Bed mattress capable of adjusting hardness degree

A technology of softness and hardness and mattress, which is applied in the direction of mattresses, spring mattresses, stuffed mattresses, etc., can solve the problems of spring rust and elasticity, Simmons mattress application limitations, failure and other problems, and achieve the best sleeping comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

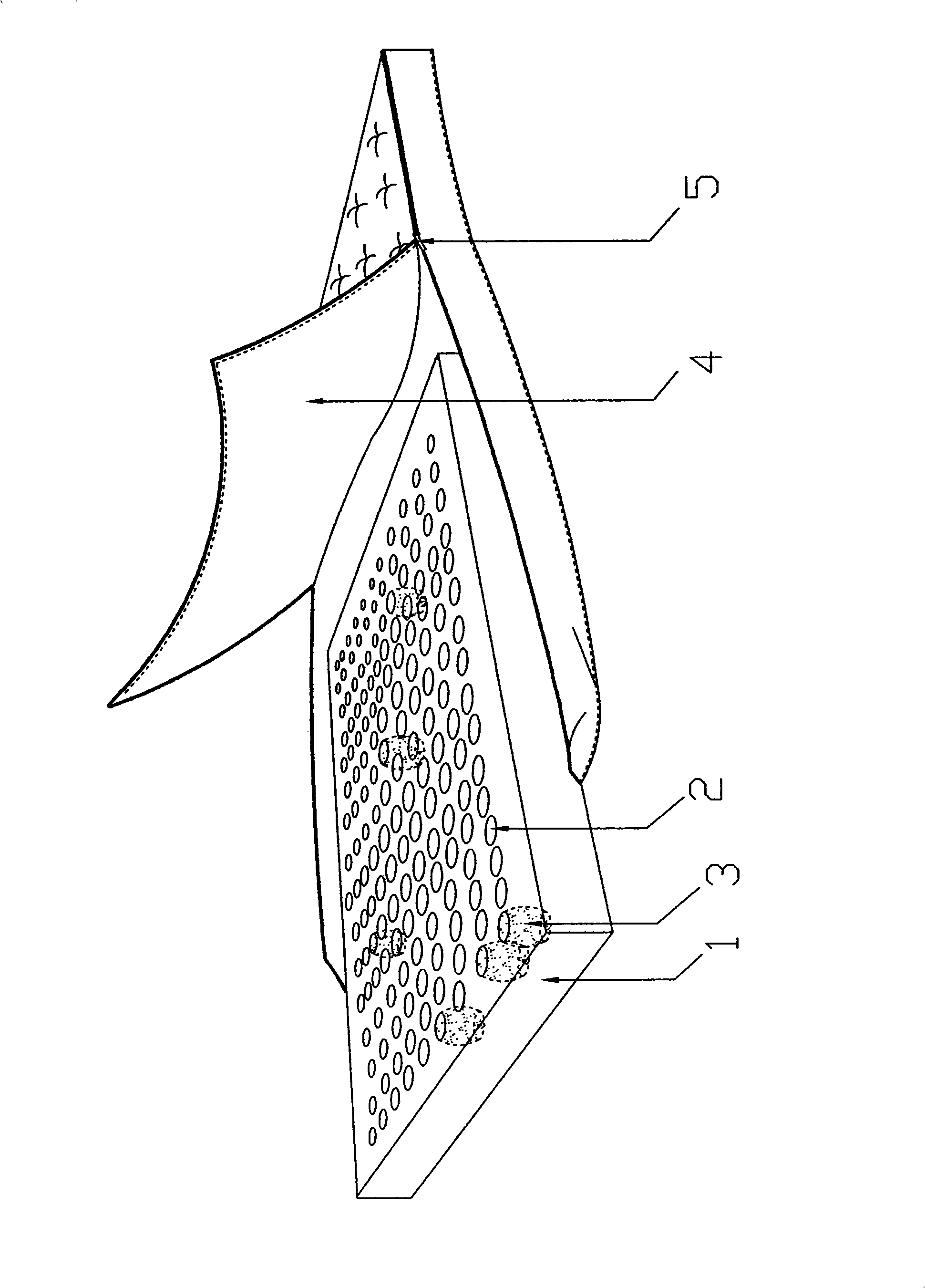

[0014] The present invention mainly consists of a soft bed core 1, a round hole 2 opened on the soft bed core 1, a rubber inflatable barrel 3 placed in the round hole 2, and a quilted surface 4 with a zipper 5 covering the outer periphery of the soft bed core 1. and so on. The circular holes 2 are arranged on the soft bed core 1 according to 100-180 per square meter. The cross-sectional diameter of the circular hole 2 is 6±3 cm.

[0015] When assembling, the user first injects different amounts of gas into each rubber inflatable barrel 3 to achieve the effect of different hardness, and then according to the user's different requirements for the soft and hard force of each part, the air is filled in all or part of the round hole 2 Place rubber inflatable barrels 3 with different inflated volumes, then cover the soft bed core 1 with a quilted face 4 and tighten the zipper 5 to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com