Apparatus and method for arranging predetermined element on target platform

A target and platform technology, applied in the structural field of detecting and improving component placement accuracy, can solve problems such as monitoring chips, and achieve the effects of improving placement accuracy, reducing rework, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

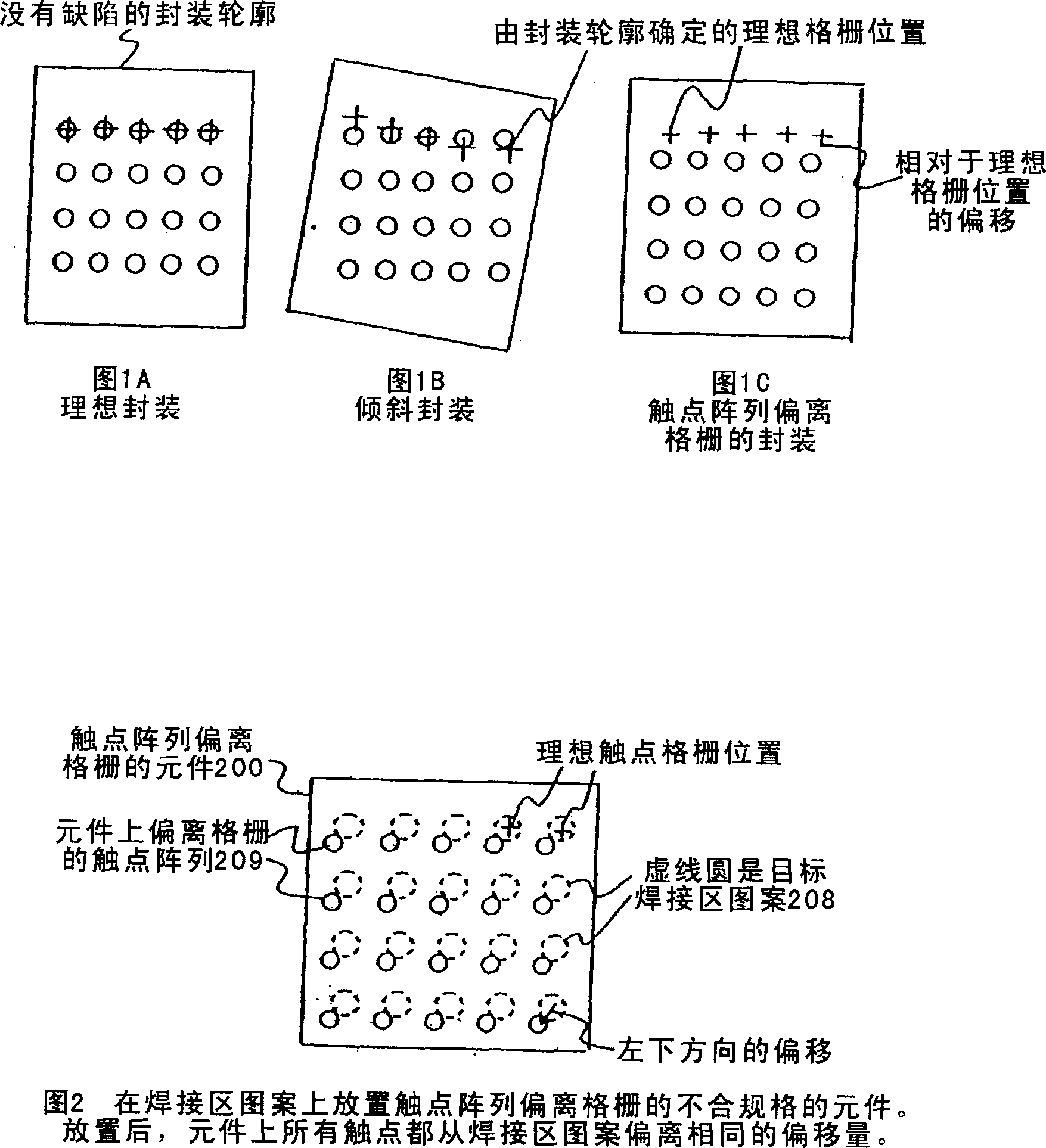

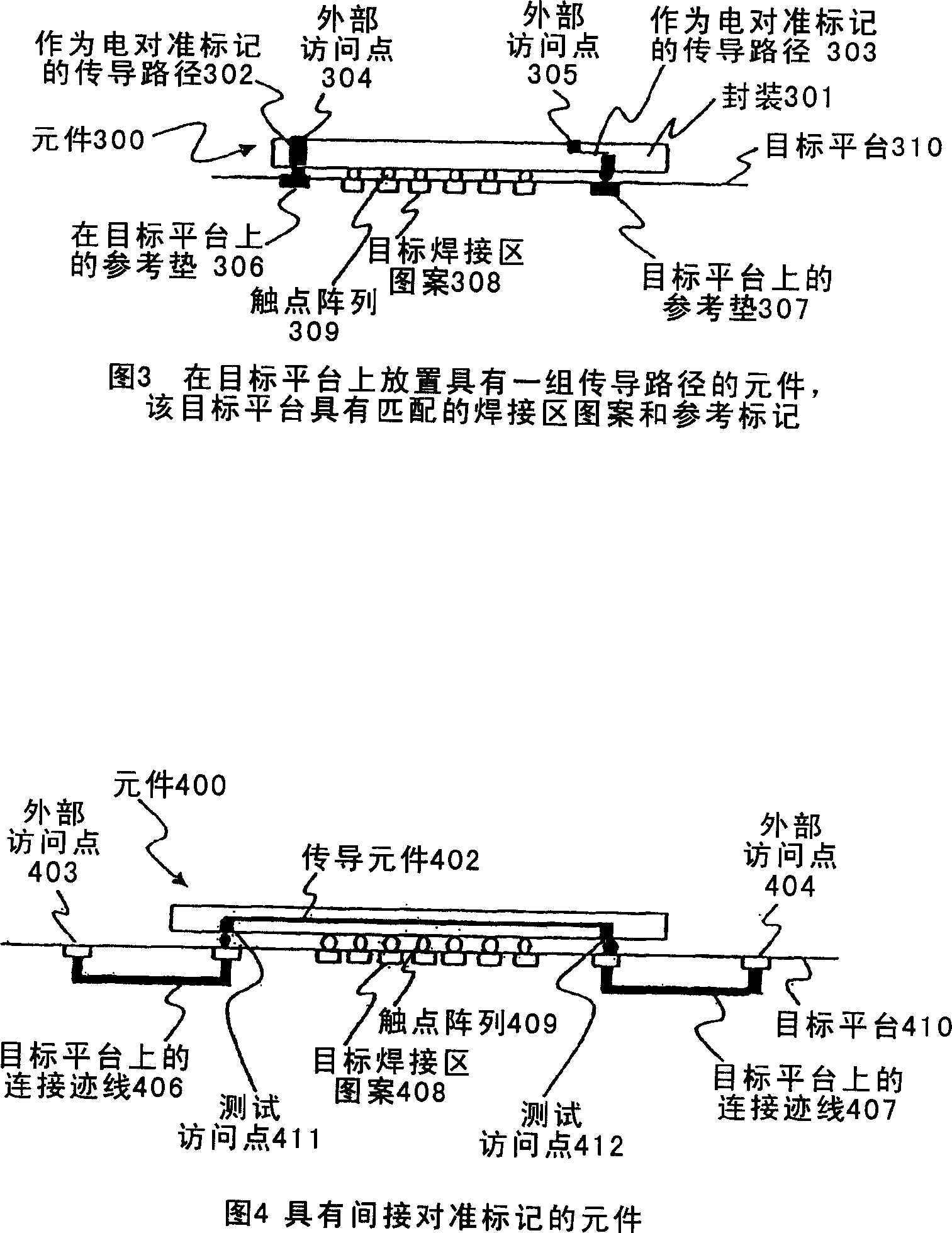

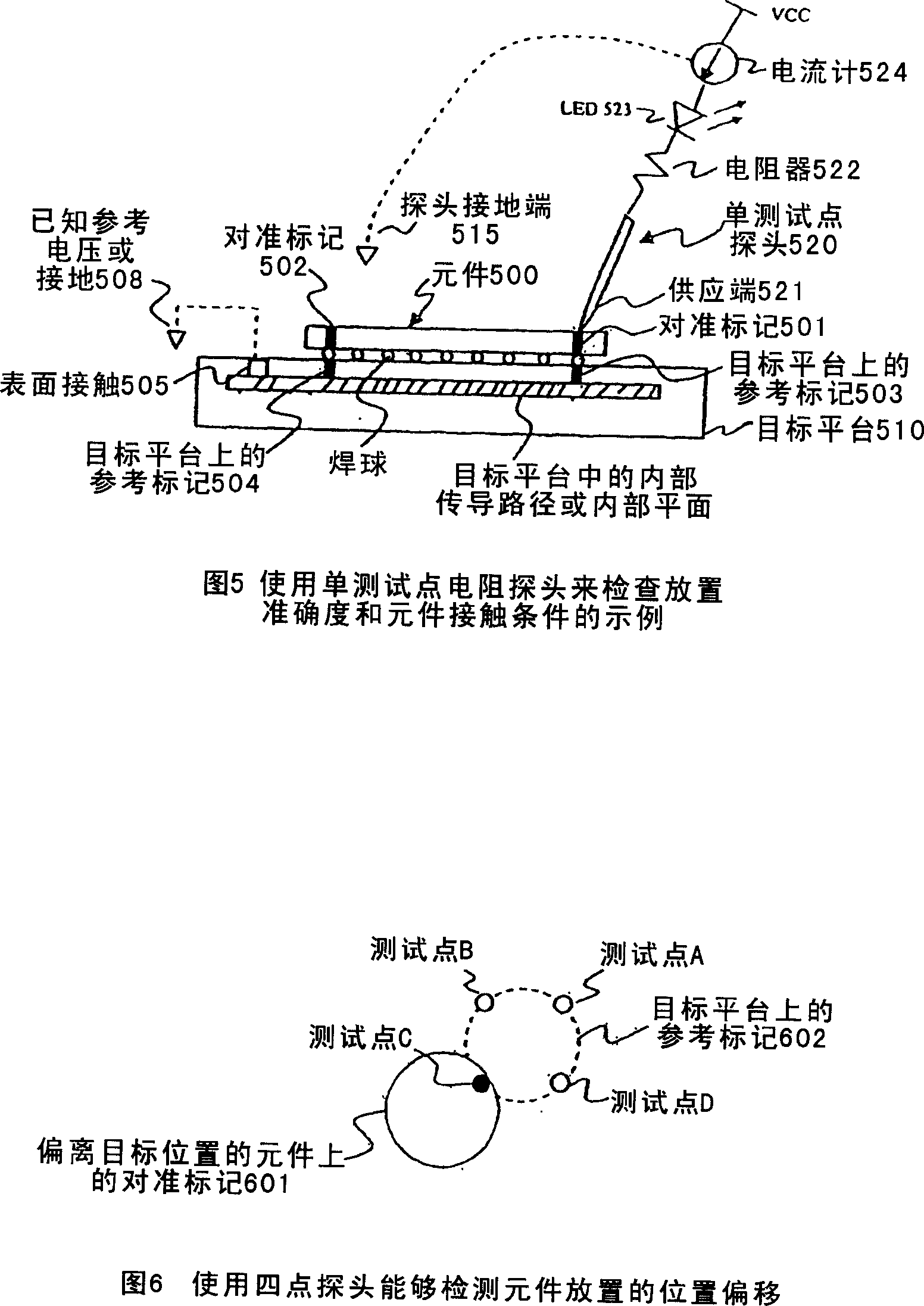

[0042] According to the present invention, alignment and probing techniques are described that improve the accuracy of component placement in assembly. More specifically, the present invention includes structures and methods for detecting and improving component placement accuracy on a target platform by incorporating alignment marks onto the component and reference marks onto the target platform using various probing techniques. A set of sensors in an array to form a multi-sensor probe capable of detecting deflection of a displacement element during assembly. Merely by way of example, the invention is applied to placing packaged devices on electronic substrates for electronic system fabrication. It should be realized, however, that the invention has broader applicability. Further details of the invention can be found throughout the specification of the invention, and in more detail below.

[0043] alignment mark

[0044] According to a preferred embodiment, the alignment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com