Blade root and wheel groove structure of turbine moving blade

A technology of wheel grooves and blades, which is applied in the direction of supporting components of blades, machines/engines, mechanical equipment, etc., and can solve problems such as not being able to meet the design of longer blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Taking the 55-inch final stage blade of a full-speed thermal power steam turbine with a back pressure of 4KPa~13KPa, a power of 4F-1200MW~1400MW or 2F-600MW~700MW or 1F-300MW~350MW, and a speed of 3000r / min as an example, this will be explained in detail. invention.

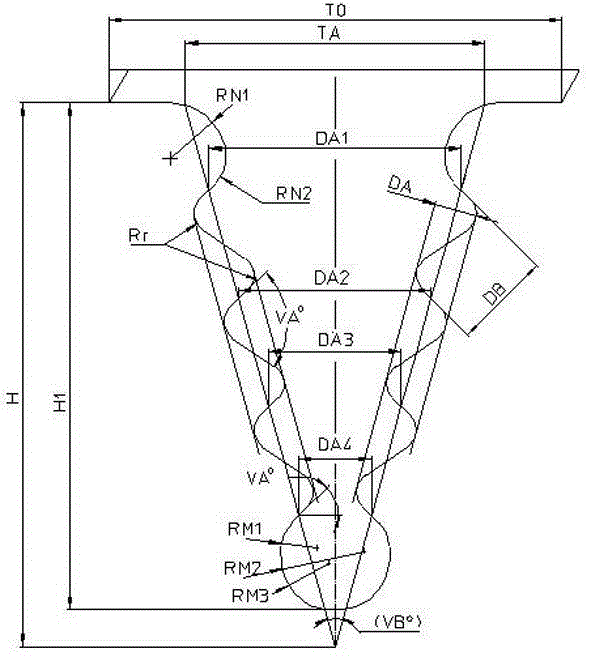

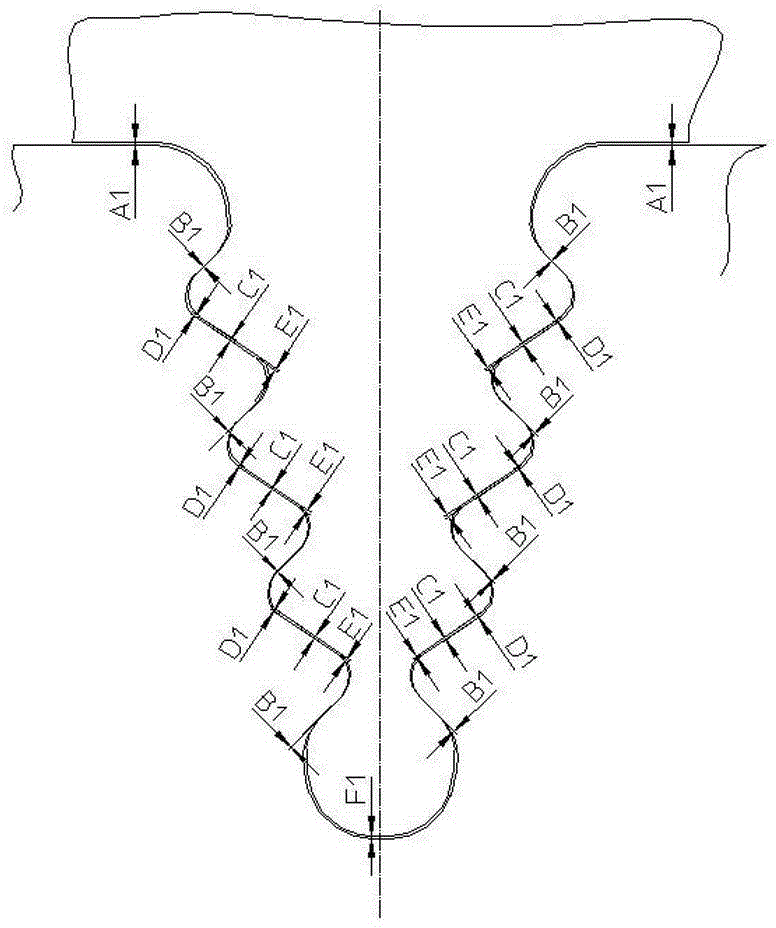

[0019] Such as figure 1 shown.

[0020] The blade root and the wheel groove structure of the turbine motor blade of the present invention, the blade root of the blade is assembled in the wheel groove of the impeller, the profile line of the blade root and the wheel groove is a fir tree type, and the fir tree type blade The root has four teeth and has characteristic parameters: the transition fillet radius Rr of the working tooth; the root pitch T0 of the blade root platform; the pitch TA at the top of the blade root; the theoretical height H of the blade root; the effective height H1 of the blade root; the height DA of the working tooth ; The distance DB between two adjacent pairs of tooth working faces,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com