High-conductive nickel-zinc ferrite and preparing process thereof

A ferrite, high-conductivity technology, applied in the field of nickel-zinc high-conductivity ferrite and its preparation, can solve problems such as the inability to meet technological development, and achieve the advantages of improving mutual isolation and reflection loss, scientific ingredient design, and reducing insertion loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

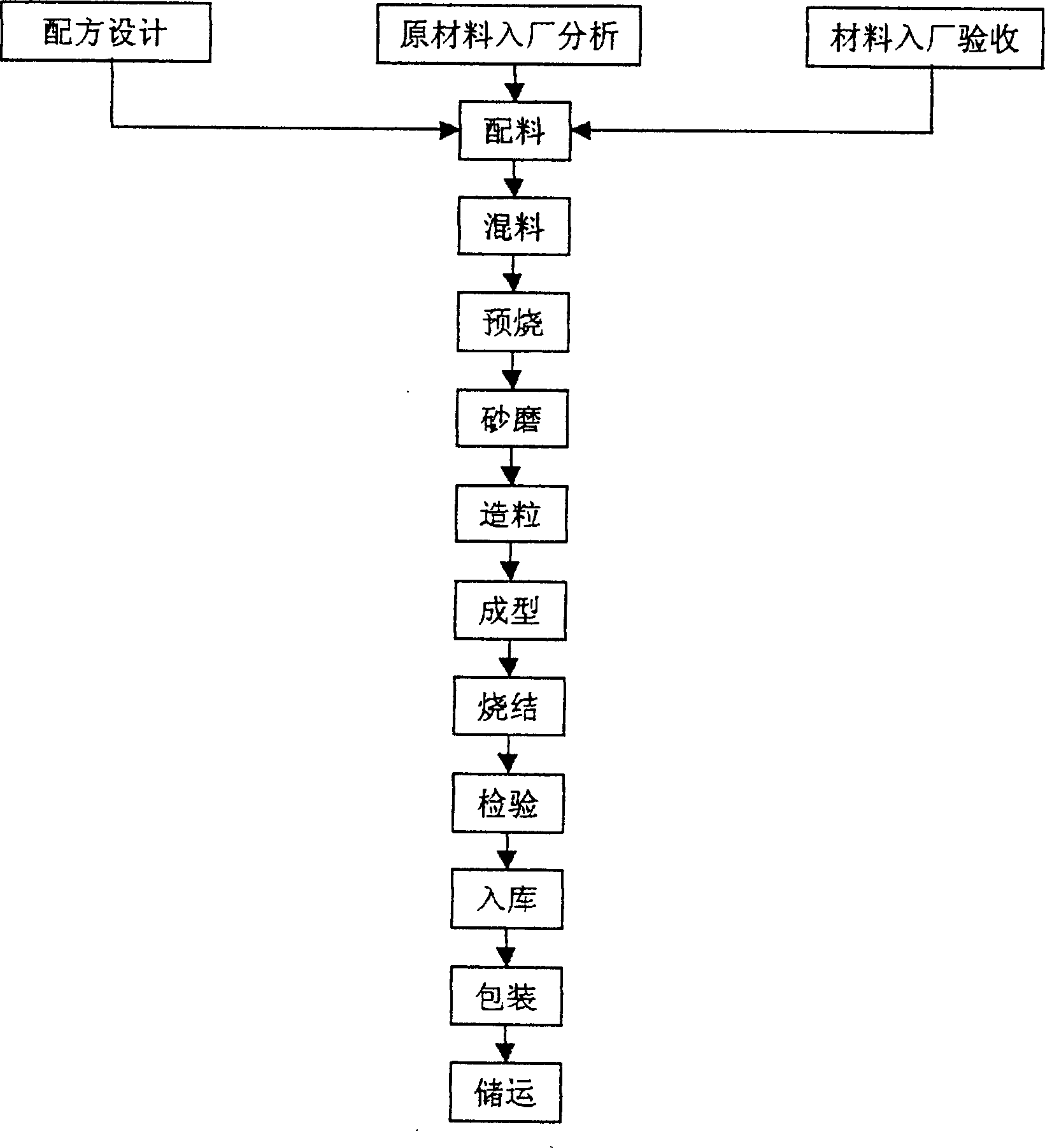

[0050] Embodiment 1~9: a kind of preparation method of nickel-zinc high-conductivity ferrite comprises the following steps:

[0051] Formulation design: high frequency NiZn is Zn +2 Replace Ni with other ions +2 , forming spinel solid solutions such as nickel ferrite and zinc ferrite, MnCO 3 and CuO are additional components to improve manufacturing process characteristics and material loss.

[0052] iron oxide

Nickel oxide

Zinc oxide

Copper oxide

1

63

7

24

3.5

2.5

2

65

8

23

2.5

1.5

3

66

9

22

2

1

4

64.4

7.6

23.2

3.2

1.6

5

64.6

7.9

23.1

2.9

1.5

6

65

8.2

22.8

2.5

1.5

7

64.2

8.2

23.35

2.6

1.65

8

64.9

8.1

23

2.4

1.6

9

64.35

7.8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com