Detachable ultrahigh pressure waterproof sealing ring

A waterproof sealing, ultra-high pressure technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of increasing difficulty in implementation, failure to meet sealing requirements, bulky flanges, snap rings and bolts, etc., to achieve The strength level is not high, stable and reliable ultra-high pressure self-tightening sealing performance, and the effect of avoiding complications or welding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

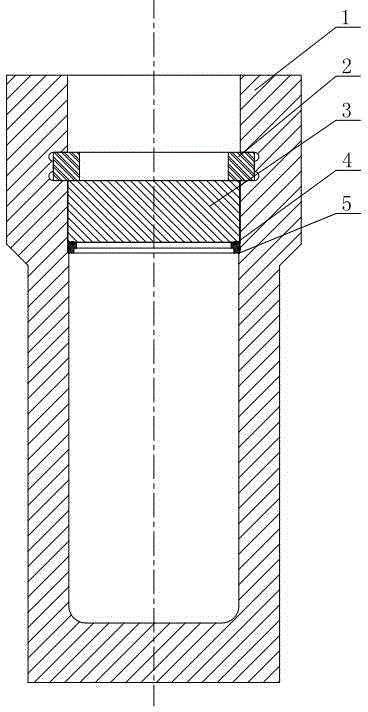

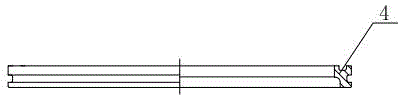

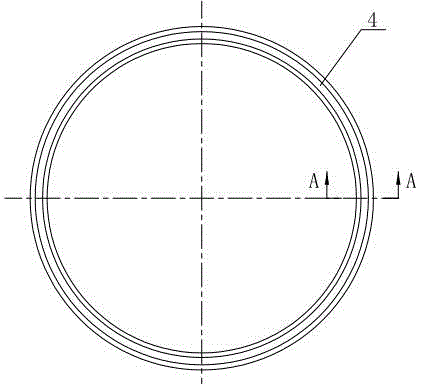

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the detachable ultra-high pressure waterproof sealing ring of this embodiment,

[0022] When assembling, use the pressure cylinder flat cover 3 to press into the opening of the pressure cylinder body 1, and the waterproof sealing ring 4 sits on the bottom of the plane step 5 and is located under the pressure cylinder flat cover 3. How much is the distance above the pressure cylinder flat cover 3? Block anti-shear block 2, and the edge of the flat cover 3 of the pressure cylinder is longitudinally constrained by the anti-shear block 2.

[0023] The specific structure of the waterproof sealing ring 4 is: the waterproof sealing ring 4 is a compact annular axisymmetric structure, and the cross-sectional shape of the waterproof sealing ring 4 is: the top and the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com