Glass kiln and method for heating glass batch

A glass furnace and batch material technology, which is applied in glass furnace equipment, glass production, glass manufacturing equipment, etc., can solve the problems of low yield of glass products, accelerated erosion of refractory materials, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

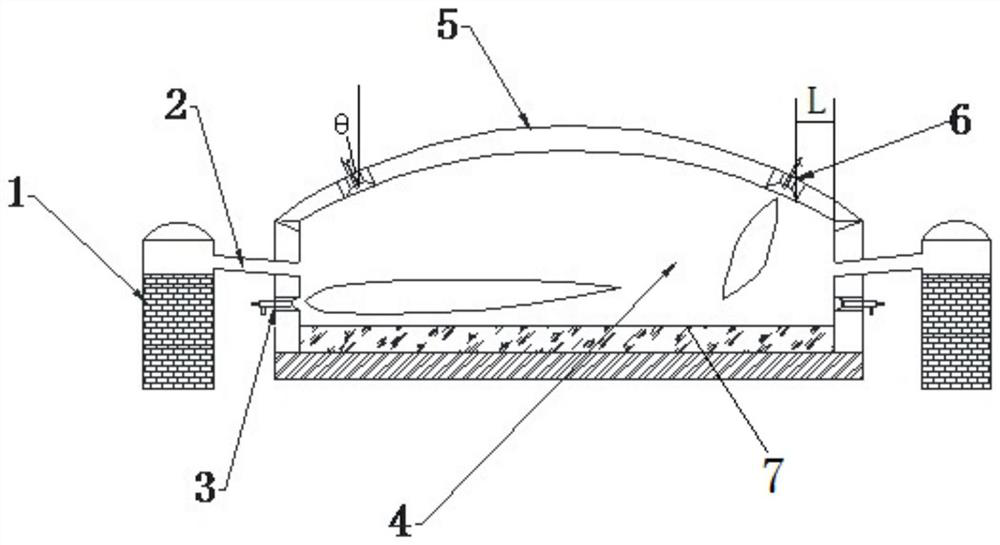

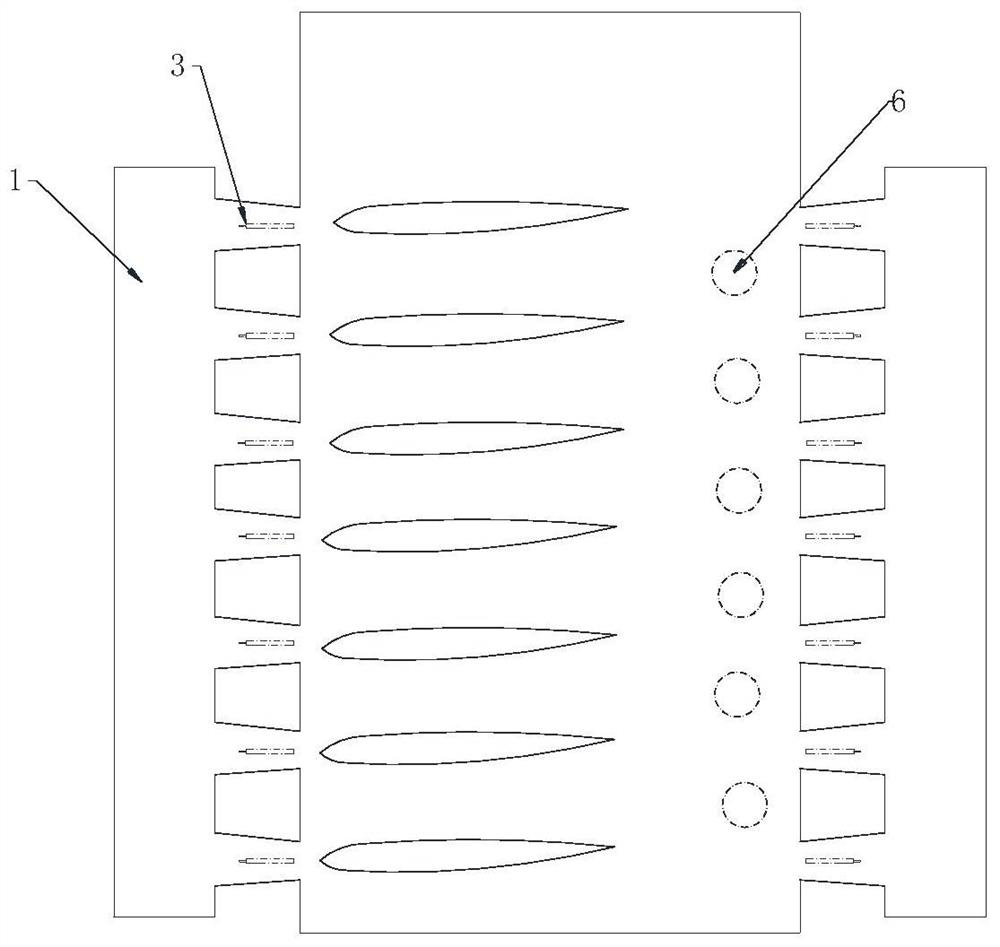

[0022] Existing air-assisted combustion glass furnaces include opposite side walls (i.e. parapets); a large sill (i.e. dome) placed on the top of the side walls and used to connect the opposite side walls to form the top of the glass kiln; The bottom of the glass is used to hold the melting pool of molten glass. When the glass furnace burns, the air preheated to a certain temperature (generally less than 1000°C) from the regenerator on this side enters the glass furnace through the small grate, meets the fuel in the flame space, and burns to generate high temperature, and the combustion products (i.e. smoke Gas) enters the regenerator on the opposite side and is discharged through the flue. The checker bricks in the regenerator on the opposite side store the heat in the flue gas. After the flue gas is discharged through the flue, the air used for combustion enters the side storage The checker bricks in the heat chamber and the regenerator use the heat collected in the flue gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com