Preparation method of CoFe2O4 magnetic nano material

A magnetic nano, cofe2o4 technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of long heat treatment time of reactants, environmental pollution, waste of resources, etc., and achieve short synthesis time, simple process flow, and high-quality products low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention is CoFe 2 o 4 The preparation method of magnetic nanometer material, its step is:

[0017] (1) Weigh ferric nitrate and cobalt nitrate into water to prepare a mixed solution, the molar ratio of ferric nitrate and cobalt nitrate is 2:1;

[0018] (2) Weigh sodium hydroxide and add water to prepare a solution as a precipitant, heat to 60~92°C, the molar ratio of sodium hydroxide to cobalt nitrate is 9~16:1; the precipitant or the aqueous solution of dimethylamine , or an aqueous solution of triethylamine, or an aqueous solution of potassium hydroxide, the molar ratio of dimethylamine, triethylamine, potassium hydroxide and cobalt nitrate is 9~16:1;

[0019] (3) Add the mixed solution to the precipitant under stirring condition at a uniform speed within 30 minutes, maintain the temperature, and age for 30 to 120 minutes, filter and wash the precipitate until the filtrate is neutral, dry the obtained product, Grinding dark brown precursor;

[0020] ...

Embodiment 1

[0026] Weigh 3.6051g of NaOH and add 100ml of distilled water into a 500ml three-necked flask as a precipitant solution, which is heated to 92°C at a stirring rate of 1500r / min. Weigh 2.9086g Co(NO 3 ) 2 .6H 2 0 and 8.0809gFe(NO 3 ) 3 .9H 2 0 to prepare a 200ml mixed solution, put it in a constant pressure dropping funnel and add it to the 100ml precipitant prepared in advance at a uniform speed within 30min. After the precipitation is complete, keep the temperature at 92°C, age for 1 hour, filter and wash the precipitate until the pH of the filtrate is 7, dry the obtained product in a vacuum oven at 105°C, and grind to obtain a dark brown precursor.

[0027] Finally, the precursor was calcined at 800 °C for 1 h to obtain black CoFe 2 o 4 magnetic nanopowder.

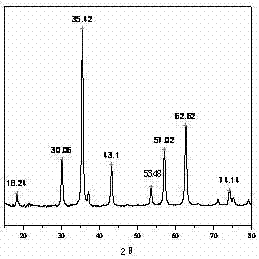

[0028] Such as figure 1 As shown, all the characteristic peaks in the spectrum: 2θ=18.24°, 30.06°, 35.44°, 43.10°, 53.48°, 57.02°, 62.62°, 74.06° and 22-1086 (CoFe 2 o 4 ) The standard spectrum is consistent...

Embodiment 2

[0031] Weigh 6.4016g of NaOH and add 100ml of distilled water into a 500ml three-necked flask as a precipitant solution, and heat it to 92°C at a stirring rate of 1500r / min. Weigh 2.9114g Co(NO 3 ) 2 .6H 2 0 and 8.0821gFe(NO 3 ) 3 .9H 2 0 to prepare a 200ml mixed solution, put it in a constant pressure dropping funnel and add it to the 100ml precipitant prepared in advance at a uniform speed within 30min. After the precipitation is complete, keep the temperature at 92°C, age for 1 hour, filter and wash the precipitate until the pH of the filtrate is 7, dry the obtained product in a vacuum oven at 105°C, and grind to obtain a dark brown precursor.

[0032] Finally, the precursor was calcined at 800 °C for 1 h to obtain black CoFe 2 o 4 magnetic nanopowder.

[0033] 2. Different aging temperature:

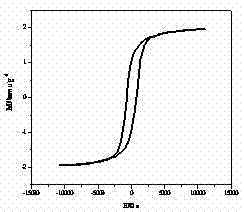

[0034] name Precipitant dosage / mol Aging temperature / ℃ Aging time / min Calcination temperature / ℃ Saturation magnetization / emu.g -1 Coercivity / Oe E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com