Continuous online emission monitoring system

A monitoring system and flue gas technology, applied in measuring devices, instruments, etc., can solve problems such as inability to monitor flue gas, equipment corrosion, and insufficient filtering, and achieve the effects of flexible use, improved accuracy, and powerful software functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

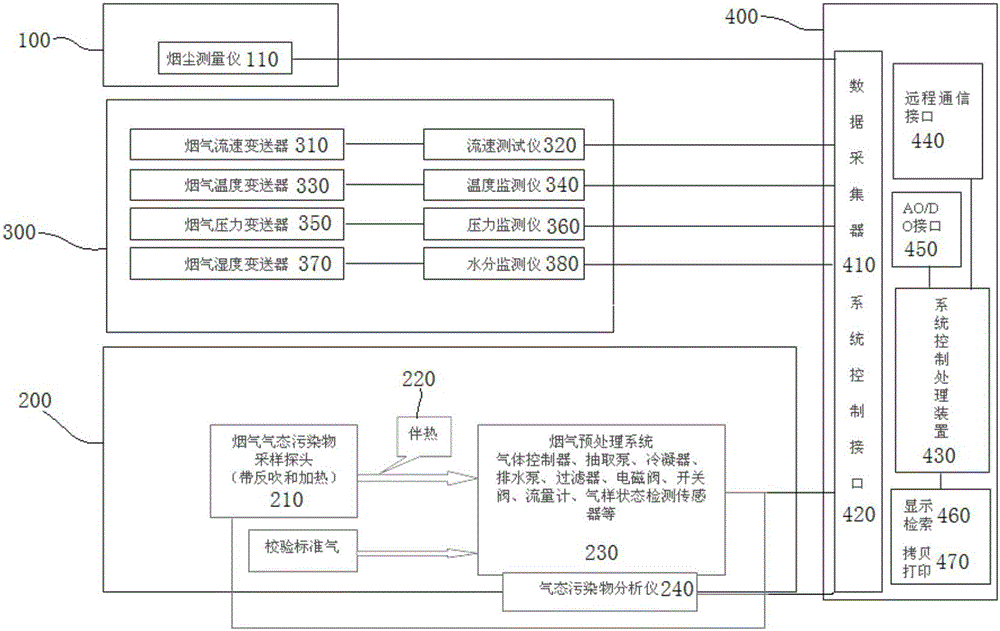

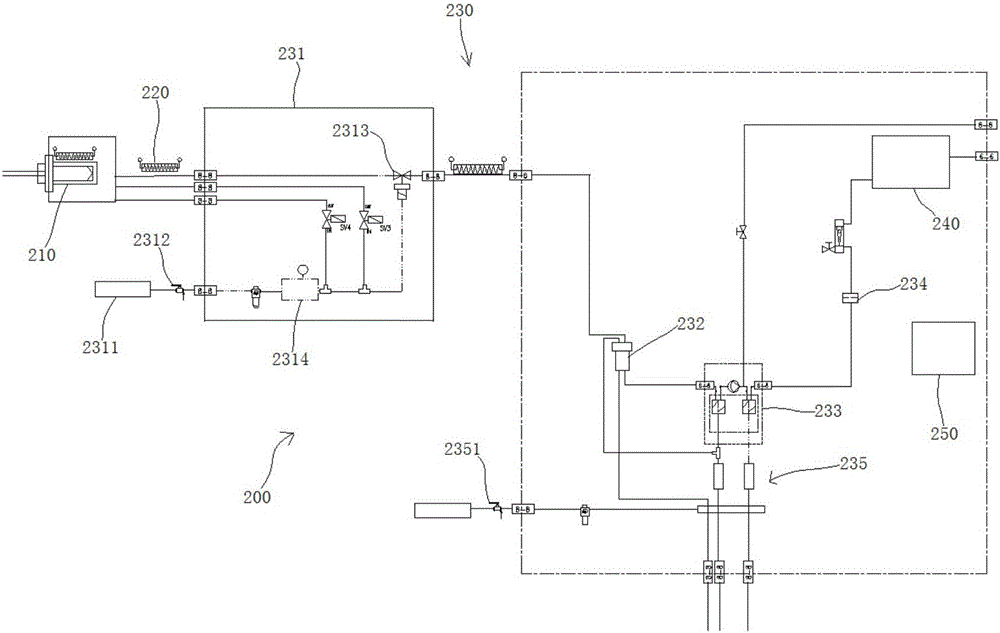

[0022] see Figure 1 to Figure 2 , shown in the figure is a continuous online flue gas monitoring system, including a continuous monitoring subsystem 100 for solid particulate matter, a continuous monitoring subsystem 200 for gaseous pollutants, and a continuous monitoring subsystem 300 for flue gas parameters installed in the chimney or flue, The solid particle continuous monitoring subsystem 100 , the gaseous pollutant continuous monitoring subsystem 200 and the flue gas parameter continuous monitoring subsystem 300 are all connected to the data processing and remote communication system 400 . By monitoring solid particles, gaseous pollutants and flue gas parameters, in conjunction with data processing and remote communication system 400, it h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com