Screen cylinder and multistage pulp pressure screen with same

A technology of pressure sieve and sieve drum, which is applied in textiles, papermaking, and fiber raw material processing, etc. It can solve the problems of rotor wear, increase the difficulty of cleaning or maintenance operations, frequent cleaning or maintenance of sieve drums, etc., and achieve convenient disassembly and washing and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

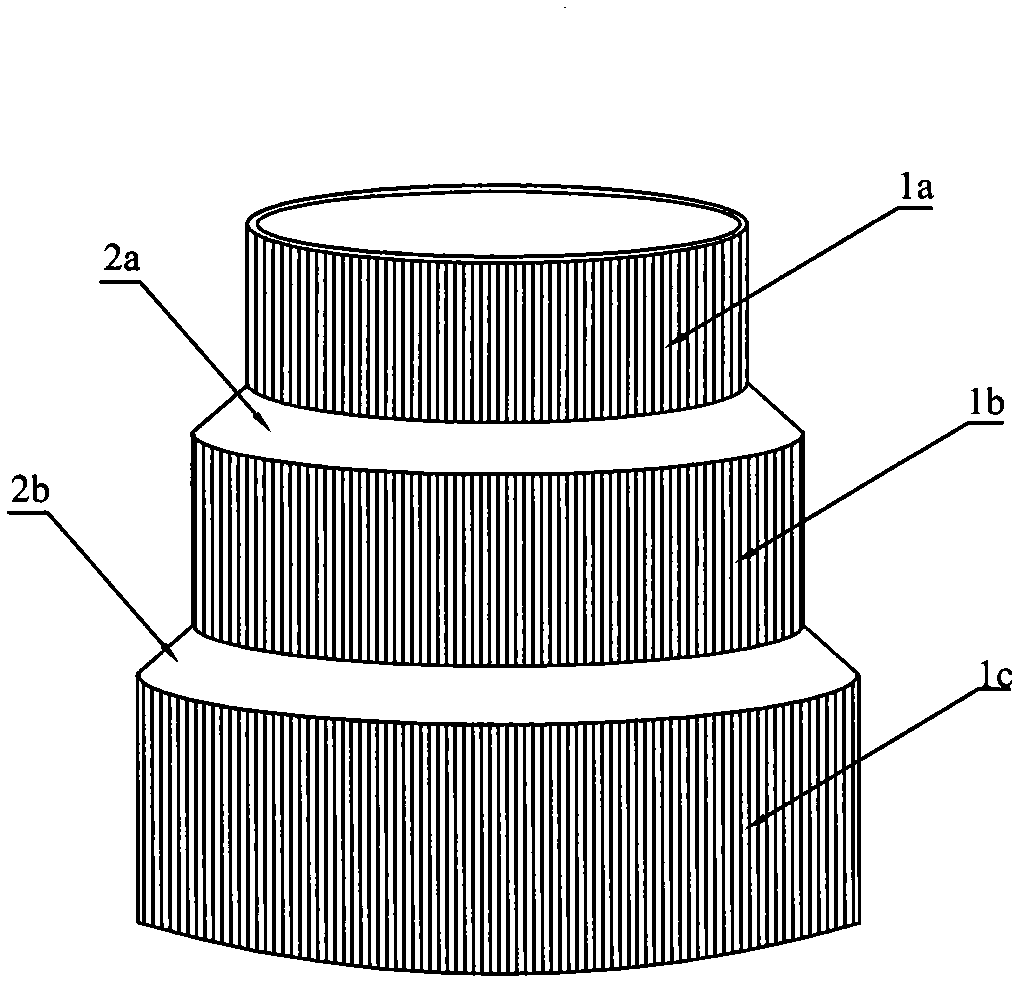

[0039] The sieve drum described in this embodiment is as figure 1 As shown, the screen drum includes three screen drum units 1a, 1b, and 1c arranged in sequence along the axial direction, and the axial centerlines of the three screen drum units coincide; along the axial direction, the three screen drum units The inner diameter of the drum unit increases; among the three screen drum units, the bottom end of the screen drum unit 1a is connected to the top end of the screen drum unit 1b through the connecting piece 2a, and the bottom end of the screen drum unit 1b is connected to the top end of the screen drum unit 1c through The connecting piece 2b is connected, and the three screen drums connected through the connecting piece can realize the overall movement relative to the pressure screen shell 4. In this embodiment, the connecting piece 2a, 2b is a closed ring support frame.

[0040] In this embodiment, along the axial direction, the bottom end of the upper-stage sieve drum u...

Embodiment 2

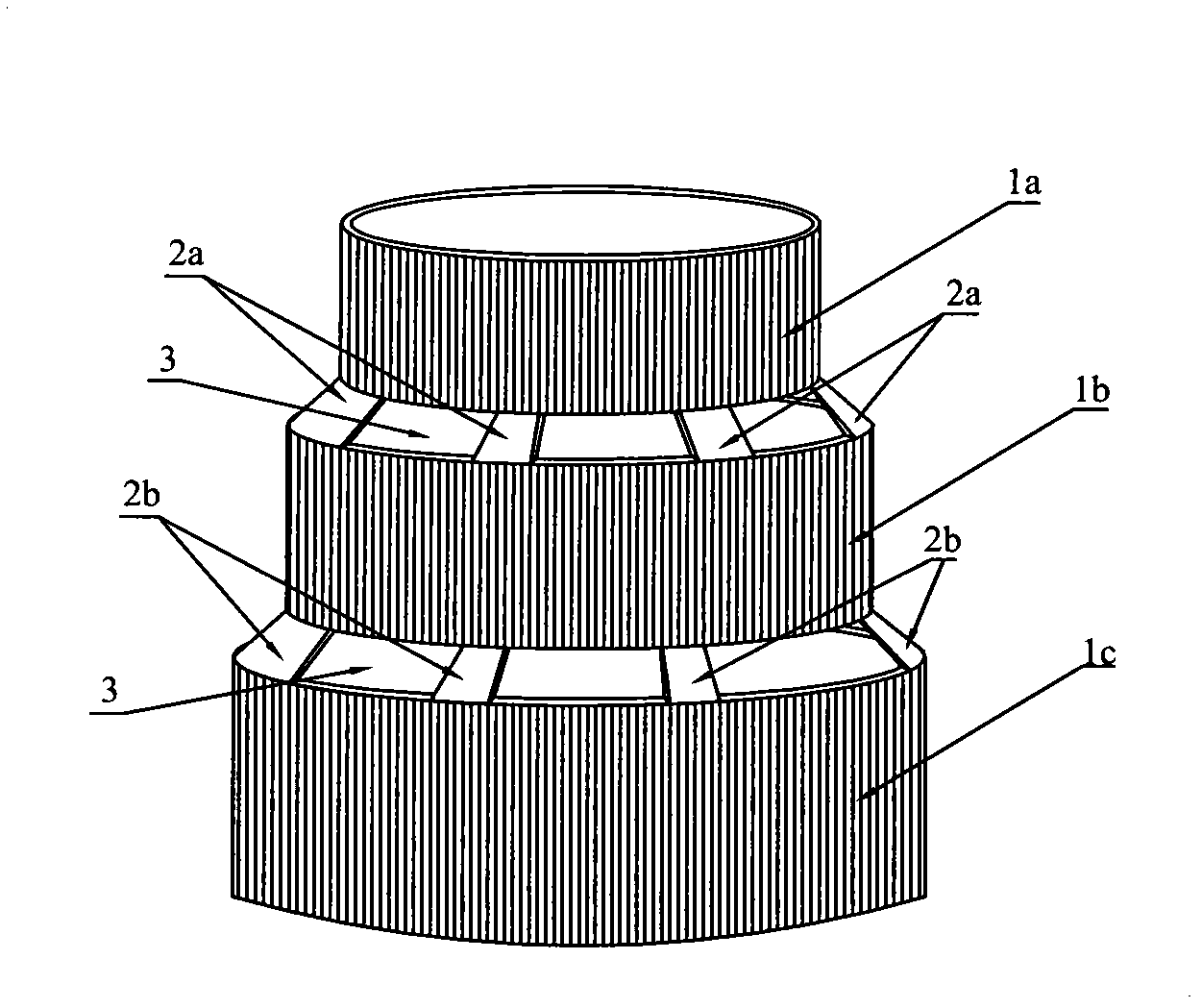

[0042] The sieve drum described in this embodiment is as figure 2 As shown, the difference between the sieve drum described in this embodiment and the sieve drum described in Embodiment 1 is that the connecting parts 2a and 2b connecting the sieve drum units in this embodiment are provided with a liquid circulation channel 3. For example, the liquid communication channel is set as a communication gap; the liquid communication channel can also be selected as a hole opened on the connecting piece, or other channels that can realize liquid communication.

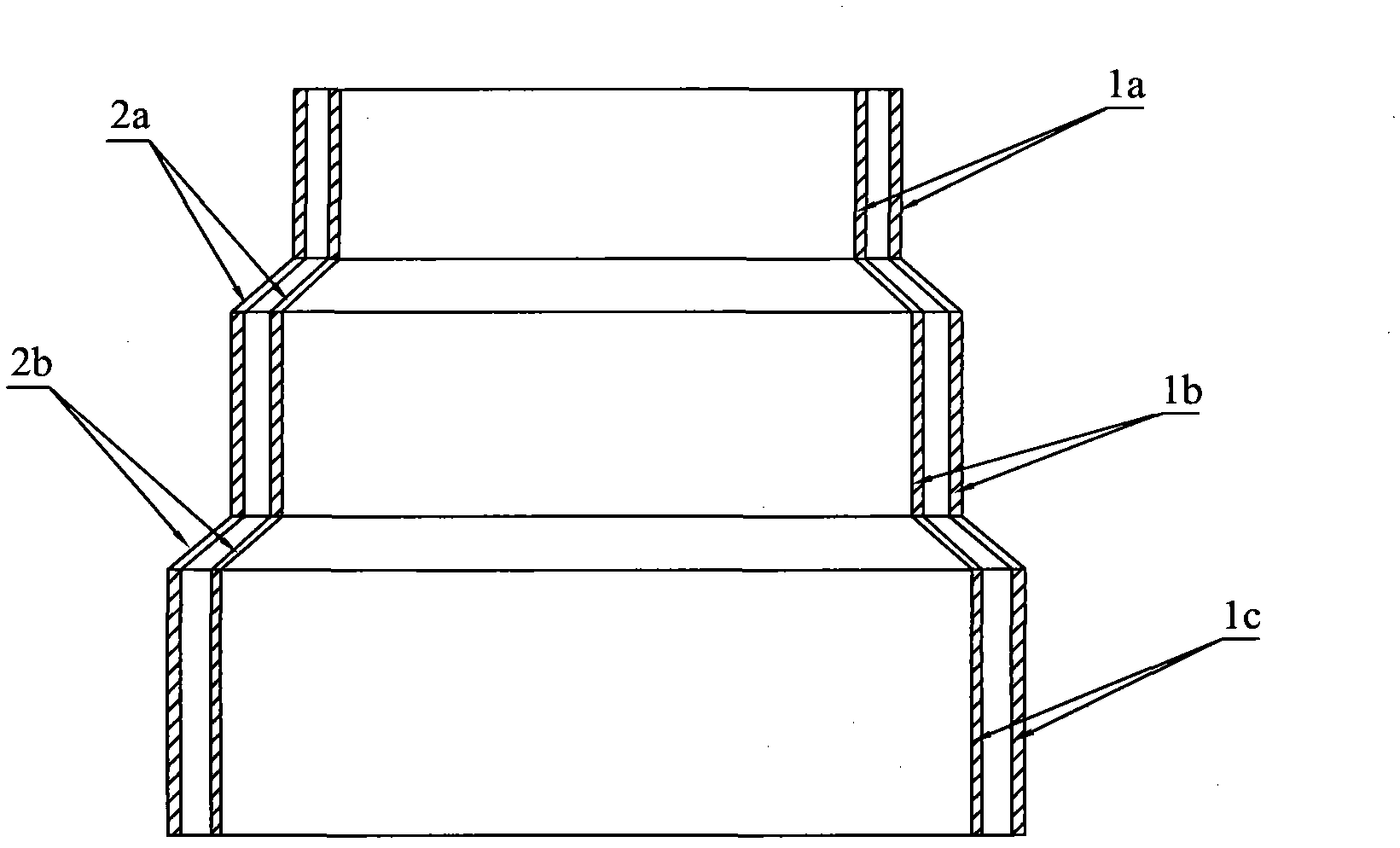

[0043] As an optional embodiment, each of the sieve drum units in the combined sieve drum can also be arranged in multiple layers, wherein each of the sieve drum units can be arranged in different layers; as a preferred embodiment, It is optional to set each of the sieve drum units as 2 layers, such as image 3 shown.

Embodiment 3

[0045] Multistage pulp pressure screen of the present invention such as Figure 4 As shown, it includes a shell 4, and a layer of screen drums is arranged in the radial direction of the shell 4. The screen drums are provided with three screen drum units 1a, 1b, and 1c arranged in sequence along the axial direction. The three screen drums The axial centerlines of the units coincide; in this embodiment, the inner diameters of the three sieve drum units increase from top to bottom in the axial direction; among the three sieve drum units, the bottom end of the sieve drum unit 1a The top end of the sieve drum unit 1b is connected with the connecting piece 2a, the bottom end of the sieve drum unit 1b is connected with the top end of the sieve drum unit 1c through the connecting piece 2b, and the three sieve drums connected by the connecting piece can realize relative pressure screen For the overall movement of the housing 4, the connecting parts 2a and 2b connecting the screen drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com