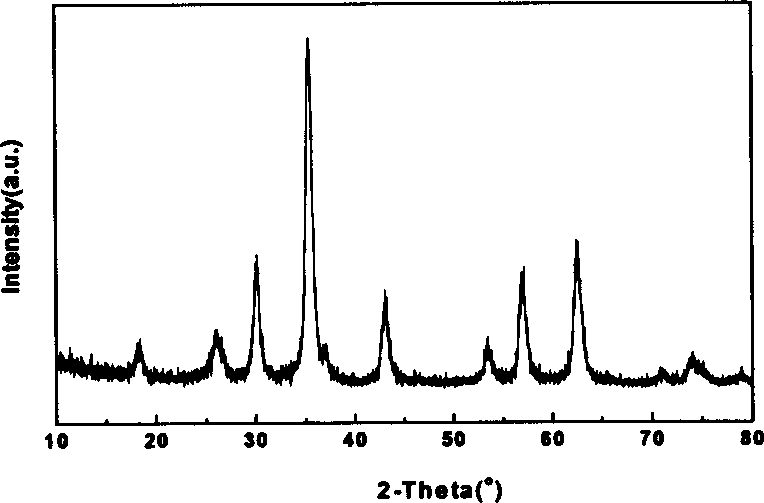

Process for preparing composite material of carbon nano tube/NiZn ferrite

A nickel-zinc ferrite, carbon nanotube technology, applied in the direction of magnetic materials, metal material coating process, magnetic objects, etc. The effect of good magnetic properties and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

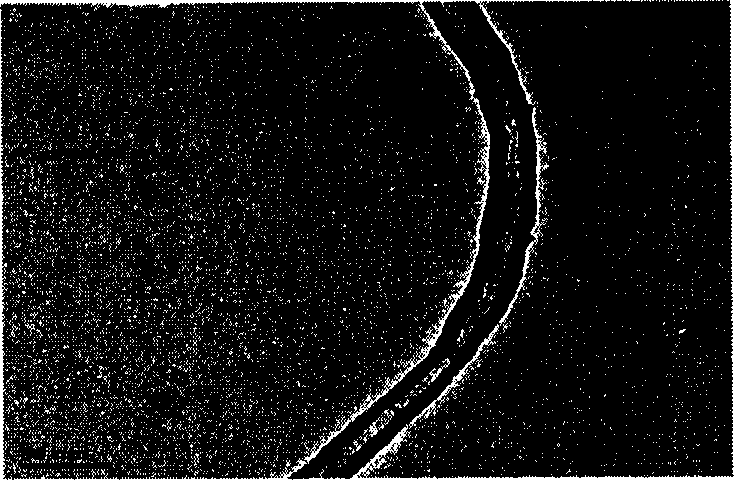

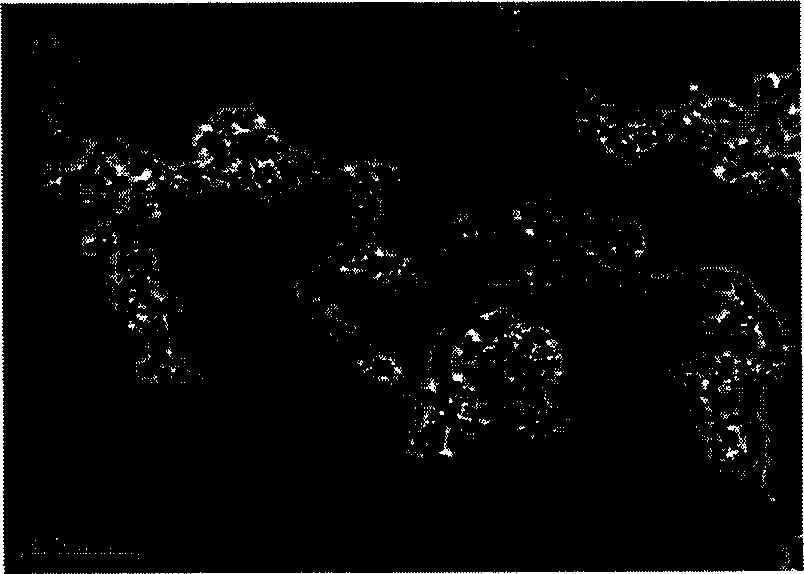

Embodiment 1

[0033] 0.5g of carbon nanotubes and 50ml of concentrated nitric acid mixture were refluxed in an oil bath at 140°C for 4.5 hours to prepare modified carbon nanotubes, and then at room temperature, press Ni 2+ : Zn 2+ : Fe 3+ The molar ratio is 0.75:0.25:2 to weigh Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, add distilled water, sonicate to dissolve the salt completely, add and Fe 3+The mass ratio is 1:10 modified carbon nanotubes, ultrasonic treatment again to make it uniformly dispersed, and then titrate the above mixture with 5mol / l NaOH solution, stirring with a magnetic stirrer at a speed of 600 rpm during the titration process , when the pH value = 9, the titration is completed, put the reactant in a 100ml hydrothermal kettle at 200°C, react for 8 hours, after the reaction is complete, wait for the system to cool to room temperature, filter the reactant, and use a large amount of distilled water Rinse with ethanol after washing to PH=7, and fu...

Embodiment 2

[0040] 0.5g of carbon nanotubes and 35ml of concentrated nitric acid mixture were refluxed in an oil bath at 150°C for 3 hours to prepare modified carbon nanotubes, and then at room temperature, press Ni 2+ : Zn 2+ : Fe 3+ The molar ratio is 0.5:0.5:2 to weigh Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, add distilled water, sonicate to dissolve the salt completely, add and Fe 3+ The mass ratio of modified carbon nanotubes is 1:15, ultrasonic treatment is used to disperse evenly, and then the above mixture is titrated with 4mol / l NaOH solution, and the magnetic stirrer is used to stir at a speed of 800 rpm during the titration process , when the pH value = 9, the titration is completed, put the reactant in a 100ml hydrothermal kettle at 180°C, react for 24 hours, after the reaction is complete, wait for the system to cool to room temperature, filter the reactant, and use a large amount of distilled water to filter the reactant Rinse with ethanol aft...

Embodiment 3

[0042] 0.5g of carbon nanotubes and 75ml of concentrated nitric acid mixture were refluxed in an oil bath at 120°C for 8 hours to prepare modified carbon nanotubes, and then at room temperature, press Ni 2+ : Zn 2+ : Fe 3+ The molar ratio is 0.25:0.75:2 to weigh Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, add distilled water, sonicate to dissolve the salt completely, add and Fe 3+ The mass ratio of the modified carbon nanotubes is 1:12, and ultrasonic treatment is used to disperse the mixture evenly, and then the above mixture is titrated with 8 mol / l kOH solution. During the titration process, a magnetic stirrer is used to stir at a speed of 400 rpm , when the pH value = 10, the titration is completed, put the reactant in a 100ml hydrothermal kettle at 280°C, react for 3 hours, after the reaction is complete, wait for the system to cool to room temperature, filter the reactant, and use a large amount of distilled water Rinse with ethanol after was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com