Involute straight tooth gear modification optimization method

A technology of spur gears and optimization methods, applied in the field of gear manufacturing, can solve problems such as no parameterization, low precision, and complicated modification methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to clearly illustrate the technical features of the present invention, the solution is described below through a specific implementation manner.

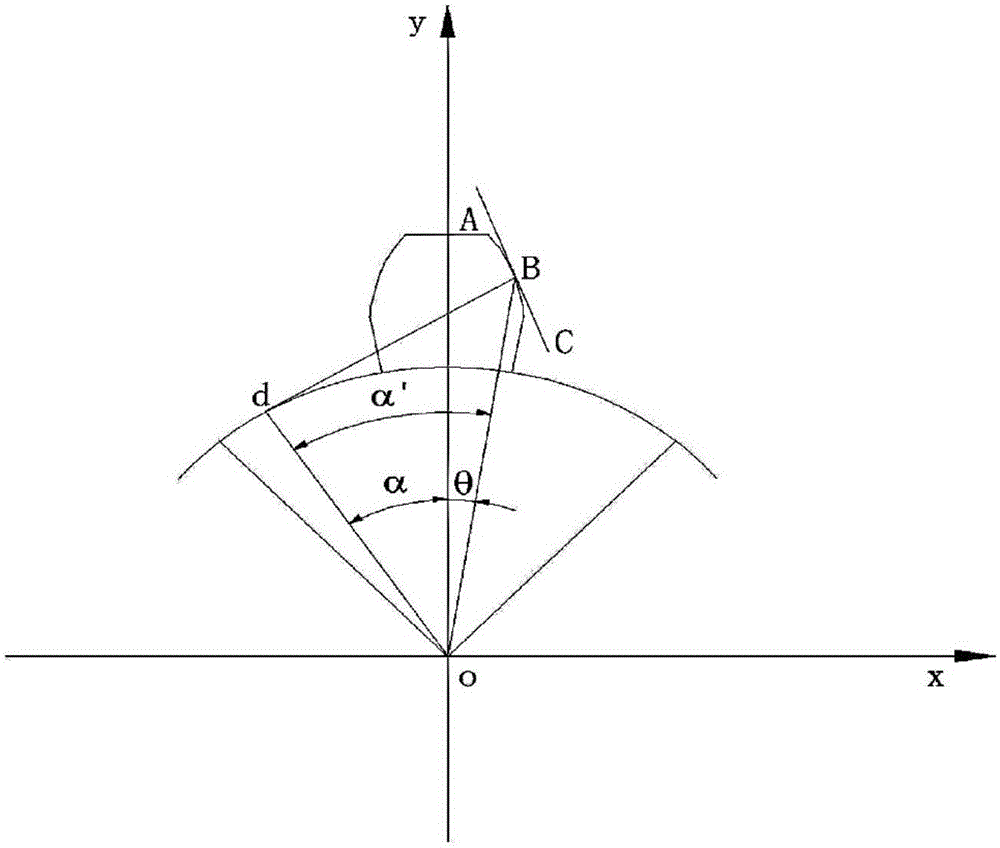

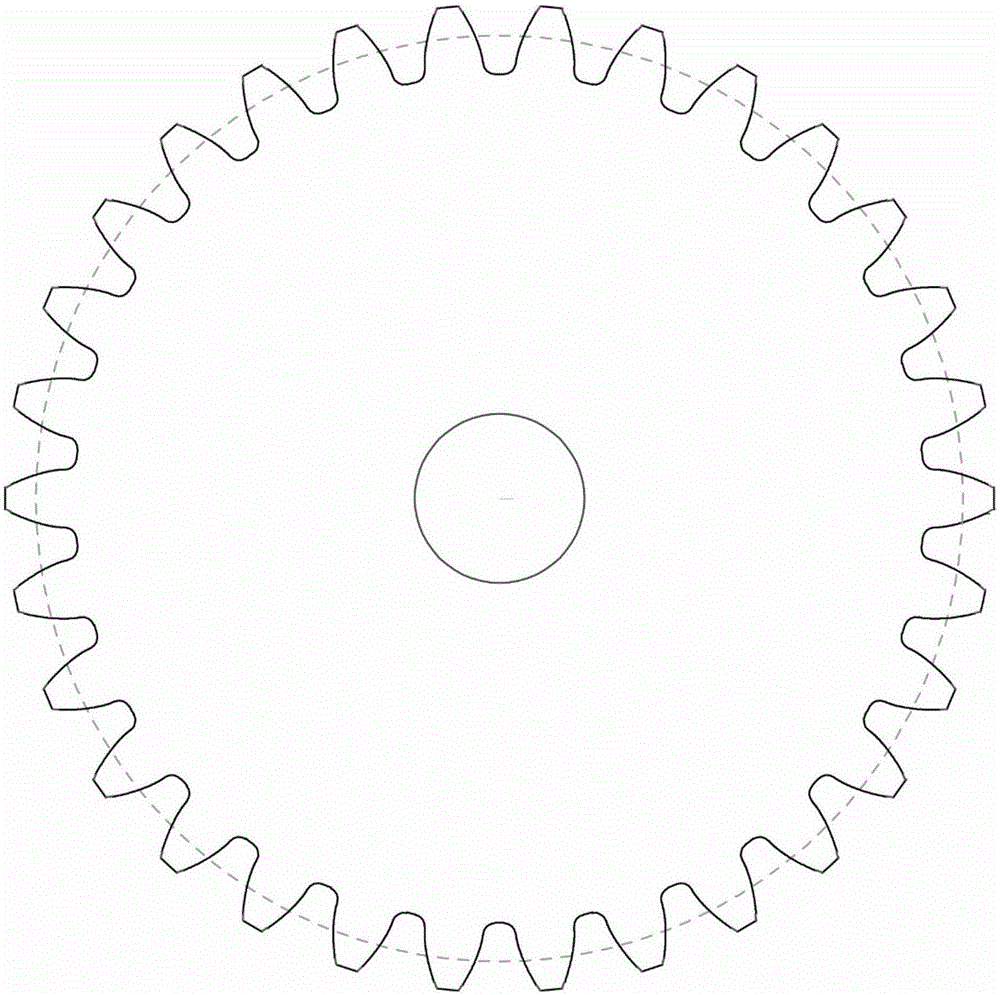

[0037] Using the involute equation, combined with the parametric drawing function of AUTOCAD, the two-dimensional diagram of the standard involute spur gear is drawn through basic drawing commands, such as figure 1 shown. Import it into ANSYS, and get the three-dimensional diagram of the standard involute spur gear through the stretch command.

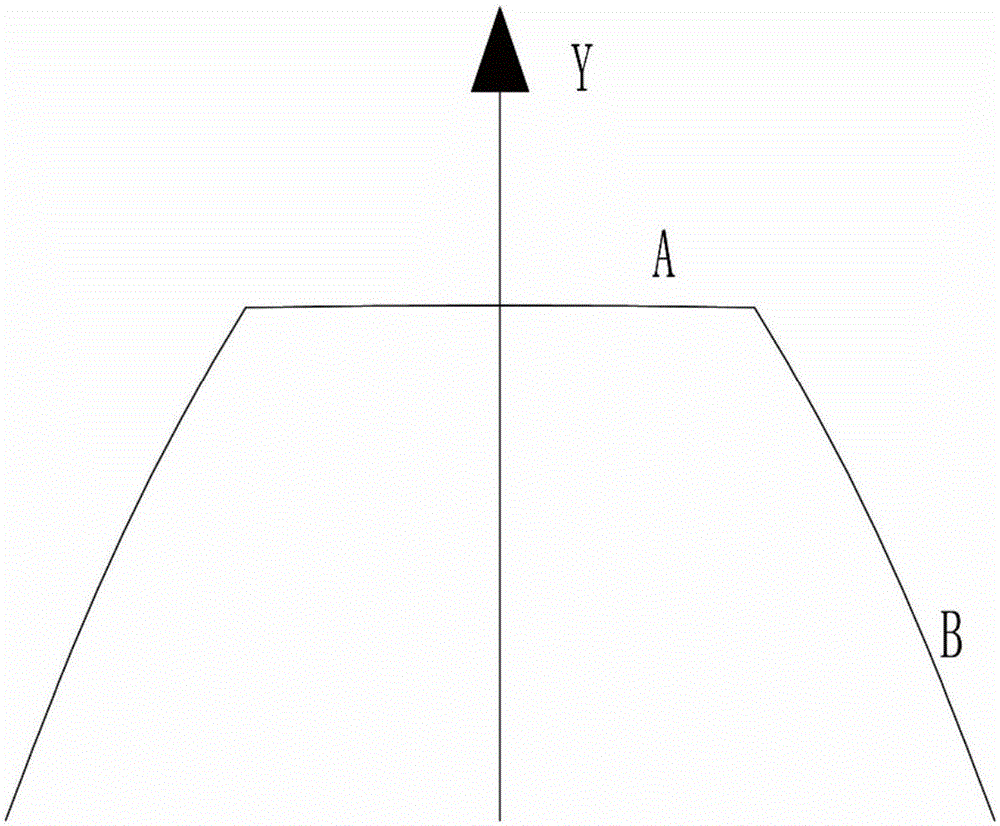

[0038] Such as figure 2 As shown, modify the shape of the AUTOCAD two-dimensional drawing obtained above. For a single tooth, A is the modification point in the tooth length direction, and B is the modification point in the tooth profile direction. Point A is equidistantly modified according to 2%-10% of the straight line length from the rightmost point on the tooth top to the Y axis, and point B is modified according to 10% of the partial involute length from the tooth r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com