Microwave film resistor, microwave film resistor network module and manufacturing method thereof

A resistor network and microwave thin film technology, which is applied in other resistor networks, resistors, non-adjustable metal resistors, etc., can solve the problems of reduced reliability of resistors, large size, and cumbersome attenuator technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A layer of TaN thin film was formed on the upper surface of the aluminum oxide substrate with a thickness of 0.381mm and a purity of 99.6% by reactive sputtering, and then Au was sputtered on the surface of the TaN thin film and the lower surface of the ceramic substrate, and then the TaN / Au surface patterning (choose 0201 size mask 1), then thicken the Au layer to 3 μm by electroplating, etch to expose the TaN layer, and finally cut and clean according to the obtained pattern size to obtain the average size of 0201 Thin Film Resistor Products without Sparing, as attached image 3 shown. Or cut and clean the electrode layer and resistance layer according to the obtained graphic size, and the size specification of the metallization layer on the back is 0201 thin film resistors, such as Figure 4 shown. The product was tested after heat treatment at 400°C for 10 minutes, and 98% of the products had a resistance value between 48.5 and 52.0Ω. Calculated according to the ...

Embodiment 2

[0082] A layer of NiCr thin film is formed on the upper surface of the aluminum oxide substrate with a thickness of 0.508mm and a purity of 99.6% by reactive sputtering, and then TiW alloy, Ni and Au are sputtered on the NiCr layer and the lower surface of the ceramic substrate, Then pattern the NiCr / TiW / Ni / Au surface (choose 0402 size mask 2), then thicken the Au layer to 4 μm by electroplating, etch to the NiCr layer, and then pattern the NiCr layer (0402 size mask 3 , resistance aspect ratio 2.0:1), corrode to the edge part to expose the ceramic substrate, and finally cut and clean according to the obtained graphic size to obtain the electrode layer, resistance layer and back metallization layer with a size specification of 0402. Thin film resistor products such as Figure 5 shown. Or cut and clean according to the obtained graphic size to obtain a thin film resistor product with a size specification of 0402 electrode layer and resistance layer with no edge left, such as ...

Embodiment 3

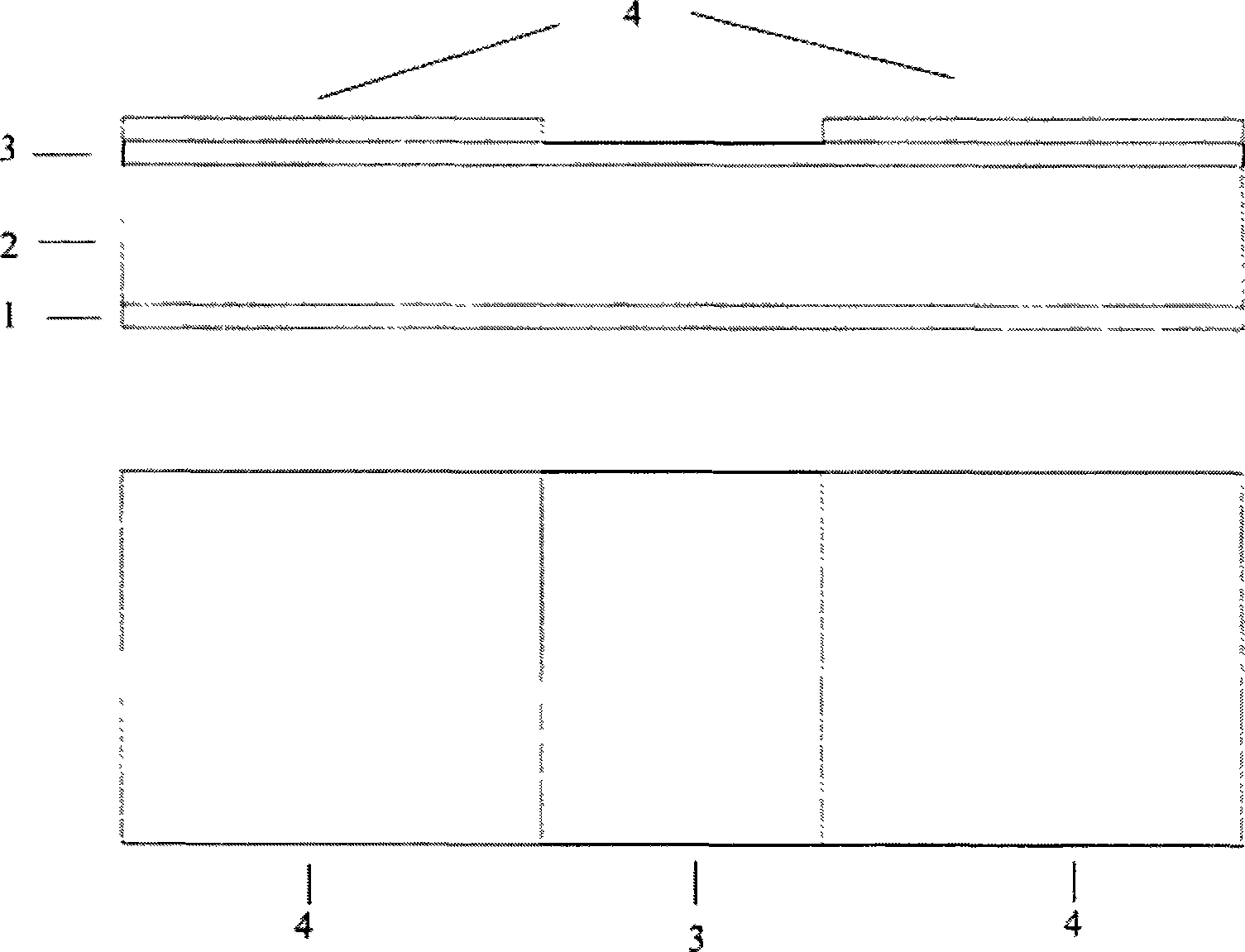

[0084] A layer of TaN film was formed by reactive sputtering on the upper surface of the aluminum nitride substrate with a thickness of 0.381 mm and a purity of 99.6%, and then TiW alloy and Au were sputtered on the lower surface of the TaN film and the ceramic substrate, and then the The surface of TaN / TiW / Au and TiW / Au is patterned (select 0201 size masks 4 and 5), and then the Au layer is thickened to 5 μm by electroplating, and etched until the TaN layer is exposed on the upper surface, and the lower surface is reserved Expose the ceramic layer, then pattern the TaN layer (0201 size mask 6, resistance aspect ratio 1.5:1) and etch until the ceramic substrate is exposed at the remaining part, and finally cut and clean according to the obtained pattern size to obtain the size specification It is a 0201 thin film resistor product, and the electrode layer, resistance layer and back metallization layer of this product have margins, such as Figure 9 shown. The product is heat-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Attenuation value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com