Rotary evaporation system based on cold trap

A technology of rotary evaporation and rotary evaporator, which is applied in the field of analysis and testing, can solve problems such as low overall efficiency, damage to the life of vacuum pumps, and steam leakage, so as to improve the efficiency of liquefaction recovery, protect safety, and prevent dangerous accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

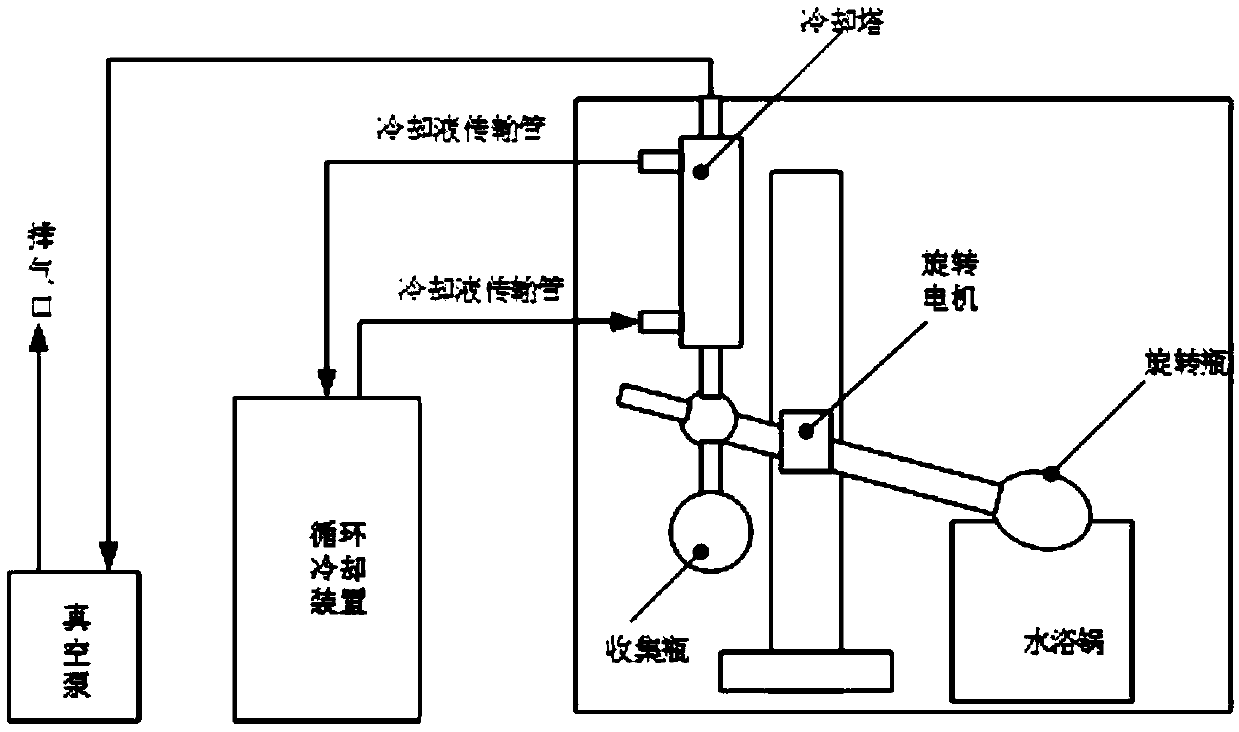

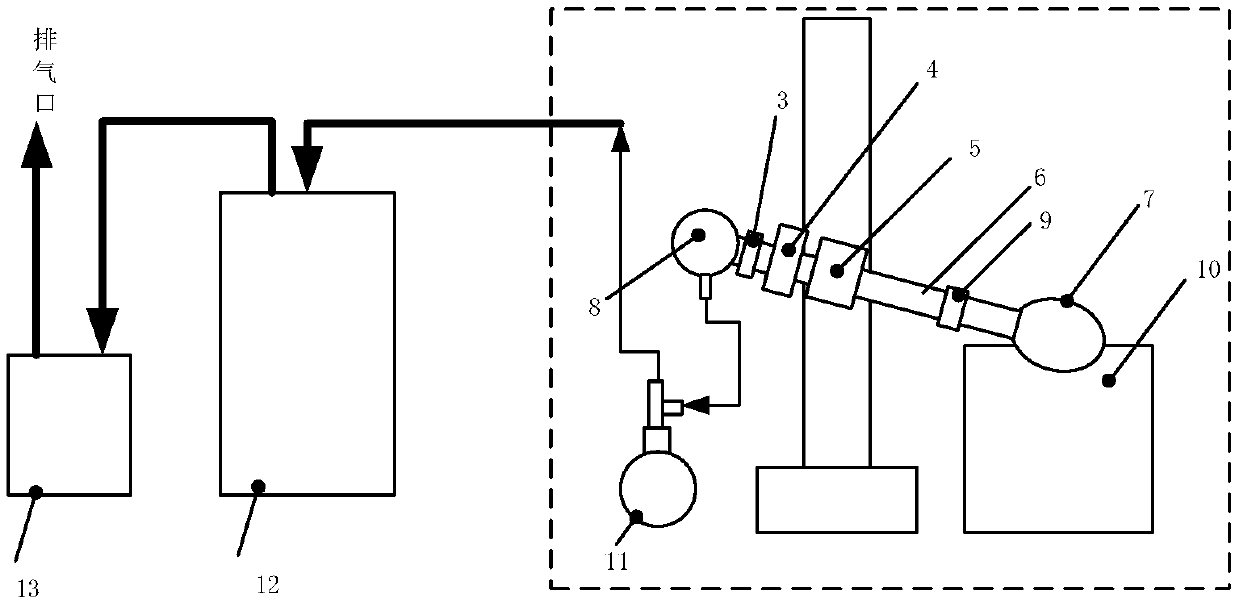

[0027] Embodiment 1: see attached figure 2 , a cold trap-based rotary evaporation system, which includes: a rotary evaporator vacuum pump 13 and a cold trap 12;

[0028] The rotary evaporator includes: a heating device 10, a rotating motor 5, a rotating bottle 7, a buffer bottle 11 and a hollow bottle 8; the output of the rotating motor 5 is connected to the rotating hollow shaft 6; one end of the rotating hollow shaft 6 is connected to the rotating bottle through the second interface 9 7. The other end of the rotating hollow shaft 6 is inserted into the sealing interface 4; the sealing interface 4 is connected to one interface of the hollow bottle 8 through the first interface 3; the second interface of the hollow bottle 8 is connected to the mouth of the buffer bottle 11 through the pipeline The other interface of the tee at the mouth of the buffer bottle 11 is connected to the gas inlet of the cold trap 12 through the pipeline, and the gas outlet of the cold trap 12 is con...

Embodiment 2

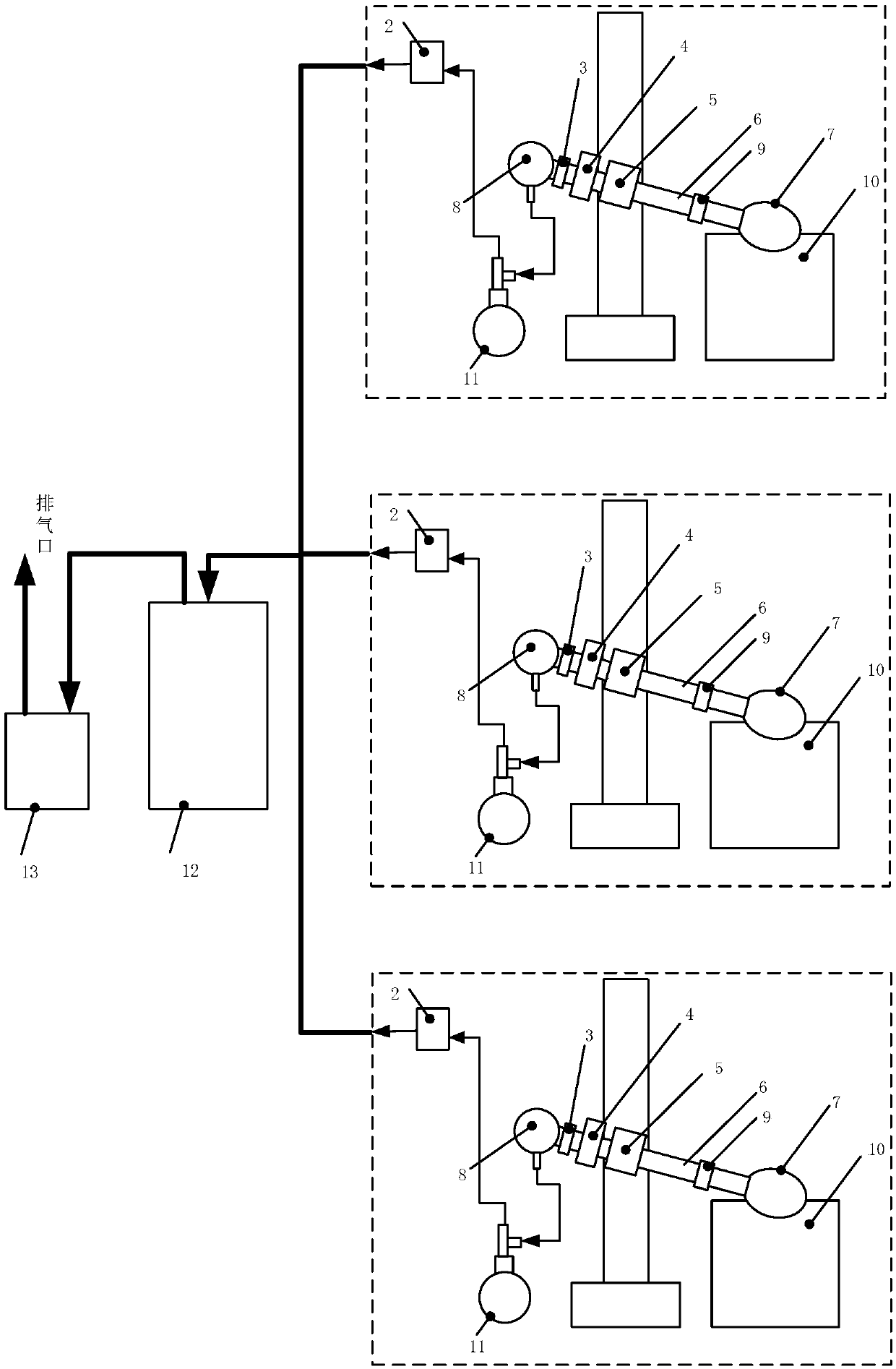

[0031] Embodiment 2: see attached image 3 , in order to realize the demand of batch processing sample, on the basis of embodiment 1, the quantity of rotary evaporator is set to more than two, arranges in array form; A switching solenoid valve 2 is arranged on the pipeline.

[0032] This solution realizes the use of multiple rotary evaporators in parallel under the condition of configuring a vacuum pump 13 and a cold trap 12, and arbitrarily terminates the work of one or more rotary evaporators, without affecting the normal operation of other rotary evaporators; Each rotary evaporator can be kept working independently by controlling the on-off of the switch solenoid valve 2 on the pipeline connecting each rotary evaporator with the cold trap 12 . When a certain rotary evaporator completes the work, the switch solenoid valve 2 of the rotary evaporator is placed in a closed state, and the switch valve is placed in a conduction state, so that the air pressure in the rotary bottl...

Embodiment 3

[0033] Embodiment 3: see attached Figure 4 , on the basis of Embodiment 1 or 2, the on-off valve and the heating device 10 are specifically defined:

[0034] The switch valve can use vacuum release solenoid valve 1 or manual rotary valve 14 or can also be as Figure 4 As shown, two kinds of valves are set at the same time; the vacuum release solenoid valve 1 is set on the pipeline between the buffer bottle 11 and the switch solenoid valve 2, and the manual rotary valve 14 is directly set at the third interface of the hollow bottle 8; Valve 1 or manual rotary valve 14 all allow the air pressure in rotary bottle 7 to be in a normal atmospheric pressure state;

[0035] The heating device 10 includes: a hot liquid tank 10.1, a water pump 10.2 and a water bath 10.3; the rotary bottle 7 is placed in the hot liquid tank 10.1; the water bath 10.3 sends hot water to the bottom of the hot liquid tank 10.1 through the water pump 10.2; the hot liquid tank 10.1 is set There is an overfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com