Filtering basket type ultrasonic extraction device for biological effective components

A biologically effective, extraction device technology, applied in the field of filter basket ultrasonic biological active ingredient extraction device and biological active ingredient extraction device, can solve the problem of solid material clogging the liquid outlet, slow extraction liquid discharge speed, and incomplete extraction liquid filtration, etc. problem, to achieve the effect of rapid drainage and easy disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

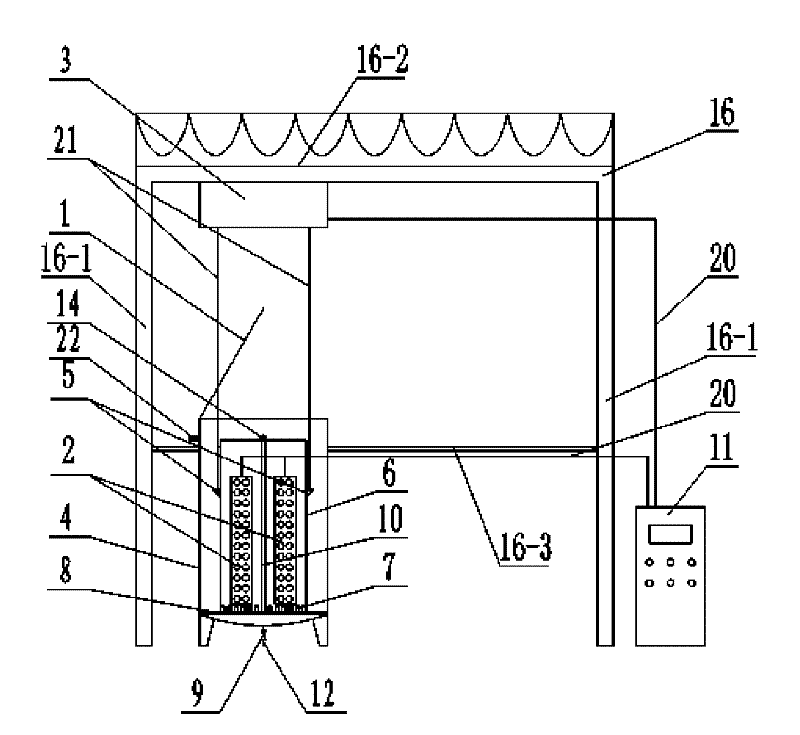

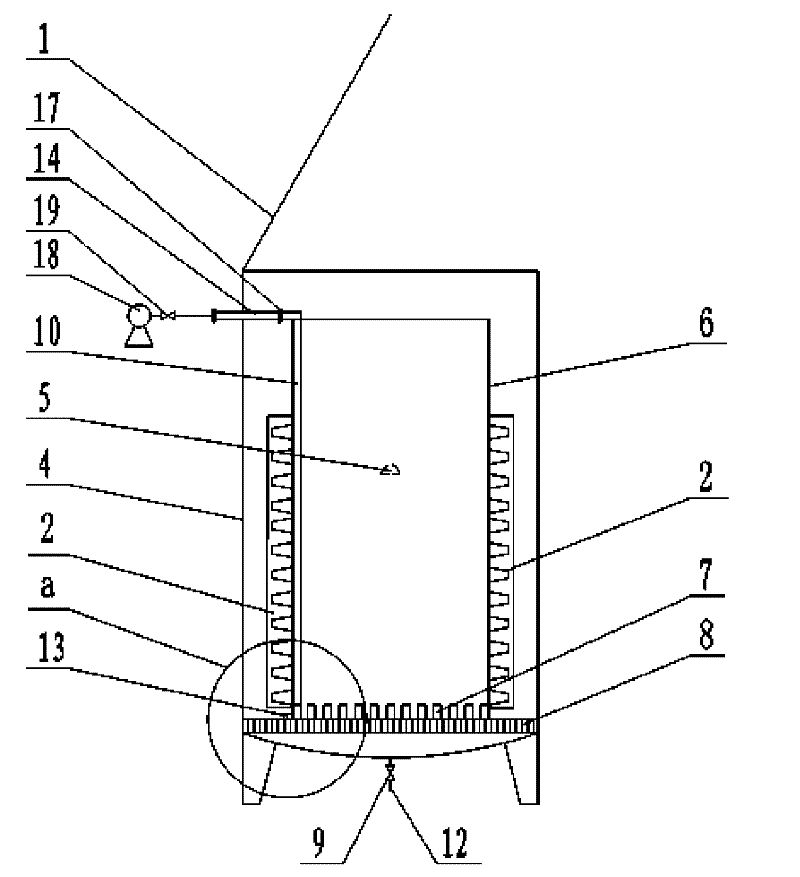

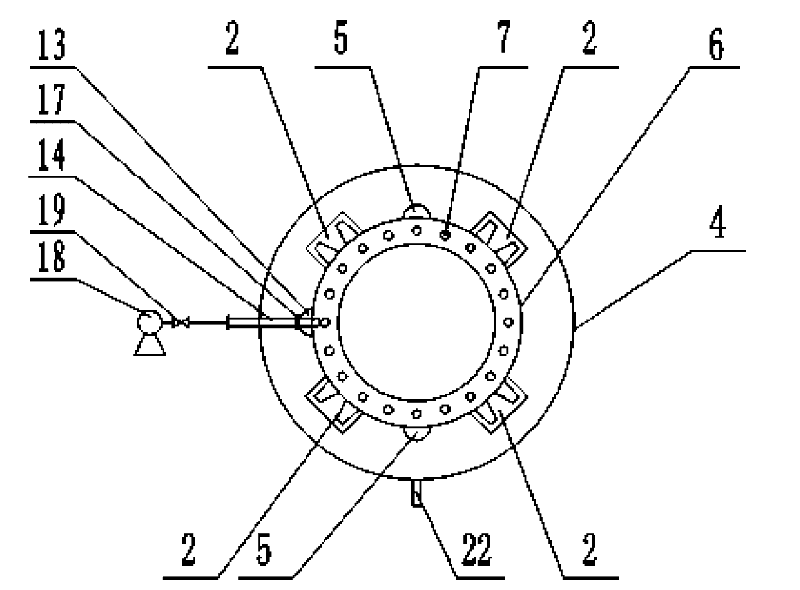

[0009] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, the filter basket type ultrasonic biological active ingredient extraction device of this embodiment is made up of suspension system and ultrasonic extraction system, and described suspension system is made up of electric lifter 3, support 16 and two suspension ropes 21, The ultrasonic extraction system includes a liquid storage tank upper cover 1, at least two ultrasonic vibration boxes 2, a liquid storage tank 4, two lifting hooks 5, a filter basket 6, an annular gas nozzle 7, a filter screen 8, a liquid discharge valve 9, The gas passes through the pipe 10, the control box 11, the liquid discharge pipe 12, the air inlet pipe 14, the joint 17, the air pump 18, the air inlet control valve 19, a plurality of cables 20 and the liquid inlet pipe 22; the bracket 16 includes a plurality of first Steel profiles 16-1 and second steel profiles 16-2, the plurality of first steel profiles 16-1 ...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination Figure 1-Figure 2 The present embodiment will be described. The lower end surface of the liquid storage tank 4 of the present embodiment is a downwardly concave arc surface. Such setting facilitates the discharge of the extraction liquid, accelerates the discharge speed, and completely discharges the liquid. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination Figure 1-Figure 3 The present embodiment will be described. The number of ultrasonic vibration boxes 2 in this embodiment is 2-5. With such setting, the extraction time is shorter and the yield is higher. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com