Prestressed wire winding recipient

A technology of prestressed steel wire and extrusion cylinder, applied in the field of metal hot extrusion, can solve the problems of poor ability to withstand impact, prone to bending, uneven metal flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

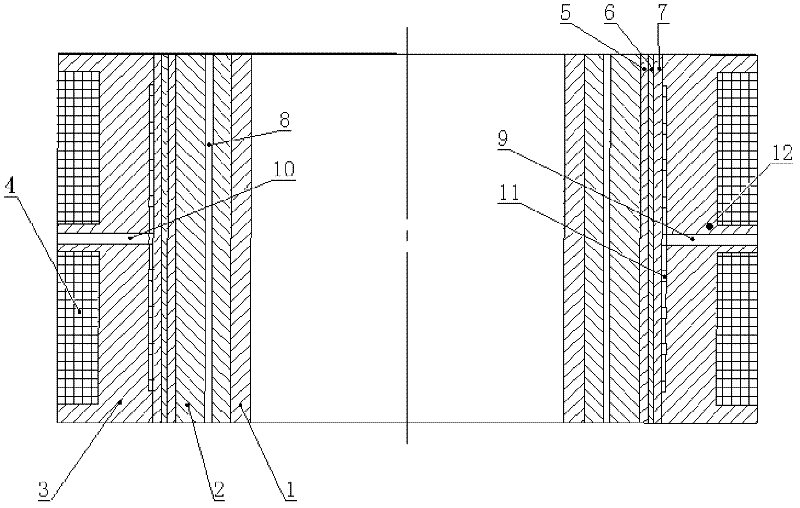

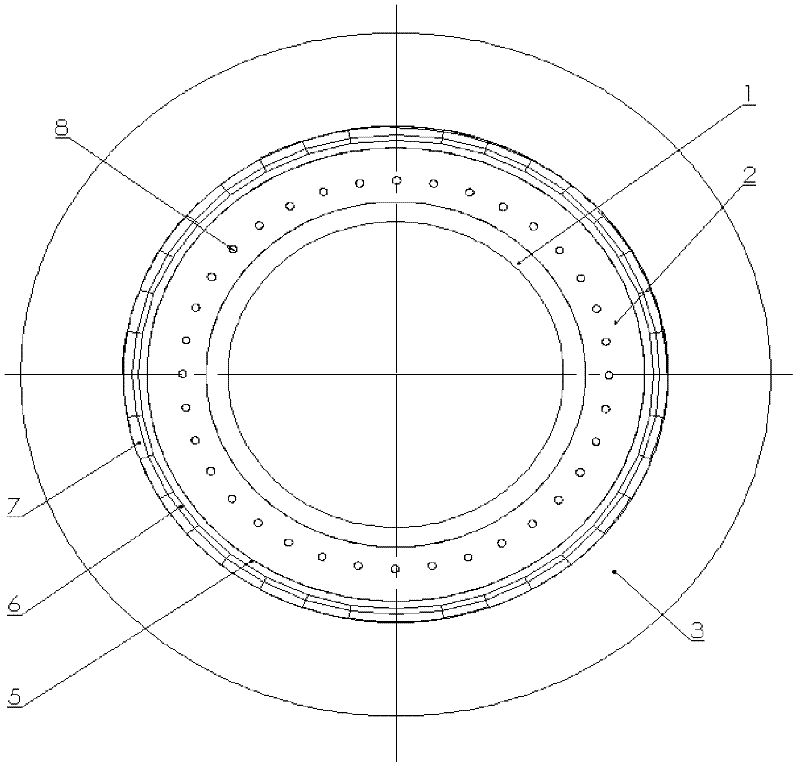

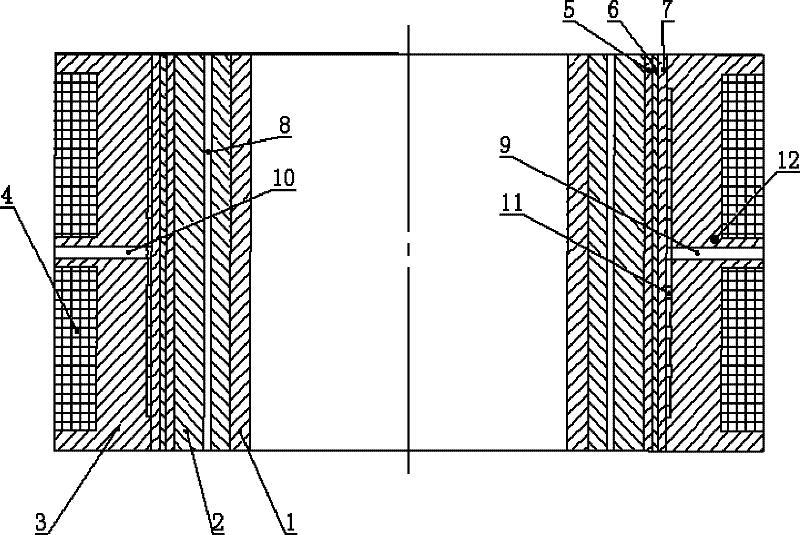

[0026] The prestressed steel wire winding extrusion cylinder includes: inner lining 1, middle lining 2, outer lining 3, heat insulation layer and steel wire layer 4. The outer lining can adopt a split structure, which is generally divided into 4 sub-parts along the symmetrical plane, and each layer is wound into a whole with prestressed steel wire.

[0027] Steel wire slots are processed on the outer lining 3 for winding prestressed steel wires, and the prestressed steel wire layer 4 is divided into upper and lower sections. Pre-heating holes 8 are processed on the lining 2, and the pre-heating holes are evenly distributed along the circumferential direction. Heating elements are placed in the pre-heating holes. The heating elements can be resistors or heating rods. The size of the pre-heating holes is determined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com