Air supplying box capable of realizing forced cooling

A technology of forced cooling and air supply box, applied in the field of workpiece cooling, can solve the problems of adjustment of workpiece cooling requirements that cannot be different, poor cooling effect, etc., and achieve the effect of increasing the coverage area and improving the cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be briefly described below in conjunction with the drawings.

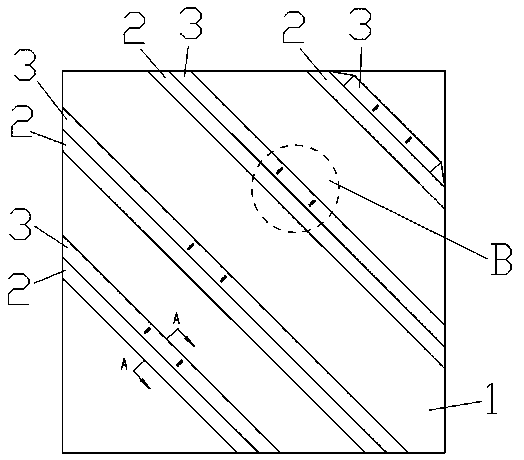

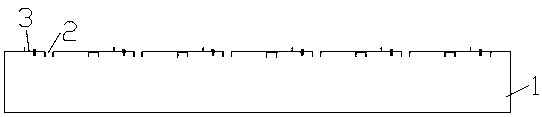

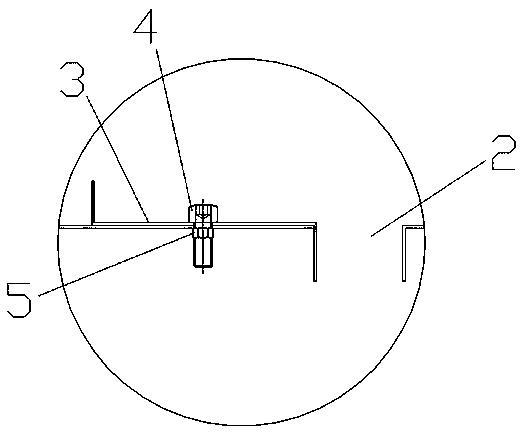

[0019] Such as Figure 1-3 As shown, a forced cooling blower box includes a blower box body 1, and the shape of the blower box body 1 can be set arbitrarily according to needs, and is preferably arranged in a rectangular parallelepiped shape. One wall of 1 is provided with a plurality of strip-shaped air outlets 2, preferably the plurality of strip-shaped air outlets 2 can be arranged parallel to each other, and the fan supplies cooling air into the air supply box 1 , The cooling air is ejected from the plurality of strip-shaped air outlets 2 to cool the batch of workpieces moving outside the air box body 1, and the preferred moving direction of the workpieces is the width direction of the strip-shaped air outlet 2 the same. It also includes a plurality of strip-shaped adjusting plates 3 respectively matched with the plurality of strip-shaped air supply o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com