Method for manufacturing automobile body through carbon fiber composite

A carbon fiber material and automobile body technology, which is applied in the field of manufacturing automobile bodies with carbon fiber composite materials, can solve the problems of large-scale promotion and application of composite manufacturing processes and differences in composite process performance, and achieves light weight, good body energy absorption, and weight. most effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings and embodiments.

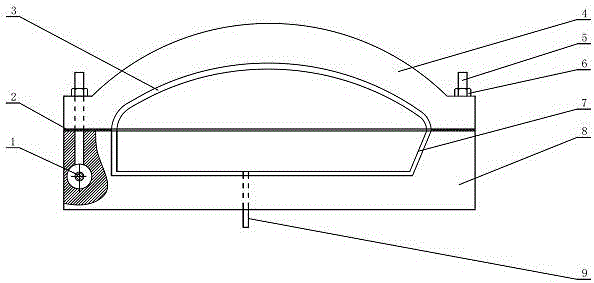

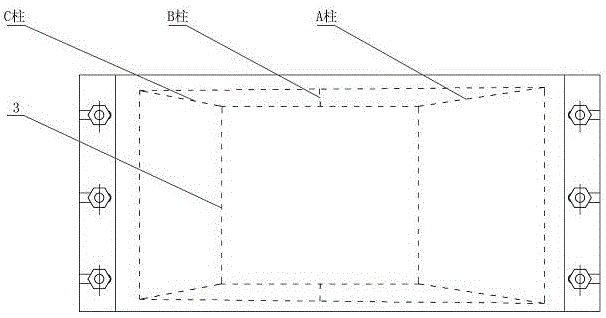

[0027] Such as figure 1 , figure 2 As shown, the method steps of the present invention are as follows:

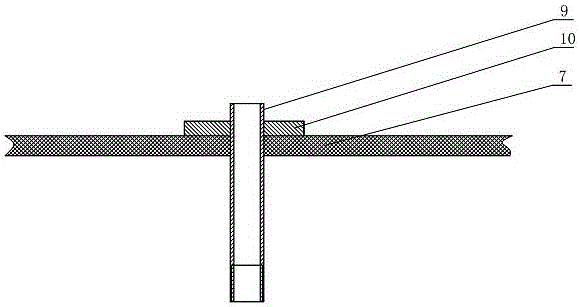

[0028] Step 1) Inflate the flexible inner mold 7 used to manufacture the car body to make it in the shape of the car body, and lay the pre-coated carbon fiber material on the outer surface of the flexible inner mold 7 according to the designed angle and number of layers. The laid carbon fiber material is the car body and meets the strength requirements;

[0029] Step 2) Place the laid flexible inner mold 7 of carbon fiber material in the outer mold for fixing and inflating and pressurizing, and then place it in a curing furnace for curing at a temperature of 100-150°C;

[0030] Step 3) After the carbon fiber composite material is solidified, cool naturally, vent the flexible inner mold and release the pressure, open the outer mold, and take out the solidified carbon fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com