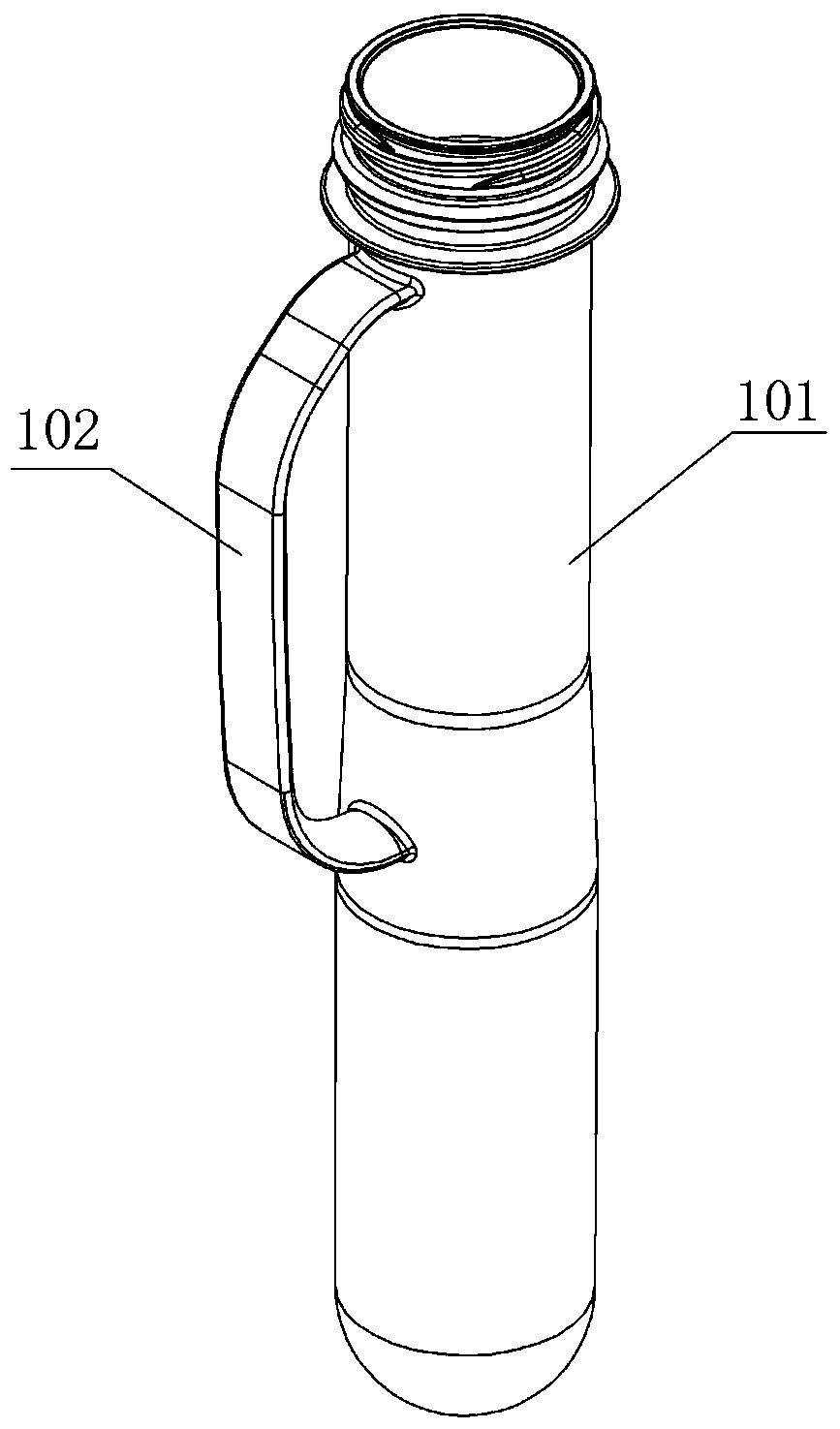

Heating device for blowing bottle preform with handle

A technology for heating devices and hand bottles, which is applied to household components, household appliances, and other household appliances, etc., and can solve problems such as complex equipment, blow molding machine installation and setting, or adverse effects and shortages in the processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

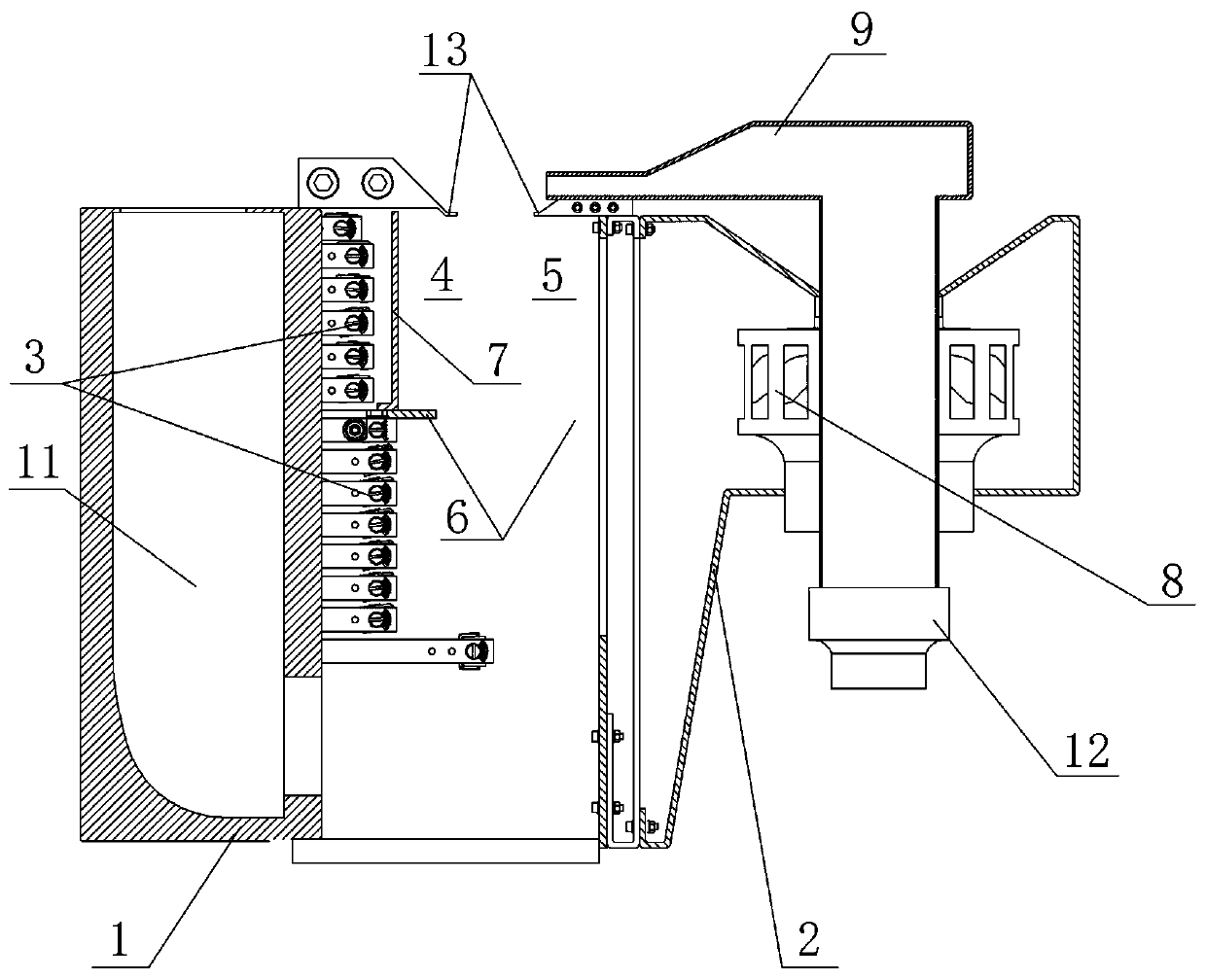

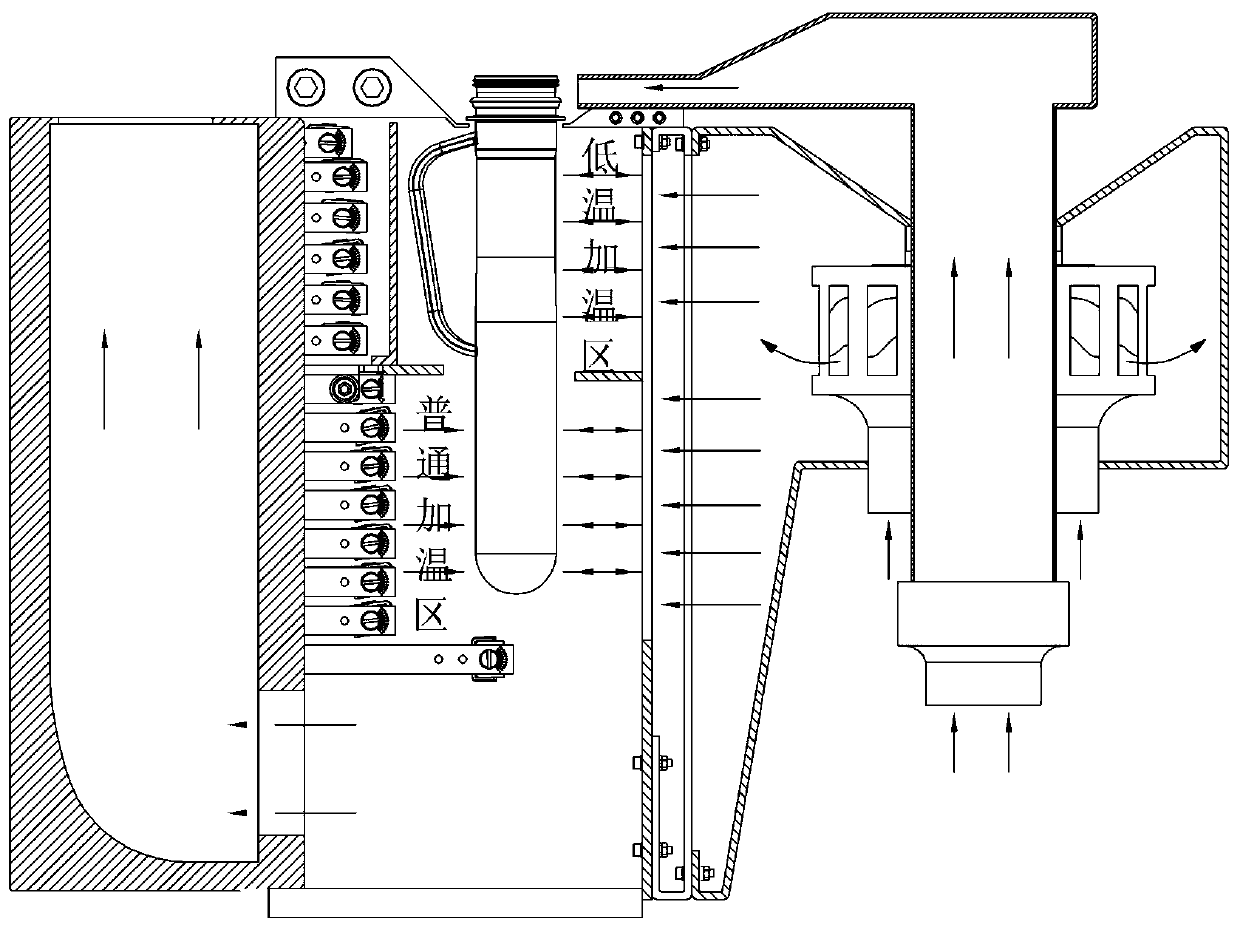

[0012] A heating device for blowing preforms with handles, comprising a heating box 1 and a heating air channel 2 for blowing cooling air, the heating box is provided with a heating area 4 equipped with a heating element 3, and the heating air channel is provided with The embryo body air outlet area 5 opposite to the heating area; the middle part of the heating area and the embryo body air outlet area is relatively equipped with a partition plate 6, and the position of the partition plate is adjacent to the end of the handle on the preform, and the heating area Shielding plates 7 are arranged at intervals along the moving direction of the preform on one side of the partition plate, and the shielding plate is opposite to the position where the handle on the preform is rotated to face the heating area.

[0013] In the heating device for blowing preforms with handles, several stress relief grooves 61 are respectively opened on the two partition plates 6, and the stress relief groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com