Pressure-sensitive device with axial sintering of ceramic metal tube shell adopted

A technology of ceramic metal and sensitive devices, which is used in the measurement of fluid pressure by changing ohmic resistance, and the measurement of property force by applying piezoelectric resistance materials. It can solve the problems of large axial size and large radial size, and achieve shrink The effect of axial dimension, firm connection and large sintered area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

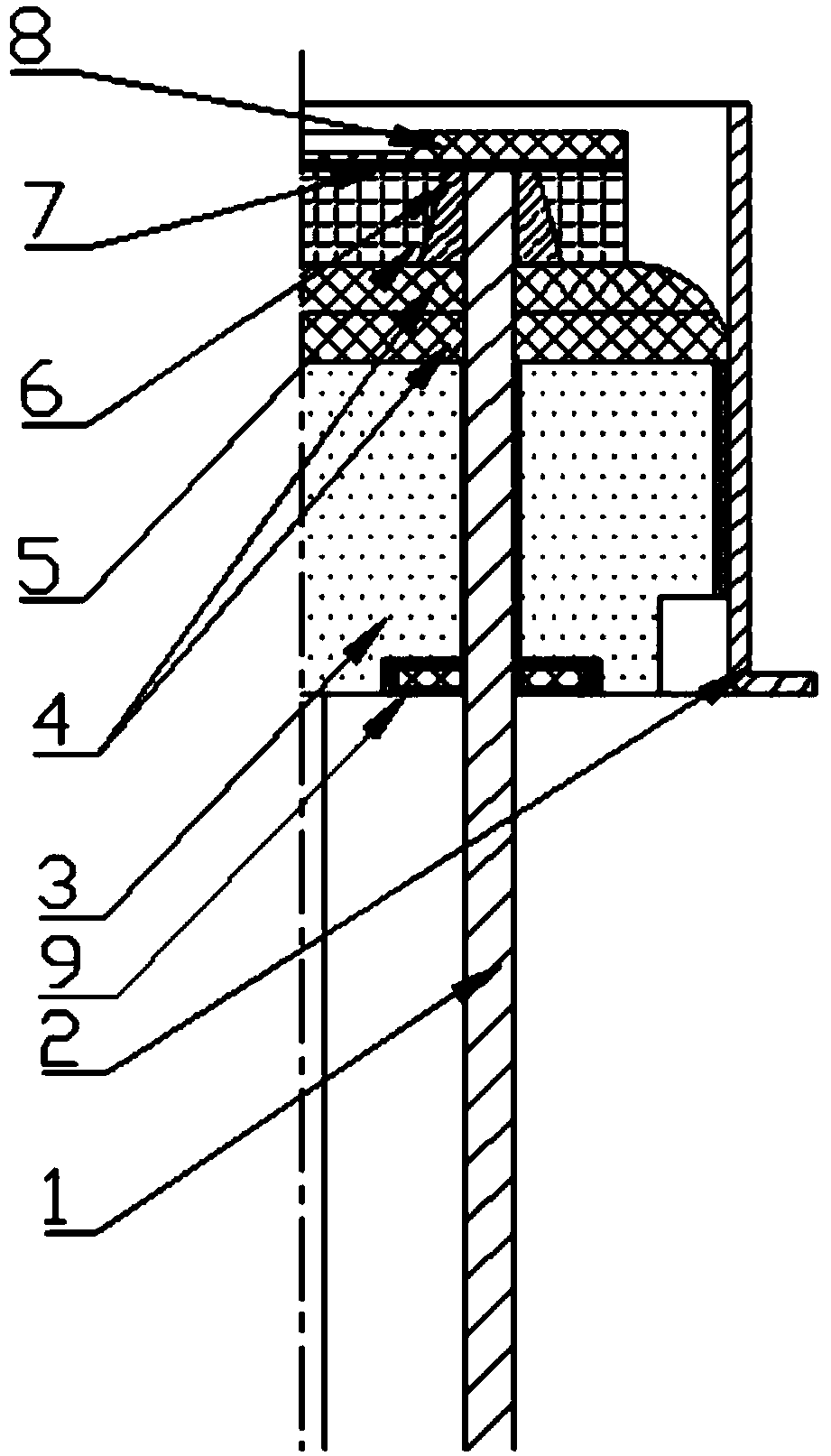

[0021] Specific implementation mode one: combine figure 1 In this embodiment, a pressure-sensitive device adopting axial sintering of a ceramic-metal shell includes a lead wire 1, a tube base 2, a ceramic insulating material 3, a multilayer composite material 4, a borosilicate glass base 5, and a glass-metal composite material 6. Metal electrode 7, chip 8 and sealing ring 9;

[0022] Among them, the ceramic insulating material 3 is sintered together with the lead wire 1 and the tube base 2 at a high temperature under a protective atmosphere; Sintered together with the ceramic insulating material 3 through solder, and sintered together with the surface of the inner hole of the lead wire 1 and the sealing ring 9 through solder;

[0023] The lead wire 1 runs through the ceramic insulating material 3, the multilayer composite material 4 and the borosilicate glass base 5, and the lead wire 1 is connected to the metal electrode 7 by sintering at a low temperature under a protective...

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ceramic insulating material 3 is Al 2 o 3 , SiC, BeO, TiO 2 , ZrO 2 , MgO, AlN, Si 3 N 4 , BN and mixtures of the above substances. Others are the same as the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the multilayer composite material 4 is a wafer structure, and the edge of the upper surface of the multilayer composite material 4 is chamfered . Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com