Preparation method for carbon-coated Ni-Zn-Fe magnetic nanometer material taking chitosan as carbon source

A technology of carbon-coated nickel-zinc and carbon-coated nickel, which is applied in the field of material preparation, can solve the problems that hinder the application of basic research on carbon-coated metal nanoparticles, complex devices, and high energy consumption, and achieve good application prospects and low residual magnetization The effect of strength and strong chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

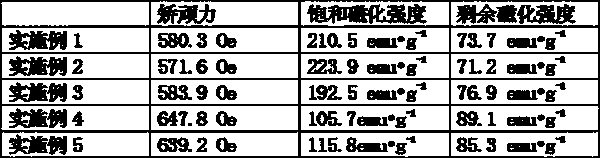

Examples

Embodiment 1

[0015] A preparation method of nickel-zinc-iron magnetic nanomaterials coated with chitosan as carbon source carbon, the preparation method is as follows:

[0016] (1) Ni 0.6 Zn 0.4 Fe 2 O 4 Preparation of granules:

[0017] Weigh 0.06mol of Ni(NO 3 ) 2 ·6H 2 O, 0.3mol Fe(NO 3 ) 3 ·9H 2 O, 0.09mol of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 50ml of absolute ethanol, 2ml of glacial acetic acid was added, and the mixture was fully mixed and placed in a 70°C water bath for microwave oscillation. 30ml of ammonia solution was added dropwise at a rate of 3ml / min to keep the pH of the solution between 9.5 and 10.0. After 100 min, the supernatant was filtered off, washed repeatedly with deionized water at 80°C and absolute ethanol, and then dried at 100°C to obtain nickel-zinc ferrite powder. The obtained nickel-zinc ferrite powder was placed in a muffle furnace for 350 ℃ calcined at high temperature for 5h, cooled to room temperature, and ground to obtain Ni 0.6 Zn 0.4 Fe ...

Embodiment 2

[0023] A preparation method of nickel-zinc-iron magnetic nanomaterials coated with chitosan as carbon source carbon, the preparation method is as follows:

[0024] (1) Ni 0.6 Zn 0.4 Fe 2 O 4 Preparation of granules:

[0025] Weigh 0.06mol of Ni(NO 3 ) 2 ·6H 2 O, 0.3mol Fe(NO 3 ) 3 ·9H 2 O, 0.09mol of Zn(NO 3 ) 2 ·6H 2O was dissolved in 50ml of absolute ethanol, 3ml of glacial acetic acid was added, and the mixture was fully mixed and placed in a 70°C water bath for microwave oscillation. 30ml of ammonia solution was added dropwise at a rate of 3ml / min to keep the pH of the solution between 9.5 and 10.0. After 120 min, the supernatant was filtered off, washed repeatedly with deionized water at 80°C and absolute ethanol, and then dried at 100°C to obtain nickel-zinc ferrite powder. The obtained nickel-zinc ferrite powder was placed in a muffle furnace for 400 ℃. ℃ calcined at high temperature for 5h, cooled to room temperature, and ground to obtain Ni 0.6 Zn 0.4 F...

Embodiment 3

[0031] A preparation method of nickel-zinc-iron magnetic nanomaterials coated with chitosan as carbon source carbon, the preparation method is as follows:

[0032] (1) Ni 0.6 Zn 0.4 Fe 2 O 4 Preparation of granules:

[0033] Weigh 0.06mol of Ni(NO 3 ) 2 ·6H 2 O, 0.3mol Fe(NO 3 ) 3 ·9H 2 O, 0.09mol of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 50ml of absolute ethanol, 4ml of glacial acetic acid was added, and the mixture was fully mixed and placed in a 70°C water bath for microwave oscillation. 30ml of ammonia solution was added dropwise at a rate of 3ml / min to keep the pH of the solution between 9.5 and 10.0. After 140 min, the supernatant was filtered off, washed repeatedly with deionized water at 80°C and absolute ethanol, and then dried at 100°C to obtain nickel-zinc ferrite powder. The obtained nickel-zinc ferrite powder was placed in a muffle furnace at 450 °C. ℃ calcined at high temperature for 5h, cooled to room temperature, and ground to obtain Ni 0.6 Zn 0.4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com