A kind of preparation device and method of helical high elastic metal fiber

A technology for metal fiber filaments and a preparation device, which is applied in the field of preparation devices for helical high-elasticity metal fiber filaments, can solve the problems of inextensibility, strong rigidity, low cohesion, etc., and achieve the effects of enhanced scalability and avoidance of brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

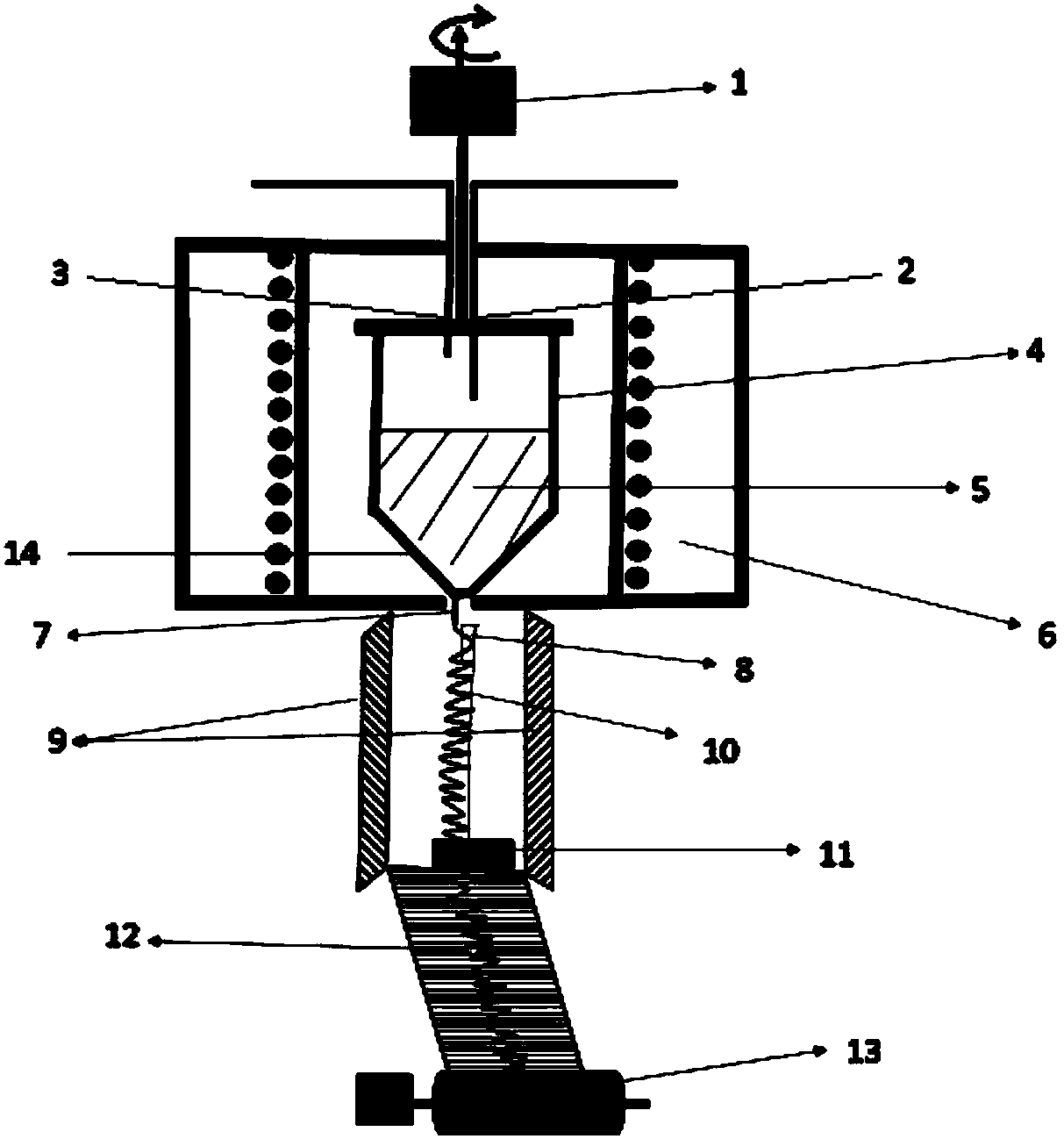

[0031] like figure 1 As shown, a preparation device for a helical highly elastic metal fiber filament includes a processing container 4, a cooling device 9, a traction device 12 and a winding device 13 connected sequentially from top to bottom;

[0032] It also includes a heating device 6 arranged outside the processing container 4, and the heating device 6 is used to heat the processing container 4;

[0033] The upper end of the processing container 4 is provided with a sealing cover for sealing the processing container 4, the sealing cover is provided with an air inlet 2 and an air outlet 3, and the bottom has a melt pressure spray hole 7, and the melt pressure spray port is relatively The central axis of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com