Automatic storage battery charging-discharging and capacity detection device

A capacity detection and storage battery technology, applied in measuring devices, measuring electrical variables, measuring electricity, etc., can solve the problems of slow frequency response, poor anti-interference ability, and high cost, achieve fast frequency response, meet high-current discharge, Simple effect of power supply circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

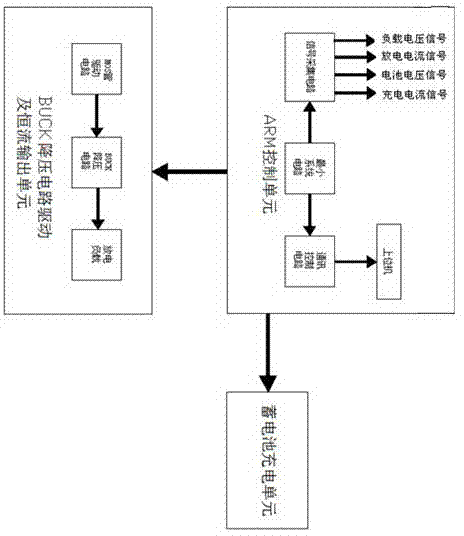

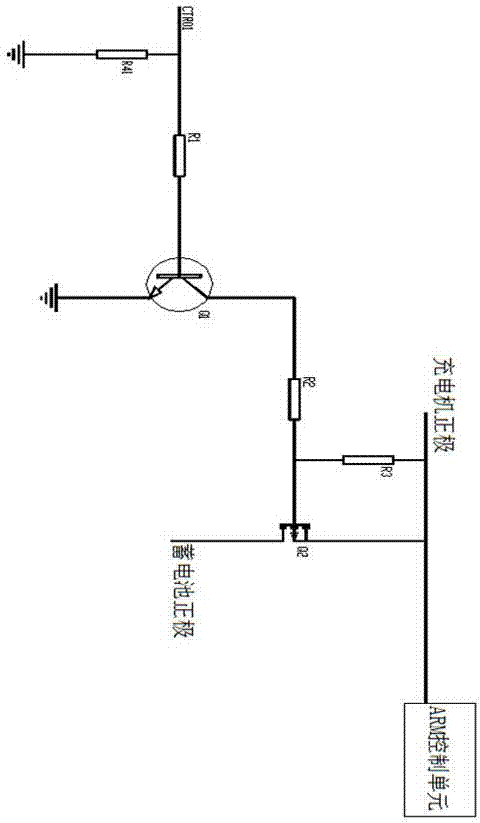

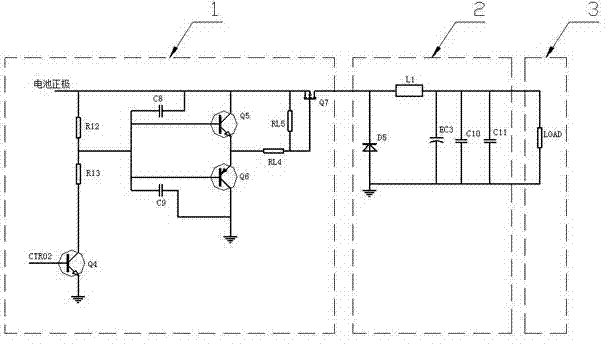

[0031] The schematic diagram of the module structure of the present invention is as figure 1 As shown, the battery automatic charging and discharging and capacity detection device includes an ARM control unit, a battery charging unit, a BUCK step-down circuit drive and a constant current output unit, and the output terminals of the ARM control unit are respectively connected to the battery charging unit, the BUCK step-down circuit The voltage circuit drive and the constant current output unit are connected, wherein the ARM control unit is composed of a signal acquisition circuit, an ARM minimum system circuit, a communication control circuit and a host computer connected in sequence; the signal acquisition circuit includes a charging current detection circuit, a discharge current A detection circuit, a battery voltage detection circuit and a load d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com