Heating system and heating means

A heating system and heating method technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of energy loss, poor heating effect of wind turbine blades, high cost, etc., and achieve the effects of low cost, not easy to fire, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

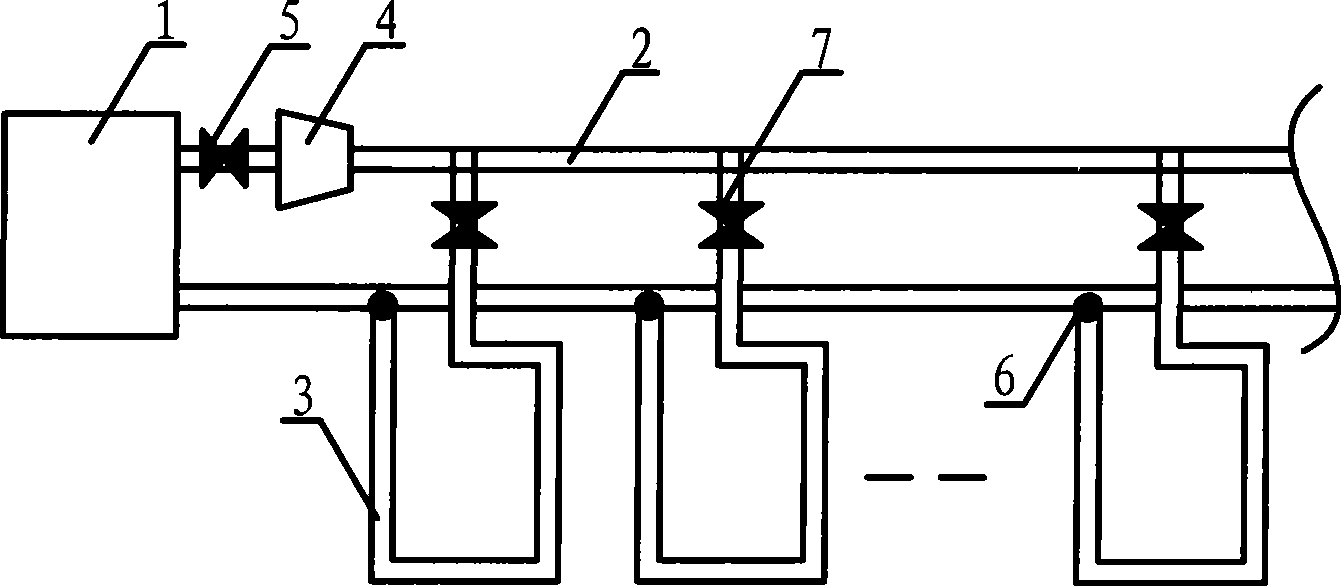

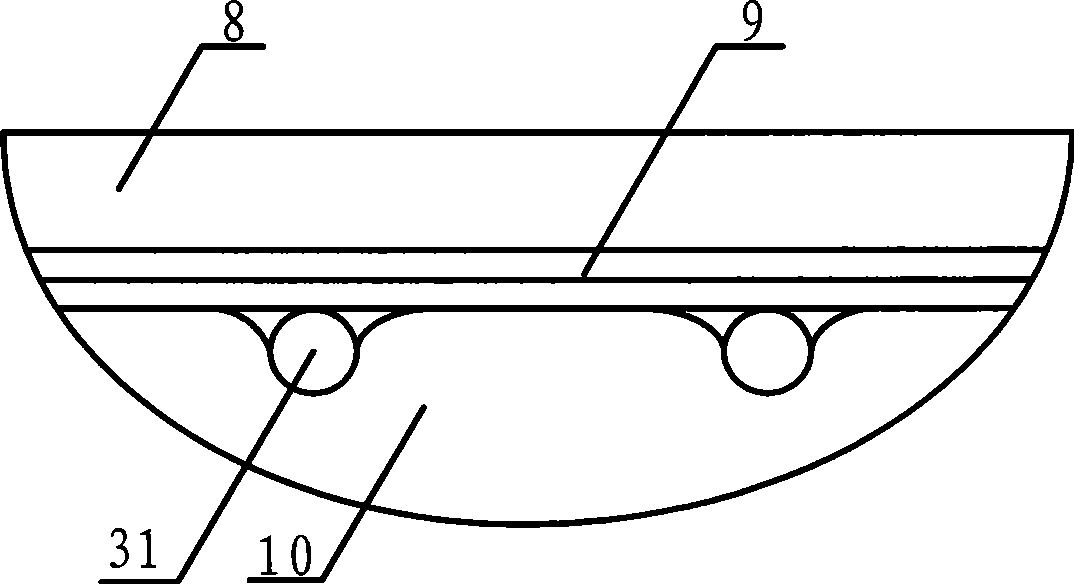

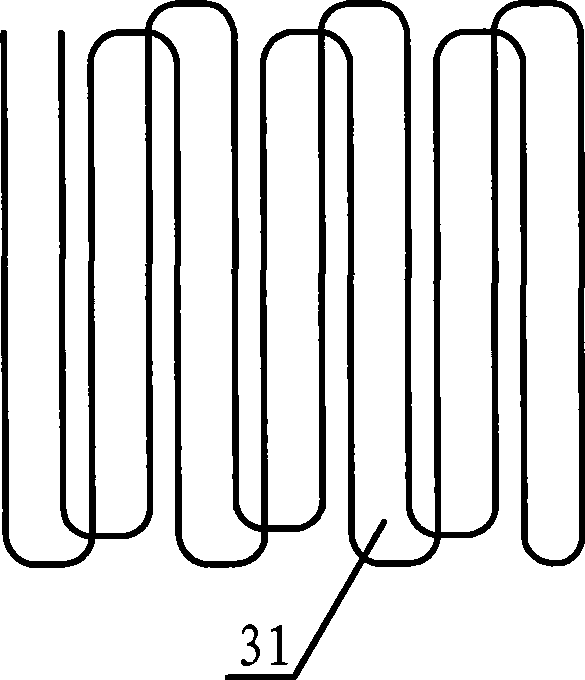

[0024] Such as figure 1 Shown is a schematic structural diagram of an embodiment of the heating system of the present invention. The heating system of this embodiment includes a heating box 1 , a main pipeline 2 , a heating unit 3 and a main valve 5 . Wherein the heating box 1 is used for storing the liquid to be heated. The main pipeline 2 is connected with the heating box 1, and the main pipeline 2 is used for transporting the liquid in the heating box 1, and one or more heating units 3 are connected in parallel on the main pipeline 2. The main pipeline 2 is provided with a main valve 5 for controlling the communication or disconnection between the heating box 1 and the main pipeline 2 .

[0025] The invention proposes a heating system capable of heat-treating wind turbine blades during their manufacture. By arranging a heating unit and a heating box, the heated liquid is injected into the heating unit embedded in the mold shell to heat the blade, so as to realize the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com