Spray guns for glass kiln and glass kiln combustion method based on spray guns

A glass furnace and spray gun technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increasing nitrogen oxide emission concentration and total emission, unbearable for glass enterprises, secondary pollution, etc. The effect of reducing NOX emission concentration and total emission, simple and stable production process, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

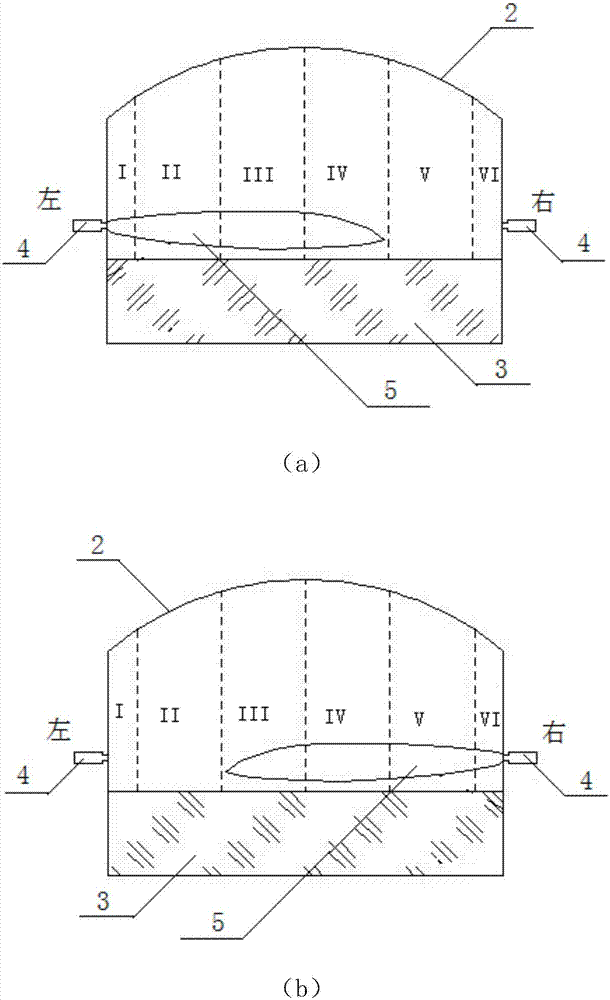

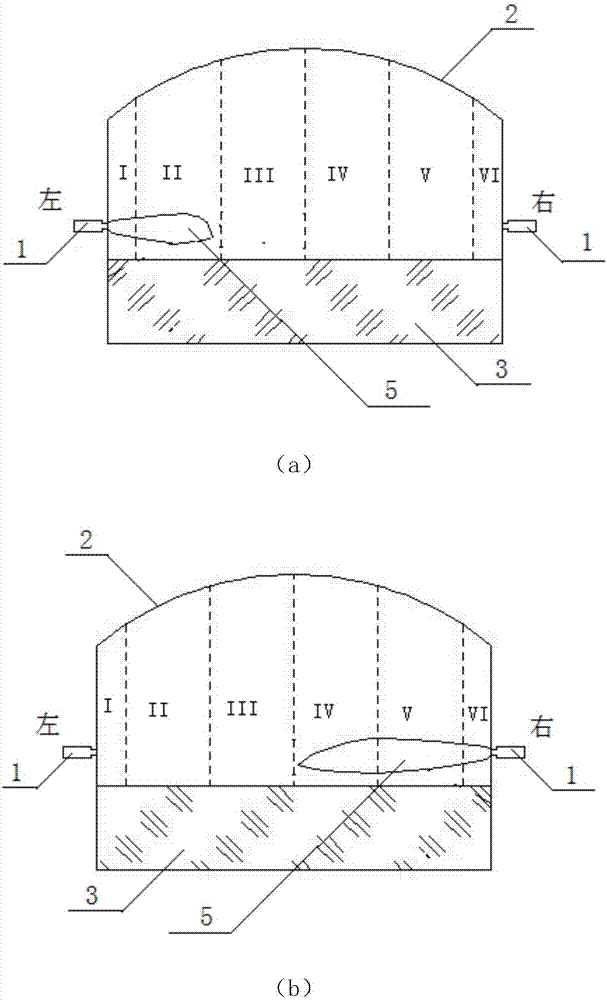

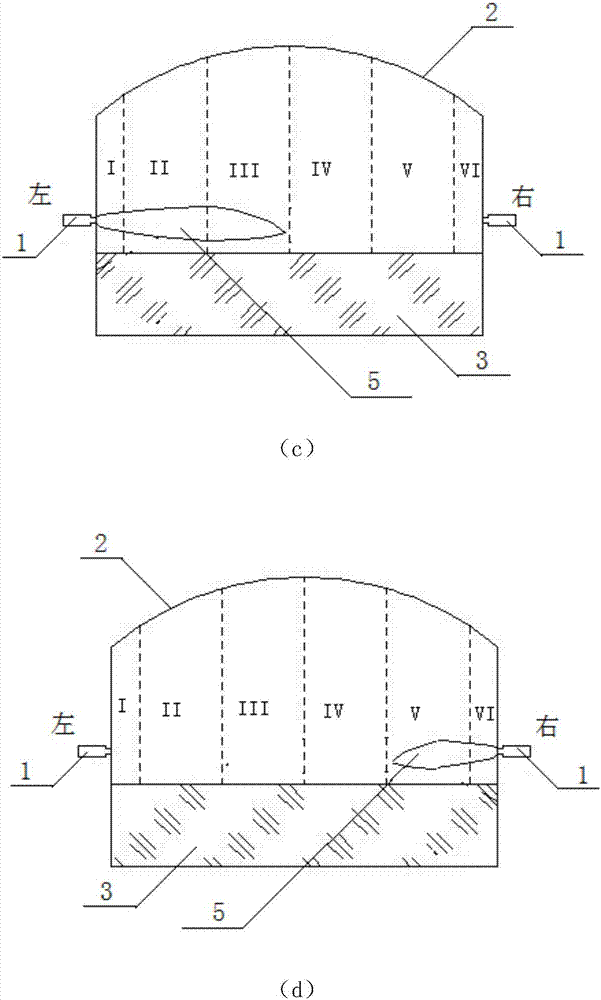

[0032] Existing glass furnaces usually adopt the reversing combustion method, and the reversing time is relatively long (generally 20-30 minutes). During the combustion process, the overlapping area of the flame continues to heat, and the temperature rises sharply, resulting in NO X Significant increase in emission concentration and total emission, if post-treatment method is used to reduce NO in flue gas XDisadvantages such as high investment, high operating cost, and easy poisoning of catalysts. In view of the above problems, the present invention provides a spray gun for glass kiln and a glass melting furnace combustion method based on the spray gun. The combustion method changes the way of fuel supply through the spray gun. Change the fuel injection speed to realize that the flame ends alternately reach a specific combustion area, avoid continuous heating of the middle combustion area, and thus realize NO in the flue gas of the glass kiln X Significant reduction in emiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com