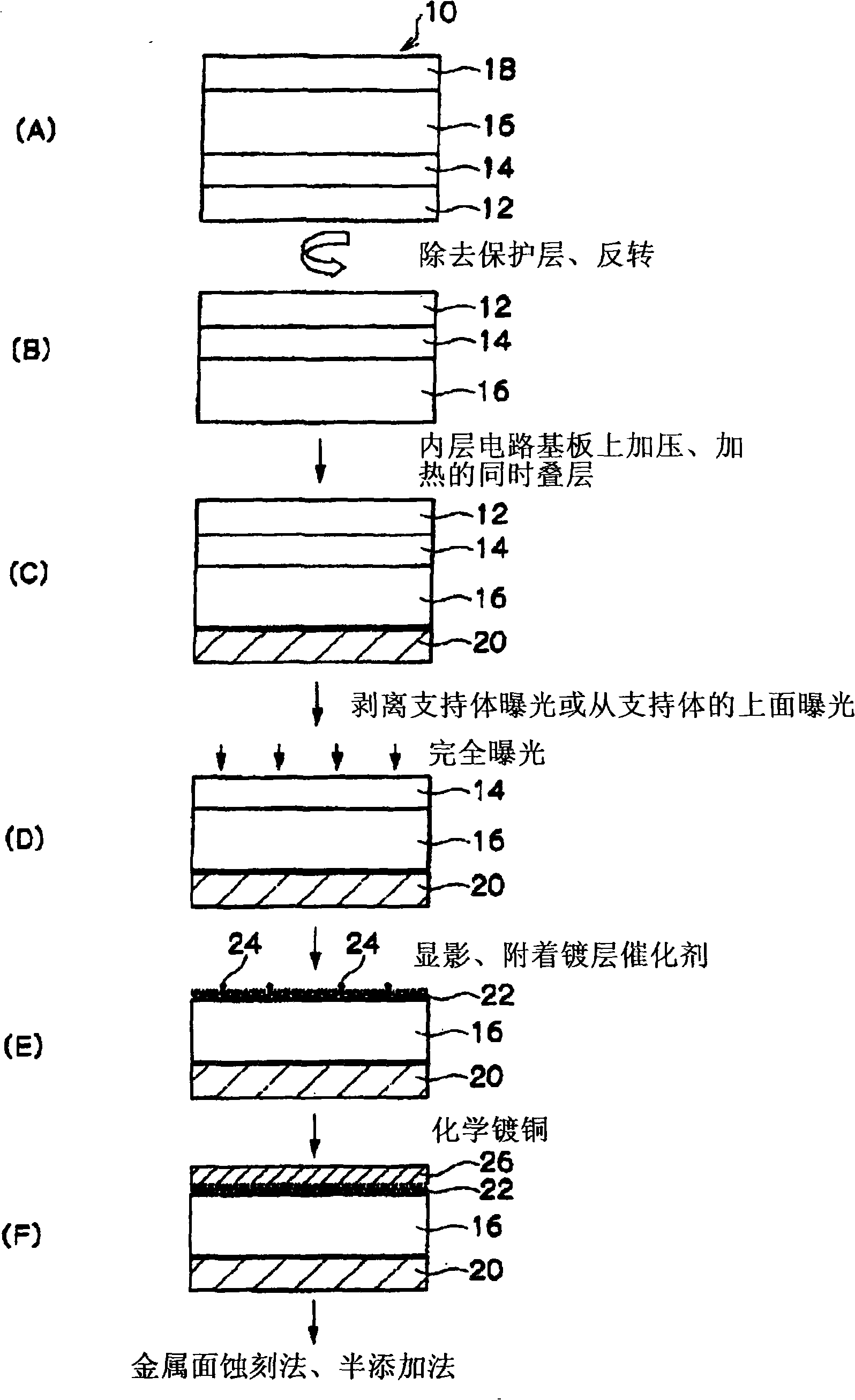

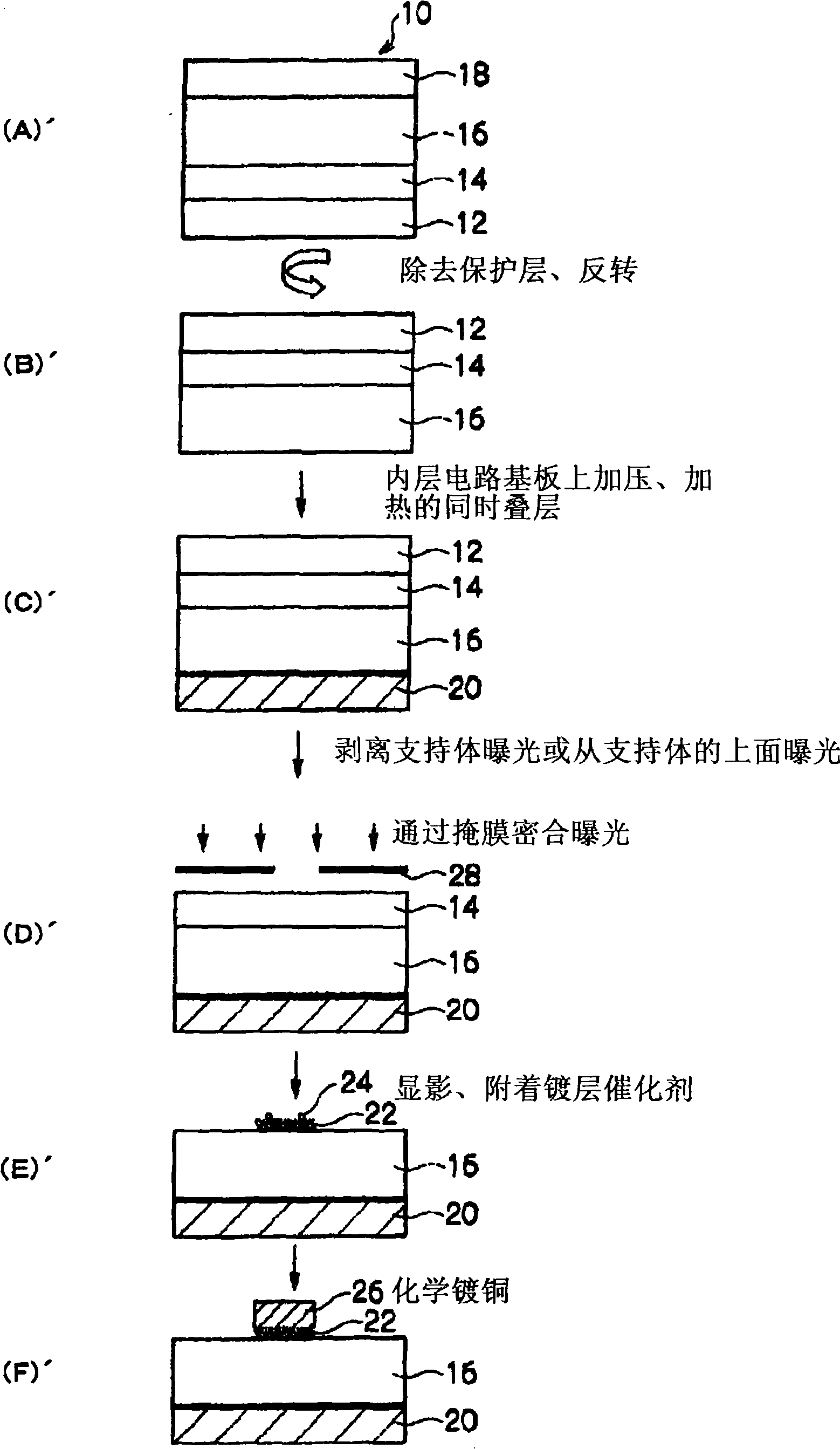

Laminate for printed wiring board, printed wiring board using same, method for manufacturing printed wiring board, electrical component, electronic component, and electrical device

A technology of printed circuit boards and laminates, which is applied in the fields of printed circuit manufacturing, printed circuit components, printed circuits, etc., which can solve problems such as difficulty in uniformity and inability to form interactions, and achieve good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0303] Hereinafter, the common points of Examples 1 to 5 will be described.

[0304] (Fabrication of a laminate in which a graft polymer precursor layer is coated on an insulating film)

[0305] On the surface of a polyethylene terephthalate film with a thickness of 16 μm as a support, it is not necessary to carry out surface treatment or pre-treatment respectively. Use a 6# rod to coat the liquid composition 1 of the following composition. Liquid composition 1, a polymer containing acryl group as a polymer compound and carboxyl group as an interactive group (hydrophilic polymer with polymerizable groups on branched chains: P-1, obtained in the following synthesis example) , and dried at 100° C. for 1 minute to form a graft polymer precursor layer. The film thickness of the polymer precursor layer is adjusted to be between 0.2 and 1.5 μm.

[0306] (Liquid Composition 1 Containing Polymeric Compound)

[0307] ・Hydrophilic polymer (P-1) with polymeric groups on the branched c...

Synthetic example

[0310] (Synthesis example: Synthesis of polymer P-1 having a double bond)

[0311] Add 60g polyacrylic acid (average molecular weight 25000, Wako Pure Chemical Industry) and 1.38g hydroquinone (Wako Pure Chemical Industry) (0.0125mol) into the 11 there-necked flask equipped with a cooling tube, then add 700g N, N-di Methylacetamide (DMAc, Wako Pure Chemical Industries) was stirred into a homogeneous solution at room temperature. While stirring this solution, 64.6 g (0.416 mol) of 2-methacryloyl hydroxyethyl isocyanate (Karenz MOI, Showa Denko) was added dropwise. Next, drop 0.79g (1.25×10 -3mol) di-n-butyltin dilaurate (Tokyo Chemical Industry). While stirring, heat in a water bath at 65°C. Stop heating after 5 hours, and cool to room temperature naturally. The acid value of this reaction liquid was 7.105 mmol / g, and the solid content accounted for 11.83%.

[0312] 300 g of the reaction solution was taken out from the beaker and cooled to 5° C. in an ice bath. While stir...

Embodiment 1

[0315] (Example 1: Formation of an epoxy insulator layer containing an initiator)

[0316] 20 parts by mass of bisphenol A type epoxy resin (epoxy equivalent 185, Epicoat 828 manufactured by Yuhua Shielu Epokishi (strain)) (the following mixing amounts are all expressed in parts by mass), 45 parts by mass of cresol novolac type epoxy Resin (epoxy equivalent 215, Dainippon Inki Chemical Industry Co., Ltd.'s Epichrome N-673), 30 parts by mass of novolac resin (phenol hydroxyl equivalent 105, Dainippon Inki Chemical Industry Co., Ltd.'s Feenolite), put on 20 mass parts Parts of ethyl diglycol acetate, 20 parts by mass of mineral spirits, heated while stirring to make it dissolve, after cooling to room temperature, add 30 parts by mass of the above-mentioned Epicoat 828 and bisphenol S to this place Cyclohexanone varnish of phenoxy resin (YL6747H30 manufactured by Yuhua Shieruyepokishi Co., Ltd., 30% by mass of non-volatile parts, weight average molecular weight 47000) and 0.8 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com