Phase change assisted heating tank-type heat collection system of solar water heater

A solar water heater and auxiliary heating technology, applied in the field of solar energy utilization, can solve the problems of low utilization rate of solar energy, great difficulty in vacuuming, low economic efficiency, etc., and achieve the effects of good social and economic benefits, increased utilization rate, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

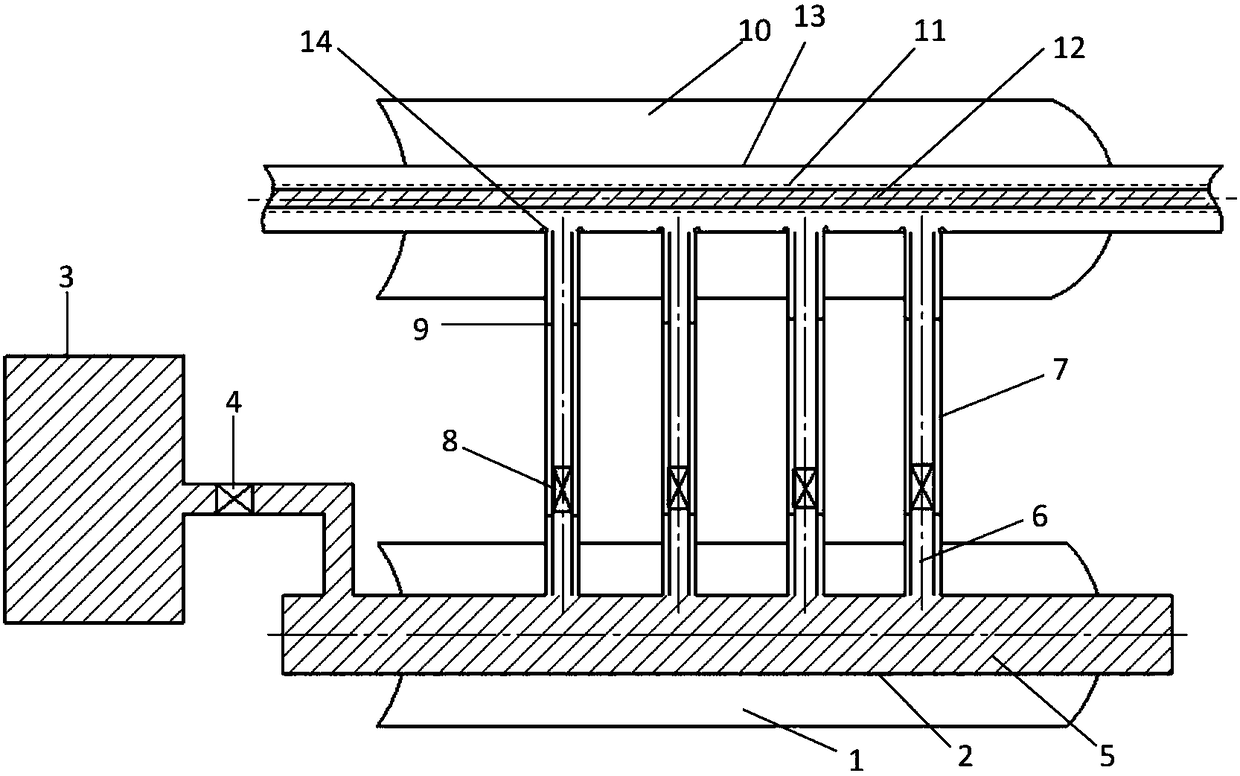

[0031] In this embodiment, a trough solar water heater heat collection system with phase change auxiliary heating includes an auxiliary heat collection device and a main heat collection device, and the auxiliary heat collection device transfers the collected solar energy to the main heat collection device through the phase change working medium 5 .

[0032] The auxiliary heat collection device includes an auxiliary heat collection tank 1, an auxiliary heat collection pipe 2, a phase change working medium storage tank 3, a valve 4, a standpipe, a throttle valve 8 and a connecting body 9, and the auxiliary heat collection pipe 2 is filled with The phase change working medium 5 is placed at the focal line of the auxiliary heat collecting tank 1 , the phase change working medium storage tank 3 is connected to the auxiliary heat collecting tube 2 , and the inner layer 6 of the standpipe is connected to the outer layer 7 of the standpipe through a connecting body 9 .

[0033] The ma...

Embodiment 2

[0039] In this embodiment, a phase-change auxiliary heating trough solar water heater heat collection system is connected to the same parts as in embodiment 1, the difference is that the auxiliary heat collection trough described in this embodiment is a trough concentrator with a length of 4m The cross-section of the auxiliary heat collecting tube is circular, the length is 4m, and the diameter is 1m; the number of the standpipes is 8, and the diameter of the outer layer of the standpipe is 100mm; the phase change working medium is water.

[0040] Taking Beijing as an example, the instantaneous solar radiation intensity in winter is about 200w / m 2 , the heat collecting area of the main heat collecting device per unit length is about 2.25m 2 , The heat collection efficiency is about 63%.

[0041] When the temperature of the water in the auxiliary heat collecting tube is 4°C, the overall thermal efficiency increases by about 174.9%; if the temperature of the water in the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com