Low-temperature-factor anti-stress nickel zinc ferrite and preparation method thereof

A nickel-zinc ferrite, temperature factor technology, applied in the field of soft ferrite, can solve problems such as unstable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

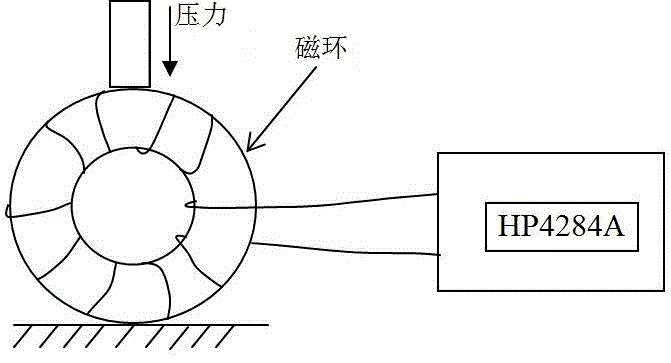

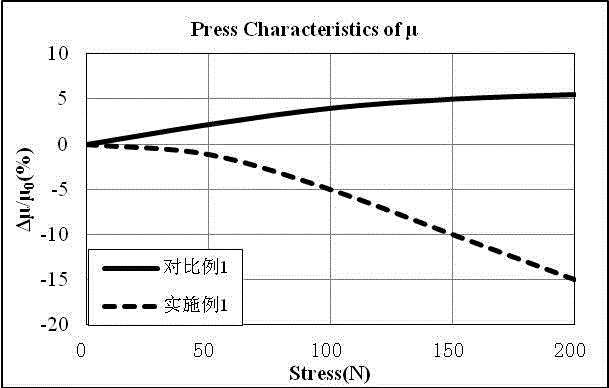

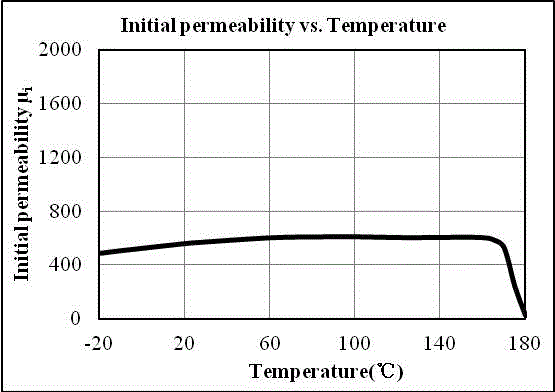

Image

Examples

Embodiment Construction

[0046] The present invention will be described below based on specific examples, but the present invention is not limited to these examples.

[0047] The stress-resistant nickel-zinc ferrite of the present invention is manufactured by a traditional oxide method, and the specific steps are as follows:

[0048] (1) Mixing and pelletizing: mix and pelletize according to the ratio of the main components listed in Table 1 (Example and Comparative Example), and then mix and pelletize. The mixing and pelletizing time is 30 to 45 minutes;

[0049] (2) Pre-burning: The mixed materials are pre-fired in a rotary kiln, the pre-fired temperature is controlled at 850±20°C, and the pre-fired amount is controlled at (90±10)kg / h;

[0050] (3) Coarse pulverization: Coarsely pulverize the above-mentioned pre-burned powder with a bucket vibrating mill for 40 to 60 minutes;

[0051] (4) Dispersion and emulsification: After adding the auxiliary components of the amount listed in Table 1 (Example a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com