Vertical, automatic-cutoff and explosion-proof capacitor

An explosion-proof capacitor technology, applied in the electronic field, can solve problems such as deformation, bursting, and expansion of capacitor shells, and achieve the effects of improving safety and solving high-temperature explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the technical solution of the present invention will be described in detail through specific examples.

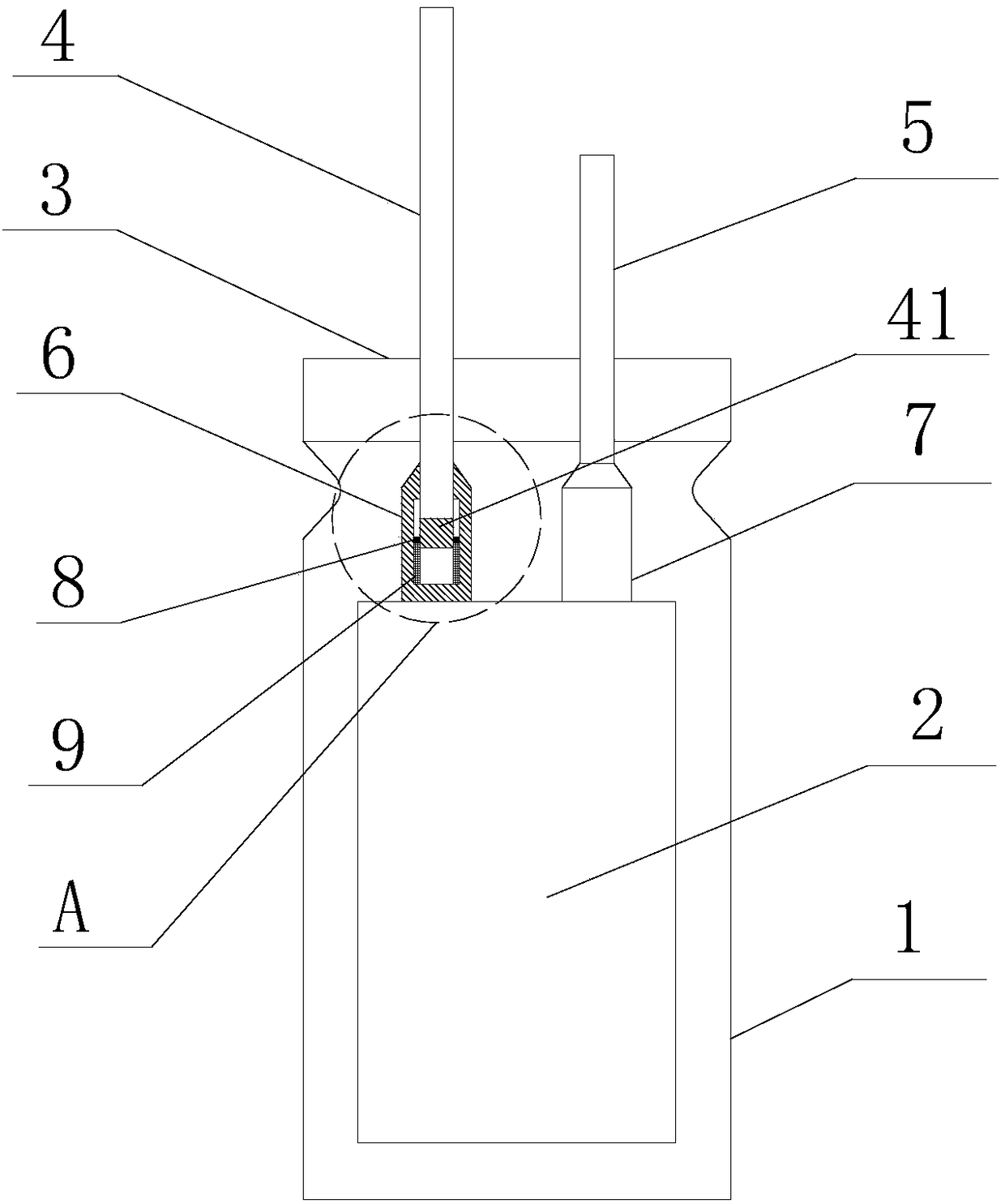

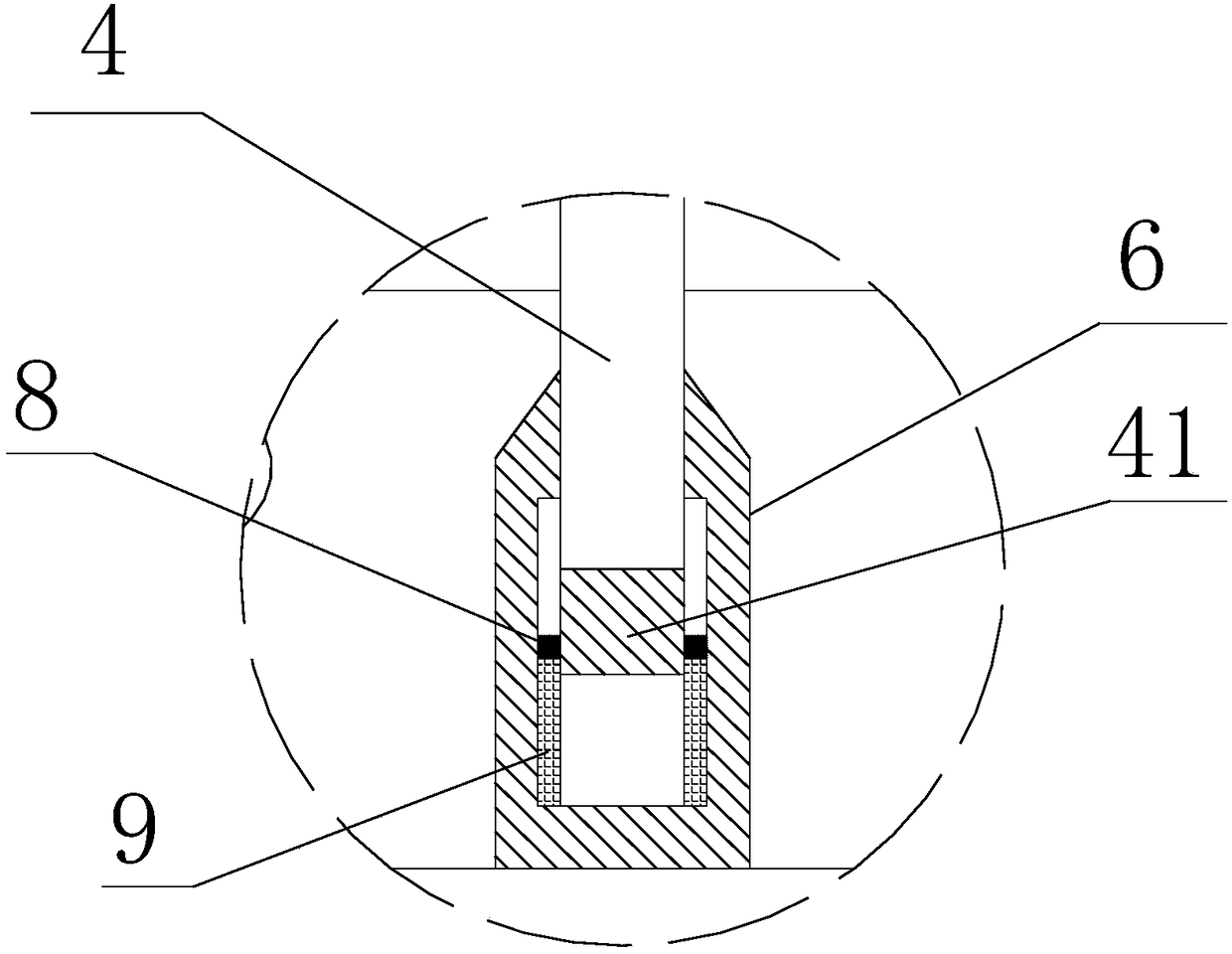

[0018] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a vertical self-cutting explosion-proof capacitor proposed by the present invention; figure 2 for figure 1 Enlarged view of A.

[0019] refer to Figure 1-2 , a vertical self-cutting explosion-proof capacitor proposed by the embodiment of the present invention, including: an outer shell 1, a core 2 arranged inside the outer shell 1, and cooperating with the outer shell 1 to encapsulate the core 2 inside the outer shell 1 The sealant cover 3, and the first lead 4 and the second lead 5, wherein:

[0020] The end of the core 2 close to the sealant cover 3 has a first electrode column 6 and a second electrode column 7 arranged vertically, and the inside of the first electrode column 6 is provided with an electrode from the end close to the sealant cover 3 to the end away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com