Vacuumizing device

A vacuuming device and vacuuming technology, which is applied in the direction of pumping device, vacuum/special atmosphere packaging, transportation and packaging, etc., can solve the problems of inconvenient cleaning, insufficient cleaning and high cost of vacuuming tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

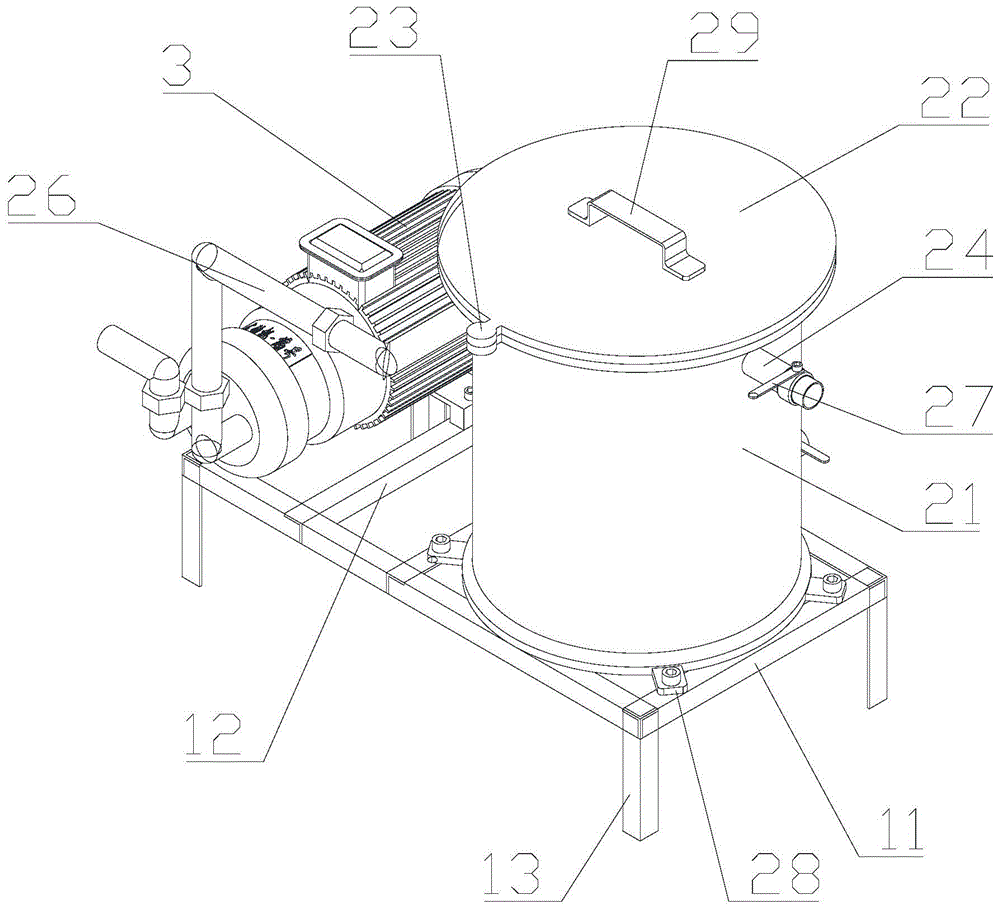

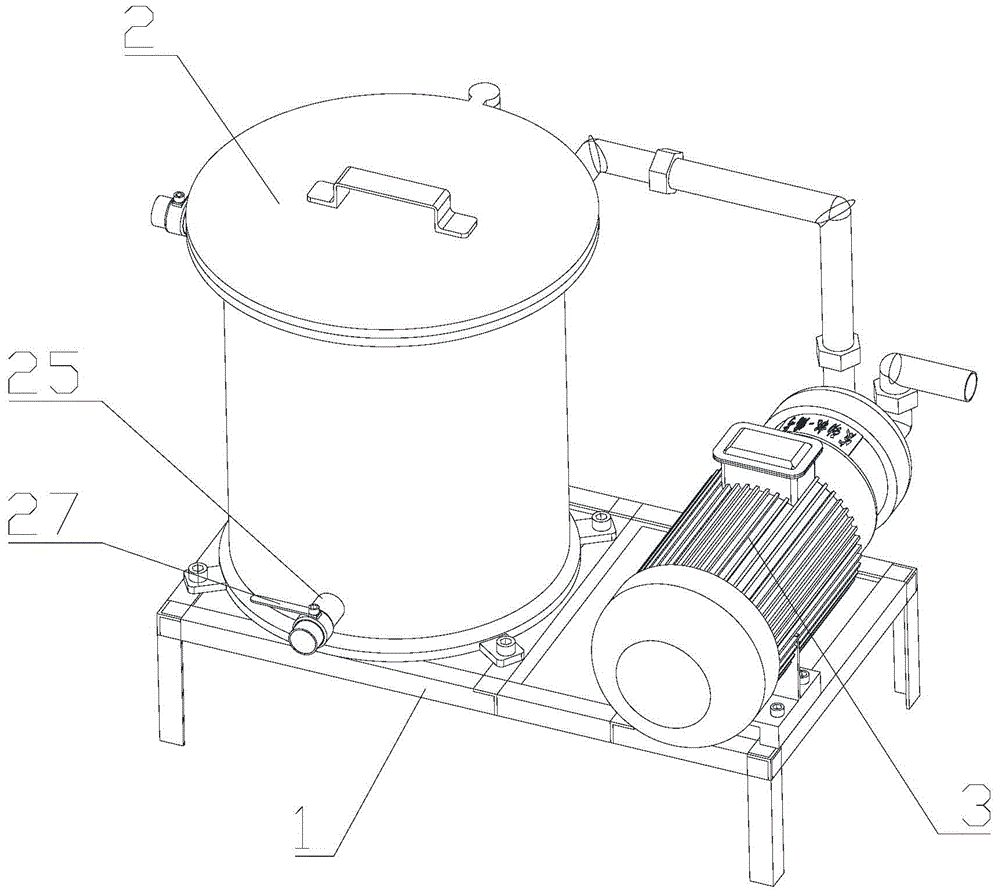

[0014] Such as figure 1 and figure 2 Shown, a kind of vacuum device comprises frame 1, vacuum tank 2 and vacuum pump 3, and vacuum tank and vacuum pump are installed on the frame. Frame comprises rectangular frame 11, connecting rod 12 and support foot 13, and described connecting rod is arranged in rectangular frame and the extending direction of connecting rod and width direction are consistent, and connecting rod divides rectangular frame into smaller rectangular frame, and described supporting leg Set at the right corners of the rectangle. The vacuum tank includes a tank body 21 with an opening and a cover 22 threaded on the tank body for sealing the opening, the tank body and the cover body are respectively provided with a cylindrical calibration part 23, and the cover body When the tank body is screwed until the two calibration parts are completely overlapped, the cover body and the tank body are sealed and fitted. The tank body is provided with a feed pipe 24, a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com