Sea wind power guiding pipe frame foundation structure

A basic structure and offshore wind power technology, applied in basic structure engineering, construction, etc., can solve the problems of complex structure shape, difficult production and processing, and large fatigue damage of the foundation transition section, and achieve light weight, reasonable stress distribution, and dynamic stress The effect of less area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

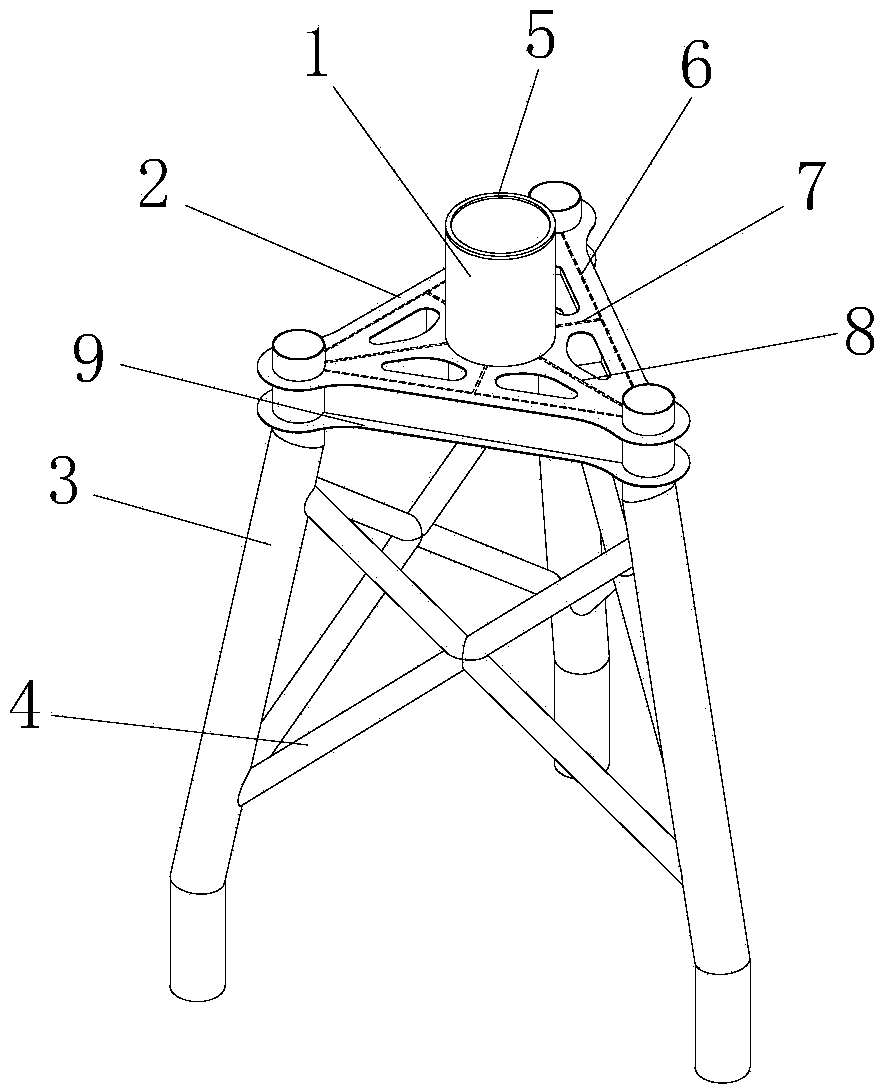

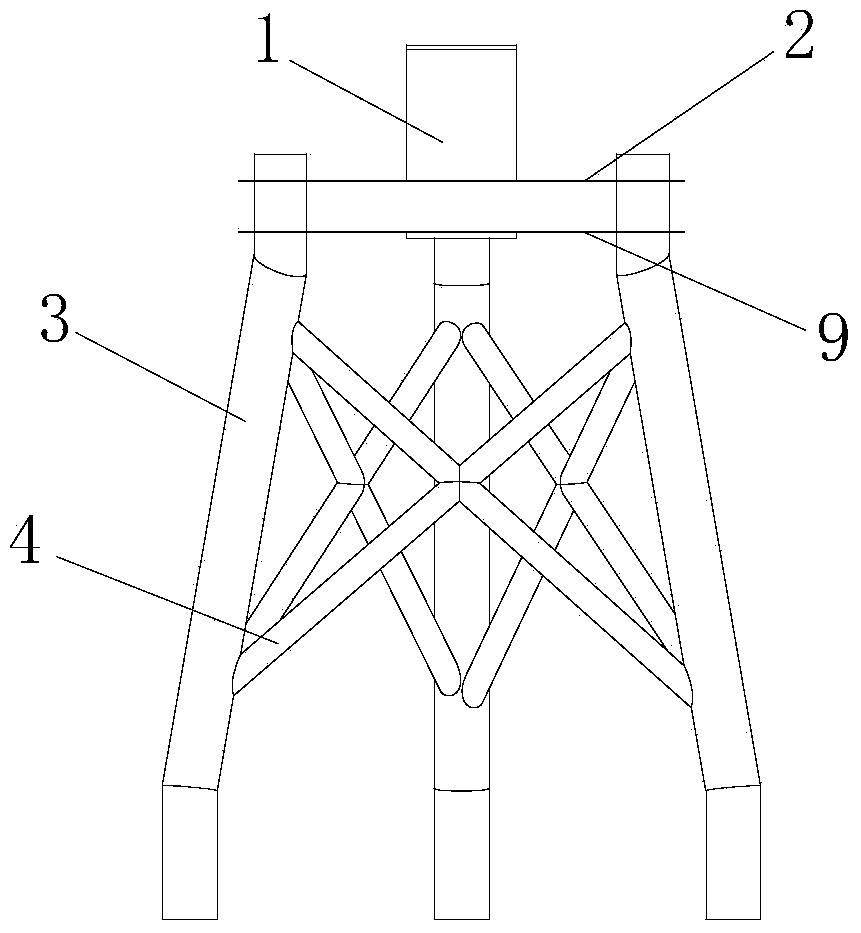

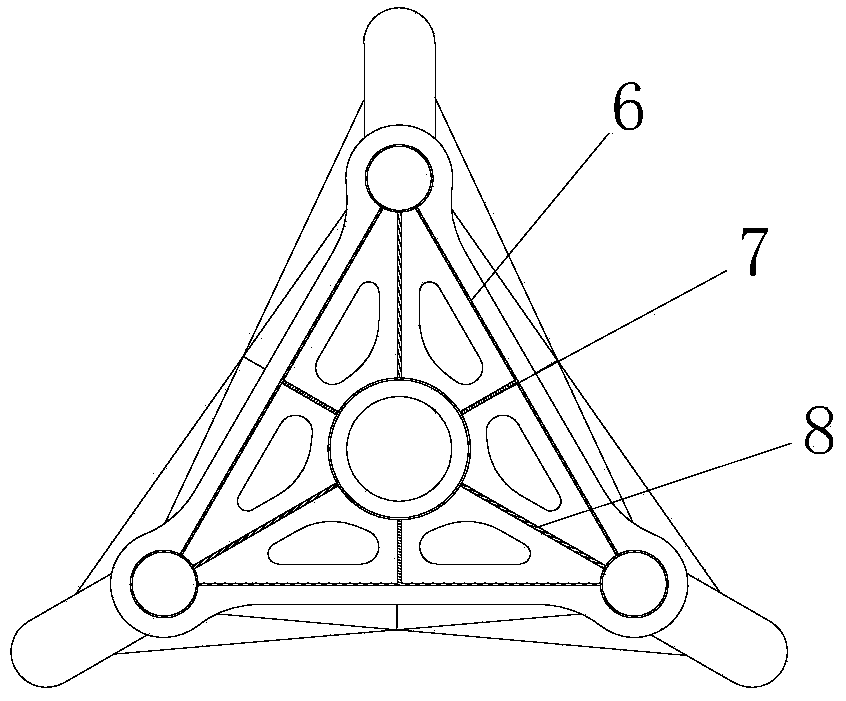

[0013] refer to Figure 1 to Figure 3 , an offshore wind power jacket foundation structure, comprising three conduits 3 arranged in a triangular cross-section, braces 4 are arranged between the conduits 3, a triangular support platform is connected to the upper part of the conduit 3, and the support platform A main cylinder 1 is arranged in the center, and a foundation flange 5 is provided on the upper part of the main cylinder 1. The support platform includes an upper sealing plate 2, a lower sealing plate 9 welded with the main cylinder 1 and the conduit 3 and The upper and lower sides are respectively welded to the side beams 6, auxiliary beams 7 and main beams 8 on the upper sealing plate 2 and the lower sealing plate 9. The main beams 8 are distributed at 120 degrees along the vertical direction, and the two ends are respectively connected to the The main cylinder 1 and the conduit 3 are welded, the side beams 6 are arranged along the sideline of the support platform, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com