Ferrite composite magnetic powder core and preparing method thereof

A magnetic powder core and ferrite technology, which is applied in the manufacture of inductors/transformers/magnets, the magnetism of inorganic materials, and electrical components, can solve the problems of reduced magnetic permeability of magnetic powder cores, no introduction of preparation methods, and inability to coat magnetic powders. Achieve the effects of preventing failure, overcoming the reduction of the magnetic properties of the matrix, and facilitating the size of the particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

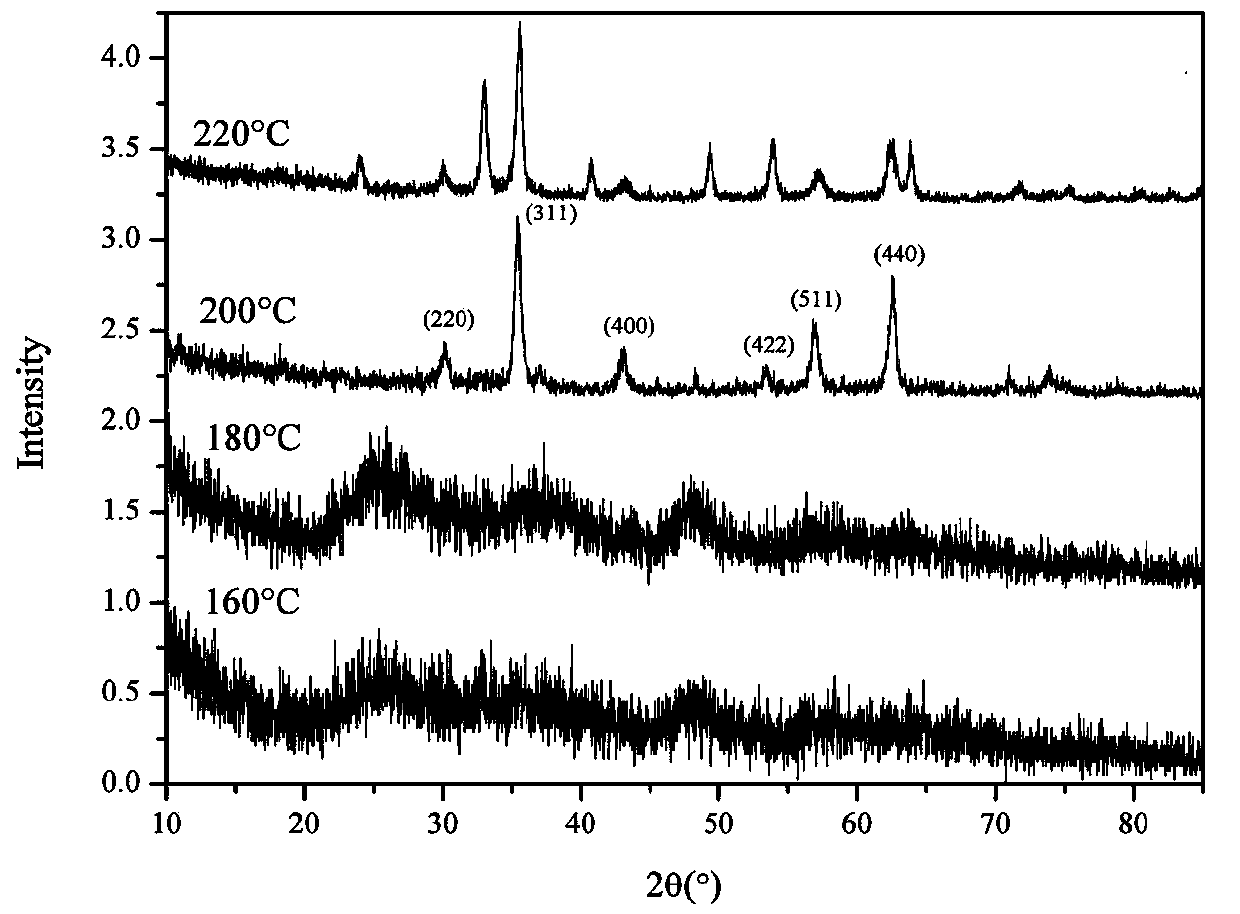

[0025] FeCl 3 、NiCl 2 Salt and ZnCl 2 Salt mole Ni x Zn 1-x Fe 2 o 4 ( x =0.2) dispersed in 50ml of ethylene glycol, FeCl 3 To 0.5mmol, stir until completely dissolved. Add 1.54gCH 3 COONH 4 and 0.8ml polyethylene glycol, stirred for 30 minutes. The mixture was transferred to a stainless steel autoclave and heated at 160 °C for 24 h. The resulting product was washed several times with ethanol and dried at 80 °C.

[0026] Take a certain amount of phosphoric acid and heat it to 85°C in a water bath. Slowly add the FeSiAl soft magnetic alloy to be passivated, stir to make the two fully mixed and react, passivate for 30min, and use 0.2 wt.% phosphoric acid.

[0027] Mechanically mix the passivated 70wt.% soft magnetic alloy with 30wt.% nickel-zinc ferrite particles, and add 0.2% water glass inorganic binder by mass of the mixed powder to continue mixing evenly.

[0028] The powder was pressed into a dense ring under a pressure of 1.9 GPa. Annealing heat treatment is...

Embodiment 2

[0030] Fe(NO 3 ) 3 , Ni (NO 3 ) 2 and Zn (NO 3 ) 2 Moore than Ni x Zn 1-x Fe 2 o 4 ( x =0.3) dispersed in 50ml of ethylene glycol, Fe (NO 3 ) 3 Salt 0.5mmol, stirred until completely dissolved. Add 1.54gCH 3 COONH 4 and 0.8ml polyethylene glycol, stirred for 30 minutes. The mixture was transferred to a stainless steel autoclave and heated at 180 °C for 12 h. The resulting product was washed several times with ethanol and dried at 80 °C.

[0031] Take a certain amount of phosphoric acid and heat it to 85°C in a water bath. Slowly add the FeSi soft magnetic alloy to be passivated, stir to make the two fully mixed and react, passivate for 30min, and the phosphoric acid dosage is 6 wt.%.

[0032] Mechanically mix the passivated 99.9wt.% soft magnetic alloy with 0.1wt.% nickel-zinc ferrite particles, and add 0.7% boron oxide inorganic binder by mass of the mixed powder to continue mixing evenly.

[0033] The powder was pressed into a dense ring under a pressure of...

Embodiment 3

[0035] Will Fe 2 (SO 4 ) 3 , NiSO 4 and ZnSO 4 Moore than Ni xZn 1-x Fe 2 o 4 ( x =0.6) dispersed in 50ml of ethylene glycol, Fe 2 (SO 4 ) 3 To 0.5mmol, stir until completely dissolved. Add 1.54gCH 3 COONH 4 and 0.8ml polyethylene glycol, stirred for 30 minutes. The mixture was transferred to a stainless steel autoclave and heated at 200 °C for 8 h. The resulting product was washed several times with ethanol and dried at 80 °C.

[0036] Take a certain amount of phosphoric acid and heat it to 85°C in a water bath. Slowly add the FeNiMo soft magnetic alloy to be passivated, stir to make the two fully mixed and react, passivate for 30min, and the phosphoric acid dosage is 3 wt.%.

[0037] Mechanically mix the passivated 85wt.% soft magnetic alloy with 15wt.% nickel-zinc ferrite particles, and add 1% of the mixed powder mass as an inorganic binder of low-melting glass powder to continue mixing evenly.

[0038] The powder was pressed into a dense ring under a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com