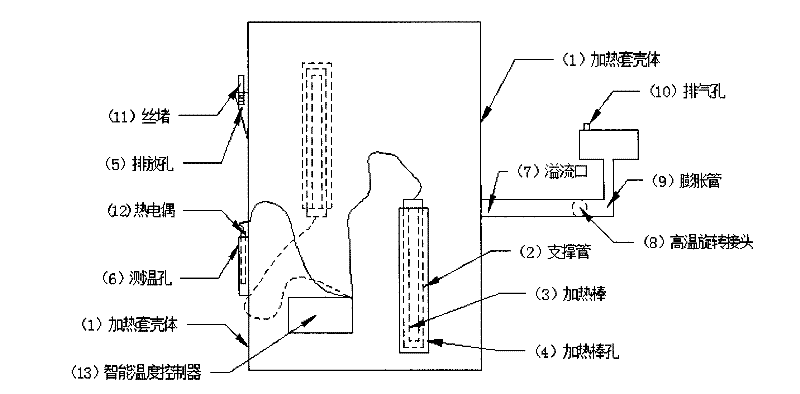

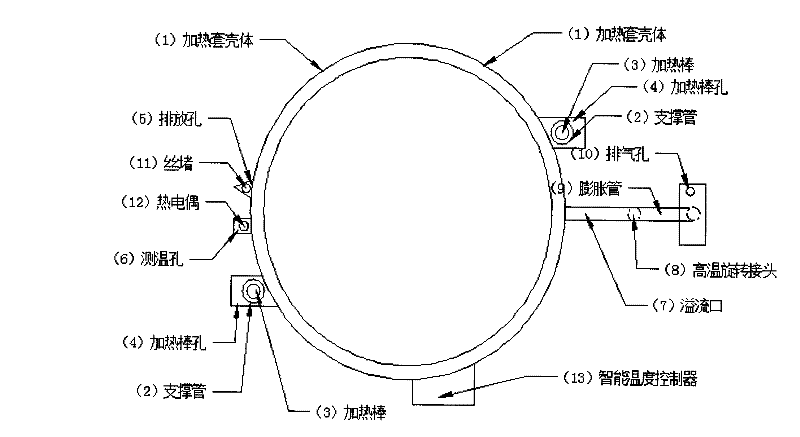

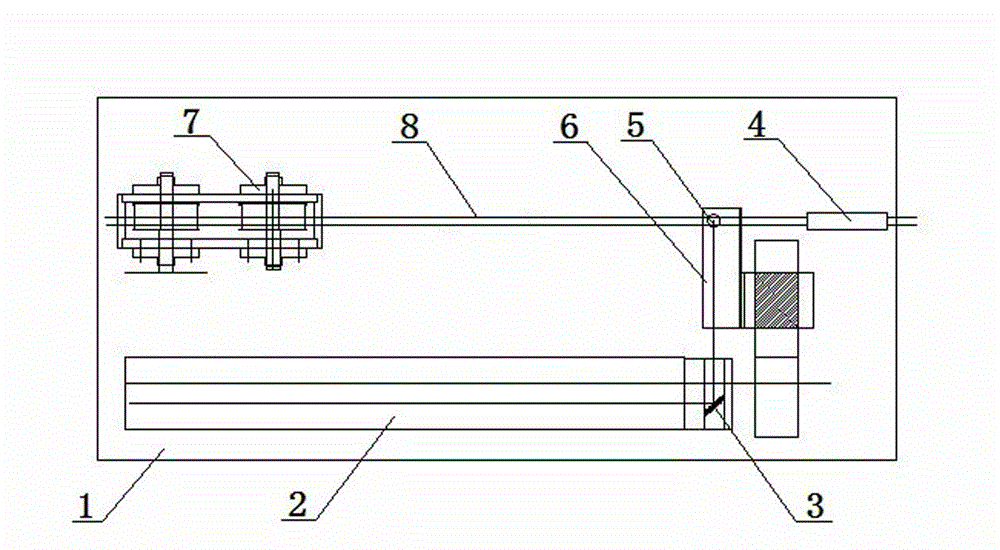

Heating device for cooking boiler

InactiveCN102517951AControllable heating temperatureHeating evenlyDigestersPaper material treatmentElectricityEngineering

The invention discloses a heating device for a cooking boiler. The device belongs to a heating jacket part of an experimental cooking boiler body, and is applied to heating the cooking boiler. A traditional heating manner for the cooking boiler comprises resistance trace heating and steam heating, and the temperature precision in the heating process is difficult to control. Electric heating is slow, thus a short circuit is easily caused; due to the high pressure, the steam heating process has hidden troubles and complex facilities are provided. The heating device heats up heat conduction liquid in a cavity which is formed between the heating device and the cooking boiler body, so that the cooking boiler body is heated up in an intermittent manner; the heat conduction liquid is integrally coated on the cooking boiler body, so that the cooking boiler is quickly, uniformly and stably heated up; the heating device is kept in the normal pressure the same as the atmosphere in the heating process, additional pressure is not applied, and external vapour is not accessed, thus the facilities are simple and the operation is safe; a rotary part is added to achieve the synchronous rotation of the cooking boiler and the heating device.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

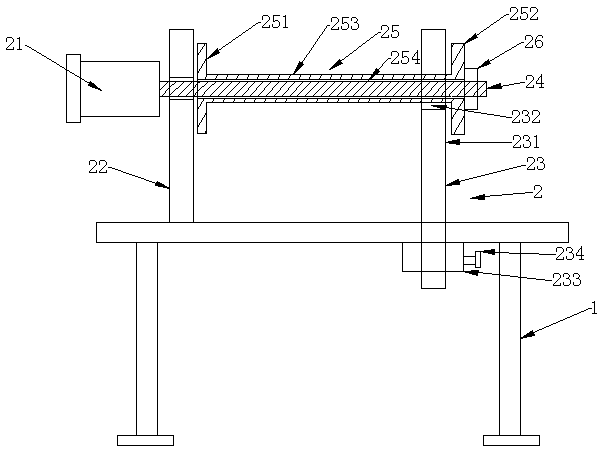

Trace heating band cutting machine

The invention relates to a trace heating band cutting machine which utilizes laser to cut a trace heating band and is characterized by comprising a machine frame. A laser generator is arranged above the machine frame, a focusing mechanism is arranged at the front end of a light outlet of the laser generator, a trace heating band conveying port is arranged on the focusing mechanism, and a focusing lens is arranged at the position on the side wall of the trace heating band conveying port corresponding to the light outlet of the laser generator. The cutting machine is used for cutting the trace heating band, is high in production efficiency and yield, and cannot damage metal wires.

Owner:陈杰

Preparation method of polymer-based PTC trace heating tape

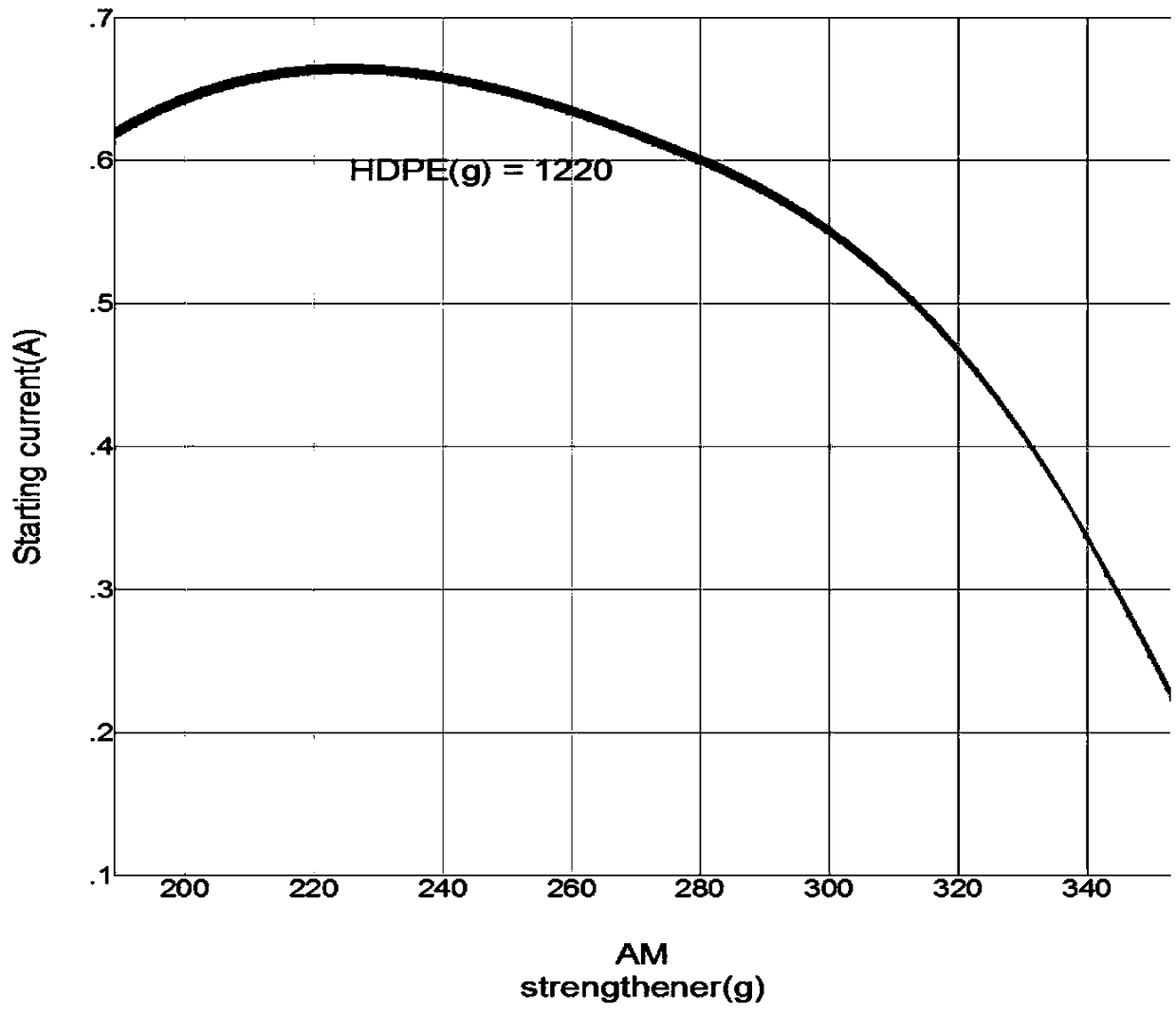

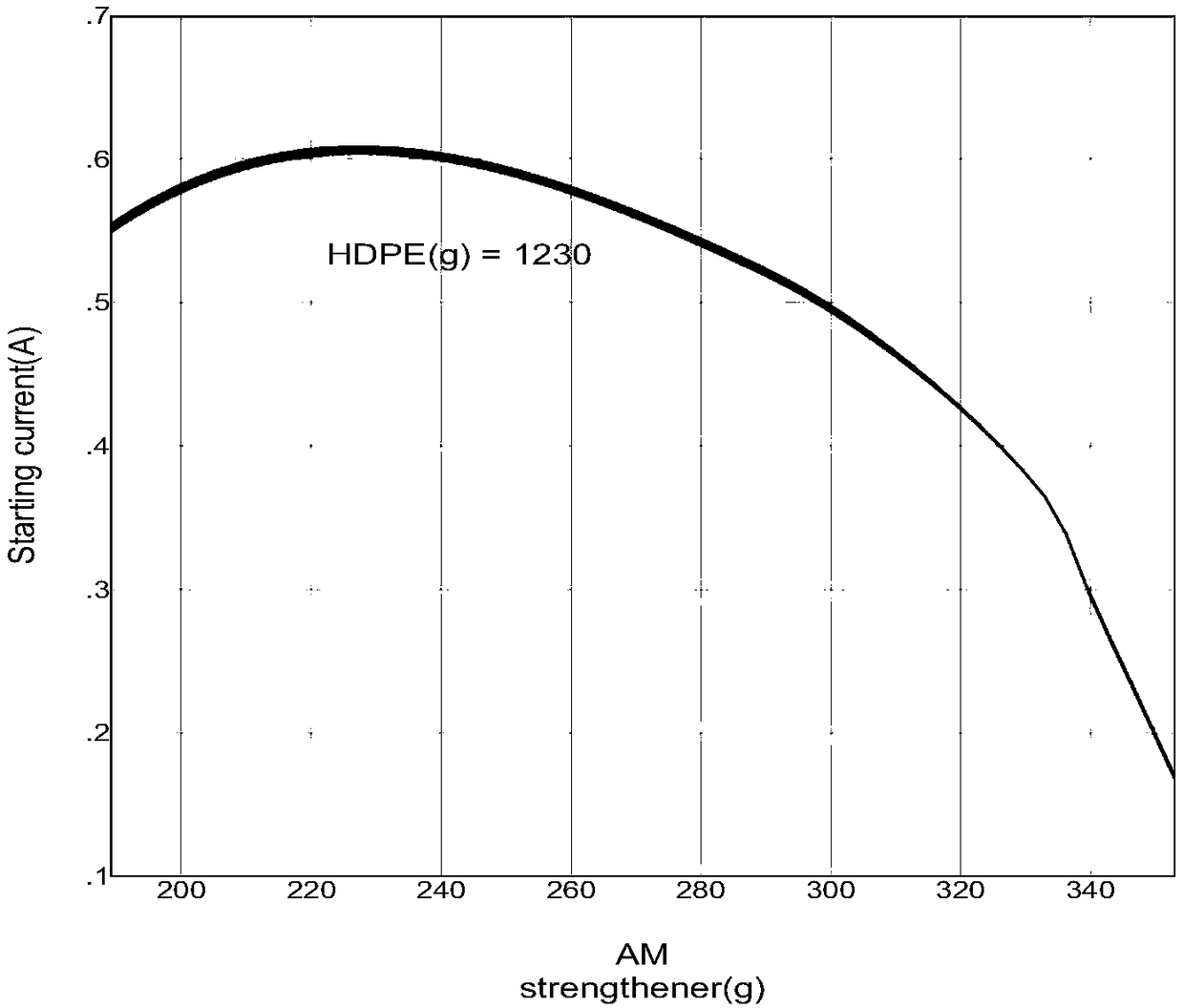

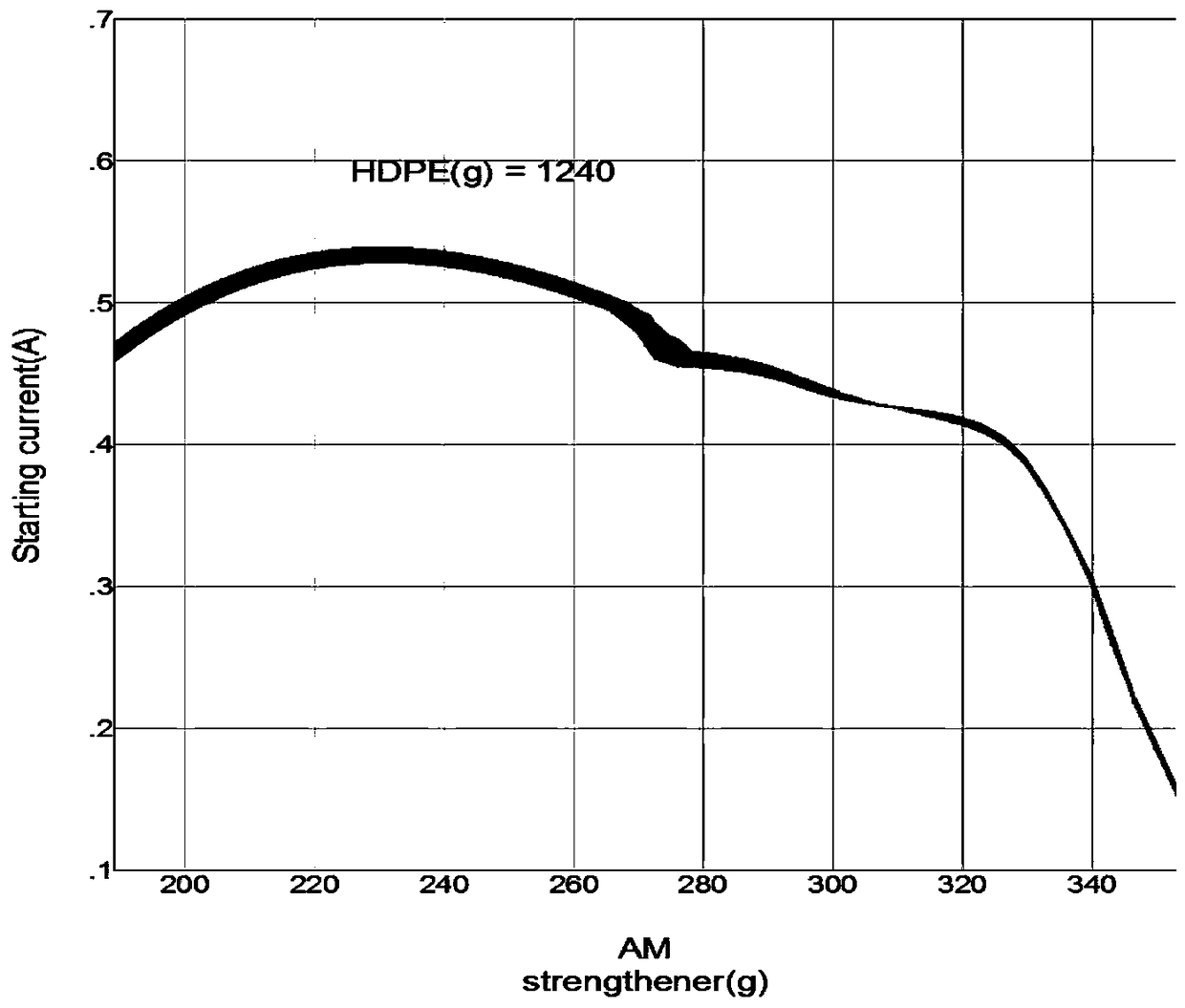

InactiveCN108948484AEvenly distributedRestricted movementChemical industryAlkali freeMechanical property

The invention discloses a preparation method of a polymer-based PTC trace heating tape, and relates to the technical field of polymer-based PTC trace heating tapes. The method is as below: firstly modifying a reinforcing material alkali-free glass fiber by using a coupling agent; then conducting melt-blending on the modified reinforcing material, an HDPE matrix material, an ultrafine magnesium hydroxide flux inhibitor and a silane coupling agent; performing forming by die molding; cutting the molded polymer-based PTC trace heating tape into standard parts; and installing a copper core. The combination of hot pressing and cold pressing is used to form the trace heating tape. The prepared trace heating tape is free of fluorine, not only has excellent thermal properties, but also gains improved mechanical properties; the raw materials are inexpensive; and the preparation method is simple and can be widely used in petroleum, chemical engineering and other aspects.

Owner:ANHUI NORMAL UNIV

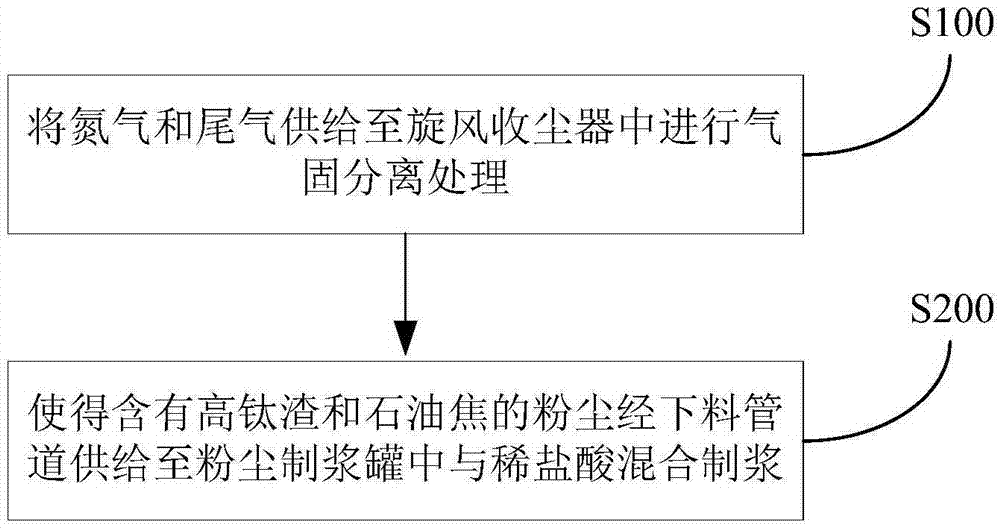

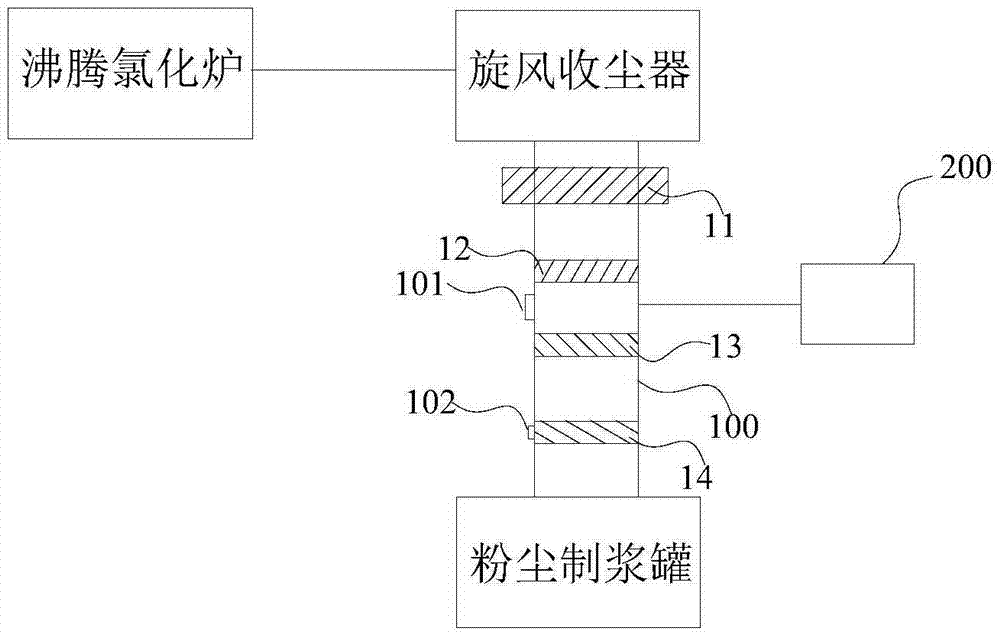

Method for tail gas dust collection and discharging in production of titanium tetrachloride

InactiveCN106865601AGuaranteed stabilitySolve the blockageTitanium halidesNitrogen gasPetroleum coke

The invention discloses a method for tail gas dust collection and discharging in production of titanium tetrachloride, wherein the method includes the steps: (1) nitrogen gas and tail gas are supplied to a cyclone dust collector and are subjected to gas-solid separation process, so as to separate to obtain gaseous titanium tetrachloride and dust containing high titanium slag and petroleum coke; and (2) an electric trace heating element and a rotary discharging valve on a discharging pipeline are opened, a pipeline seal nitrogen gas inlet and a rotary valve seal nitrogen gas inlet on the discharging pipeline are opened, at the same time, after a No.1 valve is opened for a predetermined time, the No.1 valve is closed, a No.2 valve is opened for a predetermined time, the dust containing the high titanium slag and the petroleum coke is supplied to a dust pulping tank through the discharging pipeline and is mixed and pulped with diluted hydrochloric acid, and moreover, every once in a while, a nitrogen gas gun is operated for one time to purge the discharging pipeline. The method can solve the problems of blockage of a dust collection and discharging pipeline and easily jamming of a discharging valve in the process of boiling chlorination production of titanium tetrachloride, so as to ensure the stability of production process of titanium tetrachloride.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

Testing device and method for testing thermal insulation effect of tunnel in cold region

PendingCN112858385ARealize a realistic simulationRealize acquisitionMaterial heat developmentStructural/machines measurementInsulation layerThermal insulation

The invention discloses a test device and method for testing the thermal insulation effect of a tunnel in a cold region. The test device comprises: a tunnel model; an electric heat tracing heating layer which is laid on the inner wall of the tunnel model, wherein the power supply end of the electric heat tracing heating layer is connected with the power supply; an air supply device which is arranged outside a hole in one end of the tunnel model and used for inputting air flow into the tunnel model, wherein the air flow direction is consistent with the axis direction of the tunnel model; and a plurality of environment acquisition devices which are uniformly distributed in the tunnel model. According to the invention, the tunnel model is utilized to simulate the heat transfer conditions of the actual tunnel thermal insulation layer and lining, and the air supply device is arranged to input the air flow into the tunnel model to achieve the real simulation of the actual climate environment in the tunnel; the electric heat tracing heating layer is used for actively heating the interior of the tunnel, and actual active heating and heat preservation setting in the tunnel is simulated; by arranging the environment acquisition devices, the acquisition of environment parameters is achieved, and the test of the thermal insulation effect is met; the testing device and method can be used for indoor simulation tests of different tunnels, and is simple in structure, high in accuracy and low in cost.

Owner:CHANGAN UNIV

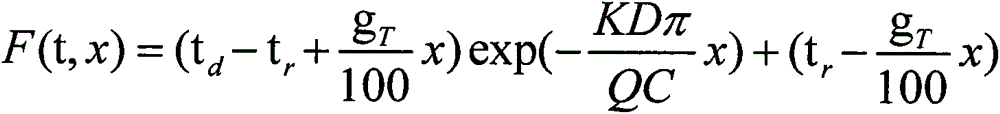

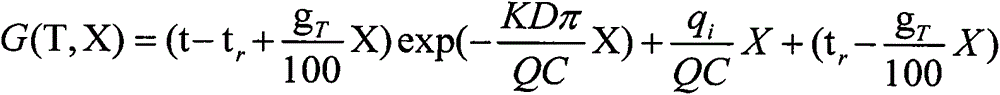

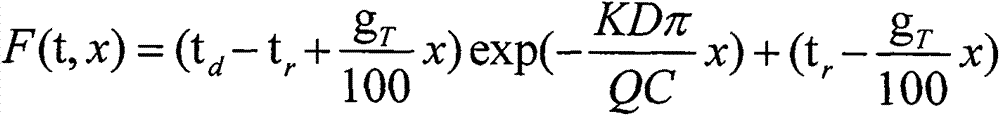

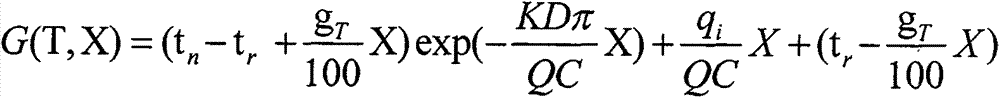

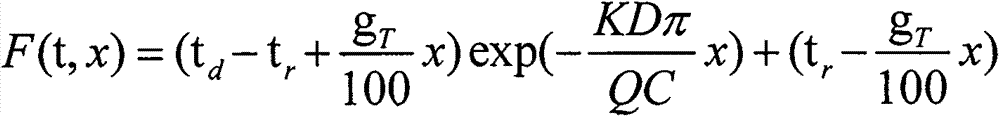

Method for determining setting depth of heating cable passing hollow sucker rod

The invention discloses a method for determining setting depth of a heating cable passing a hollow sucker rod. The method is applied to high-solidification-point high-wax-content crude oil wells of oil fields, and the heating cable is enabled to go down into a hollow of the hollow sucker rod for heat-tracing heating oil production. The method includes collecting oil well parameters and technical parameters of the hollow sucker rod waiting for being set; building a conventional oil pumping well temperature drop model and a heat-source oil pumping well temperature drop model; constructing according to setting depth calculated by the models, and checking polished rod load of an oil pumping machine. The method has the advantages that under the premise that maximum polished rod load of the oil pumping machine is met, normal production of oil wells larger than 35 DEG C in solidification point; thermal washing and chemical adding are not needed, effective time efficiency of the oil wells is improved by 10% averagely, production and running cost is saved, and labor intensity of staff is reduced.

Owner:马瑞程

Shielded fluoropolymer wire for high temperature skin effect trace heating

ActiveUS11006484B2Minimize the numberHigh voltagePipe heating/coolingInsulated cablesPolymer scienceCorona discharge

Owner:NVENT SERVICES GMBH

Shielded wire for high voltage skin effect trace heating

PendingCN109416145AThermal insulationOhmic-resistance waterproof/air-tight sealsElectrical conductorCorona discharge

A skin effect heating system for long pipelines includes a heater cable disposed in a ferromagnetic or other conductive heat tube, the heater cable and heat tube cooperating to produce heat that is applied to the carrier pipe. The heater cable includes a conductor surrounded by an insulating layer, and then a semiconductive outer layer or "jacket." The semiconductive jacket contacts the inner surface of the heat tube, where the charge density of the return current carried by the heat tube is at its highest. The semiconductive jacket material has a resistivity that is sufficiently low to reduceor eliminate arcing events such as corona discharge by allowing accumulated charge on the heat tube to dissipate. The resistivity is also high enough to prevent the return current from flowing into or through the semiconductive outer layer, so that heat production capacity of the system is maximized.

Owner:NVENT SERVICES GMBH

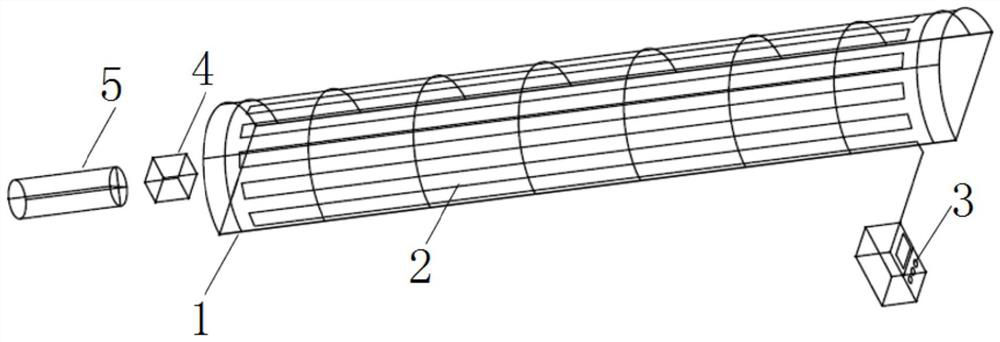

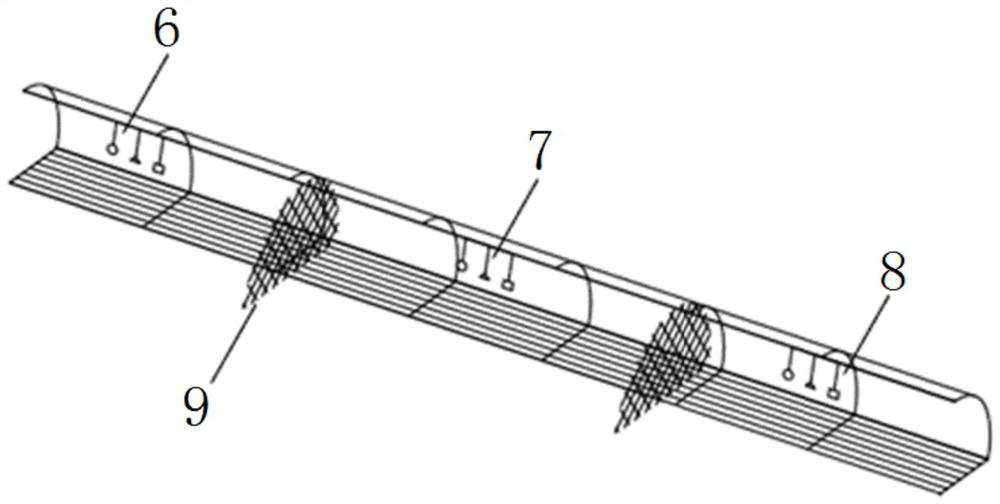

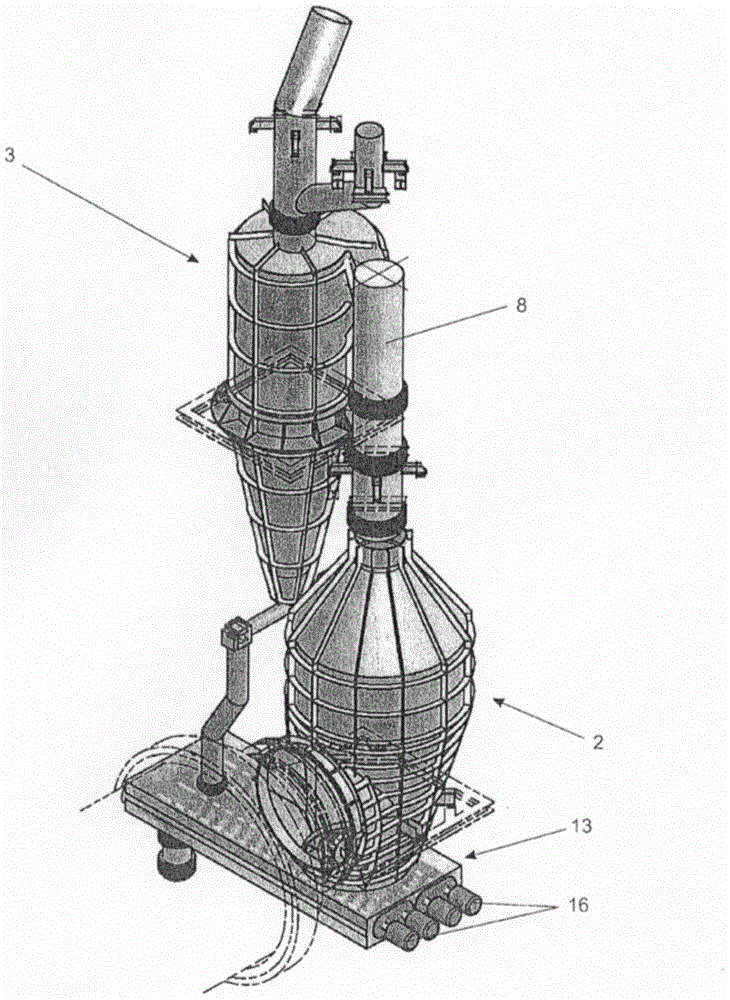

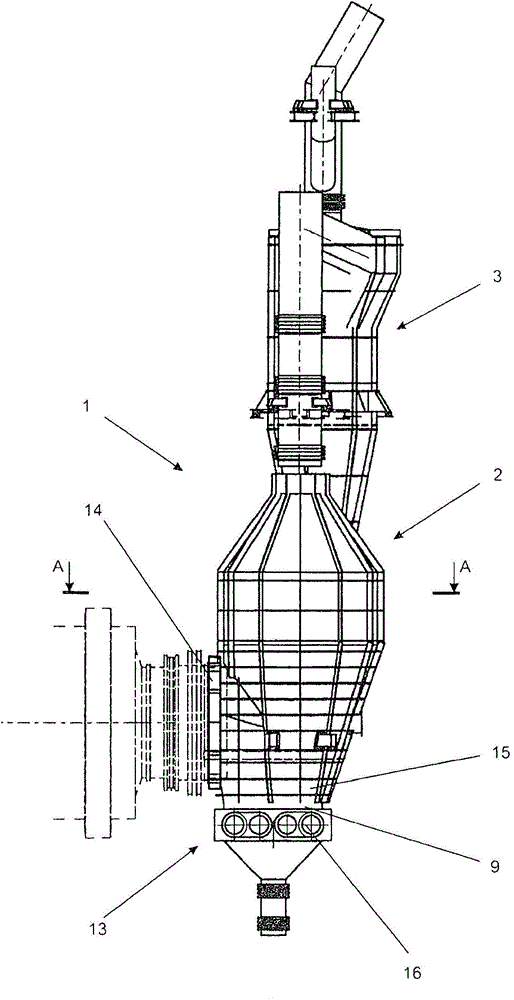

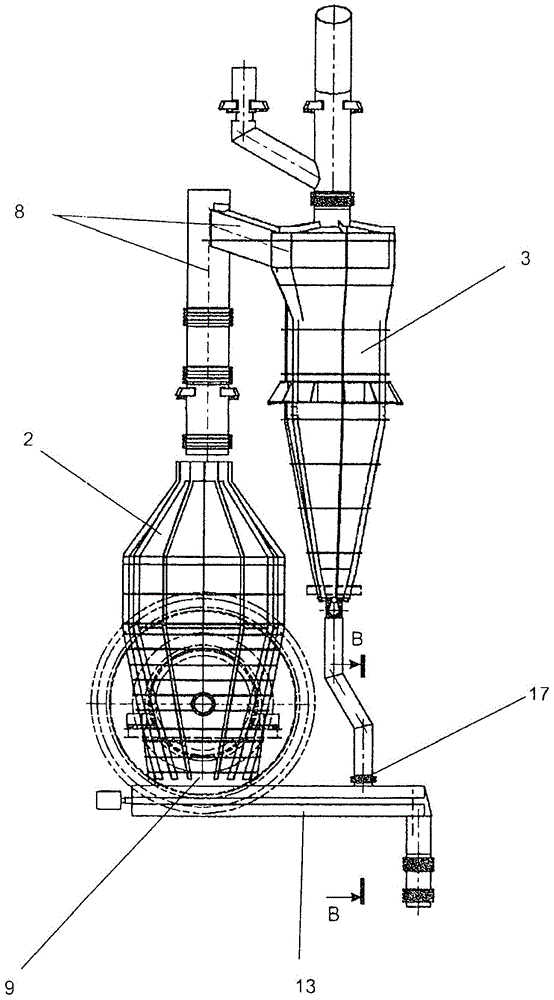

Separator for separating solid particles from a vapour-gas mixture

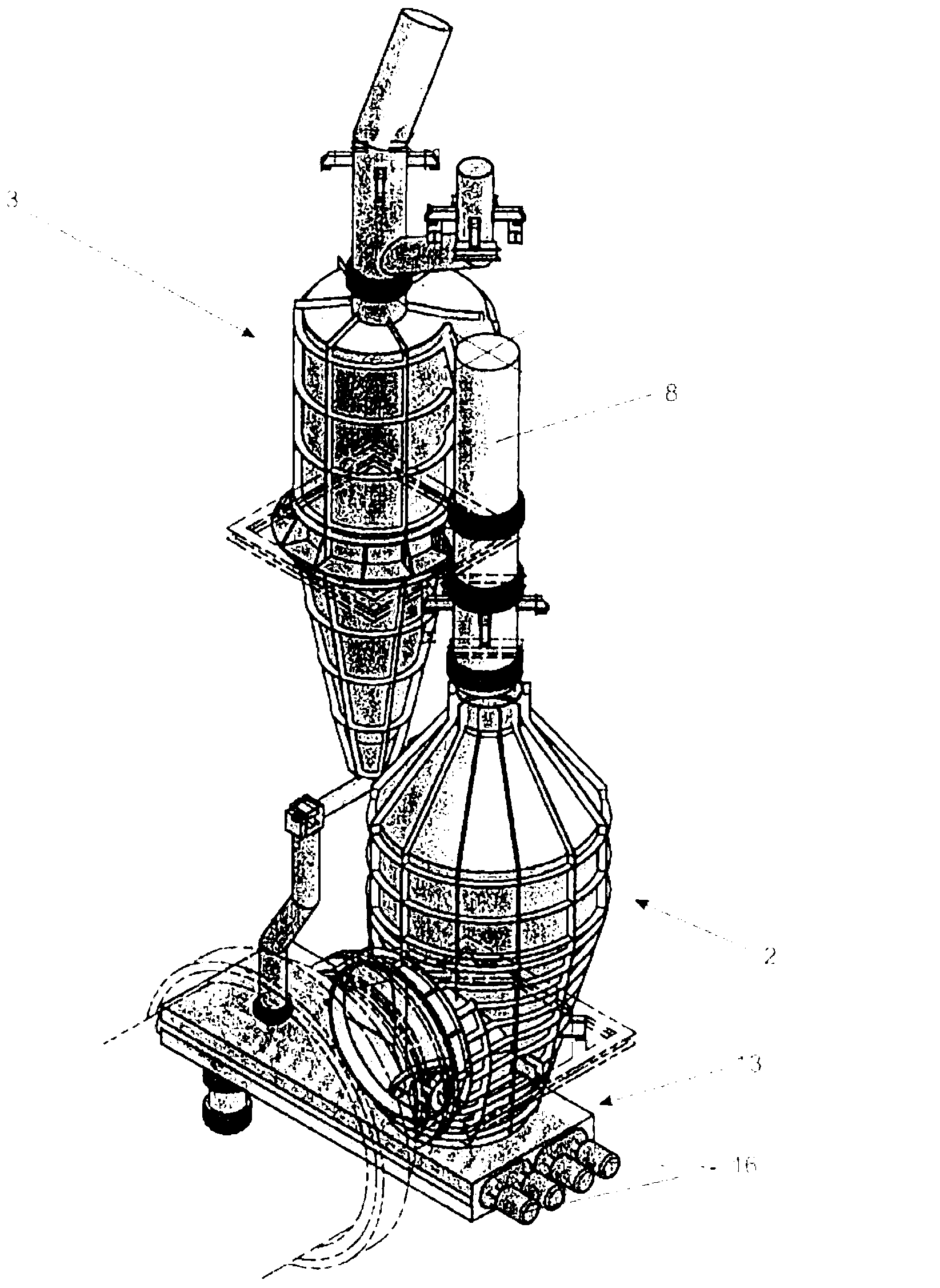

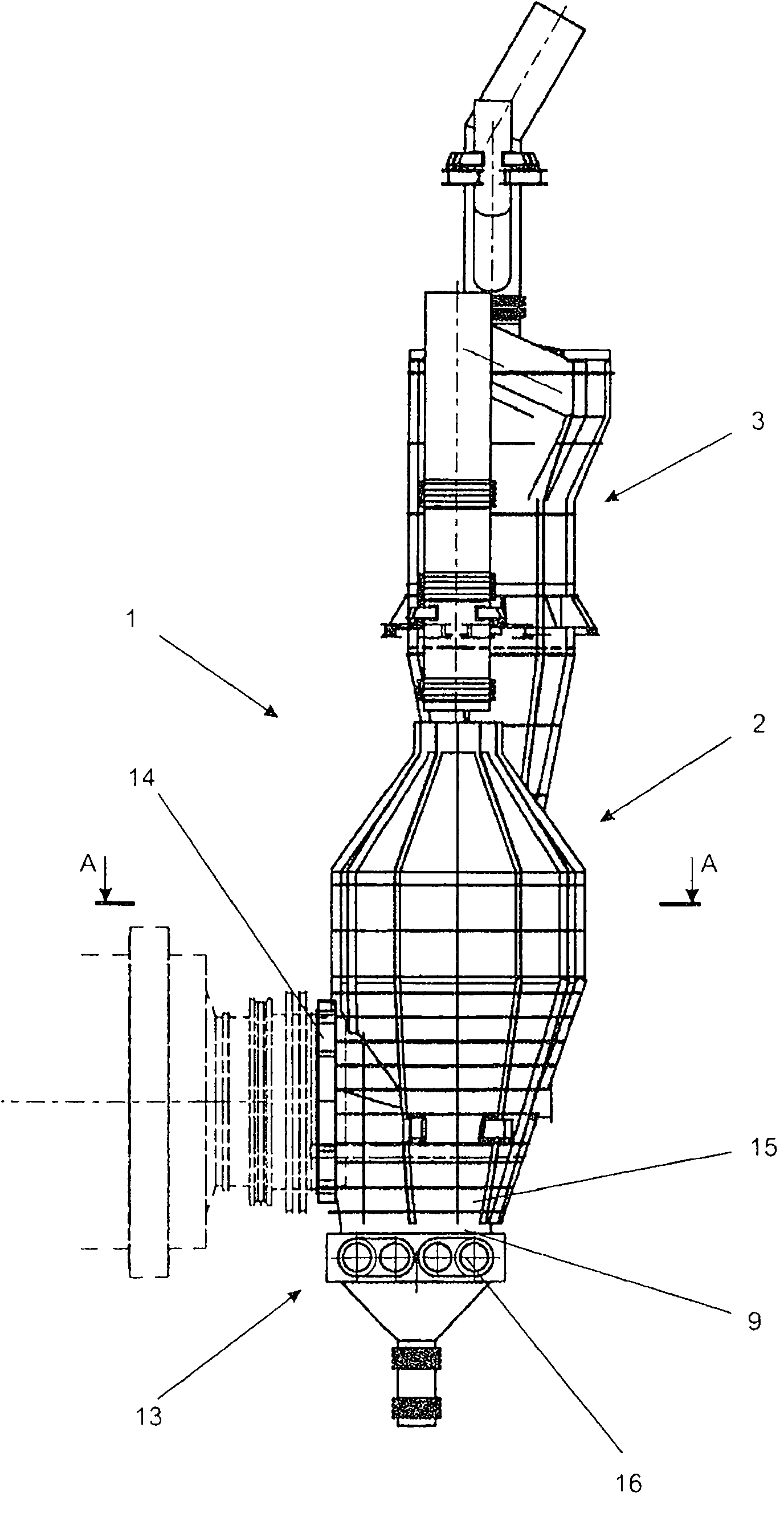

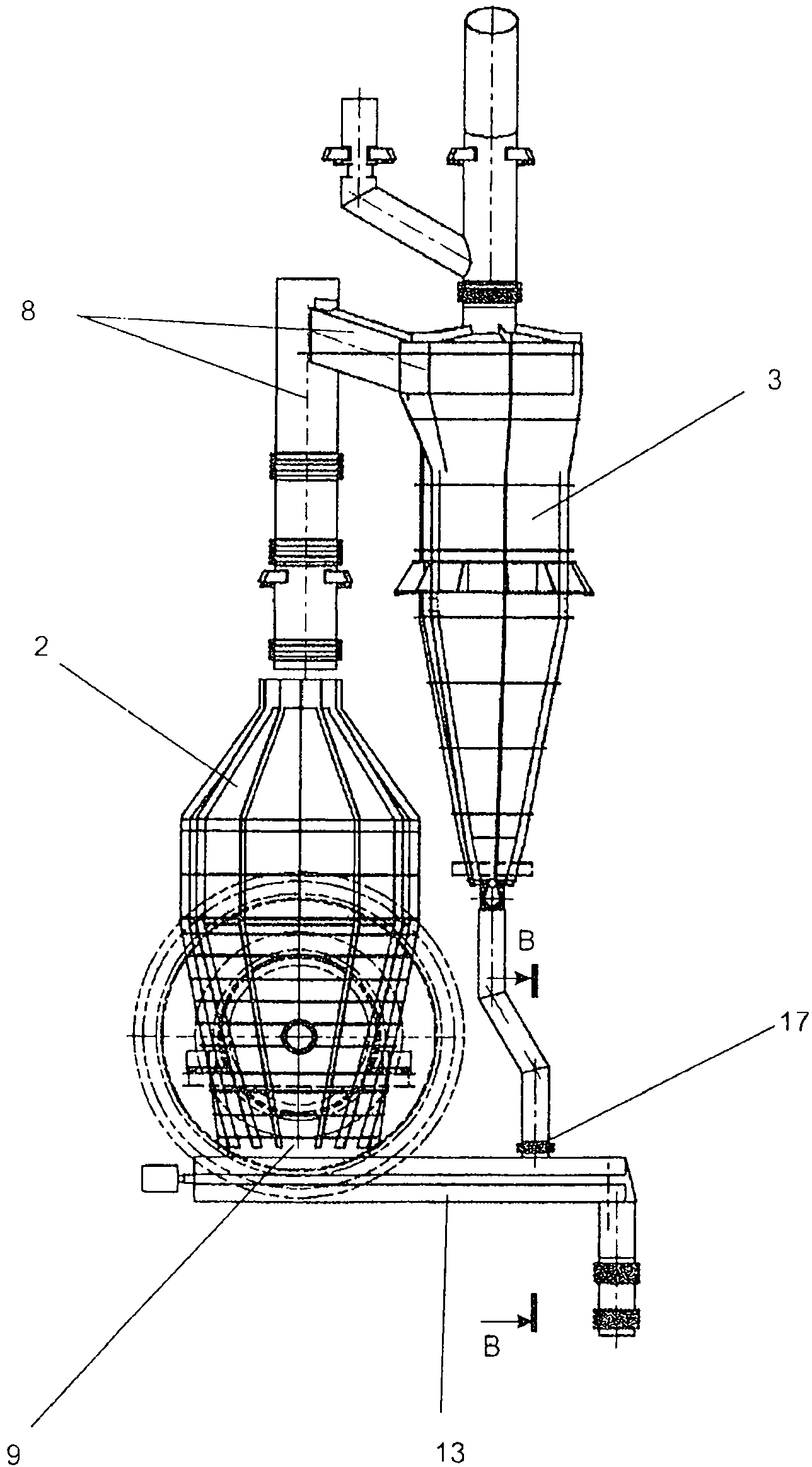

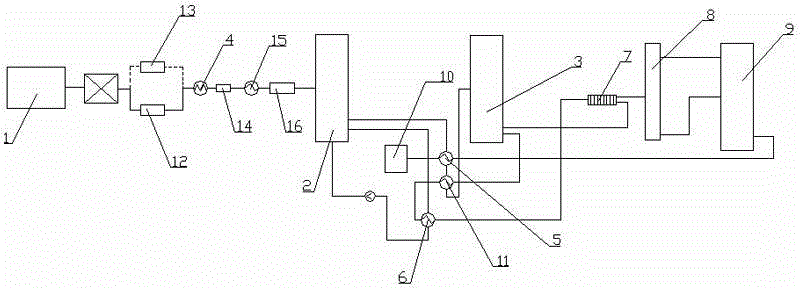

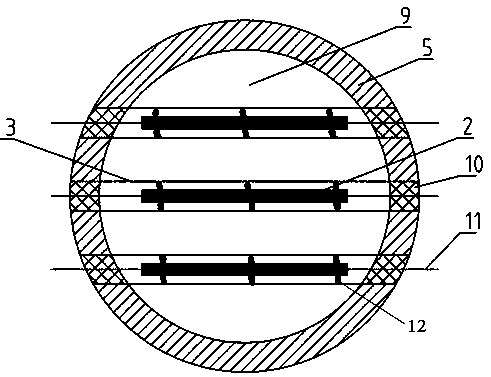

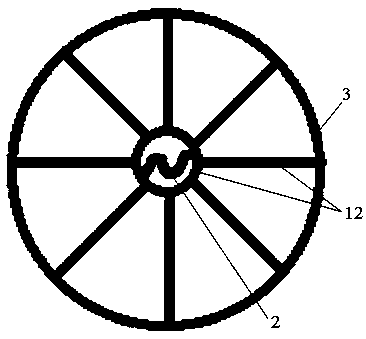

ActiveCN103269785BAvoid cloggingDispersed particle separationCleaning using toolsCycloneSolid particle

The present invention is related to the separator for separating solid particles from a vapour-gas mixture, and particularly to the structure of a dust chamber (2) as installed in the plant for processing fossil fuels or materials containing organic matter. The dust chamber (2) comprises a main body (4) having an inlet (14) for a vapour-gas mixture containing semi-coke particles and an outlet chute (9) for removal of semi-coke particles, wherein the upper part of the main body (4) is connected to the inlet of a cyclone (3) for removal of fine semi-coke particles from the vapour-gas mixture and wherein a screw conveyor unit (13) is connected to the bottom part of the main body (4). Said main body (4) is covered with an external insulation (5). Electrical trace heating cables (7) are in contact with the external surface of the main body (4) of the dust chamber (2).

Owner:ENEFIT OUTOTEC TECH OU

Separator for separating solid particles from a vapour-gas mixture

ActiveCN103269785AAvoid osmosisAvoid stickingDispersed particle separationCleaning using toolsCycloneSolid particle

The present invention is related to the separator for separating solid particles from a vapour-gas mixture, and particularly to the structure of a dust chamber (2) as installed in the plant for processing fossil fuels or materials containing organic matter. The dust chamber (2) comprises a main body (4) having an inlet (14) for a vapour-gas mixture containing semi-coke particles and an outlet chute (9) for removal of semi-coke particles, wherein the upper part of the main body (4) is connected to the inlet of a cyclone (3) for removal of fine semi-coke particles from the vapour-gas mixture and wherein a screw conveyor unit (13) is connected to the bottom part of the main body (4). Said main body (4) is covered with an external insulation (5). Electrical trace heating cables (7) are in contact with the external surface of the main body (4) of the dust chamber (2).

Owner:ENEFIT OUTOTEC TECH OU

Flashing and pressure holding combined retention tower electric tracing heating temperature holding modified pitch production technology

ActiveCN104694146AImprove energy savingImprove adhesionWorking-up pitch/asphalt/bitumen by thermal meansTube furnacePhysical chemistry

The invention relates to a flashing and pressure holding combined retention tower electric tracing heating temperature holding modified pitch production technology. The production technology is a single-heat production technology, only one tube furnace is adopted for heating in the process, energy-saving effect is remarkable, and flashing separation and continuous heating temperature holding thermal polymerization are combined. Flashing separation is conducted firstly on pitch, then oxidization thermal polymerization is conducted by controlling electric heating temperature holding accurately, an obtained target product meets the requirement of the carbon industry for pitch better, cohesiveness is excellent during mixed kneading of a carbon element mixture, and coking value is higher after roasting.

Owner:HENAN KAITAN NEW MATERIAL +1

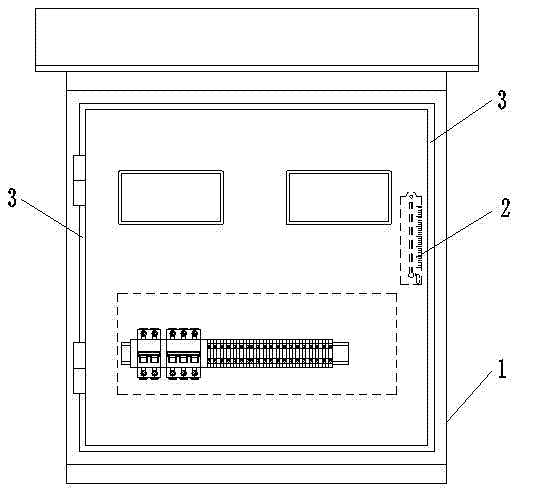

Fan instrument control cabinet thermostat of 600MW circulating fluidized bed

InactiveCN103096677AGuaranteed uptimeGuarantee normal operation and increase its service lifeCooling/ventilation/heating modificationsAutomatic controlThermostat

The invention discloses a fan instrument control cabinet thermostat of a 600MW circulating fluidized bed. The fan instrument control cabinet thermostat comprises an instrument control cabinet body, a mercurial thermometer is arranged in the instrument control cabinet body, and self regulated electric trace heating belts are arranged on the borders around the instrument control cabinet. By mounting the self regulated electric trace heating belts, the instrument control cabinet is protected automatically with constant temperature, the heated things are ensured to be in an ideal temperature range, electronic components are avoided being affected by temperature and humidity, conversion rate of electric energy and heat energy is high, temperature can be controlled automatically, output power can be regulated automatically, heating is uniform, energy consumption is low, normal operation of the instrument is guaranteed, and service life of the instrument is prolonged.

Owner:NANTONG DART POLLRICH FAN

A process for upgrading asphalt by flashing and maintaining pressure combined with electric tracing heating and maintaining temperature in retention tower

ActiveCN104694146BImprove energy savingImprove adhesionWorking-up pitch/asphalt/bitumen by thermal meansTube furnaceEngineering

The invention relates to a flashing and pressure holding combined retention tower electric tracing heating temperature holding modified pitch production technology. The production technology is a single-heat production technology, only one tube furnace is adopted for heating in the process, energy-saving effect is remarkable, and flashing separation and continuous heating temperature holding thermal polymerization are combined. Flashing separation is conducted firstly on pitch, then oxidization thermal polymerization is conducted by controlling electric heating temperature holding accurately, an obtained target product meets the requirement of the carbon industry for pitch better, cohesiveness is excellent during mixed kneading of a carbon element mixture, and coking value is higher after roasting.

Owner:HENAN KAITAN NEW MATERIAL +1

A method for determining the running depth of the heating cable through the hollow sucker rod

The invention discloses a method for determining setting depth of a heating cable passing a hollow sucker rod. The method is applied to high-solidification-point high-wax-content crude oil wells of oil fields, and the heating cable is enabled to go down into a hollow of the hollow sucker rod for heat-tracing heating oil production. The method includes collecting oil well parameters and technical parameters of the hollow sucker rod waiting for being set; building a conventional oil pumping well temperature drop model and a heat-source oil pumping well temperature drop model; constructing according to setting depth calculated by the models, and checking polished rod load of an oil pumping machine. The method has the advantages that under the premise that maximum polished rod load of the oil pumping machine is met, normal production of oil wells larger than 35 DEG C in solidification point; thermal washing and chemical adding are not needed, effective time efficiency of the oil wells is improved by 10% averagely, production and running cost is saved, and labor intensity of staff is reduced.

Owner:马瑞程

An electric heat tracing and thermal insulation device for subway pipeline equipment in cold areas

ActiveCN103867846BPlay the role of thermal protectionGuaranteed safe operationThermal insulationPipe heating/coolingTwo temperatureEngineering

The invention discloses an electric tracing heat preservation device for a cold region underground pipeline device. The electric tracing heat preservation device comprises electric tracing heating cables, a heat preservation protective layer and a temperature monitoring system. The electric tracing heating cables are laid along a pipeline, the heat preservation protective layer is arranged on the outer side of the pipeline, the temperature monitoring system is connected with the electric tracing heating cables, and temperature sensors of the temperature monitoring system are tightly attached to the outer wall of the pipeline. The heat preservation protective layer is composed of a composite silicate heat insulating layer, a glass cloth composite aluminum foil damp-proof layer and an aluminum alloy sheet protective layer. The temperature monitoring system comprises the temperature sensors and a comprehensive control device. The temperature sensors are connected with the comprehensive control device through connection terminals. Thermistors serve as the temperature sensors and are tightly attached to the outer wall of the pipeline, and each electric tracing heating cable is matched with two temperature sensors. The temperature monitoring system achieves remote monitoring, any failure of the electric tracing heat preservation device is found in time, and safety running of the cold region underground pipeline device is ensured.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

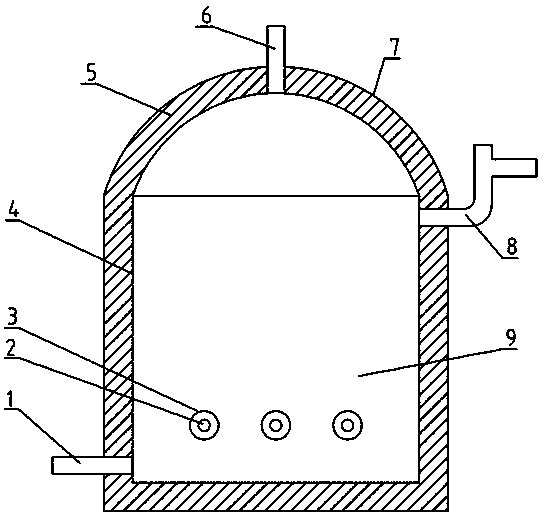

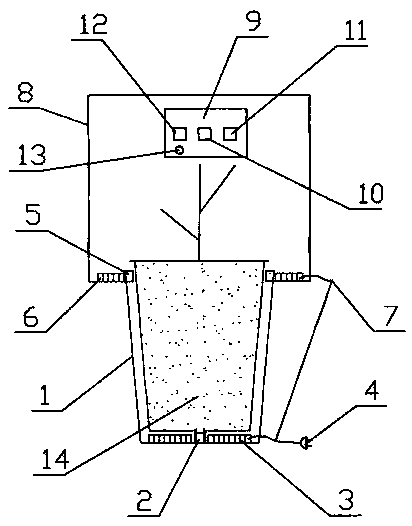

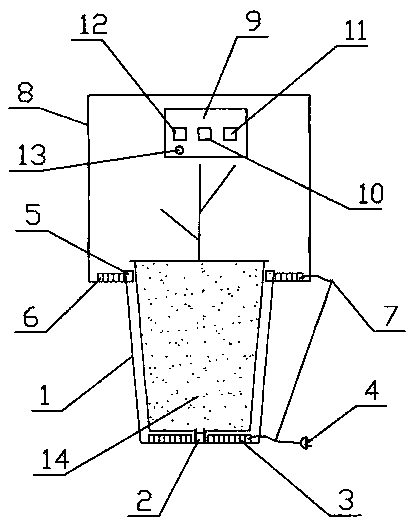

Biogas fermentation tank heat-tracing heating constant temperature device and application method thereof

PendingCN111334422AWarming up fastAchieve dynamic balanceBioreactor/fermenter combinationsBiological substance pretreatmentsInsulation layerProcess engineering

The invention discloses a biogas fermentation tank heat-tracing heating constant temperature device and an application method thereof. The biogas fermentation tank heat-tracing heating constant temperature device includes a fermentation tank, wherein the fermentation tank is provided with a material feeding pipe, a biogas pipe and an overflow material outlet pipe, and the biogas fermentation tankheat-tracing heating constant temperature device is characterized in that a heat insulation layer is arranged on the outer wall of the fermentation tank, a plurality of heating tubes are arranged at the inner bottom of the fermentation tank, and sheathed heating elements are embedded in the heating tubes; and an anaerobic fermentation area is formed between the outer walls of the heating tubes andthe inner wall of the fermentation tank, and the inner walls of the heating tubes are in contact with the heating elements. Through the biogas fermentation tank heat-tracing heating constant temperature device, the uniformity degree of the temperature in the fermentation tank can be improved effectively, disturbance in the tank can be increased, and fermentation materials can be mixed more uniformly, so that the fermentation efficiency is improved.

Owner:BIOGAS SCI RES INST MIN OF AGRI

Automatic temperature control flowerpot thermal insulation cover

InactiveCN109952898AHorticulture methodsPlant protective coveringsTemperature controlThermal insulation

The invention provides an automatic temperature-control flowerpot thermal insulation cover. The thermal insulation cover aims to solve the problem that along with the development of new urbanization in china, more and more low-temperature occasions need bonsai decoration, but at present, no perfect flowerpot capable of resisting the cold exists to adapt to the development requirement. The thermalinsulation cover comprises a plastic thermal insulation cover lower body, a temperature-control trace heating tape cable, a detachable transparent thermal insulation cover body, a temperature displayalarm and the like. The thermal insulation cover has the advantages that the heating volume can be effectively decreased to the minimum, so that the energy is saved, in addition, the application occasion of potted plants is expanded, and therefore the requirement for the development of the new urbanization is met.

Owner:北京启明兴华科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com